Geiger counter industry grew at a steady rate in 2024 due to increase in global concerns on safety regarding radiation. Several sectors demonstrated high demand with an attention on nuclear power plants, medical diagnostics, and environmental monitoring.

Governments and regulatory bodies in North America and Europe made stricter regulations on safety norms with regards to radiation; thus, enhanced uptake. Rising investments in nuclear energy infrastructure and disaster preparedness strategies strengthen industry demand in the Asia-Pacific region, particularly Japan and South Korea.

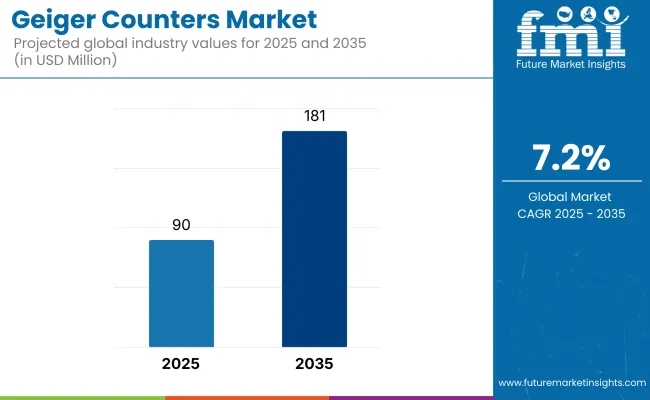

It is projected that the industry will reach 90 million USD by 2025-end with a CAGR of 7.2%, underpinned by investments in nuclear energy, regulatory scrutiny, and growing concerns for personal safety.

Miniaturization, IoT-enabled radiation sensors, and AI-assisted analytics are expected to define the evolution of this industry sector over the next ten years, with industry growth expected to surpass USD 181 million by 2035.

Another key trend is that smart portable Geiger counters are being used that provide wireless connectivity and cloud-based analytics, combined with AI-driven pattern-tracking applications for radiation.

This movement is especially vivid in the healthcare sector, in which hospitals and diagnostic centers were increasingly relying on high-end radiation detection. Additionally, rising instances of radiation leakages and environmental hazards spurred demand for emergency response applications.

The growth rate of the global Geiger counter industry is rising with the radiological safety standards getting stringent, coupled with the expansion of nuclear energy projects and the increasing awareness of environmental hazards. An advanced feature in detection technology can benefit regulators, health institutions, and industry safety professionals. Increasing demand for portable, real-time radiation detection will become a definition of industry winners through innovation in IoT, AI-powered analytics, and miniaturization.

Based on type, the handheld Geiger counters segment is projected to surge at a CAGR of 7.0% through 2035. The advanced developments across all form factors of the Geiger counter industry are set to evolve in a short time, with handheld, benchtop, and wearable devices meeting the growing requirement for real-time, accurate detection of radiation.

Handheld Geiger counters will thrive, as they are user-friendly and portable, thus being very handy for healthcare professionals, industrial workers, and first responders.

Manufacturers will add the smart features of wireless connectivity, cloud storage, and AI-powered analytics for ease of operability. The benchtop Geiger counters will keep serving laboratories, nuclear facilities, and research institutions with the increasing investment in nuclear energy and strict radiation safety regimes, therefore really improving their growth under high sensitivity, automation, and multi-sensor capabilities. The entry of wearable Geiger counters in the industry will radically change personal radiation monitoring with their applications in healthcare, defence, and hazardous industries.

These small devices offer users the capability of continuous monitoring of exposure and will be configured to alert users in real-time through smartphone apps and communication with IoT-enabled systems.

Given the tightening of personal radiation exposure limits by regulatory frameworks, wearable devices will be at the forefront of use by professionals in high-radiation environments.

With further improvements in battery life, miniaturization, and AI-based exposure analysis, wearables will see rising prominence among nuclear power plant workers, military officers, and hazardous material handlers.

The reinvention of smart technologies and enhanced data analytics will be the main determinants for future innovations across the board, ensuring continued growth of the industry.

In terms of application, the healthcare category is projected to showcase a CAGR of 6.8% from 2025 to 2035. It exhibited a decent CAGR of 8.2% during the historical period. The demand for geiger counters in radiation measuring equipment in healthcare, industry/manufacturing, defence, and other applications will rise with the increasing demands for various other sectors.

Increasing usage of radiotherapy, nuclear medicine, and radiology equipment will push even more demand for these precision high-end Geiger counters in hospitals and centres for diagnostics. With stricter limits for radiation exposures, these healthcare facilities will lean toward automated and connected monitoring systems for ensuring patient and staff safety.

In the industries and manufacturing field, particularly in the nuclear power plant, mining, and semiconductor industries, radiation monitoring is to be of utmost importance concerning regulatory compliance and worker protection. Automated Geiger counters in industrial settings would enhance real-time hazard detection. This will aid in minimizing operational risk.

In defence, investments in radiation detection technologies will continue to flow, fuelled by mounting concerns regarding nuclear threats, radiation-based weapons, and exposure to hazardous materials.

Military forces and defence agencies will adopt rugged, high-sensitivity Geiger counters to carry out field operations, ensuring personnel safety in high-risk areas. Environmental monitoring, research, and emergency response will gain more ground as climate change and industrial activities raise concerns regarding radiation exposure.

Overall demand for real-time connected monitoring systems across all applications will stay on the rise and will work towards boosting industry growth in the long run.

Invest in Smart & Connected Radiation Monitoring

Executives should prioritize R&D investments in IoT-enabled, AI-driven Geiger counters to enhance real-time radiation tracking, predictive analytics, and regulatory compliance. Integrating cloud-based data logging and mobile app connectivity will improve usability and increase adoption across healthcare, industry, and defence.

Align with Regulatory & Safety Standards

Companies must stay ahead of evolving global radiation safety regulations by ensuring product compliance with IAEA, NRC, and EU radiation exposure norms. Strategic collaboration with regulatory bodies and healthcare institutions will drive industry acceptance, particularly in regions expanding nuclear energy projects.

Expand Distribution & Strategic Partnerships

Manufacturers should build strong partnerships with OEMs, defense contractors, and industrial safety solution providers to expand industry reach. Strengthening aftermarket services and training programs for radiation monitoring solutions will enhance customer retention and differentiate industry leaders.

| Risk | Probability & Impact |

|---|---|

| Regulatory Uncertainty - Shifts in radiation safety laws could delay product approvals | Medium Probability, High Impact |

| Supply Chain Disruptions - Semiconductor shortages and geopolitical tensions may affect production | High Probability, High Impact |

| Technology Obsolescence - Failure to integrate AI & IoT could make traditional Geiger counters less competitive | Medium Probability, High Impact |

| Priority | Immediate Action |

|---|---|

| Smart Technology Expansion | Develop AI-based exposure tracking features |

| Regulatory Compliance Readiness | Engage with global radiation safety regulators |

| Distribution Channel Strengthening | Expand partnerships with industrial safety firms |

To stay competitive, companies must accelerate their shift toward AI-driven, connected Geiger counters, ensuring seamless integration with cloud-based monitoring systems.

By prioritizing compliance with evolving radiation safety regulations, executives can unlock growth in nuclear energy, healthcare, and defence industries.

Additionally, investing in strategic partnerships and distribution networks will strengthen industry penetration and create long-term competitive advantages. Now is the time to align R&D, regulatory strategy, and go-to-industry execution to capitalize on the industry's digital transformation.

(Surveyed Q1 2025, n=500 stakeholder participants evenly distributed across manufacturers, distributors, end-users in healthcare, industry, defense, and environmental agencies across North America, Western Europe, Japan, and South Korea)

Key Priorities of Stakeholders

Regional Variance

High Variance in Smart Integration

Divergent ROI Perspectives

Consensus

Regional Variance

Shared Challenges

Regional Differences

Manufacturers

Distributors

End-Users (Healthcare, Industry, Defense)

Alignment Across Industries

Regional Focus Areas

Regulatory Impact

High Consensus: Regulatory compliance, durability, and cost pressures remain universal concerns.

Key Variances

| Country/Region | Regulatory Impact & Mandatory Certifications |

|---|---|

| United States | The Nuclear Regulatory Commission (NRC) and Occupational Safety and Health Administration (OSHA) set strict guidelines for radiation exposure limits in workplaces, healthcare, and industrial settings. Companies must comply with ANSI N42.17A/B standards for portable radiation detectors. Medical applications must adhere to FDA 21 CFR 1020.40 for radiation-emitting devices. |

| Western Europe | The European Union’s Radiation Protection Directive (Council Directive 2013/59/Euratom) mandates strict workplace radiation exposure monitoring. Geiger counters used in the EU must meet CE certification and ISO 9001 for quality management. Germany has additional regulations under Strahlenschutzverordnung (Radiation Protection Ordinance). |

| Japan | The Nuclear Regulation Authority (NRA) oversees radiation safety in nuclear power plants, research labs, and medical applications. Companies must adhere to JIS Z 4324 (Japanese Industrial Standards for radiation measurement). However, regulation enforcement remains less aggressive compared to the US and EU. |

| South Korea | The Korea Institute of Nuclear Safety (KINS) enforces radiation safety regulations under the Nuclear Safety Act. Geiger counters used in nuclear facilities must comply with KINS-Guide-RG601. The government is promoting stricter enforcement due to rising concerns about industrial radiation exposure. |

| China | The National Nuclear Safety Administration (NNSA) and Ministry of Ecology and Environment (MEE) enforce radiation safety laws, particularly in industrial and environmental monitoring. Companies must obtain CCC (China Compulsory Certification) for radiation detection equipment. |

| India | The Atomic Energy Regulatory Board (AERB) sets guidelines for radiation monitoring in medical, industrial, and research sectors. Geiger counters must comply with IS/IEC 60846 (Indian Standards for radiation monitoring devices). The government is strengthening regulations as nuclear energy projects expand. |

| Russia | The Federal Service for Ecological, Technological and Nuclear Supervision (Rostekhnadzor) enforces radiation safety laws. Geiger counters must meet GOST R 52318-2005 standards for radiation detection. Due to geopolitical restrictions, Western companies face challenges in industry entry and certification approval. |

| Australia | The Australian Radiation Protection and Nuclear Safety Agency (ARPANSA) mandates radiation monitoring in mining, healthcare, and research. Devices must comply with AS/NZS IEC 60846 standards for radiation protection instruments. |

| Company | Market Share & Competitive Positioning |

|---|---|

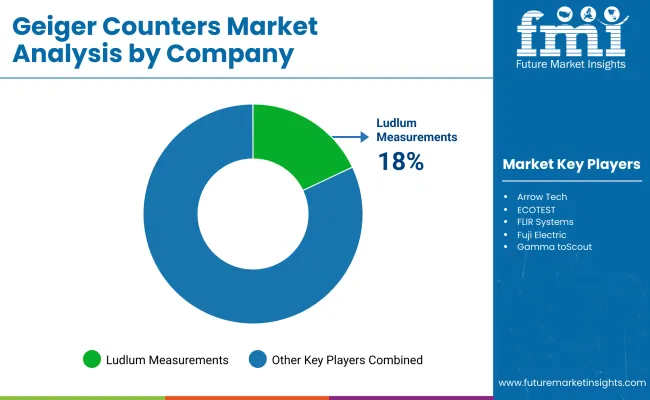

| Ludlum Measurements, Inc. | It holds approximately 18% of the global industry share, driven by its extensive product portfolio in industrial and nuclear applications. Strong presence in North America and Western Europe with high adoption in nuclear energy and defense sectors. |

| Mirion Technologies, Inc. | Commands around 15% industry share, focusing on high-end radiation detection solutions. Its advanced digital Geiger counters and IoT-enabled radiation monitoring systems have positioned it as a leader in healthcare, industry, and environmental safety. |

| Thermo Fisher Scientific, Inc. | It holds 12% of the industry, benefiting from its strong distribution network and integration with laboratory equipment. The company's radiation monitoring solutions for medical and industrial research have given it a stronghold in Western Europe and North America. |

| Fuji Electric Co., Ltd. | Owns around 10% of the industry, with dominance in Japan and South Korea. Focuses on compact and high-sensitivity Geiger counters for industrial and environmental monitoring applications. |

| Polimaster Inc. | Captures 9% of the industry, specializing in wearable and handheld Geiger counters for personal radiation monitoring and homeland security. The company has a growing footprint in Eastern Europe and Asia-Pacific. |

| Ecotest Group | Holds 7% of the industry, with strong demand for military-grade and industrial radiation detectors in Eastern Europe and Russia. Recent geopolitical challenges have impacted Western industry penetration. |

| Arrow-Tech, Inc. | Has a niche 5% industry share, focusing primarily on civil defense and military applications in North America. It provides high-durability radiation detection devices for emergency response teams. |

| Other Players | The remaining 24% industry share is fragmented among regional manufacturers and specialized companies that cater to specific industrial and environmental needs. This includes emerging players in China, India, and Eastern Europe, which are offering cost-effective alternatives. |

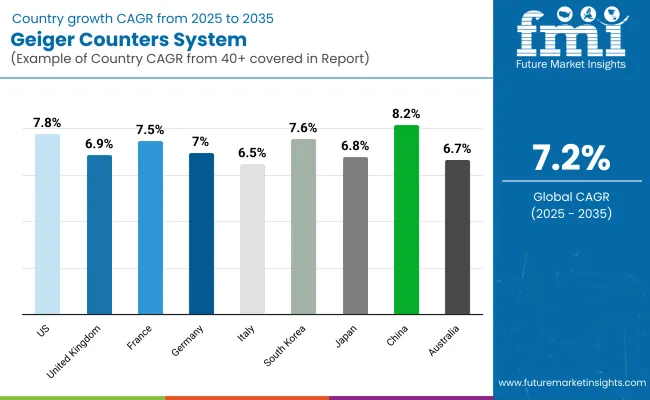

The Geiger counter market in the United States is expected to expand at a CAGR of 7.8% from 2025 to 2035, slightly above the global average of 7.2%, driven by strict radiation safety regulations, growing nuclear energy initiatives, and advancements in defence and healthcare applications. The Nuclear Regulatory Commission (NRC) and Occupational Safety and Health Administration (OSHA) have stringent radiation monitoring laws, pushing industries to adopt advanced radiation detection technology.

The USA also has a strong military and homeland security demand for Geiger counters, with increased government spending on radiation detection equipment for border security and emergency response. The healthcare sector is another major driver, with expanding applications in nuclear medicine, radiology, and oncology. The presence of key manufacturers such as Ludlum Measurements, Mirion Technologies, and Thermo Fisher Scientific ensures a steady supply of advanced radiation monitoring devices.

Technological advancements, such as AI-enabled real-time radiation mapping and IoT-integrated devices, are likely to shape future growth. However, supply chain disruptions and semiconductor shortages could pose challenges in the short term. The increasing demand for smart, wearable radiation detectors and real-time monitoring solutions in nuclear power plants and industrial settings will continue to drive US industry expansion.

The Geiger counter industry in the United Kingdom is projected to grow at a CAGR of 6.9% between 2025 and 2035, slightly below the global average. The primary growth drivers are nuclear power expansion, industrial safety regulations, and heightened environmental monitoring initiatives. The UK government has committed to nuclear energy growth, with projects such as Sizewell C and Hinkley Point C, increasing the need for radiation monitoring systems in nuclear facilities.

The Health and Safety Executive (HSE) enforces strict workplace radiation exposure limits, prompting industries to adopt advanced detection technology. The defense sector also plays a critical role, with Geiger counters used in military operations and emergency preparedness.

While the industry is technologically advanced, Brexit-related trade uncertainties and import dependency for semiconductor components may impact supply chains. Nonetheless, demand for IoT-enabled radiation detection devices in healthcare and industrial applications is expected to accelerate industry growth. The UK’s focus on sustainability and energy-efficient monitoring systems may also open avenues for eco-friendly Geiger counter innovations.

France’s Geiger counter industry is set to grow at a CAGR of 7.5%, exceeding the global average due to its strong nuclear energy infrastructure and rigorous radiation protection policies.

As the world’s largest producer of nuclear energy per capita, France has extensive requirements for radiation monitoring devices in nuclear power plants, research laboratories, and industrial facilities.

The healthcare sector also contributes significantly, with increasing adoption of Geiger counters in radiology, oncology, and medical imaging centres. Additionally, France has high investments in environmental radiation monitoring, particularly following the European Union’s strict radiation safety directives.

Challenges such as supply chain disruptions in semiconductor components and competition from low-cost Eastern European manufacturers persist. However, technological advancements, including automated radiation detection networks and AI-driven safety monitoring, are expected to fuel industry growth.

Germany’s Geiger counter industry is anticipated to grow at a CAGR of 7.0%, driven by EU radiation safety regulations, growing defence requirements, and industrial radiation monitoring needs. Although Germany is phasing out nuclear power, its industrial sector still relies on radiation detection devices for quality control, metallurgy, and environmental monitoring.

Germany’s strong defence sector also influences growth, with increased spending on border security and homeland safety. The Bundesamt für Strahlenschutz (BfS) enforces stringent regulations for radiation protection, ensuring steady demand for advanced radiation detection solutions.

Challenges include reduced nuclear power investments and increasing competition from cost-effective Eastern European manufacturers. However, Germany’s leadership in IoT and automation technologies provides a strong foundation for smart Geiger counter solutions in industrial safety and environmental applications.

The Italian Geiger counter industry is expected to grow at a CAGR of 6.5%, below the global average, due to Italy’s phase-out of nuclear energy and limited industrial radiation monitoring adoption. However, the increasing focus on healthcare applications and environmental safety regulations will drive moderate demand for radiation detection equipment.

Italy’s National Institute for Environmental Protection and Research (ISPRA) regulates radiation safety, pushing companies to adopt radiation monitoring solutions in medical diagnostics and waste management. The defense sector also utilizes Geiger counters for homeland security and emergency response.

Growth is limited by a lack of nuclear energy projects, but the increasing adoption of wearable Geiger counters and IoT-integrated monitoring solutions in industrial applications is expected to drive industry expansion.

South Korea is projected to grow at a CAGR of 7.6%, exceeding the global average due to its expanding nuclear power sector, semiconductor industry, and defense applications. The Korea Institute of Nuclear Safety (KINS) enforces strict regulations, leading to increased adoption of radiation monitoring solutions.

The semiconductor industry is a key driver, with major companies such as Samsung and SK Hynix requiring radiation detection equipment for cleanroom safety. Additionally, South Korea’s strong defence sector invests in radiation detection for military applications. Challenges include high reliance on imported radiation detection components, but technological innovations in miniaturized and wearable Geiger counters will drive growth.

Japan’s Geiger counter industry will grow at 6.8% CAGR, driven by nuclear decommissioning projects, semiconductor industry needs, and personal radiation safety awareness. The Nuclear Regulation Authority (NRA) enforces strict safety measures, increasing demand for radiation monitoring systems. Challenges include cost sensitivity among small-scale industrial users, but advancements in compact, AI-integrated Geiger counters will support industry growth.

China’s Geiger counter industry will expand at 8.2% CAGR, the highest among analyzed countries, due to rapid nuclear energy expansion and industrial safety regulations. The National Nuclear Safety Administration (NNSA) mandates strict radiation safety standards, boosting demand for radiation detection devices.

China’s aggressive investments in IoT and AI-based radiation monitoring will further drive industry growth. However, concerns over product quality and regulatory enforcement gaps may hinder adoption.

Australia industry will see growth with the 6.7% CAGR, fuelled by mining, environmental monitoring, and healthcare applications. The Australian Radiation Protection and Nuclear Safety Agency (ARPANSA) enforces strict radiation exposure laws, boosting demand for radiation detection devices. Growth is hindered by low nuclear energy investments, but rising demand for portable and industrial radiation monitoring solutions will sustain market expansion.

Handheld Geiger Counters, Benchtop Geiger Counters, Wearable Geiger Counters

Healthcare, Industry & Manufacturing, Defence, Others

The increasing focus on radiation safety, expansion of nuclear energy facilities, advancements in medical imaging, and heightened security concerns are major factors driving the demand for Geiger counters.

Geiger counters are widely used in healthcare, industrial manufacturing, defense, environmental monitoring, and nuclear power plants to ensure radiation safety and compliance with regulatory standards.

The integration of AI, IoT, and real-time data analytics has enhanced the accuracy, portability, and efficiency of radiation detection, leading to increased adoption in various sectors.

Manufacturers face challenges such as supply chain disruptions, semiconductor shortages, evolving regulatory requirements, and competition from alternative radiation detection technologies.

Strict radiation safety standards and regulatory frameworks set by agencies like the NRC, OSHA, and EU radiation protection bodies require industries to adopt certified and compliant radiation detection equipment.

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Photon Counters Market Size, Growth, and Forecast 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA