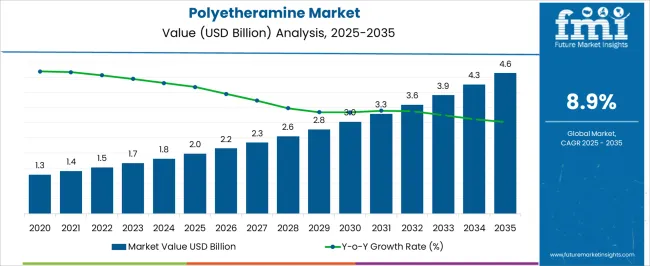

The Polyetheramine Market is estimated to be valued at USD 2.0 billion in 2025 and is projected to reach USD 4.6 billion by 2035, registering a compound annual growth rate (CAGR) of 8.9% over the forecast period.

| Metric | Value |

|---|---|

| Polyetheramine Market Estimated Value in (2025 E) | USD 2.0 billion |

| Polyetheramine Market Forecast Value in (2035 F) | USD 4.6 billion |

| Forecast CAGR (2025 to 2035) | 8.9% |

The polyetheramine market is witnessing steady expansion, supported by its widespread use in coatings, adhesives, sealants, composites, and fuel additives. Growth is being driven by increasing demand from construction, automotive, aerospace, and energy sectors where high-performance materials are required. Polyetheramines are being adopted for their superior flexibility, toughness, and chemical resistance, which enhance product performance in harsh environmental conditions.

Rapid industrialization, coupled with rising infrastructure investments in both developed and emerging economies, is further boosting consumption. Advancements in resin formulations and innovations in epoxy and polyurethane systems are contributing to broader applications of polyetheramines across industries. Additionally, sustainability trends are encouraging the use of advanced materials that provide durability and longer service life, reducing replacement costs and environmental impact.

With expanding industrial applications and growing R&D investments from leading chemical manufacturers, the polyetheramine market is expected to maintain strong growth momentum Increasing regulatory focus on energy efficiency and improved material performance is further shaping future opportunities for market expansion globally.

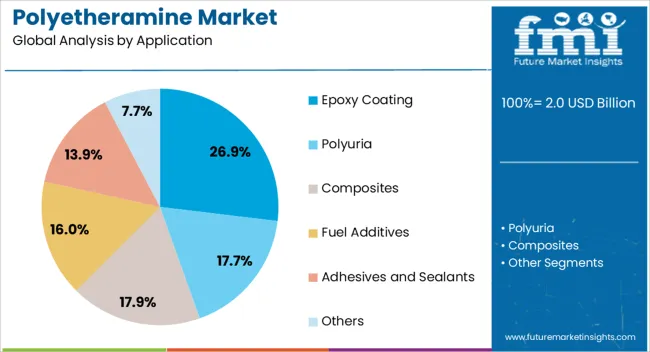

The polyetheramine market is segmented by application, and geographic regions. By application, polyetheramine market is divided into Epoxy Coating, Polyuria, Composites, Fuel Additives, Adhesives and Sealants, and Others. Regionally, the polyetheramine industry is classified into North America, Latin America, Western Europe, Eastern Europe, Balkan & Baltic Countries, Russia & Belarus, Central Asia, East Asia, South Asia & Pacific, and the Middle East & Africa.

The epoxy coating application segment is projected to account for 26.9% of the polyetheramine market revenue share in 2025, positioning it as the leading application segment. This leadership is being driven by the increasing adoption of epoxy coatings in construction, marine, automotive, and industrial sectors where high durability and chemical resistance are critical. Polyetheramines serve as curing agents that enhance the flexibility, toughness, and adhesion properties of epoxy coatings, making them suitable for demanding environments.

Rising infrastructure investments, particularly in protective and industrial coatings, are contributing to sustained demand. The growing use of epoxy coatings in floorings, concrete protection, and anti-corrosion applications is further supporting segment growth. Polyetheramine-modified epoxy systems also offer improved thermal stability, enabling performance in extreme operating conditions.

Global trends emphasizing longer-lasting and energy-efficient infrastructure are reinforcing adoption, as epoxy coatings extend asset lifecycles while reducing maintenance costs As industries prioritize materials that combine durability with performance, the epoxy coating application segment is expected to maintain its leadership within the polyetheramine market over the coming years.

Emerging Applications for Polyetheramine Products

Polyetheramines find extensive application in various industries such as adhesives, sealants, elastomers, coatings, and composites. Increasing demand in these sectors, driven by the construction, automotive, and aerospace industries, among others, was a significant trend.

Impact of Sustainability Trends on the Polyetheramine Market

Environmental concerns have been driving the shift towards eco-friendly alternatives across industries. In the case of polyetheramines, there has been a growing emphasis on developing bio-based or sustainable production methods to reduce reliance on fossil fuels and minimize environmental impact.

Innovations in Packaging for Polyetheramine Products

Research and development efforts have been ongoing to enhance the properties of polyetheramines, such as improving their performance, durability, and compatibility with other materials. Innovations in manufacturing processes to optimize efficiency and reduce costs have also been notable.

Impact of Government Regulations and Policies to Hinder Growth

The production and use of polyetheramines may raise environmental concerns due to emissions of volatile organic compounds (VOCs) during application, as well as the potential toxicity of certain formulations. Stringent environmental regulations aimed at controlling VOC emissions and promoting the use of eco-friendly alternatives could restrain growth or require costly adjustments for compliance.

The United States is experiencing growth due to factors like infrastructure development, automotive production, and consumer preferences for high-performance materials. Demand is driven by key end-use industries like construction, automotive, coatings, adhesives, and sealants.

Companies are investing in research and development to develop bio-based polyetheramines and formulations with reduced environmental impact, aligning with regulatory requirements and market preferences.

Strategic partnerships among industry players, including manufacturers, suppliers, and end-users, are forming to leverage complementary expertise and expand reach. Compliance with regulatory standards, such as the Toxic Substances Control Act (TSCA) and Occupational Safety and Health Administration (OSHA), is essential for participants.

The United Kingdom's industrial growth, particularly in construction, automotive manufacturing, electronics, and coatings, has driven a significant demand for polyetheramine. The country's infrastructure development initiatives, urbanization trends, and expanding automotive market have contributed to this growth.

The Belt and Road Initiative (BRI) and government investments in infrastructure development have also fueled growth. The market has seen consolidation as larger companies seek to expand share through mergers and acquisitions.

This trend aims to enhance product offerings, access new markets, and achieve economies of scale. Advanced polyetheramines find rising applications in automotive coatings, aerospace adhesives, and electronics manufacturing for outstanding durability and chemical resilience.

China's polyetheramine industry is experiencing growth due to technological advancements and product innovation. Leading companies are focusing on improving properties like flexibility, curing speed, and chemical resistance to meet domestic and international market needs.

Market liberalization and foreign investment are creating opportunities for multinational companies to enter or expand their presence in the market. Joint ventures, partnerships, and acquisitions are common strategies adopted by foreign companies.

China's manufacturers are also targeting international markets, leveraging its competitive advantages in production capacity, cost efficiency, and logistics infrastructure.

Polyetheramines are used as chain extenders in polyurea coating creation due to its fast curing and resilience. These coatings are popular for pipeline lining, waterproofing, and industrial flooring.

Polyetheramines are also crucial in producing epoxy adhesives, making bonds stronger and adhesion to surfaces more durable. These adhesives and sealants are used in industries like automotive, construction, and electronics for their adhesion and sealing applications.

The polyether amine market is experiencing significant growth due to leading companies investing in cost-effective and sustainable products. These companies prioritize the production of biodegradable and lower-toxicity polyetheramine products.

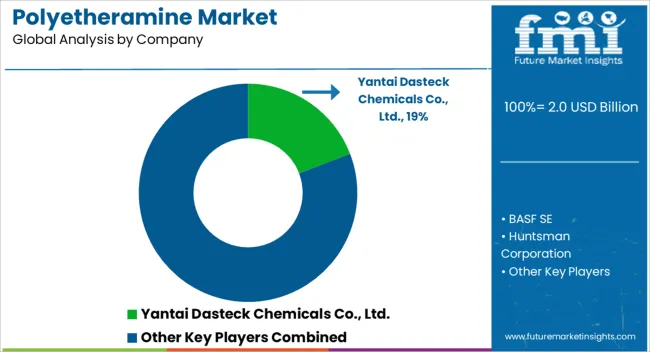

Yantai Dasteck Chemicals Co., Ltd., BASF SE, Huntsman Corporation, and Clariant, Yantai Minsheng Chemicals Co., Ltd. are the key players in the polyetheramine industry.

Key companies are leveraging various strategic actions, including product introductions, expansion efforts, and mergers and acquisitions. They are also investing heavily in research and development to expand their product lines.

Leading participants are also undertaking strategic activities such as new product launches, contractual agreements, mergers and acquisitions, higher investments, and collaborations with other organizations. Local manufacturing is a key business tactic used to benefit clients and increase the sector.

Industry Updates

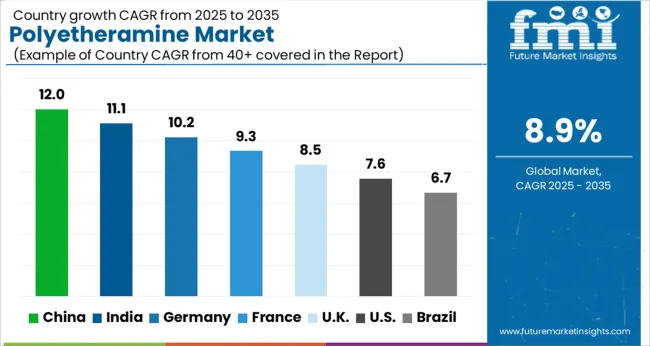

| Country | CAGR |

|---|---|

| China | 12.0% |

| India | 11.1% |

| Germany | 10.2% |

| France | 9.3% |

| UK | 8.5% |

| USA | 7.6% |

| Brazil | 6.7% |

The Polyetheramine Market is expected to register a CAGR of 8.9% during the forecast period, exhibiting varied country level momentum. China leads with the highest CAGR of 12.0%, followed by India at 11.1%. Developed markets such as Germany, France, and the UK continue to expand steadily, while the USA is likely to grow at consistent rates. Brazil posts the lowest CAGR at 6.7%, yet still underscores a broadly positive trajectory for the global Polyetheramine Market. In 2024, Germany held a dominant revenue in the Western Europe market and is expected to grow with a CAGR of 10.2%. The USA Polyetheramine Market is estimated to be valued at USD 728.7 million in 2025 and is anticipated to reach a valuation of USD 1.5 billion by 2035. Sales are projected to rise at a CAGR of 7.6% over the forecast period between 2025 and 2035. While Japan and South Korea markets are estimated to be valued at USD 94.2 million and USD 64.5 million respectively in 2025.

| Item | Value |

|---|---|

| Quantitative Units | USD 2.0 Billion |

| Application | Epoxy Coating, Polyuria, Composites, Fuel Additives, Adhesives and Sealants, and Others |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, Middle East & Africa |

| Country Covered | United States, Canada, Germany, France, United Kingdom, China, Japan, India, Brazil, South Africa |

| Key Companies Profiled | Yantai Dasteck Chemicals Co., Ltd., BASF SE, Huntsman Corporation, Clariant, Yantai Minsheng Chemicals Co., Ltd., Yangzhou Chenhua New Materials Co., Ltd, Wuxi Acryl Technology Co., Ltd., and Qingdao IRO Surfactant Co., Ltd. |

The global polyetheramine market is estimated to be valued at USD 2.0 billion in 2025.

The market size for the polyetheramine market is projected to reach USD 4.6 billion by 2035.

The polyetheramine market is expected to grow at a 8.9% CAGR between 2025 and 2035.

The key product types in polyetheramine market are epoxy coating, polyuria, composites, fuel additives, adhesives and sealants and others.

In terms of , segment to command 0.0% share in the polyetheramine market in 2025.

Our Research Products

The "Full Research Suite" delivers actionable market intel, deep dives on markets or technologies, so clients act faster, cut risk, and unlock growth.

The Leaderboard benchmarks and ranks top vendors, classifying them as Established Leaders, Leading Challengers, or Disruptors & Challengers.

Locates where complements amplify value and substitutes erode it, forecasting net impact by horizon

We deliver granular, decision-grade intel: market sizing, 5-year forecasts, pricing, adoption, usage, revenue, and operational KPIs—plus competitor tracking, regulation, and value chains—across 60 countries broadly.

Spot the shifts before they hit your P&L. We track inflection points, adoption curves, pricing moves, and ecosystem plays to show where demand is heading, why it is changing, and what to do next across high-growth markets and disruptive tech

Real-time reads of user behavior. We track shifting priorities, perceptions of today’s and next-gen services, and provider experience, then pace how fast tech moves from trial to adoption, blending buyer, consumer, and channel inputs with social signals (#WhySwitch, #UX).

Partner with our analyst team to build a custom report designed around your business priorities. From analysing market trends to assessing competitors or crafting bespoke datasets, we tailor insights to your needs.

Supplier Intelligence

Discovery & Profiling

Capacity & Footprint

Performance & Risk

Compliance & Governance

Commercial Readiness

Who Supplies Whom

Scorecards & Shortlists

Playbooks & Docs

Category Intelligence

Definition & Scope

Demand & Use Cases

Cost Drivers

Market Structure

Supply Chain Map

Trade & Policy

Operating Norms

Deliverables

Buyer Intelligence

Account Basics

Spend & Scope

Procurement Model

Vendor Requirements

Terms & Policies

Entry Strategy

Pain Points & Triggers

Outputs

Pricing Analysis

Benchmarks

Trends

Should-Cost

Indexation

Landed Cost

Commercial Terms

Deliverables

Brand Analysis

Positioning & Value Prop

Share & Presence

Customer Evidence

Go-to-Market

Digital & Reputation

Compliance & Trust

KPIs & Gaps

Outputs

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA