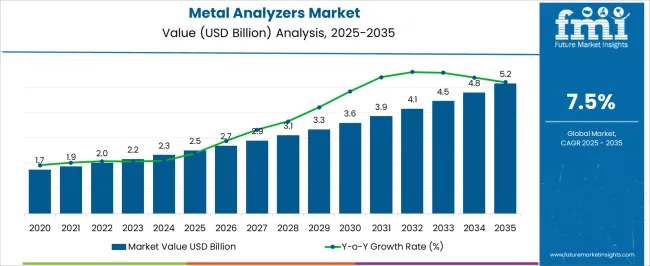

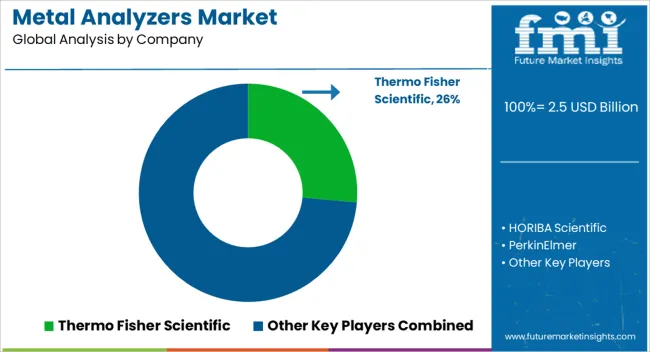

The Metal Analyzers Market is estimated to be valued at USD 2.5 billion in 2025 and is projected to reach USD 5.2 billion by 2035, registering a compound annual growth rate (CAGR) of 7.5% over the forecast period.

| Metric | Value |

|---|---|

| Metal Analyzers Market Estimated Value in (2025 E) | USD 2.5 billion |

| Metal Analyzers Market Forecast Value in (2035 F) | USD 5.2 billion |

| Forecast CAGR (2025 to 2035) | 7.5% |

The Metal Analyzers market is experiencing robust growth driven by the increasing need for rapid, accurate, and non-destructive metal composition analysis across industrial and manufacturing sectors. Current market trends reflect heightened demand for portable and on-site analytical solutions that enable real-time decision-making, quality assurance, and regulatory compliance.

The integration of advanced spectroscopy and sensor technologies has enhanced detection precision and reduced testing time, making metal analyzers essential tools in production lines, scrap processing, and research laboratories. Future growth is expected to be supported by the expansion of manufacturing facilities, rising demand for high-purity metals, and the need for improved traceability of raw materials.

Investment in digital manufacturing and automated quality control systems is further paving the way for broader adoption of metal analyzers As industries increasingly prioritize efficiency, safety, and material optimization, the market is poised to grow steadily with opportunities in portable analyzers, advanced software integration, and real-time analytics for both large-scale and small-scale industrial applications.

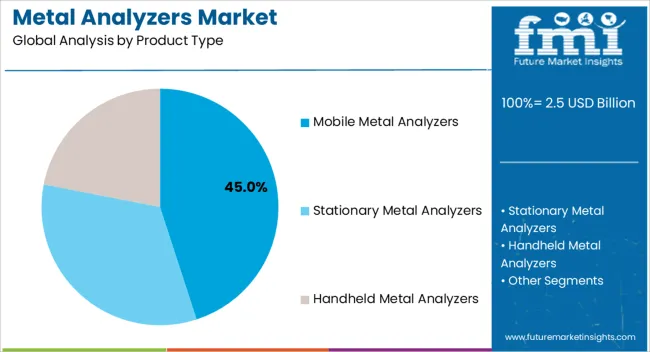

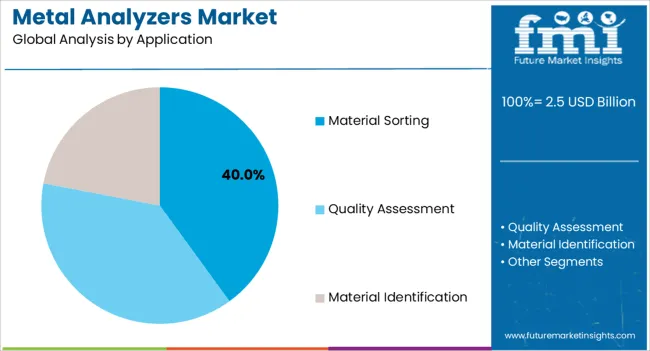

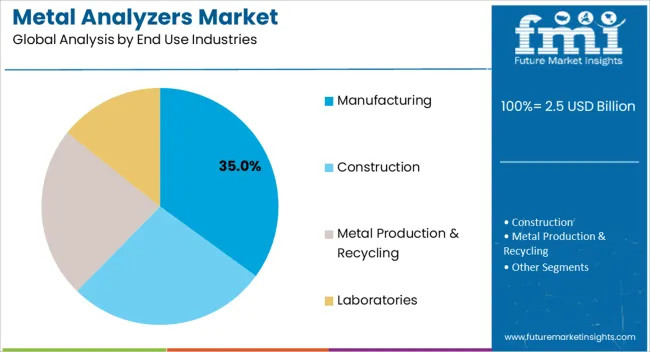

The metal analyzers market is segmented by product type, application, end use industries, and geographic regions. By product type, metal analyzers market is divided into Mobile Metal Analyzers, Stationary Metal Analyzers, and Handheld Metal Analyzers. In terms of application, metal analyzers market is classified into Material Sorting, Quality Assessment, and Material Identification. Based on end use industries, metal analyzers market is segmented into Manufacturing, Construction, Metal Production & Recycling, and Laboratories. Regionally, the metal analyzers industry is classified into North America, Latin America, Western Europe, Eastern Europe, Balkan & Baltic Countries, Russia & Belarus, Central Asia, East Asia, South Asia & Pacific, and the Middle East & Africa.

The Mobile Metal Analyzers segment is projected to hold 45.00% of the market revenue in 2025, establishing it as the leading product type. This dominance is being driven by the need for rapid, on-site metal analysis without the requirement to transport samples to central laboratories.

Portability allows industries to conduct immediate testing during production, scrap sorting, or quality inspections, which enhances operational efficiency and reduces downtime. The growth of this segment has been reinforced by advancements in handheld spectroscopy, improved battery life, and user-friendly interfaces, which enable non-specialist operators to perform accurate measurements.

Mobile analyzers also provide flexibility in diverse work environments, including industrial plants, mining sites, and recycling facilities, where mobility is crucial As industries continue to emphasize process optimization and real-time data-driven decision-making, mobile metal analyzers are expected to maintain their leading position, supported by their ability to deliver fast, precise, and actionable insights across multiple applications.

The Material Sorting application segment is anticipated to account for 40.00% of the market revenue in 2025, making it the largest application area. This leadership is being attributed to the critical role metal analyzers play in separating metals and alloys accurately for recycling, processing, and quality control purposes.

Material sorting processes benefit from high-throughput analysis and immediate feedback, enabling efficient identification of valuable metals and minimizing contamination in production lines. The adoption of advanced software algorithms in analyzers has enhanced sorting precision and reduced human error, further strengthening market demand.

Industries handling diverse metal streams, such as scrap recycling, electronics, and automotive manufacturing, increasingly rely on analyzers to meet compliance standards and ensure consistent product quality Future growth is expected to continue as global emphasis on sustainability, material efficiency, and regulatory compliance drives higher adoption of metal analyzers in material sorting processes.

The Commercial end-use industry segment is represented by the Manufacturing sector, projected to capture 35.00% of market revenue in 2025. This leading position has been influenced by the growing demand for quality control, alloy verification, and process optimization across manufacturing operations.

Metal analyzers are employed to ensure that raw materials and finished products meet stringent standards, reducing production defects and enhancing safety. The integration of portable analyzers in manufacturing plants allows operators to perform real-time inspections on production lines, which improves efficiency and reduces costs.

Additionally, the rising complexity of metal alloys and the introduction of high-performance materials in modern manufacturing have reinforced the need for precise analysis tools As manufacturers continue to adopt digital and automated systems, metal analyzers are expected to play an increasingly vital role, supporting scalable production, regulatory compliance, and overall operational excellence across the sector.

Determining the precise chemical composition and alloy grade of metal is an essential need in metals processing industries. Metal analyzers are the devices used to determine the quality and chemical compositions of metals.

The metal analyzers used for many applications in various end use industries such as, for material sorting in metal recycling and metal processing industries, quality assessment of metals for the production of different components and products, and material identification for the refining of metals.

Furthermore, there are basically three types of metal analyzers are available in the market. Mobile metal analyzers is expected to hold a significant share in the metal analyzers market owing to their mobility and versatility. They are either powered by mains or have an inbuilt battery pack for outdoor use. Mobile metal analyzers usually work on two technologies such as, Optical Emission Spectrometry (OES) and X-ray fluorescence (XRF).

Stationary Metal Analyzers usually used in the production process of metals for the process control and also for R&D activities in the laboratories. Handheld metal analyzers are the commonly used in metal analysis activities due to convenient operation and can be used single handedly for onsite analysis and in remote areas.

Additionally, introduction of new technologies such as, Laser-induced breakdown spectroscopy (LIBS) in the handheld metal analyzers which allows it to analyze the metal in few seconds is expected to drive the metal analyzers market in the future.

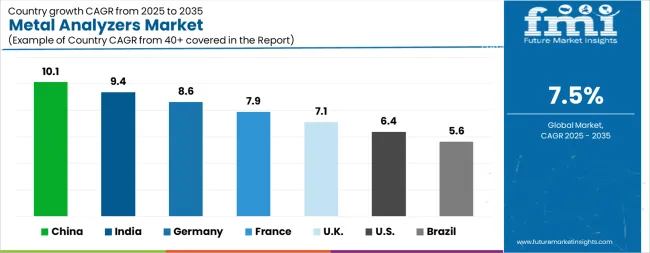

| Country | CAGR |

|---|---|

| China | 10.1% |

| India | 9.4% |

| Germany | 8.6% |

| France | 7.9% |

| U.K. | 7.1% |

| U.S. | 6.4% |

| Brazil | 5.6% |

The Metal Analyzers Market is expected to register a CAGR of 7.5% during the forecast period, exhibiting varied country level momentum. China leads with the highest CAGR of 10.1%, followed by India at 9.4%. Developed markets such as Germany, France, and the U.K. continue to expand steadily, while the U.S. is likely to grow at consistent rates. Brazil posts the lowest CAGR at 5.6%, yet still underscores a broadly positive trajectory for the global Metal Analyzers Market. In 2024, Germany held a dominant revenue in the Western Europe market and is expected to grow with a CAGR of 8.6%. The U.S. Metal Analyzers Market is estimated to be valued at USD 902.5 million in 2025 and is anticipated to reach a valuation of USD 1.7 billion by 2035. Sales are projected to rise at a CAGR of 6.4% over the forecast period between 2025 and 2035. While Japan and South Korea markets are estimated to be valued at USD 129.4 million and USD 83.0 million respectively in 2025.

| Item | Value |

|---|---|

| Quantitative Units | USD 2.5 Billion |

| Product Type | Mobile Metal Analyzers, Stationary Metal Analyzers, and Handheld Metal Analyzers |

| Application | Material Sorting, Quality Assessment, and Material Identification |

| End Use Industries | Manufacturing, Construction, Metal Production & Recycling, and Laboratories |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, Middle East & Africa |

| Country Covered | United States, Canada, Germany, France, United Kingdom, China, Japan, India, Brazil, South Africa |

| Key Companies Profiled | Thermo Fisher Scientific, HORIBA Scientific, PerkinElmer, Hitachi High-Tech Analytical Science, Oxford Instruments, Bruker Corporation, SPECTRO Analytical Instruments, and Shimadzu Corporation |

The global metal analyzers market is estimated to be valued at USD 2.5 billion in 2025.

The market size for the metal analyzers market is projected to reach USD 5.2 billion by 2035.

The metal analyzers market is expected to grow at a 7.5% CAGR between 2025 and 2035.

The key product types in metal analyzers market are mobile metal analyzers, stationary metal analyzers and handheld metal analyzers.

In terms of application, material sorting segment to command 40.0% share in the metal analyzers market in 2025.

Our Research Products

The "Full Research Suite" delivers actionable market intel, deep dives on markets or technologies, so clients act faster, cut risk, and unlock growth.

The Leaderboard benchmarks and ranks top vendors, classifying them as Established Leaders, Leading Challengers, or Disruptors & Challengers.

Locates where complements amplify value and substitutes erode it, forecasting net impact by horizon

We deliver granular, decision-grade intel: market sizing, 5-year forecasts, pricing, adoption, usage, revenue, and operational KPIs—plus competitor tracking, regulation, and value chains—across 60 countries broadly.

Spot the shifts before they hit your P&L. We track inflection points, adoption curves, pricing moves, and ecosystem plays to show where demand is heading, why it is changing, and what to do next across high-growth markets and disruptive tech

Real-time reads of user behavior. We track shifting priorities, perceptions of today’s and next-gen services, and provider experience, then pace how fast tech moves from trial to adoption, blending buyer, consumer, and channel inputs with social signals (#WhySwitch, #UX).

Partner with our analyst team to build a custom report designed around your business priorities. From analysing market trends to assessing competitors or crafting bespoke datasets, we tailor insights to your needs.

Supplier Intelligence

Discovery & Profiling

Capacity & Footprint

Performance & Risk

Compliance & Governance

Commercial Readiness

Who Supplies Whom

Scorecards & Shortlists

Playbooks & Docs

Category Intelligence

Definition & Scope

Demand & Use Cases

Cost Drivers

Market Structure

Supply Chain Map

Trade & Policy

Operating Norms

Deliverables

Buyer Intelligence

Account Basics

Spend & Scope

Procurement Model

Vendor Requirements

Terms & Policies

Entry Strategy

Pain Points & Triggers

Outputs

Pricing Analysis

Benchmarks

Trends

Should-Cost

Indexation

Landed Cost

Commercial Terms

Deliverables

Brand Analysis

Positioning & Value Prop

Share & Presence

Customer Evidence

Go-to-Market

Digital & Reputation

Compliance & Trust

KPIs & Gaps

Outputs

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Metallurgical Lighting Market Size and Share Forecast Outlook 2025 to 2035

Metal Evaporation Boat Market Size and Share Forecast Outlook 2025 to 2035

Metal Miniature Bone Plates Market Size and Share Forecast Outlook 2025 to 2035

Metal Locking Plate and Screw System Market Size and Share Forecast Outlook 2025 to 2035

Metal Pallet Market Size and Share Forecast Outlook 2025 to 2035

Metal Oxide Varistor (MOV) Surge Arresters Market Size and Share Forecast Outlook 2025 to 2035

Metal Straw Market Size and Share Forecast Outlook 2025 to 2035

Metal Can Market Size and Share Forecast Outlook 2025 to 2035

Metal IBC Market Forecast and Outlook 2025 to 2035

Metalized Barrier Film Market Forecast and Outlook 2025 to 2035

Metal Packaging Market Size and Share Forecast Outlook 2025 to 2035

Metal Bellow Market Size and Share Forecast Outlook 2025 to 2035

Metal based Safety Gratings Market Size and Share Forecast Outlook 2025 to 2035

Metal Modifiers Market Size and Share Forecast Outlook 2025 to 2035

Metallic Stearate Market Size and Share Forecast Outlook 2025 to 2035

Metallic Labels Market Size and Share Forecast Outlook 2025 to 2035

Metal Recycling Market Size and Share Forecast Outlook 2025 to 2035

Metal Forming Fluids Market Size and Share Forecast Outlook 2025 to 2035

Metal Removal Fluids Market Size and Share Forecast Outlook 2025 to 2035

Metal Deactivators Market Size and Share Forecast Outlook 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA