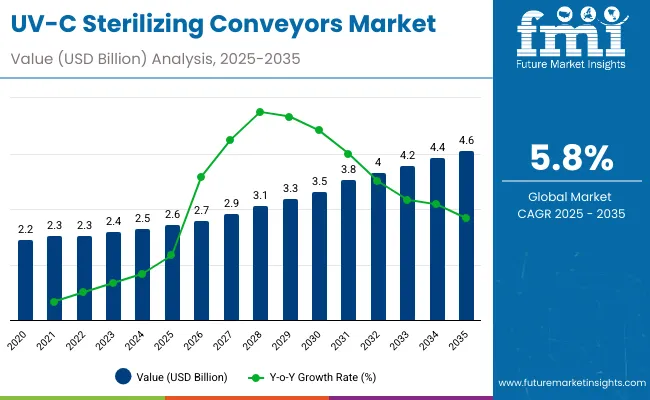

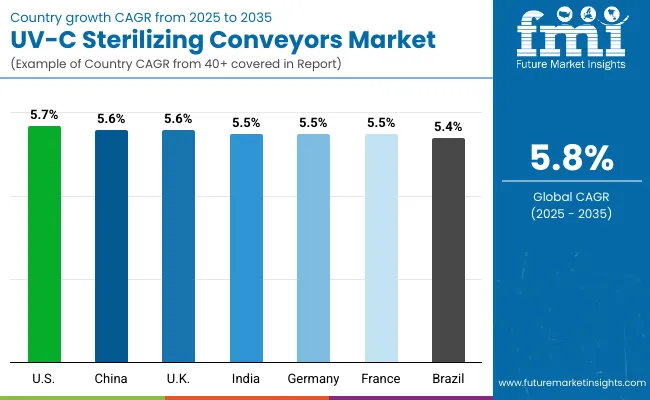

The UV-C Sterilizing Conveyors Market will rise from USD 2.6 billion in 2025 to USD 4.6 billion by 2035, at a CAGR of 5.8%. Market expansion is driven by rising hygiene mandates across healthcare, food, and cosmetic manufacturing facilities. Tunnel conveyors with UV-C sterilization ensure continuous decontamination of containers, instruments, and packaging lines. Between 2025 and 2030, advancements in IoT-integrated UV-C systems will enhance automation and real-time performance monitoring. Asia-Pacific is expected to dominate due to expanding pharmaceutical production and rapid technological deployment across packaging operations.

Between 2020 and 2024, heightened infection-control awareness accelerated the deployment of UV-C sterilization systems across global industries. Early adoption in medical and food packaging established a foundation for continuous, automated UV-C conveyor solutions. By 2035, the market will reach USD 4.6 billion, supported by clean-room compliance requirements and advances in multi-wavelength disinfection systems. Asia-Pacific will maintain leadership in production scale, while North America and Europe will drive innovation in energy-efficient UV-C emitters and AI-linked monitoring technologies.

| Metric | Value |

|---|---|

| Industry Size (2025E) | USD 2.6 billion |

| Industry Value (2035F) | USD 4.6 billion |

| CAGR (2025 to 2035) | 5.8% |

Growth is driven by the surge in hygienic manufacturing and sterilization automation across pharmaceutical and food processing sectors. UV-C conveyors offer rapid, chemical-free disinfection of materials and surfaces, improving throughput and compliance with FDA and EU standards. Rising global focus on sustainable sterilization technologies is boosting replacement demand for traditional chemical systems.

The market is segmented by conveyor type, technology, application, end-use industry, and region. Conveyor types include tunnel, roller, flat belt, and modular belt conveyors. Technologies comprise multi-wavelength sterilization systems, single-wavelength UV-C systems, and IoT-integrated conveyors. Applications range from pharmaceutical manufacturing and food packaging to cosmetic sterilization. End-use industries encompass pharmaceuticals and healthcare, food and beverages, cosmetics and personal care, and industrial manufacturing.

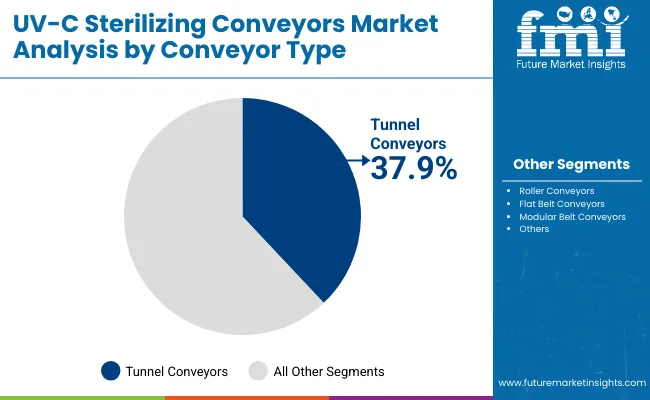

Tunnel conveyors are projected to hold 37.9% of the market in 2025, offering consistent UV-C exposure and uniform sterilization in controlled environments. Their enclosed design minimizes contamination risk while supporting continuous operation in pharmaceutical and food processing lines.

Scalability and integration with automated material handling systems enhance throughput and process reliability. These conveyors are particularly favored in clean-room applications where consistent sanitization is critical. As manufacturers seek cost-effective sterilization alternatives, tunnel conveyors remain the dominant configuration for UV-C deployment.

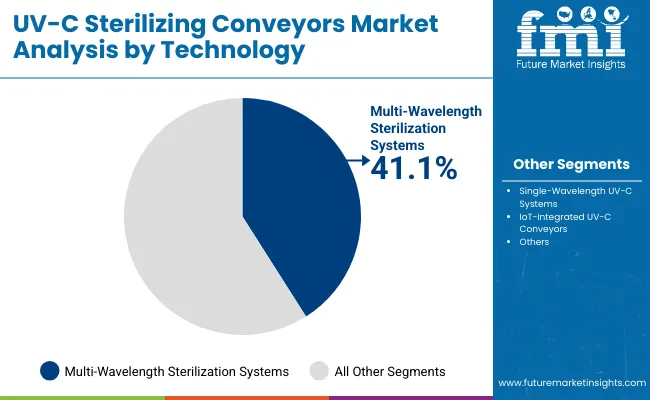

Multi-wavelength sterilization systems are expected to represent 41.1% of the market in 2025, driven by their superior microbial inactivation across a wide spectrum of bacteria and viruses. The combination of UV-C, UV-B, and UV-A wavelengths ensures deeper penetration and faster sterilization cycles.

Integration of IoT-enabled sensors provides real-time wavelength monitoring, validation, and traceability for GMP compliance. These systems optimize disinfection across varied packaging materials and surfaces. As precision and safety standards evolve, multi-wavelength systems continue to define the technological benchmark in sterilization conveyors.

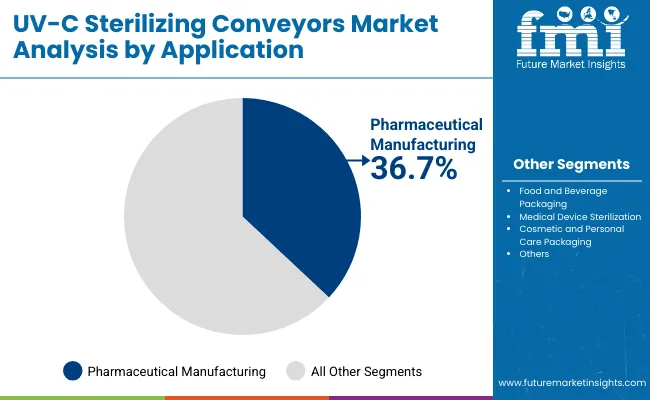

Pharmaceutical manufacturing is forecast to account for 36.8% of the market in 2025, supported by strict sterility and contamination-control requirements in production lines. UV-C conveyors ensure safe handling of vials, ampoules, and syringes during pre-filling and packaging processes.

Adoption is driven by the growing vaccine, biologics, and injectable drug segments. Compliance with Good Manufacturing Practices (GMP) mandates continuous, validated sterilization cycles. As demand for contamination-free production scales, pharmaceutical manufacturing remains the leading application for UV-C conveyors.

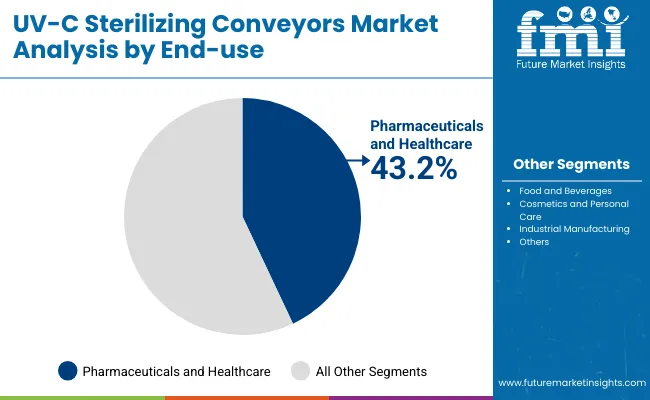

The pharmaceuticals and healthcare sector is projected to command 43.2% of the market in 2025, reflecting expanding use of sterilizing conveyors in hospitals, laboratories, and medical device facilities. These systems enhance hygiene standards while ensuring safe material transfer under sterile conditions.

Integration with robotic handling and automated inspection technologies improves efficiency and reduces human exposure risks. Growing emphasis on infection control and process reliability sustains sector-wide adoption. As sterile infrastructure modernization accelerates, pharmaceuticals and healthcare remain the core end-use market for UV-C sterilizing conveyors.

The market is driven by stringent global hygiene standards and the increasing adoption of automated disinfection systems across packaging lines to ensure sterility and compliance. However, high maintenance and lamp replacement costs pose financial challenges for smaller facilities. Opportunities lie in IoT-linked UV-C conveyors supporting predictive maintenance and analytics integration. Key trends include energy-efficient LED-based UV systems, modular automation designs, and hybrid conveyor solutions that merge sterilization with inspection for enhanced productivity.

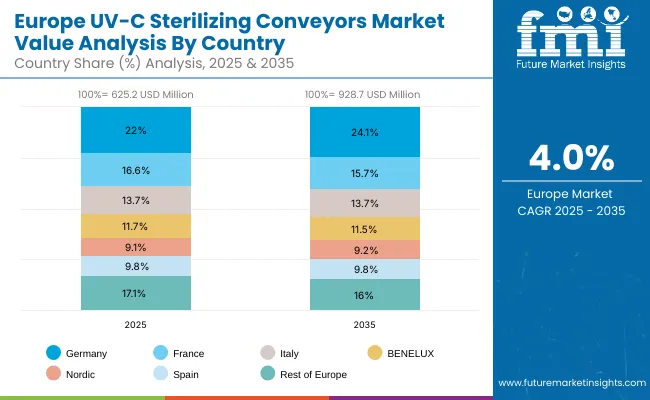

The global UV-C sterilizing conveyors market is expanding rapidly as hygiene, automation, and sustainability converge across industrial sectors. Asia-Pacific dominates production, led by Japan, China, and South Korea, with strong emphasis on compact UV-C LED modules and robotics integration. North America continues to advance FDA-compliant sterile packaging solutions and AI-based process monitoring, while Europe focuses on eco-designed, energy-optimized UV-C systems meeting strict disinfection regulations. Growing deployment in healthcare, pharmaceuticals, semiconductors, and food processing underlines UV-C’s role in next-generation clean manufacturing environments.

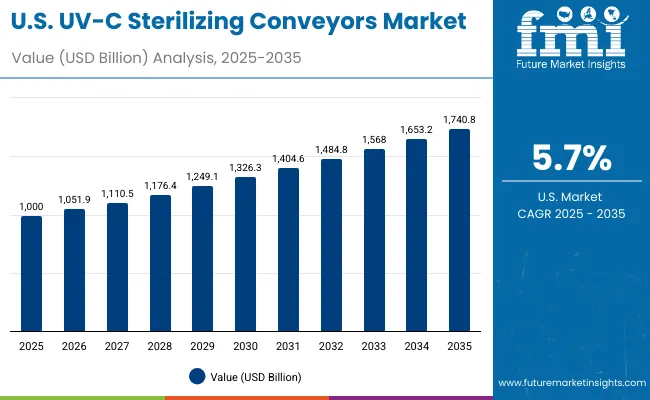

The USA will grow at 5.7% CAGR, supported by widespread adoption in pharmaceutical packaging, food processing, and medical device sterilization. Automation retrofits for clean-room conveyors are expanding under FDA compliance initiatives. AI-enabled vision and monitoring systems are improving sterilization validation and operational traceability. Strong investment in sterile packaging automation continues to shape USA market leadership.

Germany will expand at 5.5% CAGR, emphasizing sustainability and precision in UV-C conveyor design. Energy-efficient modules are driving adoption across pharmaceutical and cosmetic sectors. Compliance with EU hygiene and safety directives encourages further integration of UV-C disinfection in industrial manufacturing. Partnerships between automation specialists and material scientists enhance system performance.

The UK will grow at 5.6% CAGR, driven by automation in medical, cosmetic, and personal care packaging lines. Investments in IoT-integrated sterilization systems support real-time validation and reporting. Growth in contract sterilization and packaging services is accelerating adoption across healthcare supply chains.

China will grow at 5.6% CAGR, underpinned by strong demand from food sterilization, pharmaceutical, and bioprocessing industries. Local manufacturers are scaling cost-effective modular conveyor systems for domestic and export markets. Government hygiene initiatives and clean manufacturing policies continue to enhance industry-wide deployment.

India will grow at 5.5% CAGR, driven by industrial modernization and heightened hygiene standards in pharmaceuticals and FMCG sectors. Government incentives for clean manufacturing support UV-C technology adoption in packaging and healthcare. Demand for automated sterilization among pharmaceutical exporters continues to rise.

Japan will grow at 6.2% CAGR, leading global innovation with compact UV-C LED sterilization conveyors. Integration with robotic arms and high-speed clean-room packaging enhances operational efficiency. The nation’s focus on sustainability and automation strengthens its export position in healthcare and electronics manufacturing.

South Korea will lead with 6.3% CAGR, driven by smart factory integration and IoT-enabled sterilization systems. The country’s dominance in semiconductor and precision healthcare manufacturing fuels high adoption of UV-C conveyors. Export demand for intelligent sterilization solutions continues to strengthen regional competitiveness.

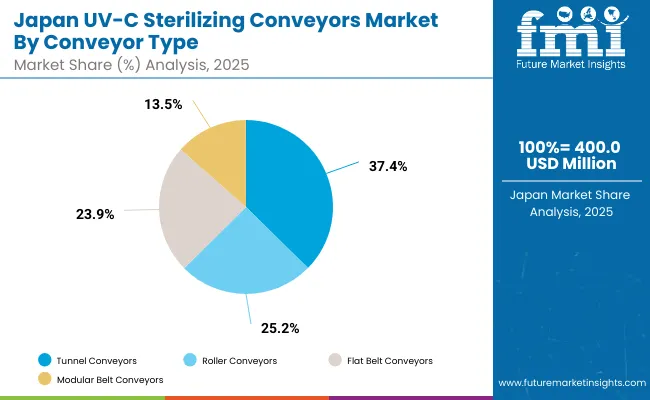

Japan’s UV-C sterilizing conveyors market, valued at USD 400.0 million in 2025, is led by tunnel conveyors with a 38.6% share, preferred for pharmaceutical and food processing environments requiring enclosed sterilization. Roller conveyors support packaging operations, while flat belt conveyors enhance throughput efficiency. Modular belt conveyors are adopted for cleanroom and laboratory product handling.

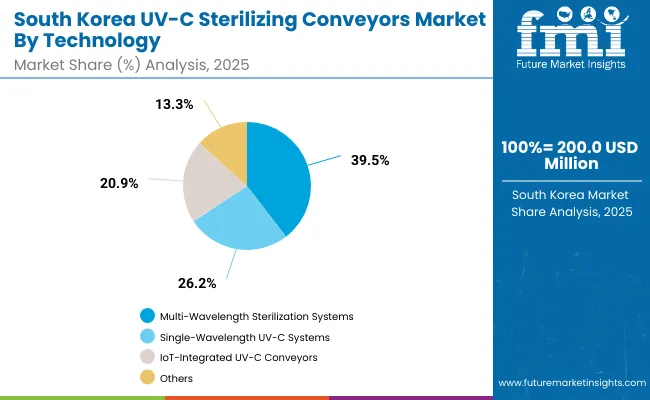

South Korea’s UV-C sterilizing conveyors market, worth USD 200.0 million in 2025, is dominated by multi-wavelength sterilization systems holding a 40.1% share due to their superior disinfection performance. Single-wavelength UV-C systems are used for cost-efficient operations, while IoT-integrated UV-C conveyors are emerging for automated monitoring in hygiene-critical manufacturing sectors.

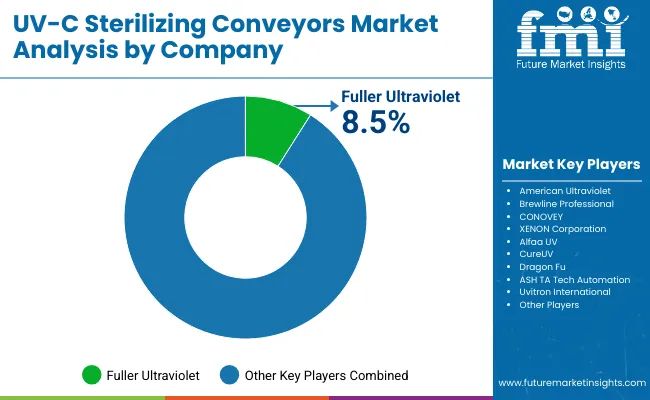

The market is moderately consolidated with key players such as Fuller Ultraviolet, American Ultraviolet, Brewline Professional, CONOVEY, XENON Corporation, Alfaa UV, CureUV, Dragon Fu, ASH TA Tech Automation, and Uvitron International. These companies focus on modular designs, smart controls, and compliance with international sterilization standards.

Key Developments

| Item | Value |

|---|---|

| Quantitative Units | USD 2.6 Billion (2025 baseline) |

| By Conveyor Type | Tunnel, Roller, Flat Belt, Modular Belt |

| By Technology | Multi-Wavelength, Single-Wavelength, IoT-Integrated UV-C Conveyors |

| By Application | Pharmaceutical, Food Packaging, Medical Devices, Cosmetics |

| By End-Use Industry | Pharmaceuticals & Healthcare, Food & Beverages, Cosmetics, Industrial |

| Key Companies Profiled | Fuller Ultraviolet, American Ultraviolet, Brewline Professional, XENON Corporation, Alfaa UV |

| Additional Attributes | Market driven by automated sterilization demand and regulatory compliance |

The UV-C Sterilizing Conveyors Market is valued at USD 2.6 billion in 2025.

The UV-C Sterilizing Conveyors Market is projected to reach USD 4.6 billion by 2035.

The market will grow at a CAGR of 5.8 % during the forecast period.

Multi-Wavelength Sterilization Systems lead with a 41.1 % share, ensuring efficient microbial elimination across diverse production environments.

The Pharmaceuticals and Healthcare sector dominates with a 43.2 % share, driven by regulatory standards for sterile production.

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

UVC Disinfection Product Market Report – Demand, Trends & Forecast 2025–2035

Conveyors and Belt Loaders Market Growth - Trends & Forecast 2025 to 2035

Pack Conveyors Market Size and Share Forecast Outlook 2025 to 2035

Chain Conveyors Market Size and Share Forecast Outlook 2025 to 2035

Vibrating Feed Conveyors Market

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA