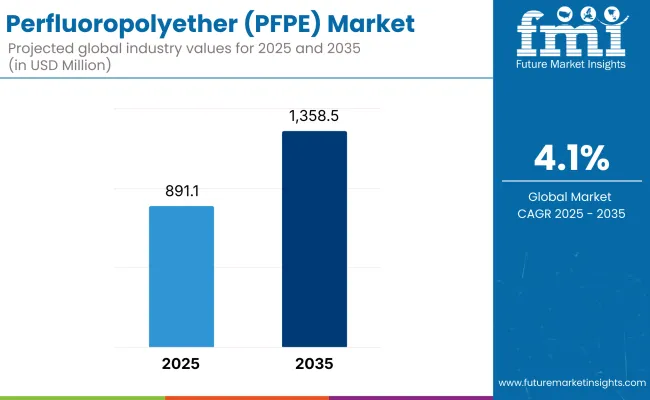

The global Perfluoropolyether (PFPE) market is estimated to be valued at USD 891.1 million in 2025. A steady expansion is projected, with the market expected to reach USD 1,358.5 million by 2035, registering a CAGR of 4.1%. Sustained momentum is being driven by the functional adoption of PFPEs across semiconductor, aerospace, and medical device industries, where performance reliability under extreme conditions remains critical.

High-performance lubricants formulated with PFPE are being preferred for vacuum chambers, deposition systems, and etching units in semiconductor fabs. In April 2025, Solvay disclosed the expansion of its Fomblin PFPE production capacity in Spinetta Marengo, Italy. The company reported, through its 2025 operational update, that "escalating global chip demand, particularly from Europe and East Asia, has necessitated capacity realignment in high-purity lubricant segments."

Medical device applications have seen expanded deployment of PFPEs due to their biocompatibility and non-reactive behavior. DuPont, in its 2024 Innovation in Materials bulletin, confirmed ongoing clinical evaluations of its Krytox PFPE range in cardiovascular implant technologies. The trials, conducted in collaboration with research institutions in Japan and Germany, demonstrated enhanced device longevity and reduced particulate shedding.

In the aerospace sector, PFPEs have been integrated into satellite bearing systems, turbopump lubrication, and cryogenic valve assemblies. Halocarbon’s PFPE formulation was certified by a major European aerospace integrator in March 2025. The company’s CEO, Jim Segrave, stated in a shareholder briefing that “our PFPEs are now flight-proven in zero-gravity cryogenic mechanisms, surpassing performance benchmarks under thermal vacuum cycling.”

Use in automotive and consumer electronics is also increasing. In January 2025, Miller-Stephenson Chemical Company noted a 12% annual rise in its PFPE coatings division. Growth was attributed to rising demand for moisture-barrier coatings in electric vehicles and sensor modules, especially from Tier 1 suppliers in South Korea and the United States.

Regionally, Asia Pacific continues to dominate PFPE demand, supported by wafer fabrication clusters in Taiwan, China, and South Korea. North America and Europe are accelerating adoption, particularly in aerospace defense and medtech production zones.

Despite high synthesis costs, new continuous fluorination technologies have emerged. In its 2024 technical series, Lubrilog described a catalytic method that lowered PFPE production energy consumption by 18%, without compromising molecular weight uniformity.

Long-term growth is being reinforced by cross-sector integration, advanced formulation R&D, and validated reliability in mission-critical systems. Adoption of PFPEs is expected to remain robust across cleanroom, surgical, and orbital environments over the forecast period.

Perfluoropolyether (PFPE) market has witnessed a significant growth owing to its unique molecular properties, which helps them in working under extreme environments in terms of temperature, viscosity, and other chemical properties in electronics, aerospace, and industrial applications. Key among these in your cleanroom-compatible and high-precision operations are the well-known PFPEs which promise excellent thermal and chemical resistance, non-flammability and very low volatility.

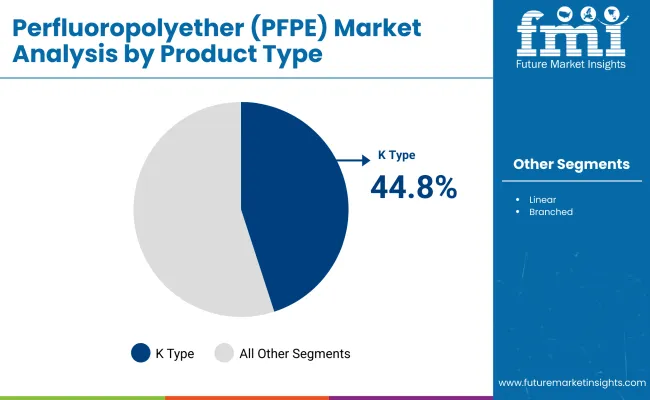

Strong adoption in electronics & semiconductors owing to superior oxidation stability and nonsolubility with sensitive materials has made K type PFPE and electronics & semiconductors largest consumed product type and end use industry across the global PFPE market.

These components enable precision lubrication, vapor management, and contamination resistance, while ensuring stringent performance and cleanliness requirements. As advanced manufacturing, miniaturization, and high frequency devices are rampant, especially in Asia Pacific, K type PFPEs are an unrivalled reliability protector of costly electronics asset against extreme mechanical and thermal shocks.

| Product Type | Market Share (2025) |

|---|---|

| K Type | 44.8% |

Because of its molecular uniformity, high thermal threshold, and strong resistance to aggressive chemicals K type PFPE dominates the product landscape. K type PFPE fluids and greases are preferred widely on account for thermal stability over broad temperature ranges, and low outgassing in vacuum, aerospace and semiconductor systems.

K-type variants are sought after in industries where high performance under extreme loads (mining) are required while having negligible interaction with metals and plastics, as well as reducing wear on extremely precise equipment. These lubricants and fluids also facilitate long service intervals, significantly reducing maintenance stoppages, particularly in sensitive environments.

K type PFPE provides the ultra-clean environments found in production environments that are demanding tighter tolerances without sacrificing reliability. This drive segment growth with their versatility across static and dynamic seal systems, valves, and micro gears.

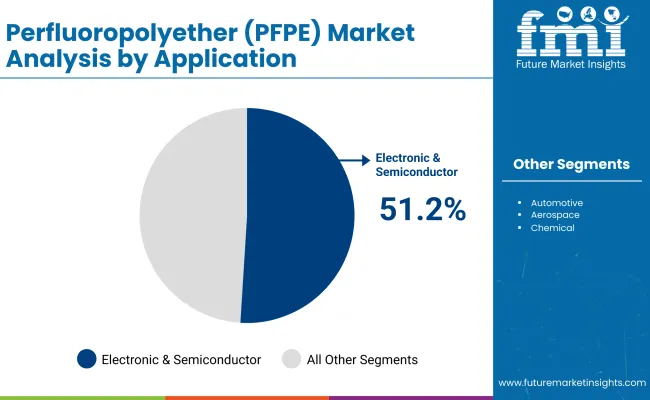

| End Use Industry | Market Share (2025) |

|---|---|

| Electronics & Semiconductors | 51.2% |

Electronics and semiconductors are the largest end use segment of PFPEs, driven by demand for high-performance materials employed in the production of wafers, data storage, microelectromechanical systems (MEMS), and cleanroom applications.

Highly sensitive environments benefit from the unmatched purity and functional stability of PFPE-based lubricants and fluids. Such materials are essential for lubrication of hard disk drives, bearings in precision actuators, and for thermal management of heat-sensitive circuitry. Low evaporation rates, compatibility with vacuum chambers, and low residual reactivity promote optimization within semiconductor fabrication yield as well as component longevity.

The demand for PFPE-based materials can be attributed to the shrinking geometries of semiconductor devices as well as the increasing prevalence of 5G, IoT, and AI hardware applications. Specifically, they guarantee performance in extreme ultraviolet lithography systems and dry etching setups, where conventional lubricants have not prevailed.

While PFPEs are also found in aerospace and industrial manufacturing, they remain most heavily embedded in the electronics segment, due to relentless innovation in chips, burgeoning data centers and the transition to precision manufacturing at nano scales.

PFPE has a strong demand in North America, particularly in semiconductor manufacturing, medical devices, and aerospace applications. PFPEs offer unrivaled performance in vacuum technology and defense-grade lubrication, and that puts the USA in the lead.

Rising adoption in FDA-compliant apparatus and Class 100/1000 cleanroom equipment will continue to drive demand for PFPE lubricants. In addition, PFPEs are used as low-outgassing and non-migrating lubricants in other optical lens coating and fiber optic cable production processes that are present in the region.

European Regulations Medicata Safety Fluorinated materials and expect High PFPE adoption inprecision machining, life sciences, and Robotics. Germany, the UK, and France are investing in PFPEies that are high-end semiconductor and other nanotech industries.

PFPE can play a role in contaminant-free operations. Sustainability initiatives and REACH regulations are driving manufacturers to move away from traditional PFAS compounds, using PFPE-based alternatives. The detailed applications in satellite systems and nuclear environments still aid regional innovation.

The Asia-Pacific is the fastest-growing market, primarily driven by growing semiconductor fabs, electronics fabrication, and automotive innovation hubs in China, South Korea, Taiwan, and Japan. Demand for PFPE is increasing in microelectronics assembly, high-speed spindles and clean-energy manufacturing.

PFPEs are finding applications in solar panel fabrication, medical sterilization in India, and food-grade lubrication systems in Southeast Asia. Low-cost manufacturing in the region and increasing demand for contamination-free environments explain the long-term growth.

Challenges

High production cost, limited scalability, and environmental scrutiny restrict broader adoption.

PFPE is produced by a complicated synthesis process that involves expensive raw materials and processing steps, which makes it less cost-effective in lower-margin industrial sectors. High-purity PFPE grades additionally demand accurate quality control and specific infrastructure, further contributing to the total price burden.

These still limit adoption beyond mission-critical use cases.Environmental concerns over long-chain perfluorinated compounds, along with evolving PFAS regulation, could increase scrutiny surrounding the lifecycle impact of fluoropolymers and fluorolubricants. In conclusion, manufacturers of PFPE-based products that are marketed for consumer-facing or food contact applications may be subject to increasing pressure to demonstrate validation of safety data.

Opportunities

Miniaturization, green fluorochemistries, and aerospace applications open growth frontiers.

There are plenty of opportunities in electronics and medical devices, where PFPE enables the lubrication of micro components without outgassing or residue as devices get smaller and performance demands increase. PFPE-based fluids and greases have superior thermal and oxidative stability as 5G infrastructure expands and wafer-level manufacturing becomes more intense.

The satellite systems in aerospace, spacecraft actuators, and vacuum-sealed mechanisms are also becoming more dependent on PFPE. A growing interest in PFPE as a safer fluorinated substitute for banned PFAS compounds fits with industry sustainability goals. Also, new commercial routes are being opened in the areas of optics, 3D printing, and nanofabrication technological directions due to the progress in PFPE-functional coatings, emulsions, and composite material additives.

The PFPE market was fueled by increasing demand in semiconductor fabrication, medical imaging and electric vehicle systems between 2020 and 2024. COVID-19 underscored the importance of contamination-free and durable lubricants in essential healthcare and diagnostic devices.

But cost and awareness constraints prevented mass-market penetration outside specialty industries, according to OECD. From 2025 the PFPE will be more deeply integrated into intelligent manufacturing, renewable energy, and space exploration. As a greater regulatory scrutiny on green chemistries, the unique performance and environmental safety of PFPE will become increasingly valuable. Investment into scalable PFPE production (fiber production, material reusability, etc) as well as AI-enabled predictive lubricant monitoring systems will emerge for cleanroom and industrial robots.

Market Shifts: A Comparative Analysis (2020 to 2024 vs. 2025 to 2035)

| Market Shift | 2020 to 2024 Trends |

|---|---|

| Regulatory Landscape | Initial PFAS safety reviews and classification |

| Consumer Trends | Usage in critical industries like med-tech and semiconductors |

| Industry Adoption | Dominated by electronics and high-vacuum applications |

| Supply Chain and Sourcing | Limited suppliers and specialty processors |

| Market Competition | Controlled by a few chemical giants and niche lubricant firms |

| Market Growth Drivers | Cleanroom needs, electronic component scaling |

| Sustainability and Impact | Moderate; focused on performance over environmental compliance |

| Smart Technology Integration | Minimal sensor compatibility |

| Sensorial Innovation | Focused on inertness and temperature tolerance |

| Market Shift | 2025 to 2035 Projections |

|---|---|

| Regulatory Landscape | Shift to fluorinated alternatives with traceability and safer profiles |

| Consumer Trends | Growth in 3D printing, aerospace, and AI-integrated precision equipment |

| Industry Adoption | Expanding into clean energy, food-grade machinery, and satellite systems |

| Supply Chain and Sourcing | Emergence of vertical integration and regionally scaled PFPE production |

| Market Competition | Entry of green fluorochemical producers and custom formulation providers |

| Market Growth Drivers | Space tech, renewable manufacturing, and sustainable chemical alternatives |

| Sustainability and Impact | Rising demand for low-impact, non-toxic, and reclaimable lubricant systems |

| Smart Technology Integration | Smart lubricant dosing, AI-monitoring, and robotic system lubrication |

| Sensorial Innovation | Added UV resistance, surface adhesion control, and biocompatible coatings |

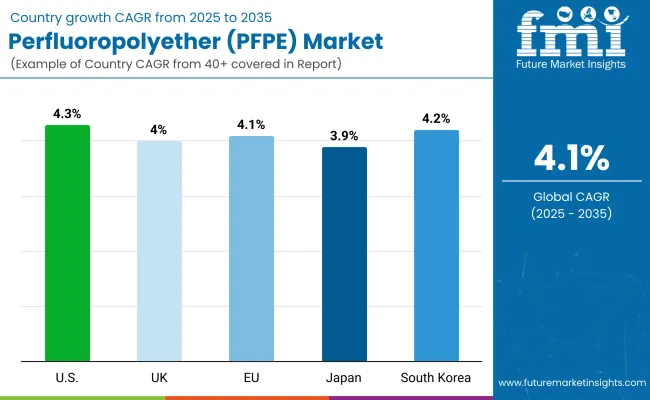

Strong demand in the aerospace, semiconductor, and medical device industries drives the growth of the USA perfluoropolyether (PFPE) market. These PFPE lubricants are essential for vacuum environments, cleanrooms, and high-temperature applications because of their chemical inertness and thermal stability.

PFPEs are still used in satellite and space hardware systems by NASA and defense contractors, where material performance is mission-critical. Domestic manufacturers are pouring investments into high-purity PFPE formulations for semiconductor etching and EUV lithography. The medical field also employs PFPEs in implantable devices and surgical instruments, facilitating innovation in biocompatible classes.

| Country | CAGR (2025 to 2035) |

|---|---|

| United States | 4.3% |

In the UK, demand for PFPE in high-precision manufacturing and research laboratories is on the rise. PFPE lubricants are trusted by aerospace and defense companies to lubricate jet engine components, actuators and cleanroom robotics. PFPEs are also being used in the rapidly-growing EV battery and electronics assembly sectors due to their heat-resistance properties and dielectric stability.

PFPE uses are being pursued in vacuum pumps, analytical instrumentation, etc. by most of universities and R&D centers. This will soon make it possible for specialty PFPE materials used in healthcare and electronics to be approved much more quickly, as part of a post-Brexit regulatory flexibility.

| Country | CAGR (2025 to 2035) |

|---|---|

| United Kingdom | 4.0% |

As these sectors increasingly rely on high-performance lubricants, the EU PFPE market is growing. Key markets are Germany, France, the Netherlands, with significant adoption in high-end gear assemblies, oxygen systems, and cleanroom manufacturing. Due to their inert and nontoxic nature, PFPEs have been widely used in MRI components and surgical equipment.

Next-generation PFPEs are also gaining market interest as restrictions on fluorinated compounds in the EU continue to influence developments in their synthesis with reduced environmental impact. R&D is dedicated to improving thermal conductivity and service life in challenging environments.

| Region | CAGR (2025 to 2035) |

|---|---|

| European Union | 4.1% |

The PFPE market in Japan is driven by its precision manufacturing industries, particularly robotics, electronics, and aerospace. With ultra-stable lubricants needed to help semiconductor vacuum chambers, and hard disk drive manufacturing, Japanese OEMs need very specific niche requirements. PFPE-based greases are crucial for cryogenic uses and optical stack ups.

Domestic companies are further developing PFPE applications in biocompatible coatings for catheters and diagnostic instruments. The Ministry of Economy, Trade and Industry (METI) is backing low global warming potential environmentally safe fluorinated materials development.

| Country | CAGR (2025 to 2035) |

|---|---|

| Japan | 3.9% |

South Korea’s PFPE market is developing at a fast pace as parallel to its increasing semiconductor and electronics industries. The major players Samsung and SK Hynixconsume PFPE lubricants for cleanroom automation and microchip assembly line. PFPEs also play vital roles in EV battery systems and optical sensor protection.

Korean companies are engaging with the emerging trend to develop hybrid PFPE materials with enhanced film-forming and anti-corrosive effects [OECD 2020]. Nanotech research funded by the government is backing advancements in PFPE derivatives in the categories of surface treatment and high-temperature lubrication.

| Country | CAGR (2025 to 2035) |

|---|---|

| South Korea | 4.2% |

The growing demand for high-performance components in various industries, including aerospace, semiconductor, medical devices, and electronics, has driven the perfluoropolyether (PFPE) market toward continuous growth, primarily due to its superior thermal stability, chemical resistance, and lubricosity.

PFPEs are the main constituents in vacuum pump oils greases and coatings for very high temperature, vacuum and reactive chemical scenarios. Demand is accelerating as a move toward miniaturization, cleanroom processing and high-end equipment manufacturing takes hold.

One of the recent trends in the PFPE manufacturers has been enabling them to highly improve or modify the properties of the PFPEs, so as to achieve low outgassing, high surface coverage, and regulatory compliance of the candidates for sensitive and mission-critical applications.

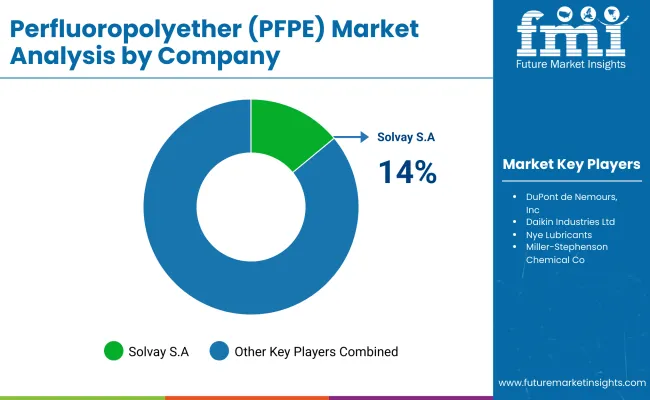

Market Share Analysis by Key Players & PFPE Providers

| Company Name | Estimated Market Share (%) |

|---|---|

| Solvay S.A. | 14 - 17% |

| DuPont de Nemours, Inc. | 11 - 14% |

| Daikin Industries Ltd. | 9 - 12% |

| Nye Lubricants (FUCHS Group) | 7 - 10% |

| Miller-Stephenson Chemical Co. | 6 - 9% |

| Other Providers | 38 - 45% |

| Company Name | Key Offerings/Activities |

|---|---|

| Solvay S.A. | In 2024 , expanded FOMBLIN® PFPE range with ultra-low volatility grades for semiconductor fabs; in 2025 , launched PFPEs for medical microfluidics with ISO 10993 compliance. |

| DuPont de Nemours, Inc. | In 2024 , introduced KRYTOX™ VPF series with improved thermal decomposition resistance; in 2025 , developed aerospace-grade greases for satellite and orbital systems. |

| Daikin Industries Ltd. | In 2024 , launched PFPE-based anti-corrosion coatings for electronic connectors; in 2025 , scaled up production of inert PFPE fluids for cleanroom and vacuum systems. |

| Nye Lubricants (FUCHS) | In 2024 , enhanced PFPE grease formulations for HDD and EV motors; in 2025 , rolled out specialty lubricants for UV-curable optical systems. |

| Miller-Stephenson | In 2024 , introduced PFPE films with anti-migration properties for MEMS; in 2025 , expanded conformal coatings for high-voltage and plasma-prone equipment. |

Key Market Insights

Solvay S.A. (14-17%)

Solvay leads the PFPE market through its FOMBLIN® brand, which is widely used in semiconductor processing, aerospace lubrication, and medical devices. In 2024, it introduced ultra-low volatility PFPE grades for vacuum environments in chip manufacturing. In 2025, Solvay launched biocompatible PFPEs for microfluidic medical devices, meeting ISO 10993 standards. Its investments align with the rapid expansion of the electronics and healthcare sectors in Asia and Europe.

DuPont de Nemours, Inc. (11-14%)

DuPont’s KRYTOX™ PFPE series remains a benchmark in high-performance lubrication. In 2024, the company introduced the VPF series designed to withstand decomposition at temperatures above 350°C. In 2025, DuPont released aerospace-grade PFPE greases for satellite deployable mechanisms and cryogenic applications. Its products comply with NASA’s outgassing standards, supporting international space missions and clean energy research initiatives.

Daikin Industries Ltd. (9-12%)

Daikin is expanding PFPE applications beyond lubricants, targeting coatings and dielectric fluids. In 2024, it launched PFPE-based coatings that shield sensitive connectors from salt spray and oxidation. In 2025, Daikin scaled up inert PFPE production for vacuum and plasma-processing equipment in display and semiconductor fabs. The company’s innovations address the increasing demand for cleanroom-compatible, chemically inert lubricants in East Asia.

Nye Lubricants (FUCHS Group) (7-10%)

Nye Lubricants is well-positioned in niche markets such as hard disk drives (HDDs), EVs, and photonics. In 2024, it enhanced PFPE-based greases for HDD bearings and EV electric motor contacts requiring low friction and oxidation resistance. In 2025, it introduced PFPE lubricants formulated for UV optics and laser lenses, providing stability under intense light and heat. Nye continues to develop PFPEs with extended operating life for high-tech OEMs.

Miller-Stephenson Chemical Co. (6-9%)

Miller-Stephenson specializes in PFPE formulations for coatings and specialty electronic assemblies. In 2024, it introduced PFPE surface films with strong anti-migration properties for MEMS and NEMS (nanoelectromechanical systems). In 2025, the company expanded PFPE-based conformal coatings for high-voltage components exposed to ozone, plasma, or corona discharge. These products support equipment longevity and safety in cleanroom, aerospace, and energy applications.

Other Key Players (38-45% Combined)

Several specialized chemical firms and research-driven startups are shaping the PFPE landscape with high-purity and custom-formulated offerings. These include:

The overall market size for the PFPE market was approximately USD 891.1 million in 2025.

The PFPE market is expected to reach approximately USD 1,358.5 million by 2035.

The demand for PFPE is rising due to its superior lubricity, thermal stability, and chemical resistance, making it ideal for electronics applications. The expansion of the electronics industry, coupled with the increasing need for high-performance lubricants, is further fueling market growth.

The top 5 countries driving the development of the PFPE market are the United States, China, Japan, Germany, and South Korea.

K type PFPE and electronics applications are expected to command significant shares over the assessment period.

Table 01: Global Market Value (US$ Million) & Volume (Tons) Forecast by Form, 2014 to 2029

Table 02: Global Market Value (US$ Million) & Volume (Tons) Forecast by Product Type, 2014 to 2029

Table 03: Global Market Value (US$ Million) & Volume (Tons) Forecast by Application, 2014 to 2029

Table 04: Global Market Value (US$ Million) & Volume (Tons) Forecast by Region, 2014 to 2029

Table 05: North America Market Volume (Tons) and Value (US$ Million) by Country, 2014 to 2029

Table 06: North America Market Volume (Tons) and Value (US$ Million) by Form, 2014 to 2029

Table 07: North America Market Volume (Tons) and Value (US$ Million) by Product Type, 2014 to 2029

Table 08: North America Market Volume (Tons) and Value (US$ Million) by Application, 2014 to 2029

Table 09: Latin America Market Volume (Tons) and Value (US$ Million) by Country, 2014 to 2029

Table 10: Latin America Market Volume (Tons) and Value (US$ Million) by Form, 2014 to 2029

Table 11: Latin America Market Volume (Tons) and Value (US$ Million) by Product Type, 2014 to 2029

Table 12: Latin America Market Volume (Tons) and Value (US$ Million) by Application, 2014 to 2029

Table 13: Europe Market Volume (Tons) and Value (US$ Million) by Country, 2014 to 2029

Table 14: Europe Market Volume (Tons) and Value (US$ Million) by Form, 2014 to 2029

Table 15: Europe Market Volume (Tons) and Value (US$ Million) by Product Type, 2014 to 2029

Table 16: Europe Market Volume (Tons) and Value (US$ Million) by Application, 2014 to 2029

Table 17: South Asia Market Volume (Tons) and Value (US$ Million) by Country, 2014 to 2029

Table 18: South Asia Market Volume (Tons) and Value (US$ Million) by Form, 2014 to 2029

Table 19: South Asia Market Volume (Tons) and Value (US$ Million) by Product Type, 2014 to 2029

Table 20: South Asia Market Volume (Tons) and Value (US$ Million) by Application, 2014 to 2029

Table 21: East Asia Market Volume (Tons) and Value (US$ Million) by Country, 2014 to 2029

Table 22: East Asia Market Volume (Tons) and Value (US$ Million) by Form, 2014 to 2029

Table 23: East Asia Market Volume (Tons) and Value (US$ Million) by Product Type, 2014 to 2029

Table 24: East Asia Market Volume (Tons) and Value (US$ Million) by Application, 2014 to 2029

Table 25: Middle East & Africa Market Volume (Tons) and Value (US$ Million) by Country, 2014 to 2029

Table 26: Middle East & Africa Market Volume (Tons) and Value (US$ Million) by Form, 2014 to 2029

Table 27: Middle East & Africa Market Volume (Tons) and Value (US$ Million) by Product Type, 2014 to 2029

Table 28: Middle East & Africa Market Volume (Tons) and Value (US$ Million) by Application, 2014 to 2029

Table 29: Oceania Market Volume (Tons) and Value (US$ Million) by Country, 2014 to 2029

Table 30: Oceania Market Volume (Tons) and Value (US$ Million) by Form, 2014 to 2029

Table 31: Oceania Market Volume (Tons) and Value (US$ Million) by Product Type, 2014 to 2029

Table 32: Oceania Market Volume (Tons) and Value (US$ Million) by Application, 2014 to 2029

Table 33: China Market Value (US$ Million) & Volume (Tons) Forecast by Form, 2014 to 2029

Table 34: China Market Value (US$ Million) & Volume (Tons) Forecast by Product Type, 2014 to 2029

Table 35: China Market Volume (Tons) and Value (US$ Million) by Application, 2014 to 2029

Table 36: India Market Value (US$ Million) & Volume (Tons) Forecast by Form, 2014 to 2029

Table 37: India Market Value (US$ Million) & Volume (Tons) Forecast by Product Type, 2014 to 2029

Table 38: India Market Volume (Tons) and Value (US$ Million) by Application, 2014 to 2029

Table 39: BENELUX Market Value (US$ Million) & Volume (Tons) Forecast by Form, 2014 to 2029

Table 40: BENELUX Market Value (US$ Million) & Volume (Tons) Forecast by Product Type, 2014 to 2029

Table 41: BENELUX Market Volume (Tons) and Value (US$ Million) by Application, 2014 to 2029

Figure 01: Global Market Value (US$ Million), 2022 to 2029

Figure 02: Global Market Absolute $ Opportunity Analysis, 2014 to 2029

Figure 03: Global Market Size (US$ Million) and Volume (Tons) Analysis, 2014 to 2021

Figure 04: Global Market Size (US$ Million) and Volume (Tons) Analysis, 2022 to 2029

Figure 05: Global GDP (US$ Billion) Forecast by Region, 2013 to 2028

Figure 06: Global Air Transport MRO Market, By Region-2021

Figure 07: Global Air Transport MRO Market (US$ Million), 2013 to 2028

Figure 08: Overall Aircraft Production by Region, 2021

Figure 09: Aircraft Production by Type

Figure 10: Airport Infrastructure Spend Outlook by Region (Y-o-Y Growth)

Figure 11: Passenger Traffic Growth Outlook (Y-o-Y Change)

Figure 12: Global Manufacturing Sector Growth Rate (%), 2016 to 2027

Figure 13: Global Chemical Industry Growth Rate (%), 2016 to 2027

Figure 14: Global Automotive Production Share by Region (2021)

Figure 15: Global Automotive Production Volume ('000 Units), 2012 to 2029

Figure 16: Supply – Demand Scenario of Base Oil

Figure 17: Global Market Share and BPS Analysis By Form, 2022 & 2029

Figure 18: Global Market Y-o-Y Growth Projections by Form, 2022 to 2029

Figure 19: Global Market Absolute $ Opportunity by PFPE – Oil Segment, 2014 to 2029

Figure 20: Global Market Absolute $ Opportunity by PFPE – Grease Segment, 2014 to 2029

Figure 21: Global Market Attractiveness Analysis Projections by Form, 2022 to 2029

Figure 22: Global Market Share and BPS Analysis By Product Type, 2022 & 2029

Figure 23: Global Market Y-o-Y Growth Projections by Product Type, 2022 to 2029

Figure 24: Global Market Absolute $ Opportunity by Linear Segment, 2014 to 2029

Figure 25: Global Market Absolute $ Opportunity by Branched Segment, 2014 to 2029

Figure 26: Global Market Attractiveness Analysis Projections by Type, 2022 to 2029

Figure 27: Global Market Share and BPS Analysis By Application, 2022 & 2029

Figure 28: Global Market Y-o-Y Growth Projections by Application, 2022 to 2029

Figure 29: Global Market Absolute $ Opportunity by Automotive Segment, 2014 to 2029

Figure 30: Global Market Absolute $ Opportunity by Aerospace Segment, 2014 to 2029

Figure 31: Global Market Absolute $ Opportunity by Electronics Segment, 2014 to 2029

Figure 32: Global Market Absolute $ Opportunity by Chemical Segment, 2014 to 2029

Figure 33: Global Market Absolute $ Opportunity by Others Segment, 2014 to 2029

Figure 34: Global Market Attractiveness Analysis Projections by Application, 2022 to 2029

Figure 35: Global Market Share and BPS Analysis By Region, 2022 & 2029

Figure 36: Global Market Y-o-Y Growth Projections by Region, 2022 to 2029

Figure 37: Global Market Absolute $ Opportunity by North America, 2014 to 2029

Figure 38: Global Market Absolute $ Opportunity by Latin America Segment, 2014 to 2029

Figure 39: Global Market Absolute $ Opportunity by Europe, 2014 to 2029

Figure 40: Global Market Absolute $ Opportunity by South Asia Segment, 2014 to 2029

Figure 41: Global Market Absolute $ Opportunity by East Asia, 2014 to 2029

Figure 42: Global Market Absolute $ Opportunity by MEA Segment, 2014 to 2029

Figure 43: Global Market Absolute $ Opportunity by Oceania, 2014 to 2029

Figure 44: Global Market Attractiveness Analysis Projections by Region, 2022 to 2029

Figure 45: North America Market Share and BPS Analysis by Country– 2022 & 2029

Figure 46: North America Market Y-o-Y (%) Growth Projections by Country, 2022 to 2029

Figure 47: North America Market Attractiveness Analysis by Country, 2022 to 2029

Figure 48: North America Market Absolute $ Opportunity by U.S., 2014 to 2029

Figure 49: North America Market Absolute $ Opportunity by Canada, 2014 to 2029

Figure 50: North America Market Share and BPS Analysis by Form– 2022 & 2029

Figure 51: North America Market Y-o-Y (%) Growth Projections by Form, 2022 to 2029

Figure 52: North America Market Attractiveness Analysis By Form, 2022 to 2029

Figure 53: North America Market Share and BPS Analysis By Product Type, 2022 & 2029

Figure 54: North America Market Y-o-Y Growth Projections by Product Type, 2022 to 2029

Figure 55: North America Market Attractiveness Analysis Projections by Type, 2022 to 2029

Figure 56: North America Market Share and BPS Analysis By Application, 2022 & 2029

Figure 57: North America Market Y-o-Y Growth Projections by Application, 2022 to 2029

Figure 58: North America Market Attractiveness Analysis Projections by Application, 2022 to 2029

Figure 59: Latin America Market Share and BPS Analysis by Country– 2022 & 2029

Figure 60: Latin America Market Y-o-Y (%) Growth Projections by Country, 2022 to 2029

Figure 61: Latin America Market Attractiveness Analysis by Country, 2022 to 2029

Figure 62: Latin America Market Absolute $ Opportunity by Brazil, 2014 to 2029

Figure 63: Latin America Market Absolute $ Opportunity by Mexico, 2014 to 2029

Figure 64: Latin America Market Absolute $ Opportunity by Rest of LA, 2014 to 2029

Figure 65: Latin America Market Share and BPS Analysis by Form– 2022 & 2029

Figure 66: Latin America Market Y-o-Y (%) Growth Projections by Form, 2022 to 2029

Figure 67: Latin America Market Attractiveness Analysis By Form, 2022 to 2029

Figure 68: Latin America Market Share and BPS Analysis By Product Type, 2022 & 2029

Figure 69: Latin America Market Y-o-Y Growth Projections by Product Type, 2022 to 2029

Figure 70: Latin America Market Attractiveness Analysis Projections by Type, 2022 to 2029

Figure 71: Latin America Market Share and BPS Analysis By Application, 2022 & 2029

Figure 72: Latin America Market Y-o-Y Growth Projections by Application, 2022 to 2029

Figure 73: Latin America Market Attractiveness Analysis Projections by Application, 2022 to 2029

Figure 74: Europe Market Share and BPS Analysis by Country– 2022 & 2029

Figure 75: Europe Market Y-o-Y (%) Growth Projections by Country, 2022 to 2029

Figure 76: Europe Market Attractiveness Analysis by Country, 2022 to 2029

Figure 77: Europe Market Absolute $ Opportunity by Germany, 2014 to 2029

Figure 78: Global Market Absolute $ Opportunity by Italy Segment, 2014 to 2029

Figure 79: Europe Market Absolute $ Opportunity by France, 2014 to 2029

Figure 80: Global Market Absolute $ Opportunity by UK Segment, 2014 to 2029

Figure 81: Europe Market Absolute $ Opportunity by Spain, 2014 to 2029

Figure 82: Global Market Absolute $ Opportunity by Russia Segment, 2014 to 2029

Figure 83: Europe Market Absolute $ Opportunity by BENELUX, 2014 to 2029

Figure 84: Global Market Absolute $ Opportunity by the Rest of Europe, 2014 to 2029

Figure 85: Europe Market Share and BPS Analysis by Form– 2022 & 2029

Figure 86: Europe Market Y-o-Y (%) Growth Projections by Form, 2022 to 2029

Figure 87: Europe Market Attractiveness Analysis By Form, 2022 to 2029

Figure 88: Europe Market Share and BPS Analysis By Product Type, 2022 & 2029

Figure 89: Europe Market Y-o-Y Growth Projections by Product Type, 2022 to 2029

Figure 90: Europe Market Attractiveness Analysis Projections by Type, 2022 to 2029

Figure 91: Europe Market Share and BPS Analysis By Application, 2022 & 2029

Figure 92: Europe Market Y-o-Y Growth Projections by Application, 2022 to 2029

Figure 93: Europe Market Attractiveness Analysis Projections by Application, 2022 to 2029

Figure 94: South Asia Market Share and BPS Analysis by Country– 2022 & 2029

Figure 95: South Asia Market Y-o-Y (%) Growth Projections by Country, 2022 to 2029

Figure 96: South Asia Market Attractiveness Analysis by Country, 2022 to 2029

Figure 97: South Asia Market Absolute $ Opportunity by India, 2014 to 2029

Figure 98: South Asia Market Absolute $ Opportunity by ASEAN, 2014 to 2029

Figure 99: South Asia Market Absolute $ Opportunity by Rest of South Asia, 2014 to 2029

Figure 100: South Asia Market Share and BPS Analysis by Form– 2022 & 2029

Figure 101: South Asia Market Y-o-Y (%) Growth Projections by Form, 2022 to 2029

Figure 102: South Asia Market Attractiveness Analysis By Form, 2022 to 2029

Figure 103: South Asia Market Share and BPS Analysis By Product Type, 2022 & 2029

Figure 104: South Asia Market Y-o-Y Growth Projections by Product Type, 2022 to 2029

Figure 105: South Asia Market Attractiveness Analysis Projections by Type, 2022 to 2029

Figure 106: South Asia Market Share and BPS Analysis By Application, 2022 & 2029

Figure 107: South Asia Market Y-o-Y Growth Projections by Application, 2022 to 2029

Figure 108: South Asia Market Attractiveness Analysis Projections by Application, 2022 to 2029

Figure 109: East Asia Market Share and BPS Analysis by Country– 2022 & 2029

Figure 110: East Asia Market Y-o-Y (%) Growth Projections by Country, 2022 to 2029

Figure 111: East Asia Market Attractiveness Analysis by Country, 2022 to 2029

Figure 112: East Asia Market Absolute $ Opportunity by China, 2014 to 2029

Figure 113: East Asia Market Absolute $ Opportunity by Japan, 2014 to 2029

Figure 114: East Asia Market Absolute $ Opportunity by South Korea, 2014 to 2029

Figure 115: East Asia Market Share and BPS Analysis by Form– 2022 & 2029

Figure 116: East Asia Market Y-o-Y (%) Growth Projections by Form, 2022 to 2029

Figure 117: East Asia Market Attractiveness Analysis By Form, 2022 to 2029

Figure 118: East Asia Market Share and BPS Analysis By Product Type, 2022 & 2029

Figure 119: East Asia Market Y-o-Y Growth Projections by Product Type, 2022 to 2029

Figure 120: East Asia Market Attractiveness Analysis Projections by Type, 2022 to 2029

Figure 121: East Asia Market Share and BPS Analysis By Application, 2022 & 2029

Figure 122: East Asia Market Y-o-Y Growth Projections by Application, 2022 to 2029

Figure 123: East Asia Market Attractiveness Analysis Projections by Application, 2022 to 2029

Figure 124: Middle East & Africa Market Share and BPS Analysis by Country– 2022 & 2029

Figure 125: Middle East & Africa Market Y-o-Y (%) Growth Projections by Country, 2022 to 2029

Figure 126: Middle East & Africa Market Attractiveness Analysis by Country, 2022 to 2029

Figure 127: MEA Market Absolute $ Opportunity by GCC Countries, 2014 to 2029

Figure 128: MEA Market Absolute $ Opportunity by South Africa, 2014 to 2029

Figure 129: MEA Market Absolute $ Opportunity by Turkey, 2014 to 2029

Figure 130: MEA Market Absolute $ Opportunity by Rest of MEA, 2014 to 2029

Figure 131: Middle East & Africa Market Share and BPS Analysis by Form– 2022 & 2029

Figure 132: Middle East & Africa Market Y-o-Y (%) Growth Projections by Form, 2022 to 2029

Figure 133: Middle East & Africa Market Attractiveness Analysis By Form, 2022 to 2029

Figure 134: Middle East & Africa Market Share and BPS Analysis By Product Type, 2022 & 2029

Figure 135: Middle East & Africa Market Y-o-Y Growth Projections by Product Type, 2022 to 2029

Figure 136: Middle East & Africa Market Attractiveness Analysis Projections by Type, 2022 to 2029

Figure 137: Middle East & Africa Market Share and BPS Analysis By Application, 2022 & 2029

Figure 138: Middle East & Africa Market Y-o-Y Growth Projections by Application, 2022 to 2029

Figure 139: Middle East & Africa Market Attractiveness Analysis Projections by Application, 2022 to 2029

Figure 140: Oceania Market Share and BPS Analysis by Country– 2022 & 2029

Figure 141: Oceania Market Y-o-Y (%) Growth Projections by Country, 2022 to 2029

Figure 142: Oceania Market Attractiveness Analysis by Country, 2022 to 2029

Figure 143: Oceania Market Absolute $ Opportunity by Australia, 2014 to 2029

Figure 144: Oceania Market Absolute $ Opportunity by New Zealand, 2014 to 2029

Figure 145: Oceania Market Share and BPS Analysis by Form– 2022 & 2029

Figure 146: Oceania Market Y-o-Y (%) Growth Projections by Form, 2022 to 2029

Figure 147: Oceania Market Attractiveness Analysis By Form, 2022 to 2029

Figure 148: Oceania Market Share and BPS Analysis By Product Type, 2022 & 2029

Figure 149: Oceania Market Y-o-Y Growth Projections by Product Type, 2022 to 2029

Figure 150: Oceania Market Attractiveness Analysis Projections by Type, 2022 to 2029

Figure 151: Oceania Market Share and BPS Analysis By Application, 2022 & 2029

Figure 152: Oceania Market Y-o-Y Growth Projections by Application, 2022 to 2029

Figure 153: Oceania Market Attractiveness Analysis Projections by Application, 2022 to 2029

Figure 154: Emerging Markets Market Share by Country, 2019

Figure 155: Global Market Share by Region, 2019

Figure 156: Global & Emerging Countries PFPE Market Y-o-Y Growth Projections, 2022 to 2029

Figure 157: China Market Share and BPS Analysis By Form, 2022 & 2029

Figure 158: China Market Y-o-Y Growth Projections by Form, 2022 to 2029

Figure 159: China Market Attractiveness Analysis Projections by Form, 2022 to 2029

Figure 160: China Market Share and BPS Analysis By Product Type, 2022 & 2029

Figure 161: China Market Y-o-Y Growth Projections by Product Type, 2022 to 2029

Figure 162: China Market Attractiveness Analysis Projections by Product Type, 2022 to 2029

Figure 163: China Market Share and BPS Analysis By Application, 2022 & 2029

Figure 164: China Market Y-o-Y Growth Projections by Application, 2022 to 2029

Figure 165: China Market Attractiveness Analysis Projections by Application, 2022 to 2029

Figure 166: India Market Share and BPS Analysis By Form, 2022 & 2029

Figure 167: India Market Y-o-Y Growth Projections by Form, 2022 to 2029

Figure 168: India Market Attractiveness Analysis Projections by Form, 2022 to 2029

Figure 169: India Market Share and BPS Analysis By Product Type, 2022 & 2029

Figure 170: India Market Y-o-Y Growth Projections by Product Type, 2022 to 2029

Figure 171: India Market Attractiveness Analysis Projections by Product Type, 2022 to 2029

Figure 172: India Market Share and BPS Analysis By Application, 2022 & 2029

Figure 173: India Market Y-o-Y Growth Projections by Application, 2022 to 2029

Figure 174: India Market Attractiveness Analysis Projections by Application, 2022 to 2029

Figure 175: BENELUX Market Share and BPS Analysis By Form, 2022 & 2029

Figure 176: BENELUX Market Y-o-Y Growth Projections by Form, 2022 to 2029

Figure 177: BENELUX Market Attractiveness Analysis Projections by Form, 2022 to 2029

Figure 178: BENELUX Market Share and BPS Analysis By Product Type, 2022 & 2029

Figure 179: BENELUX Market Y-o-Y Growth Projections by Product Type, 2022 to 2029

Figure 180: BENELUX Market Attractiveness Analysis Projections by Product Type, 2022 to 2029

Figure 181: BENELUX Market Share and BPS Analysis By Application, 2022 & 2029

Figure 182: BENELUX Market Y-o-Y Growth Projections by Application, 2022 to 2029

Figure 183: BENELUX Market Attractiveness Analysis Projections by Application, 2022 to 2029

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA