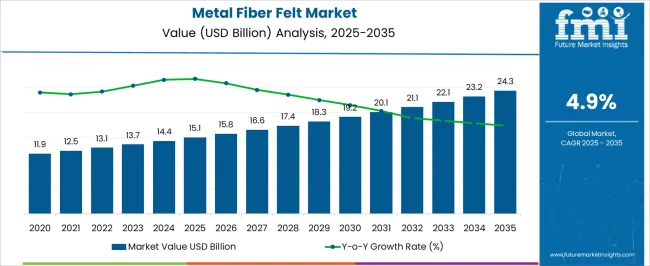

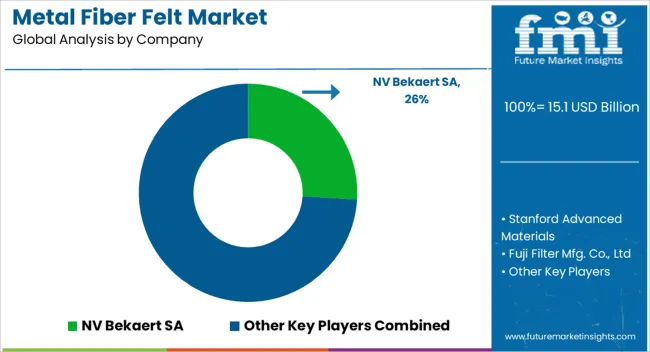

The Metal Fiber Felt Market is estimated to be valued at USD 15.1 billion in 2025 and is projected to reach USD 24.3 billion by 2035, registering a compound annual growth rate (CAGR) of 4.9% over the forecast period.

| Metric | Value |

|---|---|

| Metal Fiber Felt Market Estimated Value in (2025 E) | USD 15.1 billion |

| Metal Fiber Felt Market Forecast Value in (2035 F) | USD 24.3 billion |

| Forecast CAGR (2025 to 2035) | 4.9% |

The Metal Fiber Felt market is experiencing steady growth, driven by increasing demand for advanced filtration solutions across industrial, automotive, and environmental applications. The market’s current scenario reflects a rising preference for high-performance, durable, and thermally stable filtration media capable of operating in harsh environments. The adoption of metal fiber felt is being propelled by its superior mechanical strength, corrosion resistance, and high porosity, which allow it to efficiently capture fine particles while maintaining flow rates.

Future growth is expected to be influenced by expanding automotive production, stringent emission control regulations, and increasing industrial processing requirements that demand high-quality filtration. Additionally, technological advancements in manufacturing processes, including precision fiber bonding and sintering techniques, are enhancing product performance and application versatility.

Rising awareness of sustainable filtration systems and the push for energy-efficient industrial solutions are further supporting market expansion As industrialization continues globally and environmental standards tighten, metal fiber felt is anticipated to remain a preferred material for critical filtration applications, offering long-term reliability and performance.

The metal fiber felt market is segmented by metal, filtration type, end-use industry, and geographic regions. By metal, metal fiber felt market is divided into Stainless Steel, Nickel Alloys, Titanium Alloys, and Others. In terms of filtration type, metal fiber felt market is classified into Liquid Filtration, Air Filtration, and Gaseous Filtration. Based on end-use industry, metal fiber felt market is segmented into Automotive, Chemical & Petrochemical, Food & Beverage, Medical & Pharmaceutical, Aviation, Industrial Machinery & Equipment, and Power Generation. Regionally, the metal fiber felt industry is classified into North America, Latin America, Western Europe, Eastern Europe, Balkan & Baltic Countries, Russia & Belarus, Central Asia, East Asia, South Asia & Pacific, and the Middle East & Africa.

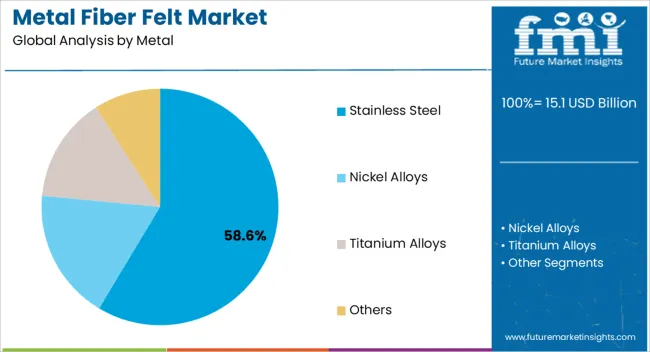

The stainless steel segment is projected to account for 58.60% of the Metal Fiber Felt market revenue in 2025, making it the leading material type. This dominance is attributed to stainless steel’s exceptional resistance to corrosion, high temperature stability, and structural integrity under demanding operating conditions. Stainless steel metal fiber felt is widely deployed in automotive exhaust systems, industrial liquid and gas filtration, and high-temperature processing environments, where reliability and long service life are critical.

Growth in this segment has been reinforced by the increasing adoption of durable filtration solutions that can withstand chemical and thermal stress without compromising performance. Additionally, stainless steel fiber felts provide superior mechanical strength while maintaining high porosity, allowing for efficient flow and particulate capture.

The combination of low maintenance, adaptability to various filtration formats, and compatibility with automated manufacturing processes has facilitated widespread industrial uptake As industries continue to seek robust and sustainable filtration media, the stainless steel segment is expected to sustain its market leadership.

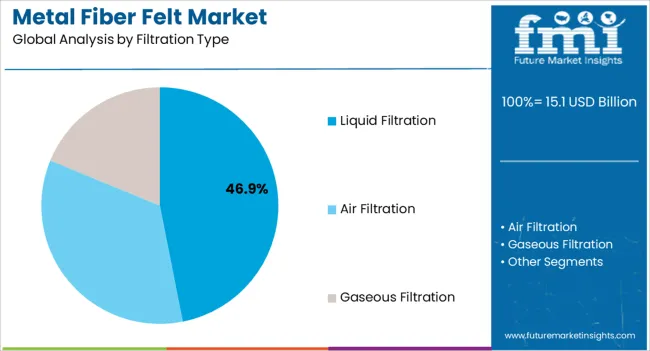

The liquid filtration application segment is expected to hold 46.90% of total Metal Fiber Felt market revenue in 2025, emerging as the most prominent application area. This growth is driven by increasing demand for high-efficiency filtration in automotive, chemical, and process industries, where the removal of fine particulates and contaminants is critical to system performance.

Metal fiber felt is favored in liquid filtration due to its high porosity, corrosion resistance, and ability to maintain flow rates under variable pressures. The widespread adoption of automated and continuous industrial processes has further encouraged the use of metal fiber felt, as it allows for consistent filtration performance with minimal maintenance.

Regulatory standards requiring cleaner effluents and high-quality fluid processing have also contributed to segment growth As industries continue to prioritize operational efficiency, reduced downtime, and environmentally compliant fluid handling, liquid filtration applications are expected to remain a major driver for the Metal Fiber Felt market.

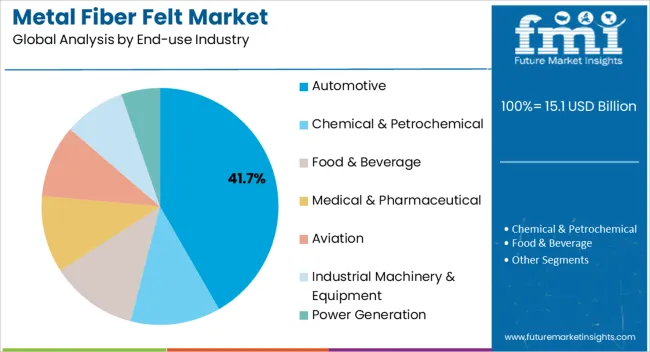

The automotive end-use industry segment is projected to hold 41.70% of Metal Fiber Felt market revenue in 2025, making it the leading consumer sector. This prominence is being driven by the increasing integration of metal fiber felt in exhaust systems, emission control units, and engine filtration applications, where high temperature tolerance and durability are essential.

The growth of this segment has been reinforced by global trends in vehicle production, stricter emission standards, and demand for lightweight, high-performance filtration solutions that extend component life. Metal fiber felt’s ability to withstand thermal and mechanical stress while maintaining filtration efficiency has made it the preferred material in modern automotive systems.

Additionally, the adoption of advanced manufacturing processes in the automotive sector has facilitated the incorporation of custom-shaped and precision-cut metal fiber felts, enhancing their application versatility As automotive OEMs continue to focus on sustainability, emission reduction, and operational efficiency, the demand for metal fiber felt in this industry is expected to remain robust and contribute significantly to overall market growth.

Metal fiber felt is a synthetic non-woven textile material manufactured from micron grade metallic fiber. It is produced by taking extremely fine metallic fiber material through processes such as compression, lamination and sintering at high temperatures. Metal fiber felt possesses the functionality of porous materials while exhibiting the intrinsic properties of a metal substance. It is produced most commonly from stainless steel, however other alloys are also used for the manufacturing of metal fiber felt.

Metal fiber felt finds extensive use in filtration applications due to its physical properties. It has good mechanical strength and is highly resistant to corrosion. Also, metal fiber felt has significantly higher dirt holding capacity, which is extremely useful and advantageous in filtration applications as compared to other types of filter media. Metal fiber felt is easy to fold, pleat and weld and thus, provides huge flexibility in deployment for filtration applications. It has uniform distribution of pore sizes and excellent porosity and permeability, which combined with its durability provides for ideal utilization in harsh industrial environments.

Considering these aspects of metal fiber felt, the study of the trends and forecasts of the metal fiber felt market becomes an important read.

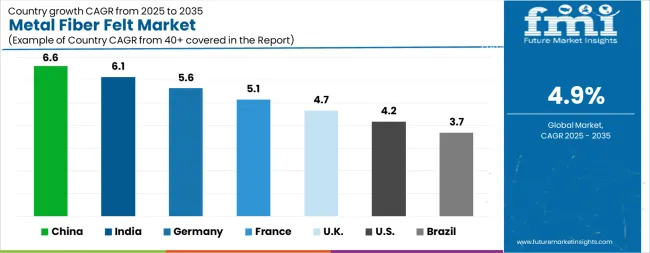

| Country | CAGR |

|---|---|

| China | 6.6% |

| India | 6.1% |

| Germany | 5.6% |

| France | 5.1% |

| UK | 4.7% |

| USA | 4.2% |

| Brazil | 3.7% |

The Metal Fiber Felt Market is expected to register a CAGR of 4.9% during the forecast period, exhibiting varied country level momentum. China leads with the highest CAGR of 6.6%, followed by India at 6.1%. Developed markets such as Germany, France, and the UK continue to expand steadily, while the USA is likely to grow at consistent rates. Brazil posts the lowest CAGR at 3.7%, yet still underscores a broadly positive trajectory for the global Metal Fiber Felt Market. In 2024, Germany held a dominant revenue in the Western Europe market and is expected to grow with a CAGR of 5.6%. The USA Metal Fiber Felt Market is estimated to be valued at USD 5.2 billion in 2025 and is anticipated to reach a valuation of USD 7.9 billion by 2035. Sales are projected to rise at a CAGR of 4.2% over the forecast period between 2025 and 2035. While Japan and South Korea markets are estimated to be valued at USD 760.3 million and USD 466.0 million respectively in 2025.

| Item | Value |

|---|---|

| Quantitative Units | USD 15.1 Billion |

| Metal | Stainless Steel, Nickel Alloys, Titanium Alloys, and Others |

| Filtration Type | Liquid Filtration, Air Filtration, and Gaseous Filtration |

| End-use Industry | Automotive, Chemical & Petrochemical, Food & Beverage, Medical & Pharmaceutical, Aviation, Industrial Machinery & Equipment, and Power Generation |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, Middle East & Africa |

| Country Covered | United States, Canada, Germany, France, United Kingdom, China, Japan, India, Brazil, South Africa |

| Key Companies Profiled | NV Bekaert SA, Stanford Advanced Materials, Fuji Filter Mfg. Co., Ltd, Heanjia Super Metals Co. Ltd, XinXiang XinLi Filter Technology Co., Ltd, Purolator EFP LLC, Boegger Industrial Limited, Ayater Filtration Solutions, and Raj Filters |

The global metal fiber felt market is estimated to be valued at USD 15.1 billion in 2025.

The market size for the metal fiber felt market is projected to reach USD 24.3 billion by 2035.

The metal fiber felt market is expected to grow at a 4.9% CAGR between 2025 and 2035.

The key product types in metal fiber felt market are stainless steel, nickel alloys, titanium alloys and others.

In terms of filtration type, liquid filtration segment to command 46.9% share in the metal fiber felt market in 2025.

Explore Similar Insights

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA