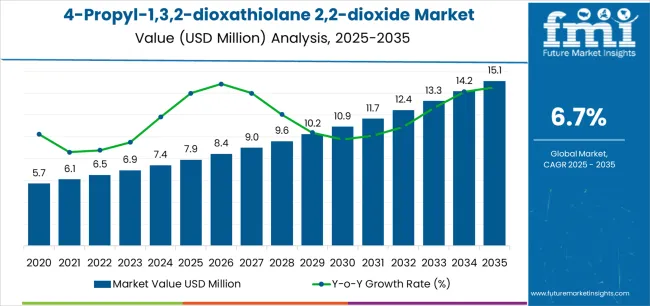

The global 4-propyl-1,3,2-dioxathiolane 2,2-dioxide market is valued at USD 7.9 million in 2025 and is slated to reach USD 15.1 million by 2035, recording an absolute increase of USD 7.27 million over the forecast period. This translates into a total growth of 91.4%, with the market forecast to expand at a compound annual growth rate (CAGR) of 6.7% between 2025 and 2035. The overall market size is expected to grow by approximately 1.91X during the same period, supported by increasing demand for advanced electrolyte additives, growing adoption of lithium-ion battery technologies across global energy storage markets, and rising preference for high-performance chemical compounds across battery manufacturing and industrial applications.

The 4-propyl-1,3,2-dioxathiolane 2,2-dioxide market represents a specialized segment of the global chemical additives industry, characterized by steady technological advancement and consistent demand across battery manufacturing and chemical processing channels. Market dynamics are influenced by changing battery technology requirements, growing interest in energy storage solutions, and expanding partnerships between chemical manufacturers and battery producers in developed and emerging economies. Traditional electrolyte formulation patterns continue evolving as manufacturers seek proven chemical additives that offer enhanced performance benefits and reliable stability characteristics.

Consumer behavior in the 4-propyl-1,3,2-dioxathiolane 2,2-dioxide market reflects broader industrial trends toward high-performance, effective additives that provide both technical benefits and manufacturing improvements. The market benefits from the growing popularity of lithium-ion battery systems, which are recognized for their energy density advantages and versatile application integration across multiple industries. Additionally, the versatility of 4-propyl-1,3,2-dioxathiolane 2,2-dioxide as both standalone chemical additive and integrated formulation component supports demand across multiple industrial applications and price segments.

Regional adoption patterns vary significantly, with Asian markets showing strong preference for liquid formulations, while European and North American markets demonstrate increasing adoption of specialized chemical solutions alongside conventional battery manufacturing systems. The industrial landscape continues to evolve with sophisticated and quality-controlled chemical products gaining traction in mainstream battery brands, reflecting manufacturer willingness to invest in proven chemical additive improvements and performance-oriented features.

The competitive environment features established chemical manufacturers alongside specialized additive providers that focus on unique synthesis capabilities and advanced processing methods. Manufacturing efficiency and product development optimization remain critical factors for market participants, particularly as raw material costs and quality standardization continue to fluctuate. Distribution strategies increasingly emphasize multi-channel approaches that combine traditional chemical supply chains with direct industrial partnerships through specialized distributors and manufacturing agreements.

Market consolidation trends indicate that larger chemical manufacturers are acquiring specialized additive producers to diversify their product portfolios and access specialized synthesis segments. Custom formulation development has gained momentum as battery companies seek to differentiate their offerings while maintaining competitive performance structures. The emergence of specialized variants, including high-purity and industrial-grade options, reflects changing industrial priorities and creates new market opportunities for innovative chemical developers. Manufacturing automation and quality control improvements enable consistent production scaling while maintaining traditional performance characteristics that manufacturers expect from established chemical brands.

Between 2025 and 2030, the 4-propyl-1,3,2-dioxathiolane 2,2-dioxide market is projected to expand from USD 7.9 million to USD 10.3 million, resulting in a value increase of USD 2.3 million, which represents 32.5% of the total forecast growth for the decade. This phase of development will be shaped by increasing adoption of advanced electrolyte systems, rising demand for quality-controlled and certified solutions, and growing emphasis on battery performance features with enhanced stability characteristics. Chemical manufacturers are expanding their specialized additive capabilities to address the growing demand for specialized implementations, advanced synthesis options, and custom formulation offerings across battery segments.

| Metric | Value |

|---|---|

| Estimated Value (2025E) | USD 7.9 million |

| Forecast Value (2035F) | USD 15.2 million |

| Forecast CAGR (2025-2035) | 6.70% |

From 2030 to 2035, the market is forecast to grow from USD 10.32 million to USD 15.2 million, adding another USD 4.91 million, which constitutes 67.5% of the overall ten-year expansion. This period is expected to be characterized by the expansion of high-purity systems, the integration of innovative synthesis solutions, and the development of specialized implementations with enhanced stability profiles and extended shelf life capabilities. The growing adoption of industrial-grade certification will drive demand for 4-propyl-1,3,2-dioxathiolane 2,2-dioxide with superior quality characteristics and compatibility with advanced battery manufacturing technologies across chemical production operations.

Between 2020 and 2025, the 4-propyl-1,3,2-dioxathiolane 2,2-dioxide market experienced steady growth, driven by increasing demand for electrolyte additives and growing recognition of specialized chemicals as essential components for modern battery programs across industrial and energy storage applications. The market developed as battery manufacturers recognized the potential for specialized chemical solutions to provide both performance benefits and safety advantages while enabling convenient formulation protocols. Technological advancement in synthesis techniques and industrial-grade development began emphasizing the critical importance of maintaining product purity and consistency in diverse battery environments.

Market expansion is being supported by the increasing global demand for electrolyte additives and the corresponding need for specialized chemicals that can provide superior performance benefits and technical advantages while enabling enhanced battery outcomes and extended compatibility across various industrial and energy storage applications. Modern manufacturers and battery industry specialists are increasingly focused on implementing proven chemical additives that can deliver effective performance enhancement, minimize conventional electrolyte limitations, and provide consistent performance throughout complex battery configurations and diverse usage environments. 4-Propyl-1,3,2-dioxathiolane 2,2-dioxide proven ability to deliver exceptional technical efficacy against conventional alternatives, enable advanced battery integration, and support modern manufacturing protocols makes it an essential component for contemporary battery manufacturing and industrial operations.

The growing emphasis on battery performance and advanced chemistry adoption is driving demand for 4-propyl-1,3,2-dioxathiolane 2,2-dioxide that can support large-scale manufacturing requirements, improve technical outcomes, and enable advanced formulation systems. Industrial preference for products that combine effective performance enhancement with proven stability and technical benefits is creating opportunities for innovative chemical implementations. The rising influence of energy storage trends and battery technology awareness is also contributing to increased demand for 4-propyl-1,3,2-dioxathiolane 2,2-dioxide that can provide advanced purity, seamless battery integration, and reliable performance across extended operational periods.

The 4-propyl-1,3,2-dioxathiolane 2,2-dioxide market is poised for steady growth and technological advancement. As battery manufacturers across Asia-Pacific, North America, Europe, and emerging markets seek chemicals that deliver exceptional technical quality, advanced purity capabilities, and reliable performance options, 4-propyl-1,3,2-dioxathiolane 2,2-dioxide solutions are gaining prominence not just as chemical additives but as strategic enablers of battery technologies and advanced industrial functionality.

Rising lithium battery adoption in Asia-Pacific and expanding energy storage initiatives globally amplify demand, while manufacturers are leveraging innovations in synthesis engineering, advanced processing integration, and quality management technologies.

Pathways like high-purity implementations, industrial-grade platforms, and specialized battery solutions promise strong margin uplift, especially in premium battery segments. Geographic expansion and product diversification will capture volume, particularly where local industrial preferences and advanced quality adoption are critical. Regulatory support around quality certification, performance standards, and safety protocols give structural support.

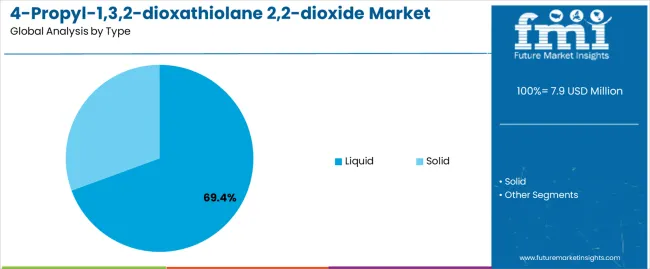

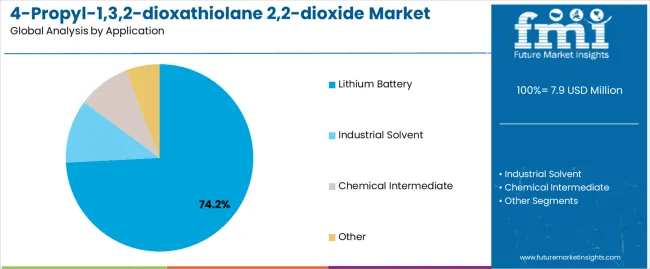

The market is segmented by type, application, purity grade, distribution channel, end-use sector, and region. By type, the market is divided into Liquid and Solid categories. By application, it covers Lithium Battery, Industrial Solvent, Chemical Intermediate, and Other segments. By purity grade, the market includes High Purity, Industrial Grade, and Standard Grade. By distribution channel, it comprises Direct Sales, Chemical Distributors, Online Platforms, and Specialty Suppliers. By end-use sector, the market is categorized into Battery Manufacturers, Chemical Companies, Research Institutions, and Others. Regionally, the market is divided into North America, Europe, East Asia, South Asia & Pacific, Latin America, and the Middle East & Africa.

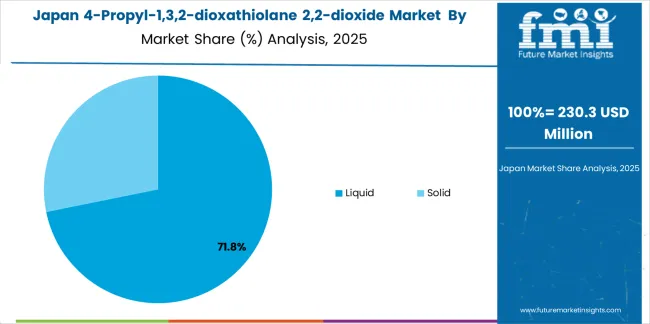

The liquid segment is projected to account for 69.4% of the 4-propyl-1,3,2-dioxathiolane 2,2-dioxide market in 2025, reaffirming its position as the leading type category. Battery manufacturers and chemical integrators increasingly utilize liquid implementations for their superior handling properties when operating across diverse formulation platforms, excellent mixing characteristics, and widespread acceptance in applications ranging from basic electrolyte formulations to premium battery operations. Liquid technology's standardized processing methods and proven handling capabilities directly address the manufacturer requirements for efficient chemical solutions in complex battery environments.

This type segment forms the foundation of modern battery additive adoption patterns, as it represents the implementation with the greatest processing flexibility and established market demand across multiple battery categories and industrial segments. Manufacturer investments in liquid processing standardization and handling consistency continue to strengthen adoption among battery producers and chemical companies. With manufacturers prioritizing processing efficiency and formulation compatibility, liquid implementations align with both functionality preferences and operational expectations, making them the central component of comprehensive battery additive strategies.

Lithium battery applications are projected to represent 74.2% of 4-propyl-1,3,2-dioxathiolane 2,2-dioxide demand in 2025, underscoring their critical role as the primary integration channel for chemical additives across battery manufacturing, product development, and energy storage applications. Battery manufacturers prefer 4-propyl-1,3,2-dioxathiolane 2,2-dioxide for their exceptional performance characteristics, scalable formulation options, and ability to enhance battery efficacy while ensuring consistent additive performance throughout diverse battery platforms and manufacturing processes. Positioned as essential performance components for modern battery production, 4-propyl-1,3,2-dioxathiolane 2,2-dioxide solutions offer both technical advantages and manufacturing efficiency benefits.

The segment is supported by continuous innovation in battery technologies and the growing availability of specialized implementations that enable diverse battery requirements with enhanced performance uniformity and extended stability capabilities. Additionally, battery manufacturers are investing in advanced additives to support large-scale production integration and product development. As energy storage trends become more prevalent and industrial battery awareness increases, lithium battery applications will continue to represent a major implementation market while supporting advanced battery utilization and additive integration strategies.

The 4-propyl-1,3,2-dioxathiolane 2,2-dioxide market is advancing steadily due to increasing demand for electrolyte additives and growing adoption of specialized chemicals that provide superior technical characteristics and performance benefits while enabling enhanced battery outcomes across diverse industrial and energy storage applications. The market faces challenges, including complex synthesis requirements, evolving quality standards, and the need for specialized chemical expertise and testing programs. Innovation in synthesis engineering and advanced processing systems continues to influence product development and market expansion patterns.

The growing adoption of advanced battery systems, enhanced performance management capabilities, and energy storage awareness is enabling chemical developers to produce advanced 4-propyl-1,3,2-dioxathiolane 2,2-dioxide solutions with superior technical positioning, enhanced purity profiles, and seamless formulation functionalities. Advanced chemical synthesis systems provide improved performance outcomes while allowing more efficient manufacturing workflows and reliable performance across various battery applications and usage conditions. Developers are increasingly recognizing the competitive advantages of chemical integration capabilities for market differentiation and technical positioning.

Modern 4-propyl-1,3,2-dioxathiolane 2,2-dioxide providers are incorporating advanced synthesis technology, quality control integration, and sophisticated processing solutions to enhance product appeal, enable intelligent technical features, and deliver value-added solutions to battery customers. These technologies improve synthesis efficiency while enabling new market opportunities, including standardized purity, optimized stability, and enhanced performance characteristics. Advanced quality integration also allows developers to support comprehensive industrial chemical technologies and market expansion beyond traditional additive approaches.

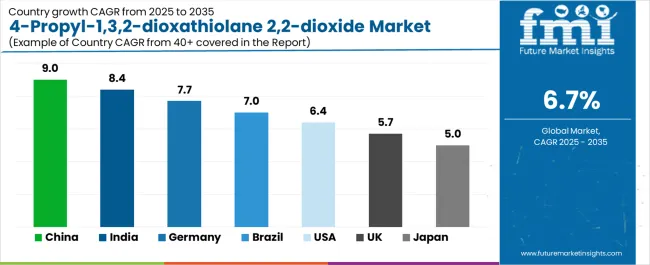

| Country | CAGR (2025-2035) |

|---|---|

| China | 9.0% |

| India | 8.4% |

| Germany | 7.7% |

| Brazil | 7.0% |

| United States (USA) | 6.4% |

| United Kingdom (UK) | 5.7% |

| Japan | 5.0% |

The 4-propyl-1,3,2-dioxathiolane 2,2-dioxide market is experiencing robust growth globally, with China leading at a 9.0% CAGR through 2035, driven by expanding battery manufacturing capacity, growing chemical production modernization programs, and significant investment in energy storage development. India follows at 8.4%, supported by increasing industrial chemical production expansion, growing battery manufacturing integration patterns, and expanding modern industrial infrastructure. Germany shows growth at 7.7%, emphasizing chemical engineering leadership and quality technology development. Brazil records 7.0%, focusing on expanding chemical manufacturing capabilities and industrial integration modernization. The USA demonstrates 6.4% growth, prioritizing advanced battery technology development and chemical adoption trends. The UK exhibits 5.7% growth, emphasizing chemical technology innovation and premium industrial development. Japan shows 5.0% growth, supported by quality excellence initiatives and technology-focused production patterns.

The report covers an in-depth analysis of 40+ countries top-performing countries are highlighted below.

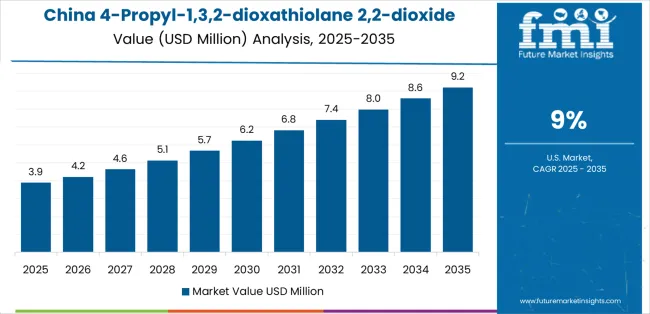

Revenue from 4-propyl-1,3,2-dioxathiolane 2,2-dioxide in China is projected to exhibit robust growth with a CAGR of 9.0% through 2035, driven by expanding battery manufacturing capacity and rapidly growing chemical integration supported by government initiatives promoting energy storage development. The country's strong position in battery production and increasing investment in chemical processing infrastructure are creating substantial demand for advanced chemical implementations. Major battery manufacturers and chemical companies are establishing comprehensive processing capabilities to serve both domestic industrial demand and expanding export markets.

Revenue from 4-propyl-1,3,2-dioxathiolane 2,2-dioxide in India is expanding at a CAGR of 8.4%, supported by the country's growing industrial chemical sector, expanding battery manufacturing capacity, and increasing adoption of specialized chemical technologies. The country's initiatives promoting industrial modernization and growing battery technology awareness are driving requirements for quality-controlled chemical systems. International battery providers and domestic chemical companies are establishing extensive processing and manufacturing capabilities to address the growing demand for industrial chemical solutions.

Revenue from 4-propyl-1,3,2-dioxathiolane 2,2-dioxide in Germany is expanding at a CAGR of 7.7%, supported by the country's chemical engineering heritage, strong emphasis on quality chemical technology, and robust demand for advanced chemical additives in premium and industrial applications. The nation's mature chemical sector and technology-focused operations are driving sophisticated chemical implementations throughout the industrial sector. Leading manufacturers and chemical specialists are investing extensively in quality development and advanced processing technologies to serve both domestic and international markets.

Revenue from 4-propyl-1,3,2-dioxathiolane 2,2-dioxide in Brazil is growing at a CAGR of 7.0%, driven by the country's expanding chemical manufacturing sector, growing industrial integration programs, and increasing investment in battery development. Brazil's large industrial market and commitment to manufacturing advancement are supporting demand for diverse chemical solutions across multiple industrial segments. Manufacturers are establishing comprehensive processing capabilities to serve the growing domestic market and expanding industrial opportunities.

Revenue from 4-propyl-1,3,2-dioxathiolane 2,2-dioxide in the USA is expanding at a CAGR of 6.4%, supported by the country's advanced chemical technology sector, strategic focus on battery solutions, and established chemical manufacturing capabilities. The USA's chemical innovation leadership and quality technology integration are driving demand for specialized chemical implementations in premium batteries, industrial applications, and advanced chemical products. Manufacturers are investing in comprehensive chemical development to serve both domestic specialty markets and international quality applications.

Revenue from 4-propyl-1,3,2-dioxathiolane 2,2-dioxide in the UK is growing at a CAGR of 5.7%, driven by the country's focus on chemical technology advancement, emphasis on premium industrial innovation, and strong position in technical chemical development. The UK's established chemical innovation capabilities and commitment to technology diversification are supporting investment in specialized chemical technologies throughout major industrial regions. Industry leaders are establishing comprehensive technology integration systems to serve domestic premium chemical production and industrial applications.

Revenue from 4-propyl-1,3,2-dioxathiolane 2,2-dioxide in Japan is expanding at a CAGR of 5.0%, supported by the country's chemical excellence initiatives, growing quality technology sector, and strategic emphasis on advanced chemical development. Japan's advanced quality control capabilities and integrated chemical systems are driving demand for high-quality chemical platforms in premium batteries, industrial chemicals, and advanced technology applications. Leading manufacturers are investing in specialized capabilities to serve the stringent requirements of technology-focused industrial and premium chemical industries.

How Are Evolving Industrial Programs Shaping Market Growth Across Europe?

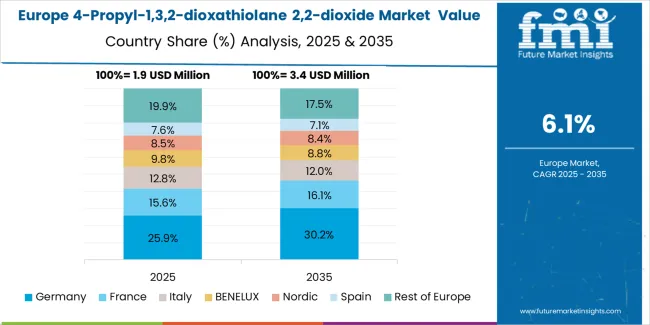

The 4-propyl-1,3,2-dioxathiolane 2,2-dioxide market in Europe is projected to grow from USD 1.8 million in 2025 to USD 2.7 million by 2035, registering a CAGR of 4.2% over the forecast period. Germany is expected to maintain its leadership position with a 42.1% market share in 2025, declining slightly to 41.8% by 2035, supported by its strong chemical engineering culture, sophisticated chemical manufacturing capabilities, and comprehensive industrial sector serving diverse 4-propyl-1,3,2-dioxathiolane 2,2-dioxide applications across Europe.

France follows with a 18.7% share in 2025, projected to reach 19.2% by 2035, driven by robust demand for premium chemical technologies in industrial applications, advanced battery programs, and chemical markets, combined with established industrial infrastructure and technology integration expertise. The United Kingdom holds a 15.3% share in 2025, expected to reach 15.8% by 2035, supported by strong chemical technology sector and growing premium industrial activities. Italy commands a 12.4% share in 2025, projected to reach 12.9% by 2035, while Spain accounts for 7.8% in 2025, expected to reach 8.2% by 2035. The Netherlands maintains a 2.9% share in 2025, growing to 3.1% by 2035. The Rest of Europe region, including Nordic countries, Eastern Europe, Belgium, Poland, and other nations, is anticipated to maintain momentum, with its collective share moving from 0.8% to -1.0% by 2035, attributed to increasing industrial modernization in Eastern Europe and growing technology penetration in Nordic countries implementing advanced chemical programs.

The 4-propyl-1,3,2-dioxathiolane 2,2-dioxide market is characterized by competition among established chemical manufacturers, specialized additive developers, and integrated industrial solution providers. Companies are investing in synthesis technology research, technical optimization, advanced processing system development, and comprehensive chemical portfolios to deliver consistent, high-quality, and application-specific 4-propyl-1,3,2-dioxathiolane 2,2-dioxide solutions. Innovation in advanced synthesis integration, purity enhancement, and battery compatibility improvement is central to strengthening market position and competitive advantage.

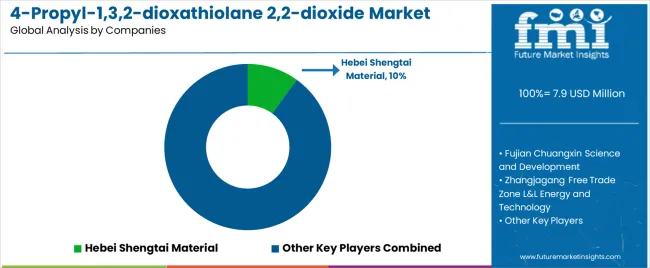

Hebei Shengtai Material leads the market with 10% share, offering comprehensive chemical solutions including quality synthesis platforms and advanced processing systems with a focus on premium and industrial battery applications. Fujian Chuangxin Science and Development provides specialized chemical capabilities with an emphasis on advanced implementations and innovative industrial solutions. Zhangjagang Free Trade Zone L&L Energy and Technology delivers comprehensive chemical services with a focus on integrated platforms and large-scale battery applications. Other key players focus on specialized chemical products and innovative technology solutions for various industrial segments.

| Item | Value |

|---|---|

| Quantitative Units | USD 7.9 Million |

| Type | Liquid; Solid |

| Application | Lithium Battery; Industrial Solvent; Chemical Intermediate; Other |

| Purity Grade | High Purity; Industrial Grade; Standard Grade |

| Distribution Channels | Direct Sales; Chemical Distributors; Online Platforms; Specialty Suppliers |

| End-Use Sector | Battery Manufacturers; Chemical Companies; Research Institutions; Others |

| Regions Covered | North America; Europe; East Asia; South Asia & Pacific; Latin America; Middle East & Africa |

| Countries Covered | China; India; Germany; Brazil; United States; United Kingdom; Japan; and 40+ additional countries |

| Key Companies Profiled | Hebei Shengtai Material; Fujian Chuangxin Science and Development; Zhangjagang Free Trade Zone L&L Energy and Technology |

| Additional Attributes | Dollar sales by type and application category; regional demand trends; competitive landscape; technological advancements in synthesis engineering; advanced technical development; quality innovation; battery integration protocols |

The global 4-propyl-1,3,2-dioxathiolane 2,2-dioxid market is estimated to be valued at USD 7.9 million in 2025.

The market size for the 4-propyl-1,3,2-dioxathiolane 2,2-dioxid market is projected to reach USD 15.1 million by 2035.

The 4-propyl-1,3,2-dioxathiolane 2,2-dioxid market is expected to grow at a 6.7% CAGR between 2025 and 2035.

The key product types in 4-propyl-1,3,2-dioxathiolane 2,2-dioxid market are liquid and solid.

In terms of application, lithium battery segment to command 74.2% share in the 4-propyl-1,3,2-dioxathiolane 2,2-dioxid market in 2025.

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA