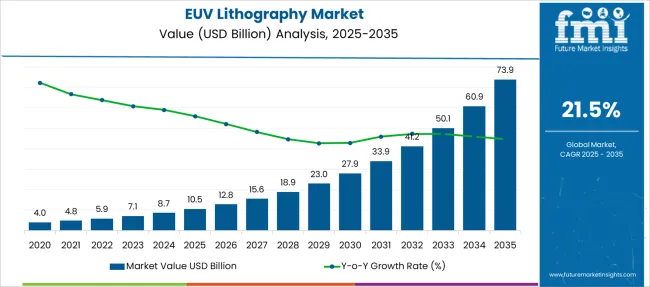

The EUV Lithography Market is estimated to be valued at USD 10.5 billion in 2025 and is projected to reach USD 73.9 billion by 2035, registering a compound annual growth rate (CAGR) of 21.5% over the forecast period.

| Metric | Value |

|---|---|

| EUV Lithography Market Estimated Value in (2025 E) | USD 10.5 billion |

| EUV Lithography Market Forecast Value in (2035 F) | USD 73.9 billion |

| Forecast CAGR (2025 to 2035) | 21.5% |

The EUV lithography market is experiencing rapid growth driven by the increasing demand for advanced semiconductor manufacturing technologies. Industry trends point to escalating requirements for smaller feature sizes and higher transistor densities, which have accelerated the adoption of EUV lithography in chip production.

Technological advancements have improved EUV system reliability and throughput, making it the preferred choice for leading-edge semiconductor fabrication. The growing need for powerful processors in applications like artificial intelligence, 5G, and high-performance computing has further fueled investments in EUV-enabled manufacturing lines.

Industry initiatives aimed at reducing production costs and increasing yield have supported broader integration of EUV lithography. The market outlook remains positive as chipmakers push the limits of Moore’s law and transition to new nodes. Segment growth is expected to be dominated by Integrated Device Manufacturers (IDMs), who invest heavily in in-house fabrication capabilities to maintain competitive advantages and ensure supply chain control.

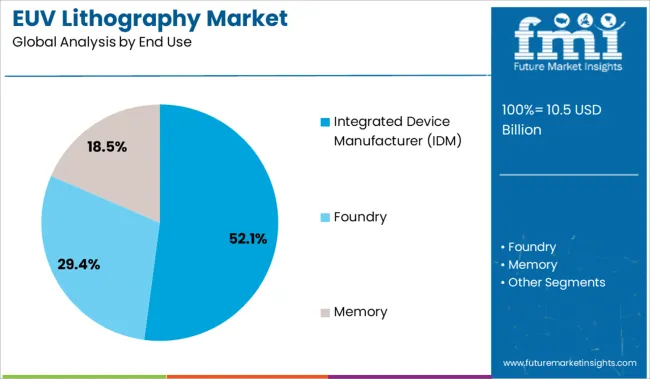

The market is segmented by End Use and region. By End Use, the market is divided into Integrated Device Manufacturer (IDM), Foundry, and Memory. Regionally, the market is classified into North America, Latin America, Western Europe, Eastern Europe, Balkan & Baltic Countries, Russia & Belarus, Central Asia, East Asia, South Asia & Pacific, and the Middle East & Africa.

The Integrated Device Manufacturer segment is projected to account for 52.1% of the EUV lithography market revenue in 2025, maintaining its lead in end-use adoption. This segment’s growth has been driven by IDMs’ strategic focus on vertical integration, allowing them to control the entire semiconductor production process from design to manufacturing.

Investments in state-of-the-art EUV equipment enable IDMs to produce cutting-edge chips with smaller geometries and higher performance. The ability to innovate rapidly and customize manufacturing processes provides IDMs with a competitive edge in the global semiconductor market.

Furthermore, supply chain disruptions have encouraged IDMs to strengthen their in-house production capabilities, increasing reliance on advanced lithography technologies. As semiconductor complexity rises and demand for high-performance chips grows, IDMs are expected to continue leading EUV lithography adoption.

| Market Statistics | Details |

|---|---|

| H1,2024 (A) | 14.6% |

| H1,2025 Projected (P) | 20.9% |

| H1,2025 Outlook (O) | 18.3% |

| BPS Change : H1,2025 (O) - H1,2025 (P) | (-) 264 ↓ |

| BPS Change : H1,2025 (O) - H1,2024 (A) | (+) 373 ↑ |

Future Market Insights presents a comprehensive comparison and review analysis of the extreme ultraviolet (EUV) lithography market which is principally subjected to tremendous growth owing to its increasing demand for advanced lithographic systems.

Extreme Ultraviolet Lithography is a cutting-edge technique for fabricating semiconductors that uses short light wavelengths (14 nanometers and below) to print intricate patterns on integrated circuits.

According to FMI analysis, the change in BPS values observed in the market for digital oilfield solutions for the current estimation for the first half of 2025 as compared to the projected one for the same period is expected to be at a 264-unit decrease. However, as per the current estimates, the market is predicted to rise by 373 basis points in H1-2025 in comparison to H1-2024.

This huge difference between the change in growth rate is due to the complicated nature of EUV lithography systems and the presence of very less players in the manufacturing domain.

EUV lithography systems are becoming increasingly popular on the international market as a result of the rising demand for micro technologies like microprocessors, integrated circuits (IC), and other semiconductors.

Another reason driving demand for the integrated device maker category in the projection period is the rising need for advanced semiconductors, which feature a variety of potentially transformational technologies. To increase their range of technological solutions that meet client objectives, major companies in the EUV lithography market are concentrating on a data-centric strategy.

Extreme Ultraviolet Lithography is a next-generation technology for semiconductor manufacturing that produces short light wavelengths (14 nanometers and below) to create minuscule patterns on integrated circuits. The market is driven by growing technological advancements for high-volume manufacturing of microchips that are significantly used in several applications. The Global EUV Lithography Market is estimated to grow at a CAGR of 21.5% during the forecast period.

Significant investment in research & development to enhance EUV technology, as well as investing in technology providers for mutual cooperation in product development is one of the key factors fuelling the demand for EUV lithographic systems. Manufacturers are also collaborating with technology providers to develop next-generation EUV lithography systems in the market.

The demand for EUV lithographic systems between 2014 and 2024 grew by 65.9% due to a reduction in the cost of manufacturing components as well as continuous investment in Research and Development. Since the market has been established in the recent past, it had witnessed a substantial CAGR over the past years.

Rising automation in the automotive industry is a significant factor accelerating the demand for EUV lithographic systems in the market. The growth in the electric vehicle segment as they contain semiconductors, in developed as well as developing countries across the globe will also contribute to the growing sales of EUV lithographic systems.

Growing investments in research & development to create a new range of integrated circuits (IC), power devices, semiconductors, and others are differentiating factors increasing the overall demand for EUV lithographic systems.

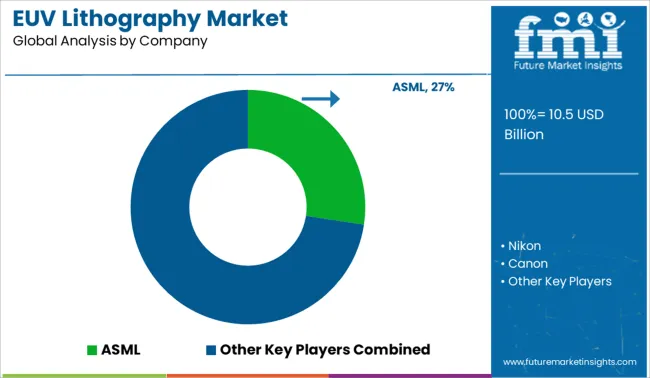

EUV lithography systems are incredibly complicated and require over 10,000 different components to build one unit hence the market is dominated by very fewer manufacturers which gives them a monopoly over the market and ramps up their production volume. Thus manufacturers focus on developing new solutions to cater to the market needs.

The increasing demand for micro technologies like microprocessors, integrated chips (IC), and other semiconductors is also fuelling the demand for EUV lithographic systems in the global market. These are some of the key factors for the boosting demand for EUV lithography systems all over the globe.

By end use, the integrated device manufacturers (IDM) segment is anticipated to remain one of the fastest-growing segments in the EUV lithography market. Increasing wafer capacity is driving the lithography market in the forecast period. New leading-edge nodes with increased lithography intensity are estimated to further drive the lithography demand for the IDM segment.

Rising demand for advanced semiconductors that have a wide range of potentially transformative technologies is also a factor that is increasing demand for the integrated device manufacturer segment in the forecast period. This segment is projected to create an absolute dollar opportunity of more than USD 6,956.8 Million during the forecast period of 2025 to 2035.

Key players in the EUV Lithography market are focusing on a data-centric approach with an aim of expanding their portfolio of technology solutions that address customer needs. Many key players are also using innovation to expand their product offerings to meet customer requirements. Players are aiming at research & development to develop new products.

For Instance:

The latest study conducted by Future Market Insights covers all the strategies and success factors of key manufacturers of the market.

*The list is not exhaustive and is only for representational purposes. Full competitive intelligence with SWOT analysis is available in the report.

| Attribute | Details |

|---|---|

| Forecast Period | 2025 to 2035 |

| Historical Data Available for | 2014 to 2024 |

| Market Analysis | USD Million for Value and Units for Volume |

| Key Regions Covered | Americas, EMEA, and Asia Pacific |

| Key Countries Covered | USA, Germany, France, China, Japan, South Korea, and Singapore |

| Key Segments Covered | By End Use, By Region |

| Key Companies Profiled | ASML; Nikon; Canon; Carl Zeiss; Toppan Printing; NTT Advanced Technology; Intel; Samsung; SK Hynix; Toshiba; TSMC; Global Foundries |

| Report Coverage | Market Forecast, Company Share Analysis, Competition Intelligence, Drivers, Restraints, Opportunities and Threats Analysis, Market Dynamics and Challenges, and Strategic Growth Initiatives |

| Customization & Pricing | Available upon Request |

The global EUV lithography market is estimated to be valued at USD 10.5 billion in 2025.

The market size for the EUV lithography market is projected to reach USD 73.9 billion by 2035.

The EUV lithography market is expected to grow at a 21.5% CAGR between 2025 and 2035.

The key product types in EUV lithography market are integrated device manufacturer (idm), foundry and memory.

In terms of , segment to command 0.0% share in the EUV lithography market in 2025.

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Lithography Equipment Market Size and Share Forecast Outlook 2025 to 2035

Stencil Lithography Market Size and Share Forecast Outlook 2025 to 2035

Extreme Ultraviolet Lithography (EUV) Market Analysis by Light Source Type, Application, and Region through 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA