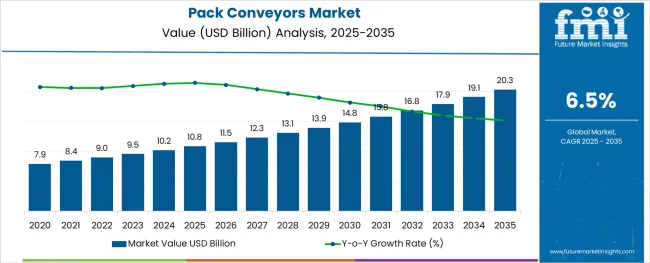

The Pack Conveyors Market is estimated to be valued at USD 10.8 billion in 2025 and is projected to reach USD 20.3 billion by 2035, registering a compound annual growth rate (CAGR) of 6.5% over the forecast period.

The pack conveyors market is experiencing steady expansion, fueled by rising demand for integrated material handling systems across food, beverage, pharmaceutical, and consumer goods industries. Manufacturers are prioritizing automation and modularity to improve operational efficiency, reduce downtime, and support high-throughput packaging lines. Regulatory requirements for hygiene and traceability in product handling have further accelerated the deployment of conveyors tailored for primary and secondary packaging stages.

Advances in sensor integration, motor efficiency, and control architecture are enabling real-time monitoring and optimized flow management. Moreover, end users are increasingly seeking conveyor systems that support flexible layouts, accommodate multiple package types, and offer rapid changeovers.

Growth opportunities are expected to emerge from smart manufacturing investments and the integration of Industry 4.0 technologies, where conveyors function as vital components within digitally connected packaging ecosystems.

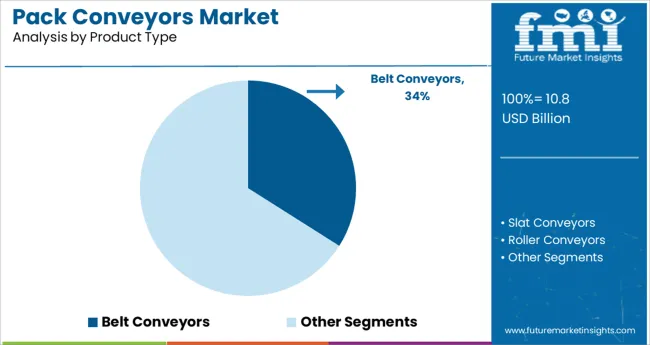

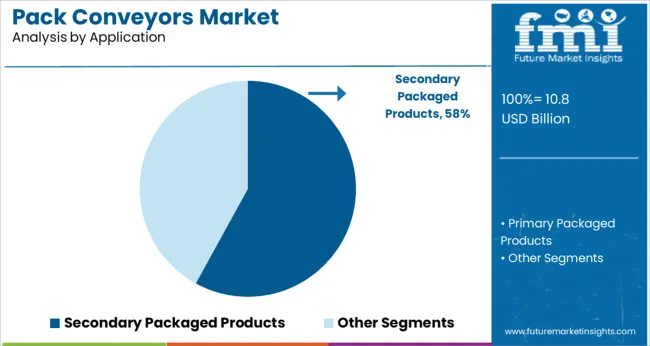

The market is segmented by Product Type, Application, Type, and End Use Industry and region. By Product Type, the market is divided into Belt Conveyors, Slat Conveyors, Roller Conveyors, Accumulation Conveyors, and LBP Conveyors. In terms of Application, the market is classified into Secondary Packaged Products and Primary Packaged Products.

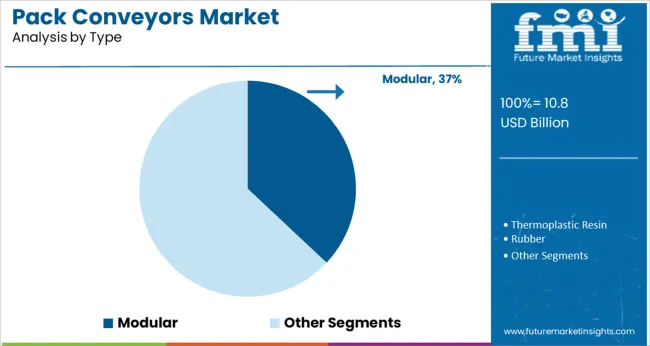

Based on Type, the market is segmented into Modular, Thermoplastic Resin, Rubber, and Roller. By End Use Industry, the market is divided into Food Industry, Healthcare Industry, Automotive Industry, and Aerospace Industry. Regionally, the market is classified into North America, Latin America, Western Europe, Eastern Europe, Balkan & Baltic Countries, Russia & Belarus, Central Asia, East Asia, South Asia & Pacific, and the Middle East & Africa.

Belt conveyors are projected to account for 34.0% of the total market revenue in 2025, positioning them as the leading product type segment. Their dominance is being attributed to their versatility, low maintenance needs, and smooth handling capabilities across a variety of package shapes and sizes. Belt conveyors offer gentle yet continuous transport, making them suitable for both primary and secondary packaging lines.

Their ability to maintain product orientation and prevent slippage supports efficiency in automated inspection, labeling, and sorting tasks.

The modular design of belt conveyors allows for easy integration into complex production layouts, enhancing flexibility without compromising throughput. With increased focus on reducing manual handling and ensuring consistent flow, belt conveyors remain a preferred choice across industries prioritizing reliability, hygiene, and adaptability in their packaging operations.

Secondary packaged products are expected to account for 58.0% of the market revenue in 2025, establishing this as the dominant application segment. This growth is being driven by increased volume handling requirements and the need for precise, synchronized movement of cartons, trays, and shrink-wrapped goods. Conveyors designed for secondary packaging provide structural robustness and compatibility with end-of-line processes such as case packing, palletizing, and stretch wrapping.

The focus on minimizing packaging waste, improving production efficiency, and maintaining unit integrity during transportation has further fueled demand in this segment. Industries are investing in high-speed conveyors that support bulk product handling while reducing manual labor and bottlenecks in logistics workflows.

As packaging formats become more diverse and automation more prevalent, conveyor systems tailored for secondary packaged products are gaining broader adoption across sectors focused on operational scalability and shipment-ready output.

Modular conveyors are projected to capture 37.0% of market revenue in 2025, positioning them as a key type segment within the pack conveyors market. Their growth is being supported by increasing demand for configurable, space-saving systems that offer flexibility in layout and quick adaptation to production changes. Modular conveyor systems enable manufacturers to reconfigure lines with minimal downtime, making them ideal for facilities with dynamic product mixes or seasonal demand fluctuations.

Their standardized components and plug-and-play design allow for efficient maintenance and reduced engineering time during installation. Additionally, modular conveyors are often equipped with hygienic construction features and open-access designs, which are critical in industries with stringent cleanliness standards.

The scalability and customization potential of modular systems are making them increasingly popular among manufacturers seeking long-term value, performance reliability, and ease of expansion in their packaging operations.

Pack conveyors are used to deliver packs or products from one sector of a firm or a machine to another. Pack conveyors are built on a solid steel frame and it protects the packs which are loaded on it, against friction and chafing. It transports different pack types like cartons and plastic crates safely to their fixed destination.

One of the major factors, expected to facilitate growth of the global pack conveyors market is, almost all of its components are pre-assembled and therefore, is ready for use within a small interval, based on “plug-and-play” principle. A pack conveyor of proven resistance is capable of supporting heavy product flow, which is expected to drive growth of the global pack conveyors market.

Ease of operation and durability are some of the other attributes expected to catapult the global pack conveyors market. Pack conveyors are customizable, and therefore, can be modified to suit different pack requirements.

The various types of pack conveyors available in the market include belt conveyors, slat conveyors, and roller conveyors, among others, which are equipped with automatic format change and can be either multi or single way.

The dynamic nature of pack conveyors allow them to be integrated with some of the most common machinery available in the market, which include dividers, applicators and palletizers.

Pack conveyors are used for quick and heavy transportation of a variety of materials or packs which increases their preference in material handling and packaging industries. Pack conveyors are also equipped with low consumption motors, which also facilitates their maintenance. Among the sub types of pack conveyors, belt conveyors held the largest market share in 2020.

Rapid modernization and increase in production volume are some of the major factors, which are expected to drive growth of the global pack conveyors market. Pack Conveyors help to simplify the task of bulk or heavy material handling and play a significant role by reducing and minimizing the probability of human errors.

There is also an increasing demand of pack conveyors in various storage, distributor centres and warehouses, which is anticipated to directly translate into growth of the global pack conveyors market. There are other trends, which are expected to facilitate growth of the global pack conveyors market, including, emergence of eco-friendly pack conveyors, ushering in a new era of green conveying.

Geographically, the pack conveyors market can be segmented into

The rise in manufacturing and other industries will drive growth of the pack conveyors market in the APAC region. Asia-Pacific is expected to experience the most prominent growth, over the forecast period. India and China are forecast to be the key contributors to the global pack conveyors market in this region. Europe is expected to lead the global pack conveyors market, in terms of volume.

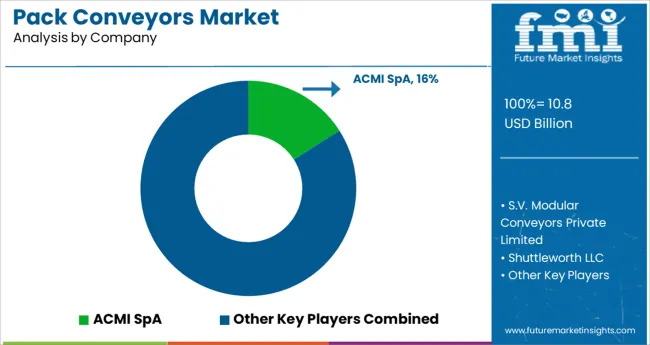

Few of the key players operating in the global pack conveyors market are - ACMI SpA, S.V. Modular Conveyors Private Limited, Shuttleworth LLC, Bando Chemical Industries, Ltd., Power Pack Conveyor Company, Integrated Conveyors and Pacline Automation Technologies, Phoenix Conveyor Belt Systems GmbH, and Vetromeccanica srl.

The report is a compilation of first-hand information, qualitative and quantitative assessment by industry analysts, inputs from industry experts and industry participants across the value chain.

The report provides in-depth analysis of parent market trends, macro-economic indicators and governing factors along with market attractiveness as per segments. The report also maps the qualitative impact of various market factors on market segments and geographies.

The global pack conveyors market is estimated to be valued at USD 10.8 billion in 2025.

It is projected to reach USD 20.3 billion by 2035.

The market is expected to grow at a 6.5% CAGR between 2025 and 2035.

The key product types are belt conveyors, slat conveyors, roller conveyors, accumulation conveyors and lbp conveyors.

secondary packaged products segment is expected to dominate with a 58.0% industry share in 2025.

Our Research Products

The "Full Research Suite" delivers actionable market intel, deep dives on markets or technologies, so clients act faster, cut risk, and unlock growth.

The Leaderboard benchmarks and ranks top vendors, classifying them as Established Leaders, Leading Challengers, or Disruptors & Challengers.

Locates where complements amplify value and substitutes erode it, forecasting net impact by horizon

We deliver granular, decision-grade intel: market sizing, 5-year forecasts, pricing, adoption, usage, revenue, and operational KPIs—plus competitor tracking, regulation, and value chains—across 60 countries broadly.

Spot the shifts before they hit your P&L. We track inflection points, adoption curves, pricing moves, and ecosystem plays to show where demand is heading, why it is changing, and what to do next across high-growth markets and disruptive tech

Real-time reads of user behavior. We track shifting priorities, perceptions of today’s and next-gen services, and provider experience, then pace how fast tech moves from trial to adoption, blending buyer, consumer, and channel inputs with social signals (#WhySwitch, #UX).

Partner with our analyst team to build a custom report designed around your business priorities. From analysing market trends to assessing competitors or crafting bespoke datasets, we tailor insights to your needs.

Supplier Intelligence

Discovery & Profiling

Capacity & Footprint

Performance & Risk

Compliance & Governance

Commercial Readiness

Who Supplies Whom

Scorecards & Shortlists

Playbooks & Docs

Category Intelligence

Definition & Scope

Demand & Use Cases

Cost Drivers

Market Structure

Supply Chain Map

Trade & Policy

Operating Norms

Deliverables

Buyer Intelligence

Account Basics

Spend & Scope

Procurement Model

Vendor Requirements

Terms & Policies

Entry Strategy

Pain Points & Triggers

Outputs

Pricing Analysis

Benchmarks

Trends

Should-Cost

Indexation

Landed Cost

Commercial Terms

Deliverables

Brand Analysis

Positioning & Value Prop

Share & Presence

Customer Evidence

Go-to-Market

Digital & Reputation

Compliance & Trust

KPIs & Gaps

Outputs

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Package Shell for Optical Communication Modules Market Size and Share Forecast Outlook 2025 to 2035

Package Pumping Station Market Size and Share Forecast Outlook 2025 to 2035

Packaging Supply Market Size and Share Forecast Outlook 2025 to 2035

Package Testing Silicone Rubber Socket Market Size and Share Forecast Outlook 2025 to 2035

Packaging Testing Services Market Size and Share Forecast Outlook 2025 to 2035

Packaging Tubes Market Size and Share Forecast Outlook 2025 to 2035

Packaging Jar Market Forecast and Outlook 2025 to 2035

Packaging Barrier Film Market Size and Share Forecast Outlook 2025 to 2035

Packaging Films Market Size and Share Forecast Outlook 2025 to 2035

Packaging Laminate Market Size and Share Forecast Outlook 2025 to 2035

Packaging Burst Strength Test Market Size and Share Forecast Outlook 2025 to 2035

Packaging Tapes Market Analysis - Size, Share, & Forecast Outlook 2025 to 2035

Packaging Materials Market Size and Share Forecast Outlook 2025 to 2035

Packaging Labels Market Size and Share Forecast Outlook 2025 to 2035

Packaging Equipment Market Size and Share Forecast Outlook 2025 to 2035

Packaged Coconut Water Market Size and Share Forecast Outlook 2025 to 2035

Packaging Resins Market Size and Share Forecast Outlook 2025 to 2035

Packaging Inspection Systems Market Size and Share Forecast Outlook 2025 to 2035

Packaging Design And Simulation Technology Market Size and Share Forecast Outlook 2025 to 2035

Packaging Suction Cups Market Size and Share Forecast Outlook 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA