The Metal based Safety Gratings Market is estimated to be valued at USD 3.1 billion in 2025 and is projected to reach USD 5.2 billion by 2035, registering a compound annual growth rate (CAGR) of 5.4% over the forecast period.

| Metric | Value |

|---|---|

| Metal based Safety Gratings Market Estimated Value in (2025 E) | USD 3.1 billion |

| Metal based Safety Gratings Market Forecast Value in (2035 F) | USD 5.2 billion |

| Forecast CAGR (2025 to 2035) | 5.4% |

The Metal Based Safety Gratings market is experiencing steady growth driven by increasing adoption across industrial, commercial, and infrastructure projects where durability, load-bearing capacity, and safety compliance are critical. Growth is being influenced by rising industrialization, the expansion of manufacturing plants, and modernization of construction projects globally. The need for robust flooring and walkway solutions in sectors such as manufacturing, petrochemical, power generation, and transportation has created consistent demand for metal-based safety gratings.

Advancements in fabrication technology, including automated welding and corrosion-resistant coatings, are enhancing product quality while reducing installation and maintenance costs. The trend toward modular and standardized grating solutions is further enabling faster deployment in large-scale projects.

Increasing focus on workplace safety regulations and the enforcement of industrial safety standards is also supporting market expansion As industries continue to prioritize durability, load capacity, and compliance with safety standards, the Metal Based Safety Gratings market is expected to maintain steady growth with ample opportunities for high-performance, customizable solutions.

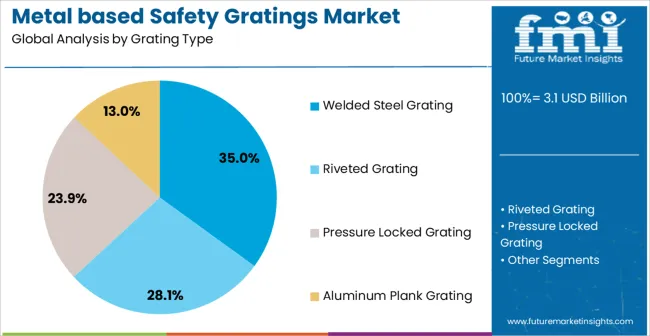

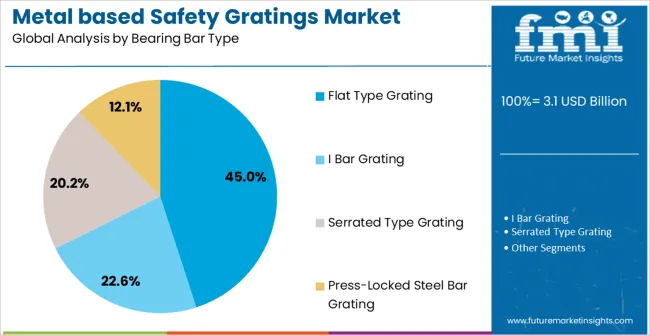

The metal based safety gratings market is segmented by grating type, metal type, bearing bar type, top finish, application, end use, and geographic regions. By grating type, metal based safety gratings market is divided into Welded Steel Grating, Riveted Grating, Pressure Locked Grating, and Aluminum Plank Grating. In terms of metal type, metal based safety gratings market is classified into Mild Steel Gratings, Stainless Steel Gratings, and Aluminum Gratings. Based on bearing bar type, metal based safety gratings market is segmented into Flat Type Grating, I Bar Grating, Serrated Type Grating, and Press-Locked Steel Bar Grating.

By top finish, metal based safety gratings market is segmented into Galvanized and Powder Coated Gratings. By application, metal based safety gratings market is segmented into Architecture, Walkways, Ladders & Stair Treads, Work Platforms, Machine Guarding, Vehicle Steps, and Equipment Steps And Platforms. By end use, metal based safety gratings market is segmented into Industrial, Commercial, Manufacturing, Petrochemical, Construction & Mining, Oil & Gas, Automotive, and Others. Regionally, the metal based safety gratings industry is classified into North America, Latin America, Western Europe, Eastern Europe, Balkan & Baltic Countries, Russia & Belarus, Central Asia, East Asia, South Asia & Pacific, and the Middle East & Africa.

The welded steel grating segment is projected to account for 35.0% of the Metal Based Safety Gratings market revenue in 2025, making it the leading grating type. This segment’s growth is being driven by the structural strength and stability provided by welded connections, which enhance load-bearing capacity and reduce maintenance requirements. Welded steel gratings are favored in industrial and commercial environments due to their ability to withstand high impact and heavy load conditions.

The modular design and ease of customization allow rapid installation in large-scale flooring, walkway, and platform applications. In addition, compatibility with surface treatments such as galvanization or powder coating enhances durability and resistance to corrosion, further driving adoption.

As regulatory standards for industrial safety and structural reliability continue to tighten, welded steel gratings are increasingly preferred by engineers and safety professionals seeking long-term, low-maintenance solutions The segment’s prominence is reinforced by the balance of performance, durability, and cost-effectiveness that it offers to end users across multiple industries.

The mild steel gratings segment is expected to capture 40.0% of the market revenue in 2025, representing the leading metal type in the Metal Based Safety Gratings market. Growth in this segment has been fueled by mild steel’s inherent strength, versatility, and affordability, which make it suitable for a wide range of industrial and commercial applications. Mild steel gratings are easily fabricated, allowing for custom sizes and configurations that meet specific project requirements.

The metal’s capacity to endure heavy loads while maintaining structural stability has made it a preferred choice for flooring, walkways, platforms, and stair treads. Additionally, mild steel’s compatibility with protective coatings such as galvanization ensures resistance to corrosion and longer service life in harsh industrial environments.

Increased adoption is being reinforced by stringent workplace safety regulations, which demand durable and reliable flooring solutions The balance of cost efficiency, mechanical strength, and ease of installation positions mild steel gratings as a dominant segment in the market, with sustained growth anticipated in industrial, commercial, and infrastructure projects.

The flat type grating segment is projected to hold 45.0% of the Metal Based Safety Gratings market revenue in 2025, making it the leading bearing bar type. The growth of this segment has been influenced by the flat bar’s ability to provide a smooth walking surface, improved load distribution, and enhanced safety for industrial and commercial applications. Flat type gratings are widely used in walkways, platforms, mezzanines, and staircases due to their anti-slip properties and ability to reduce tripping hazards.

The ease of installation and low maintenance requirements further support adoption in large-scale industrial and infrastructure projects. Additionally, the uniform surface facilitates cleaning and debris removal, which is critical in environments such as manufacturing plants, chemical facilities, and food processing units.

The preference for flat type gratings is also being reinforced by their structural versatility, allowing seamless integration with various grating types and support systems As industries continue to focus on safety, ergonomics, and operational efficiency, the flat type grating segment is expected to maintain its leading position in the market.

Gratings are regularly spaced collection of parallel and elongated elements generally made of metal. Gratings are widely used for safety applications such as prevention of slippage, machine guarding etc. in various industries across the globe.

Moreover, significant range of metal based safety grating products are available in the market depending upon the type of gratings, material type and application for which it is supposed to be used. Manufacturers of metal based safety gratings are also providing customized offerings to the end uses according to the required dimensions and safety standards.

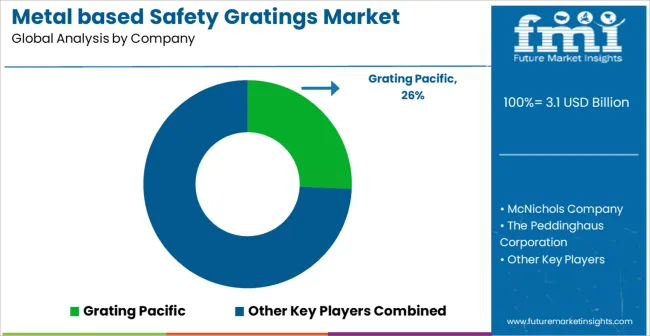

Furthermore, the market for metal based safety gratings is highly fragmented. Significant number of players are present in the market for the manufacturing and sales of metal based safety gratings. This is making the market highly competitive and forcing the manufacturers to provide customer specific product offerings.

The growing number of industrial establishments such as manufacturing units, warehouses, factories for various industries along with their stringent safety standards is expected to fuel the demand for metal based safety gratings in the global market during the forecast period.

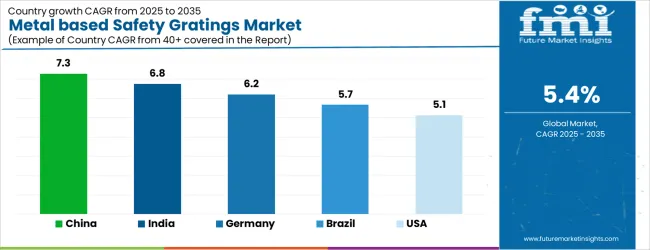

| Country | CAGR |

|---|---|

| China | 7.3% |

| India | 6.8% |

| Germany | 6.2% |

| Brazil | 5.7% |

| USA | 5.1% |

| UK | 4.6% |

| Japan | 4.1% |

The Metal based Safety Gratings Market is expected to register a CAGR of 5.4% during the forecast period, exhibiting varied country level momentum. China leads with the highest CAGR of 7.3%, followed by India at 6.8%. Developed markets such as Germany, France, and the UK continue to expand steadily, while the USA is likely to grow at consistent rates. Japan posts the lowest CAGR at 4.1%, yet still underscores a broadly positive trajectory for the global Metal based Safety Gratings Market. In 2024, Germany held a dominant revenue in the Western Europe market and is expected to grow with a CAGR of 6.2%. The USA. Metal based Safety Gratings Market is estimated to be valued at USD 1.2 billion in 2025 and is anticipated to reach a valuation of USD 1.2 billion by 2035. Sales are projected to rise at a CAGR of 0.0% over the forecast period between 2025 and 2035. While Japan and South Korea markets are estimated to be valued at USD 156.6 million and USD 95.1 million respectively in 2025.

| Item | Value |

|---|---|

| Quantitative Units | USD 3.1 Billion |

| Grating Type | Welded Steel Grating, Riveted Grating, Pressure Locked Grating, and Aluminum Plank Grating |

| Metal Type | Mild Steel Gratings, Stainless Steel Gratings, and Aluminum Gratings |

| Bearing Bar Type | Flat Type Grating, I Bar Grating, Serrated Type Grating, and Press-Locked Steel Bar Grating |

| Top Finish | Galvanized and Powder Coated Gratings |

| Application | Architecture, Walkways, Ladders & Stair Treads, Work Platforms, Machine Guarding, Vehicle Steps, and Equipment Steps And Platforms |

| End Use | Industrial, Commercial, Manufacturing, Petrochemical, Construction & Mining, Oil & Gas, Automotive, and Others |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, Middle East & Africa |

| Country Covered | United States, Canada, Germany, France, United Kingdom, China, Japan, India, Brazil, South Africa |

| Key Companies Profiled | Grating Pacific, McNichols Company, The Peddinghaus Corporation, AMICO, Ohio Gratings, Fisher & Ludlow, Harsco Industrial IKG, Meiser, Nucor Grating, and Webforge |

The global metal based safety gratings market is estimated to be valued at USD 3.1 billion in 2025.

The market size for the metal based safety gratings market is projected to reach USD 5.2 billion by 2035.

The metal based safety gratings market is expected to grow at a 5.4% CAGR between 2025 and 2035.

The key product types in metal based safety gratings market are welded steel grating, riveted grating, pressure locked grating and aluminum plank grating.

In terms of metal type, mild steel gratings segment to command 40.0% share in the metal based safety gratings market in 2025.

Our Research Products

The "Full Research Suite" delivers actionable market intel, deep dives on markets or technologies, so clients act faster, cut risk, and unlock growth.

The Leaderboard benchmarks and ranks top vendors, classifying them as Established Leaders, Leading Challengers, or Disruptors & Challengers.

Locates where complements amplify value and substitutes erode it, forecasting net impact by horizon

We deliver granular, decision-grade intel: market sizing, 5-year forecasts, pricing, adoption, usage, revenue, and operational KPIs—plus competitor tracking, regulation, and value chains—across 60 countries broadly.

Spot the shifts before they hit your P&L. We track inflection points, adoption curves, pricing moves, and ecosystem plays to show where demand is heading, why it is changing, and what to do next across high-growth markets and disruptive tech

Real-time reads of user behavior. We track shifting priorities, perceptions of today’s and next-gen services, and provider experience, then pace how fast tech moves from trial to adoption, blending buyer, consumer, and channel inputs with social signals (#WhySwitch, #UX).

Partner with our analyst team to build a custom report designed around your business priorities. From analysing market trends to assessing competitors or crafting bespoke datasets, we tailor insights to your needs.

Supplier Intelligence

Discovery & Profiling

Capacity & Footprint

Performance & Risk

Compliance & Governance

Commercial Readiness

Who Supplies Whom

Scorecards & Shortlists

Playbooks & Docs

Category Intelligence

Definition & Scope

Demand & Use Cases

Cost Drivers

Market Structure

Supply Chain Map

Trade & Policy

Operating Norms

Deliverables

Buyer Intelligence

Account Basics

Spend & Scope

Procurement Model

Vendor Requirements

Terms & Policies

Entry Strategy

Pain Points & Triggers

Outputs

Pricing Analysis

Benchmarks

Trends

Should-Cost

Indexation

Landed Cost

Commercial Terms

Deliverables

Brand Analysis

Positioning & Value Prop

Share & Presence

Customer Evidence

Go-to-Market

Digital & Reputation

Compliance & Trust

KPIs & Gaps

Outputs

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Aqueous-based Metal Cleaner Market Size and Share Forecast Outlook 2025 to 2035

Metallurgical Lighting Market Size and Share Forecast Outlook 2025 to 2035

Metal Evaporation Boat Market Size and Share Forecast Outlook 2025 to 2035

Metal Miniature Bone Plates Market Size and Share Forecast Outlook 2025 to 2035

Metal Locking Plate and Screw System Market Size and Share Forecast Outlook 2025 to 2035

Safety Label Market Size and Share Forecast Outlook 2025 to 2035

Metal Pallet Market Size and Share Forecast Outlook 2025 to 2035

Metal Oxide Varistor (MOV) Surge Arresters Market Size and Share Forecast Outlook 2025 to 2035

Metal Straw Market Size and Share Forecast Outlook 2025 to 2035

Metal Can Market Size and Share Forecast Outlook 2025 to 2035

Metal IBC Market Forecast and Outlook 2025 to 2035

Metalized Barrier Film Market Forecast and Outlook 2025 to 2035

Metal Packaging Market Size and Share Forecast Outlook 2025 to 2035

Metal Bellow Market Size and Share Forecast Outlook 2025 to 2035

Metal Modifiers Market Size and Share Forecast Outlook 2025 to 2035

Metallic Stearate Market Size and Share Forecast Outlook 2025 to 2035

Metallic Labels Market Size and Share Forecast Outlook 2025 to 2035

Metal Recycling Market Size and Share Forecast Outlook 2025 to 2035

Metal Forming Fluids Market Size and Share Forecast Outlook 2025 to 2035

Metal Removal Fluids Market Size and Share Forecast Outlook 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA