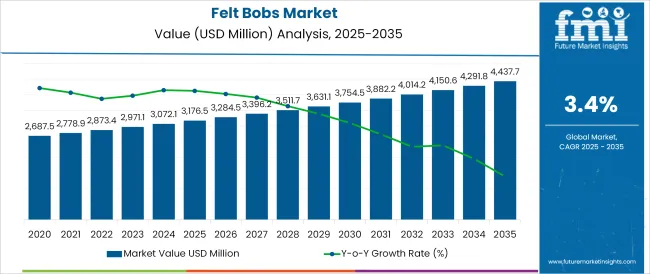

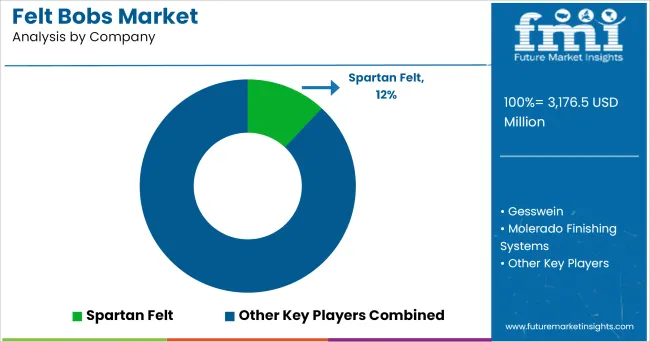

The Felt Bobs Market is estimated to be valued at USD 3,176.5 million in 2025 and is projected to reach USD 4,437.7 million by 2035, registering a compound annual growth rate (CAGR) of 3.4% over the forecast period.

The felt bobs market is witnessing consistent growth due to rising demand for precision surface finishing in industries such as metalworking, jewellery, electronics, and automotive components. Felt bobs, known for their durability, consistency, and ability to conform to intricate geometries, are being increasingly used in deburring, polishing, and buffing operations across diverse manufacturing environments.

Manufacturers are emphasizing versatility through shape variations and density customization to suit both soft and hard material surfaces. With sustainability and waste-reduction efforts gaining traction, the reusability and long operational life of felt bobs are gaining favor among industrial buyers.

In parallel, automation in finishing processes and integration of robotic tools has heightened demand for uniform abrasives like felt bobs that ensure precision and repeatability. Growth opportunities are expected to deepen as OEMs and repair centres globally seek cost-effective, adaptable polishing tools that offer consistency across multiple surface types and configurations.

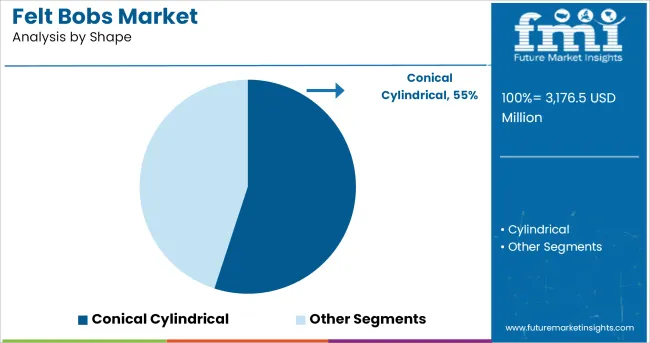

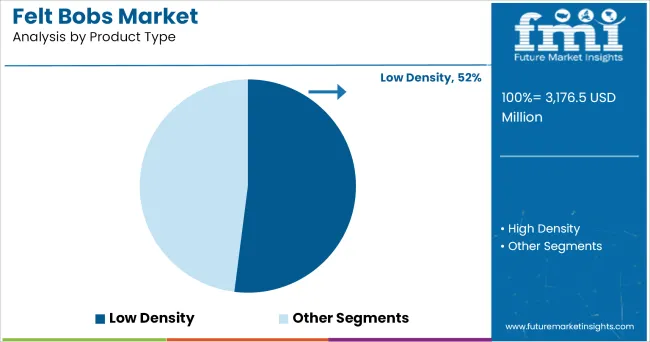

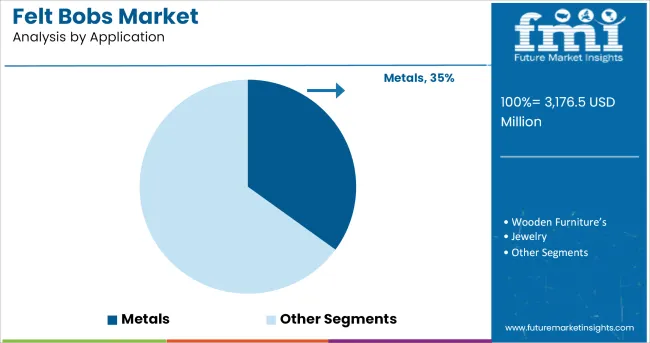

The market is segmented by Shape, Product Type, Application, and Distribution Channel and region. By Shape, the market is divided into Conical Cylindrical and Cylindrical. In terms of Product Type, the market is classified into Low Density and High Density. Based on Application, the market is segmented into Metals, Wooden Furniture’s, Jewelry, and Others.

By Distribution Channel, the market is divided into Wholesalers/ Distributors, Specialty Stores, Independent Polishing Equipment Stores, Online Retailers, and Others. Regionally, the market is classified into North America, Latin America, Western Europe, Eastern Europe, Balkan & Baltic Countries, Russia & Belarus, Central Asia, East Asia, South Asia & Pacific, and the Middle East & Africa.

The conical cylindrical shape segment is projected to hold 55.0% of total market revenue in 2025, marking it as the dominant configuration in the felt bobs market. This leadership is attributed to its adaptability in reaching tight or contoured spaces, which is critical in polishing, fine deburring, and intricate finishing applications.

The conical cylindrical design allows users to access grooves, holes, and complex profiles without compromising surface uniformity or tool stability. Manufacturers have optimized this shape to deliver balanced pressure distribution, reducing vibration and enhancing control during both manual and automated processes.

The growing use of conical cylindrical felt bobs in high-precision sectors such as aerospace component polishing and mold finishing has reinforced its continued dominance. Its compatibility with a wide range of polishing compounds and abrasive pastes has further enhanced its applicability, securing its position as the preferred shape for versatile finishing needs.

Low density felt bobs are projected to account for 52.0% of the revenue share in 2025 under the product type category, making it the leading variant. This is primarily due to their superior flexibility, which makes them well-suited for polishing delicate surfaces without risking abrasion or over-removal of material. Low density felt allows for better adaptation to uneven or complex geometries, making it ideal for fine finishing tasks.

Their lightweight structure enables high-speed operation with reduced heat generation, an essential factor in precision applications. The growing demand for fine detailing in industries like jewellery, optics, and consumer electronics has favored the adoption of low density bobs.

Additionally, their ability to retain polishing compounds efficiently, along with lower material cost and ease of replacement, has contributed to their widespread use and revenue leadership in the felt bobs market.

The metals application segment is expected to capture 35.0% of the total market revenue in 2025, positioning it as the leading end-use category. This leadership is driven by the extensive use of felt bobs in finishing ferrous and non-ferrous metal surfaces across automotive, aerospace, tool manufacturing, and metal fabrication industries.

The ability of felt bobs to deliver uniform surface finishes without damaging underlying substrates has made them indispensable in polishing, deburring, and surface preparation. They are frequently used with abrasives or polishing compounds to achieve reflective or matte finishes depending on the requirement.

The increased focus on component aesthetics and tolerance compliance in metal goods has elevated the need for reliable polishing tools, where felt bobs have proven advantageous. As demand grows for higher finish standards in machined parts and fabricated structures, the metals segment is expected to maintain its dominant share within the felt bobs market.

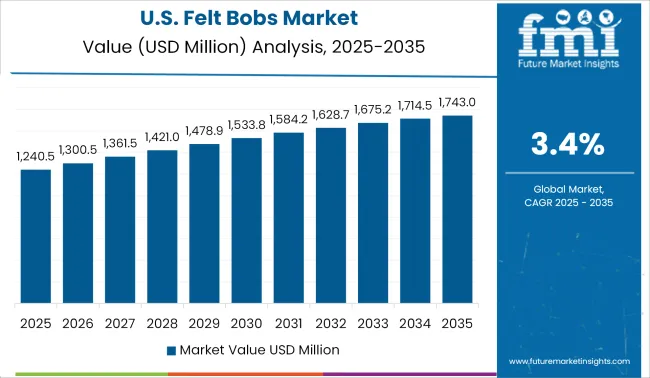

The felt bobs market is set to witness steady growth during 2025 to 2035, with a CAGR of around 3.4%.

Felt bobs market experiences varying demand outlook. Moreover, the recovering construction industry and the growing demand among customers for an aesthetic and premium look in residential sectors are likely to boost the demand for the felt bobs industry.

With the growing construction industry, the residential areas are expanding with time and thus, demand for the use of special tools in order to bring shine and enhance the life of furniture with the help of polishing the surface is projected to increase the demand for felt bobs.

The demand for coating operation of furniture in the residential sectors has been forever, therefore, evolving the felt bob industry.

Additionally, felt bobs serves the purpose of coating and providing with fine detailed and tight corners.

Wool is used in felt bobs, due to its ability to deliver a rich look to the surface polished. Further, the innovation in tools has eased the applicability of felt bobs, reducing input time without compromising the output.

Moreover, using felt bobs on the surface make it easy to clean the surface.

The application of felt bobs enhances the strength of material especially metals, therefore, sealing the surface and preventing the actions of microorganisms, and protecting from corrosion for a longer duration. Such positive factors are anticipated to grow the felt bobs industry.

Considering the developments in the construction industry under the residential areas, the need and demand to innovate the furniture industry has been growing consistently.

Further, the growing demands and economic strength of the customers require delivering fast and productive solutions in all sectors without affecting the quality of the product.

Additionally, the availability of various varnishes that are applied using felt bobs on different kinds of metal alloys on machines and furniture has created a vast growth opportunity for the felt bobs industry.

Moreover, the growing demand for an aesthetic look in every segment is favoring as an important factor for the growth of the felt bob industry.

The countries of North America are estimated to contribute maximum to the felt bobs industry owing to the rise in the number of the requirement of durable, wear-resistant, and long-lasting metal products in residential and commercial sectors.

Moreover, the presence of an adaptive mindset allows the consumers and manufacturers to shift from traditional technologies to modern technologies that help create new opportunities for all industries; therefore, growing the felt bobs industry.

The USA felt bobs sales were impacted by the construction sector in 2024, as the industry faces a challenging year. However, low mortgage rates will lead a growing optimism and new opportunities in early 2025. The momentum is likely to hold ground, which will provide an impetus to a range of construction materials, including felt bobs.

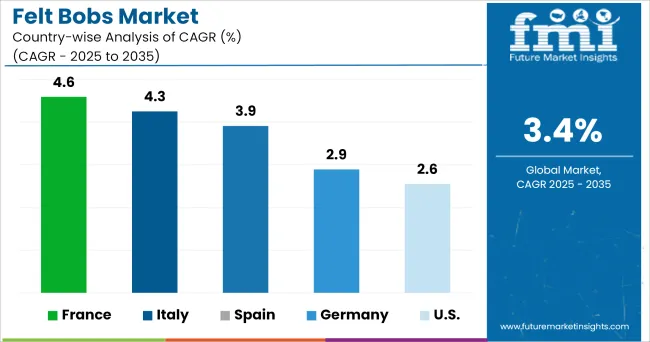

The presence of various prominent manufacturers and dealers of the automotive industry in the countries of Europe is likely to augment the sales of felt bobs.

Consumption of metal and metal alloys in automotive is high and thus, is the need to protect them from damage due to rain and heat. Additionally, the manufactures in Europe believe in providing the customer with satisfying and long-lasting products, thereby, growing the sale of felt bobs industry.

Some of the leading manufacturers and suppliers of felt bobs include

The report is a compilation of first-hand information, qualitative and quantitative assessment by industry analysts, inputs from industry experts and industry participants across the value chain.

The report provides an in-depth analysis of parent market trends, macro-economic indicators, and governing factors along with market attractiveness as per segments.

The report also maps the qualitative impact of various market factors on market segments and geographies.

The global felt bobs market is estimated to be valued at USD 3,176.5 million in 2025.

The market size for the felt bobs market is projected to reach USD 4,437.7 million by 2035.

The felt bobs market is expected to grow at a 3.4% CAGR between 2025 and 2035.

The key product types in felt bobs market are conical cylindrical and cylindrical.

In terms of product type, low density segment to command 52.0% share in the felt bobs market in 2025.

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Klinefelter Syndrome Therapeutics Market - Growth & Demand 2025 to 2035

Metal Fiber Felt Market Size and Share Forecast Outlook 2025 to 2035

Carbon And Graphite Felt Market Size and Share Forecast Outlook 2025 to 2035

Semiconductor Grade Carbon Fiber Soft Felts Market Analysis - Size, Share, and Forecast Outlook 2025 to 2035

Semiconductor Grade Carbon Fiber Rigid Felts Market Analysis - Size, Share, and Forecast Outlook 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA