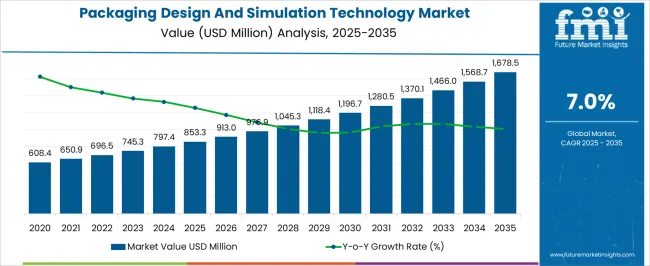

The Packaging Design And Simulation Technology Market is estimated to be valued at USD 853.3 million in 2025 and is projected to reach USD 1678.5 million by 2035, registering a compound annual growth rate (CAGR) of 7.0% over the forecast period.

| Metric | Value |

|---|---|

| Packaging Design And Simulation Technology Market Estimated Value in (2025 E) | USD 853.3 million |

| Packaging Design And Simulation Technology Market Forecast Value in (2035 F) | USD 1678.5 million |

| Forecast CAGR (2025 to 2035) | 7.0% |

The packaging design and simulation technology market is undergoing significant advancement as digitalization transforms traditional packaging workflows into predictive, automated, and customer-focused ecosystems. Brand owners and packaging converters are increasingly adopting digital platforms that integrate structural design, virtual prototyping, and environmental simulation to reduce time-to-market and minimize physical testing.

The push for sustainability has accelerated the use of simulation tools that enable lightweighting, material optimization, and carbon footprint assessment during the design stage. In parallel, e-commerce growth and omnichannel retailing have elevated the need for packaging that meets both branding and functional durability requirements.

Companies are also prioritizing packaging that enhances customer engagement through form factor, shelf impact, and ease of use, further reinforcing the value of digital design tools. Investment in cloud-based platforms, AI-driven design engines, and real-time collaboration tools is expected to define future growth, especially as packaging complexity increases and global brands seek scalable solutions for rapid innovation cycles.

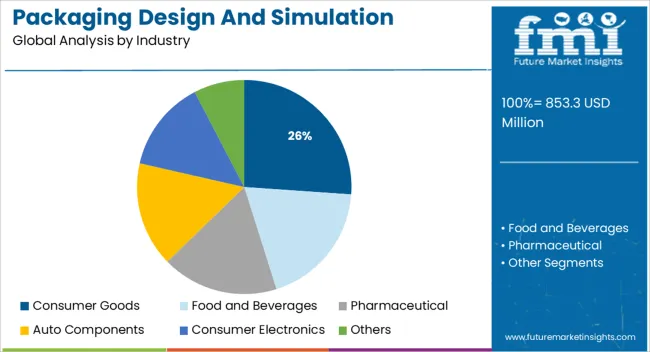

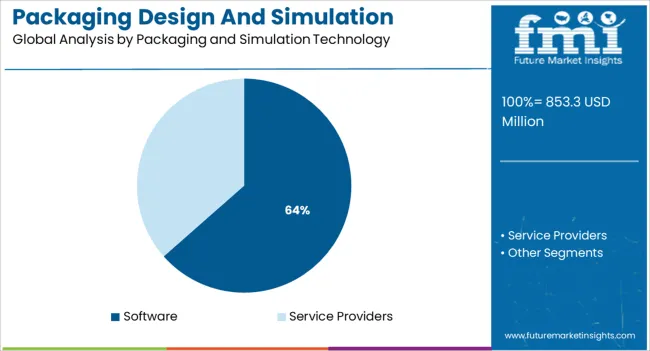

The market is segmented by Industry and Packaging and Simulation Technology and region. By Industry, the market is divided into Consumer Goods, Food and Beverages, Pharmaceutical, Auto Components, Consumer Electronics, and Others. In terms of Packaging and Simulation Technology, the market is classified into Software and Service Providers. Regionally, the market is classified into North America, Latin America, Western Europe, Eastern Europe, Balkan & Baltic Countries, Russia & Belarus, Central Asia, East Asia, South Asia & Pacific, and the Middle East & Africa.

The consumer goods segment is projected to account for 26.1% of revenue within the industry category in 2025, making it the leading vertical. This is being driven by continuous innovation in product packaging aimed at enhancing consumer experience, shelf appeal, and environmental sustainability.

The high turnover rate and competitive nature of the consumer goods sector have placed pressure on companies to reduce design cycles and develop optimized packaging using simulation-based platforms. These tools allow virtual testing of packaging performance under various transportation, storage, and environmental conditions.

Additionally, the demand for flexible, lightweight, and recyclable materials in consumer packaging has required simulation to ensure performance integrity while reducing material waste. The alignment of packaging strategy with brand differentiation and ESG goals has positioned simulation technologies as essential enablers in this segment, securing its dominant share in the market.

Software is expected to dominate the packaging and simulation technology segment with a 63.5% revenue share in 2025. This segment’s leadership is attributed to its central role in virtual prototyping, performance analysis, and packaging lifecycle optimization.

The ability of software solutions to integrate design visualization, digital twins, structural simulations, and sustainability analytics has revolutionized packaging development processes. Software platforms are enabling faster decision-making, improved cross-functional collaboration, and reduced reliance on physical mockups, thereby cutting costs and accelerating go-to-market strategies.

With increasing demand for customization, compliance, and eco-efficiency in packaging, businesses are investing heavily in simulation and design software that can accommodate evolving packaging formats and regulatory requirements. Furthermore, cloud-enabled tools and AI-enhanced features have made simulation software more accessible and intelligent, strengthening its role as the core technology in the packaging design and simulation value chain.

Product packaging designers are faced with conflicting requirements throughout the development process. Good pack aesthetics are vital for the success of the product, whilst unit costs must be minimized and suitability for stacking and transportation maintained.

Packaging design depends on choosing the right materials to pack, 3-dimensional look of the package, and how is it unpacked so that it can or cannot be reused. Packaging design process is scattered across multiple groups and suppliers.

These suppliers use multiple steps such as quality checks, recalls, and incur higher costs which gradually delays the process. Simulation technology used in packaging design enables the groups and suppliers to collaborate together and create designs which allows to monitor the physical behavior of the products and materials in order to improve the performance, reliability, safety having the benefit of reduced development time and manufacturing costs.

Packaging design and simulation technology market has led from constant innovation and evolution in various departments such as packaging development, optimization technology, and automated simulation. Simulation technology makes packaging more sustainable by helping in several ways like reducing the costs, enabling secure shipment and minimizes the impacts on environment.

Companies invest in R&D to improve the brand portfolio and have rewarding product experiences by improving their packaging design which impact positively to the packaging design and simulation technology market. The shift towards usage of recyclable products reduces the packaging material cost, whose feasibility is inspected by simulation technology this phenomenon drives the packaging design and simulation technology market.

With the advancement of technology and automation, majority of the companies are looking forward to packaging design and simulation technology encouraging the packaging design and simulation technology market.

Consumer product packaging designers are confronted with differing requirements throughout the improvement process.

Factors such as good packing is important for the success of the product, at the same time unit costs must be reduced and aptness for transportation needs to be maintained which urges the companies to use simulation technology for their package designing driving the packaging design and simulation technology market.

Costs such as initial investment is high for the software, proper training to the staff to use the software correctly which again is included in expenses. Such challenges can affect packaging design and simulation technology market growth.

Segmentation for the packing design and simulation technology market can be done based on industry. On the basis of industry, packing and simulation technology market can be segmented into consumer goods, food and beverages, pharmaceutical, auto components, consumer electronics and others. The market can be further segmented into software and service providers.

North American region dominates among all the other regions in the packaging design and simulation technology market as a few players have decided to standardize the simulation process for their respective vendors. This would help in simulation process and test performance in fast decision making.

European and Asia Pacific regions are considered to have the most potential with advancement of technology and the raising awareness among the consumers about the environmental hazards. Middle East and Africa and Latin America are also among the potential markets but are listed after APAC and Europe region.

Key vendors of packaging design and simulation technology include 3 Dassault Systems, Altair Product Design Inc., ANSYS inc., MSC Software Corporation, NEFAB Group, Axiom Consulting, Mentor Graphics, ESI Group, Bosch Rexroth AG, and AVID Technology Inc.

The report is a compilation of first-hand information, qualitative and quantitative assessment by industry analysts, inputs from industry experts and industry participants across the value chain. The report provides in-depth analysis of parent market trends, macro-economic indicators and governing factors along with market attractiveness as per segments. The report also maps the qualitative impact of various market factors on market segments and geographies.

The global packaging design and simulation technology market is estimated to be valued at USD 853.3 million in 2025.

The market size for the packaging design and simulation technology market is projected to reach USD 1,678.5 million by 2035.

The packaging design and simulation technology market is expected to grow at a 7.0% CAGR between 2025 and 2035.

The key product types in packaging design and simulation technology market are consumer goods, food and beverages, pharmaceutical, auto components, consumer electronics and others.

In terms of packaging and simulation technology, software segment to command 63.5% share in the packaging design and simulation technology market in 2025.

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Industry Share & Competitive Positioning in Packaging Design And Simulation Technology

Packaging Supply Market Size and Share Forecast Outlook 2025 to 2035

Packaging Testing Services Market Size and Share Forecast Outlook 2025 to 2035

Packaging Tubes Market Size and Share Forecast Outlook 2025 to 2035

Packaging Jar Market Forecast and Outlook 2025 to 2035

Packaging Barrier Film Market Size and Share Forecast Outlook 2025 to 2035

Packaging Films Market Size and Share Forecast Outlook 2025 to 2035

Packaging Laminate Market Size and Share Forecast Outlook 2025 to 2035

Packaging Burst Strength Test Market Size and Share Forecast Outlook 2025 to 2035

Packaging Tapes Market Analysis - Size, Share, & Forecast Outlook 2025 to 2035

Packaging Materials Market Size and Share Forecast Outlook 2025 to 2035

Packaging Labels Market Size and Share Forecast Outlook 2025 to 2035

Packaging Equipment Market Size and Share Forecast Outlook 2025 to 2035

Packaging Resins Market Size and Share Forecast Outlook 2025 to 2035

Packaging Inspection Systems Market Size and Share Forecast Outlook 2025 to 2035

Packaging Suction Cups Market Size and Share Forecast Outlook 2025 to 2035

Packaging Coating Market Analysis - Size, Share, & Forecast Outlook 2025 to 2035

Packaging Testing Equipment Market Analysis & Growth 2025 to 2035

Packaging Bins Market Trends - Growth & Demand 2025 to 2035

Packaging Inserts Market Insights - Growth & Forecast 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA