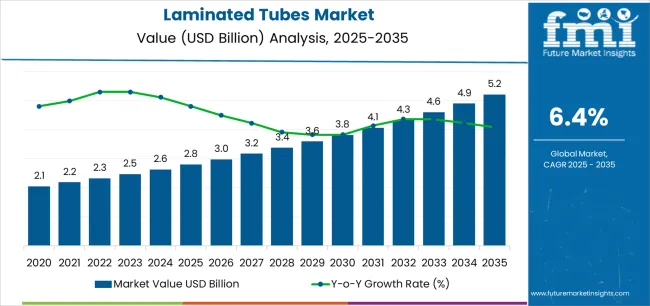

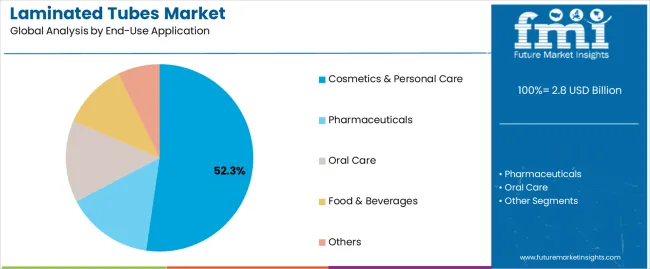

The laminated tubes market is projected to grow from USD 2.8 billion in 2025 to USD 5.2 billion by 2035, advancing at a CAGR of 6.4%. The market is driven by increasing demand for protective packaging in the cosmetics industry, with cosmetics & personal care leading the end-use application segment, holding a 52.3% share in 2025. This growth is supported by the rising popularity of premium tube formats in skincare, hair care, and personal care products, along with the growing adoption of high-barrier laminated tubes with enhanced branding and printing capabilities.

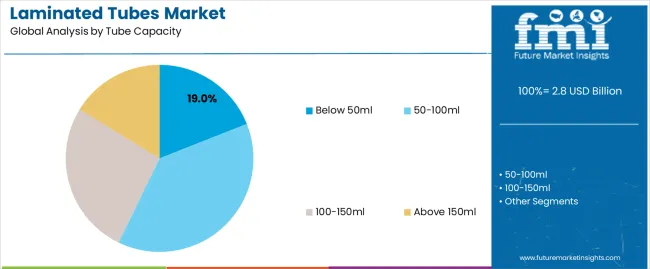

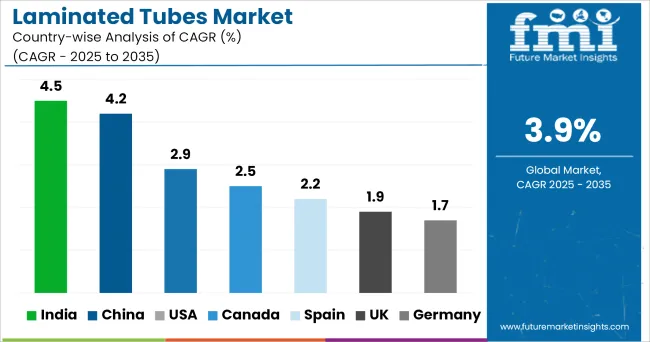

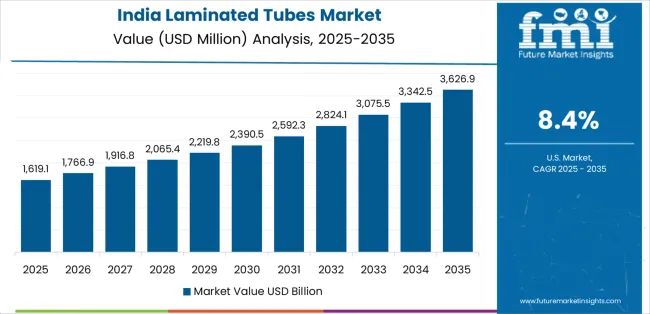

The 50-100ml tube capacity segment is set to dominate, accounting for 38.2% of the market, driven by the widespread use of this size in facial creams, body lotions, and other personal care products. The demand for advanced digital printing technologies and smart packaging solutions will also contribute to the market's expansion. India leads growth at 8.4% CAGR, supported by expanding cosmetics and pharmaceutical manufacturing industries, while China follows with 7.8% CAGR, bolstered by rapid skincare consumption and rising domestic production. The USA and Germany show steady growth at 5.6% and 5.3%, respectively, prioritizing premium packaging and pharmaceutical-grade tube applications.

The demand for laminated tubes is increasing due to their use in packaging topical creams, ointments, and gels. These products require packaging that ensures their effectiveness and safety while preventing contamination. Laminated tubes provide an airtight, sealed environment that helps preserve the potency of pharmaceutical products, making them a popular choice for packaging medications. As the global pharmaceutical industry continues to expand, particularly with the rising demand for over-the-counter and prescription products, the adoption of laminated tubes for packaging medical creams and ointments is expected to grow.

Technological advancements in laminated tube production are also driving market growth. Innovations in materials and manufacturing processes are enhancing the strength, flexibility, and aesthetic appeal of laminated tubes. The development of high-quality printing techniques has enabled brands to create more visually appealing packaging, which can improve product differentiation and attract consumers. Additionally, improvements in tube sealing and dispensing mechanisms are increasing the functionality of laminated tubes, making them more convenient for consumers and more efficient for manufacturers.

The production of high-quality laminated tubes, particularly those made from multiple layers of materials, can be more expensive compared to simpler packaging options. The cost of raw materials, such as plastics and aluminum, can also fluctuate, impacting the overall pricing structure for laminated tubes. Smaller businesses, particularly in emerging markets, may find it challenging to adopt laminated tubes due to these higher costs. However, as the market continues to grow, economies of scale and advancements in production technology are expected to reduce costs and make laminated tubes more accessible to a wider range of manufacturers.

| Metric | Value |

|---|---|

| Estimated Value in (2025E) | USD 2.8 billion |

| Forecast Value in (2035F) | USD 5.2 billion |

| Forecast CAGR (2025 to 2035) | 6.4% |

Market expansion is being supported by the increasing global demand for cosmetic packaging solutions and the corresponding need for tube formats that can provide superior barrier protection and product integrity while enabling premium branding and convenient dispensing across various beauty and pharmaceutical distribution applications. Modern cosmetic manufacturers and pharmaceutical companies are increasingly focused on implementing packaging solutions that can protect product efficacy, prevent contamination, and provide consistent dispensing performance throughout complex distribution networks. Laminated tube packaging's proven ability to deliver exceptional barrier properties, enable brand differentiation through decoration, and support regulatory compliance make them essential packaging formats for contemporary skincare and pharmaceutical operations.

The growing emphasis on product differentiation and brand presentation is driving demand for laminated tubes that can support premium printing requirements, improve shelf appeal, and enable innovative decoration formats. Manufacturers' preference for tubes that combine effective barrier protection with aesthetic sophistication and filling efficiency is creating opportunities for innovative laminated tube implementations. The rising influence of natural cosmetics production and premium beauty markets is also contributing to increased demand for laminated tubes that can provide oxygen barrier protection, light resistance, and distinctive appearance across diverse product categories.

The laminated tubes market is poised for rapid growth and transformation. As industries across cosmetics, pharmaceuticals, oral care, and specialty personal care seek packaging that delivers exceptional barrier protection, dispensing convenience, and brand appeal, laminated tubes are gaining prominence not just as functional containers but as strategic enablers of product preservation and consumer engagement.

Rising premium cosmetics consumption in Asia-Pacific and expanding natural beauty markets globally amplify demand, while manufacturers are leveraging innovations in lamination precision, digital printing technologies, and advanced barrier layer formulations.

Pathways like mono-material structures, premium decoration capabilities, and application-specific barrier configurations promise strong margin uplift, especially in high-value segments. Geographic expansion and vertical integration will capture volume, particularly where local manufacturing capabilities and cosmetic industry proximity are critical. Regulatory pressures around product safety requirements, packaging compliance standards, cosmetic regulations, and pharmaceutical packaging specifications give structural support.

The market is segmented by tube capacity, layer structure, end-use application, material type, closure type, and region. By tube capacity, the market is divided into below 50ml, 50-100ml, 100-150ml, and above 150ml. By layer structure, it covers 3-layer, 5-layer, 7-layer, and others. By end-use application, it includes cosmetics & personal care, pharmaceuticals, oral care, food & beverages, and others. By material type, it is categorized into polyethylene-based laminates, aluminum-barrier laminates, EVOH-barrier laminates, and others. By closure type, it covers flip-top caps, screw caps, nozzle caps, and others. Regionally, the market is divided into North America, Europe, East Asia, South Asia & Pacific, Latin America, and the Middle East & Africa.

The 50-100ml segment is projected to account for 38.2% of the laminated tubes market in 2025, reaffirming its position as the leading capacity category. Cosmetic producers and personal care manufacturers increasingly utilize 50-100ml laminated tubes for their optimal compatibility with standard product volumes, excellent handling characteristics, and widespread adoption in facial cream, body lotion, and hand cream applications. The 50-100ml tube technology's established market standardization and consistent filling performance directly address the industrial requirements for reliable product dispensing in high-volume cosmetic manufacturing environments.

This capacity segment forms the foundation of modern cosmetic packaging operations, as it represents the tube size with the greatest market penetration and established demand across multiple beauty categories and global markets. Manufacturer investments in enhanced barrier layer technologies and advanced printing systems continue to strengthen adoption among cosmetics producers and personal care manufacturers. With companies prioritizing product preservation and brand presentation, 50-100ml laminated tubes align with both performance requirements and consumer convenience objectives, making them the central component of comprehensive packaging strategies.

Cosmetics & personal care applications are projected to represent 52.3% of laminated tubes demand in 2025, underscoring their critical role as the primary industrial consumers of laminated tube packaging for skincare product distribution, hair care applications, and premium beauty product packaging. Cosmetic manufacturers prefer laminated tubes for their exceptional barrier protection capabilities, superior product preservation, and ability to prevent oxidation while ensuring product efficacy with protective packaging. Positioned as essential packaging formats for modern skincare and beauty operations, laminated tubes offer both functional advantages and brand differentiation benefits.

The segment is supported by continuous innovation in decoration technologies and the growing availability of specialized barrier formulations that enable oxygen resistance with enhanced moisture protection and aesthetic customization. Additionally, cosmetic producers are investing in high-speed filling systems to support large-volume laminated tube utilization and packaging efficiency. As premium skincare consumption becomes more prevalent and natural cosmetics production increases, cosmetics & personal care applications will continue to dominate the end-use market while supporting advanced tube decoration and product preservation strategies.

The laminated tubes market is advancing rapidly due to increasing demand for barrier-protection packaging in cosmetic industries and growing adoption of premium tube solutions that provide superior product preservation and brand presentation while enabling convenient dispensing across diverse beauty and pharmaceutical distribution applications. However, the market faces challenges, including raw material price fluctuations, competition from alternative packaging formats, and the need for specialized lamination equipment investments. Innovation in digital printing capabilities and advanced barrier layer formulations continues to influence product development and market expansion patterns.

The growing adoption of digital printing systems, rotogravure processes, and sophisticated oFFSet techniques is enabling manufacturers to produce laminated tubes with superior graphic reproduction, enhanced brand presentation, and customization functionalities. Advanced decoration systems provide improved visual appeal while allowing more efficient short-run production and consistent quality across various filling applications and product lines. Manufacturers are increasingly recognizing the competitive advantages of premium decoration capabilities for product differentiation and luxury market positioning.

Modern laminated tube producers are incorporating QR code integration, NFC technology, and serialization systems to enhance product authentication, enable consumer engagement, and deliver value-added traceability solutions to cosmetic brands and pharmaceutical customers. These technologies improve brand protection while enabling new operational capabilities, including product verification, consumer interaction, and counterfeit prevention. Advanced feature integration also allows manufacturers to support brand owners and regulatory compliance beyond traditional packaging approaches.

| Country | CAGR (2025-2035) |

|---|---|

| China | 7.8% |

| India | 8.4% |

| USA | 5.6% |

| South Korea | 7.2% |

| Germany | 5.3% |

| Brazil | 6.9% |

| France | 5.8% |

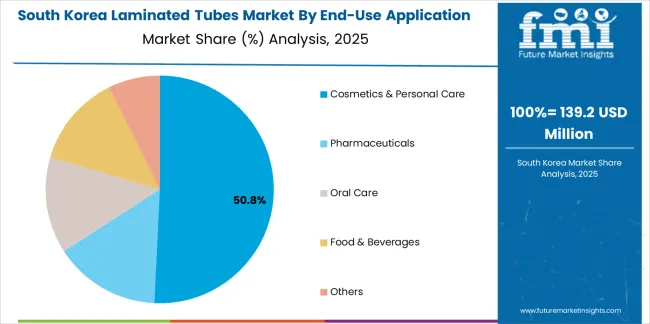

The laminated tubes market is experiencing strong growth globally, with India leading at an 8.4% CAGR through 2035, driven by the expanding cosmetics industry, growing pharmaceutical manufacturing, and significant investment in beauty product distribution infrastructure. China follows at 7.8%, supported by rapid skincare consumption growth, increasing domestic cosmetic production, and growing export packaging demand. South Korea shows growth at 7.2%, emphasizing K-beauty innovation and premium cosmetic packaging development. Brazil records 6.9%, focusing on personal care market expansion and growing beauty product consumption. USA demonstrates 5.6% growth, prioritizing natural cosmetics and premium packaging solutions. France exhibits 5.8% growth, emphasizing luxury beauty packaging and prestige cosmetic applications. Germany shows 5.3% growth, supported by pharmaceutical tube demand and precision manufacturing excellence.

The report covers an in-depth analysis of 40+ countries top-performing countries are highlighted below.

Revenue from laminated tubes in India is projected to exhibit exceptional growth with a CAGR of 8.4% through 2035, driven by expanding cosmetics production and rapidly growing beauty product consumption supported by rising disposable incomes promoting domestic cosmetic brand development. The country's strong position in pharmaceutical manufacturing and increasing investment in packaging infrastructure are creating substantial demand for laminated tube solutions. Major cosmetic producers and pharmaceutical manufacturers are establishing comprehensive tube sourcing capabilities to serve both domestic packaging demand and export markets.

Revenue from laminated tubes in China is expanding at a CAGR of 7.8%, supported by the country's massive skincare market, expanding cosmetic production activities, and increasing adoption of automated filling solutions. The country's government initiatives promoting quality standards and growing middle-class beauty consumption are driving requirements for sophisticated packaging capabilities. International suppliers and domestic manufacturers are establishing extensive production and distribution capabilities to address the growing demand for laminated tube products.

Revenue from laminated tubes in South Korea is expanding at a CAGR of 7.2%, supported by the country's thriving K-beauty industry, strong emphasis on premium packaging aesthetics, and robust demand for high-performance tubes in skincare and cosmetic applications. The nation's innovative beauty sector and brand-focused operations are driving sophisticated decorated laminated tube systems throughout the supply chain. Leading manufacturers and technology providers are investing extensively in printing equipment and barrier technologies to serve both domestic and international markets.

Revenue from laminated tubes in Brazil is growing at a CAGR of 6.9%, driven by the country's expanding personal care market, growing beauty product consumption, and increasing investment in modern packaging facilities. Brazil's large domestic cosmetics market and commitment to beauty industry development are supporting demand for laminated tube solutions across multiple production segments. Manufacturers are establishing comprehensive production capabilities to serve the growing domestic market and regional export opportunities.

Revenue from laminated tubes in the USA is expanding at a CAGR of 5.6%, supported by the country's natural cosmetics movement, advanced packaging capabilities, and strategic focus on premium tube production. USA's innovation excellence and quality focus are driving demand for laminated tubes in skincare packaging, pharmaceutical applications, and specialty personal care products. Manufacturers are investing in comprehensive decoration capabilities to serve both domestic brands and international specialty markets.

Revenue from laminated tubes in France is growing at a CAGR of 5.8%, driven by the country's expertise in luxury cosmetics, emphasis on premium packaging, and strong position in prestige beauty product manufacturing. France's established cosmetic technology capabilities and commitment to excellence are supporting investment in advanced tube production technologies throughout major manufacturing centers. Industry leaders are establishing comprehensive quality systems to serve luxury skincare producers and pharmaceutical manufacturers.

Revenue from laminated tubes in Germany is expanding at a CAGR of 5.3%, supported by the country's pharmaceutical tube concentration, advanced manufacturing excellence, and strategic position in European healthcare markets. Germany's precision engineering capabilities and integrated packaging infrastructure are driving demand for high-quality laminated tubes in pharmaceutical packaging, dermatological products, and specialty cosmetic applications. Leading manufacturers are investing in specialized capabilities to serve the stringent requirements of pharmaceutical and medical device industries.

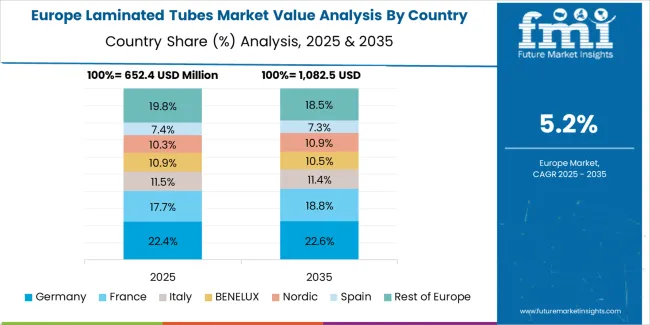

The laminated tubes market in Europe is projected to grow from USD 0.8 billion in 2025 to USD 1.5 billion by 2035, registering a CAGR of 6.5% over the forecast period. Germany is expected to maintain its leadership position with a 26.5% market share in 2025, declining slightly to 26.0% by 2035, supported by its strong pharmaceutical manufacturing base, advanced tube production capabilities, and comprehensive cosmetic and healthcare packaging sector serving diverse laminated tube applications across Europe.

France follows with a 24.0% share in 2025, projected to reach 24.5% by 2035, driven by robust demand for laminated tubes in luxury cosmetics packaging, prestige skincare applications, and premium beauty product manufacturing, combined with established luxury brand infrastructure and export-oriented packaging expertise. The United Kingdom holds a 16.5% share in 2025, expected to reach 17.0% by 2035, supported by strong pharmaceutical production and growing natural cosmetics activities. Italy commands a 15.0% share in 2025, projected to reach 15.5% by 2035, while Spain accounts for 8.5% in 2025, expected to reach 9.0% by 2035. Poland maintains a 4.5% share in 2025, growing to 4.7% by 2035. The Rest of Europe region, including Nordic countries, Eastern Europe, Netherlands, Switzerland, and other nations, is anticipated to maintain momentum, with its collective share moving from 5.0% to 3.3% by 2035, attributed to increasing cosmetic production in Eastern Europe and growing pharmaceutical manufacturing in Nordic countries implementing advanced packaging programs.

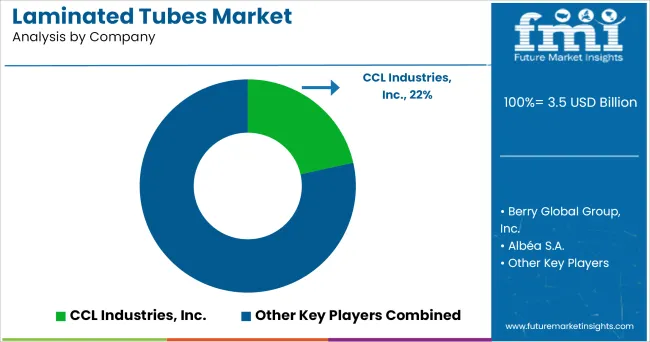

The laminated tubes market features 10–15 players with moderate concentration, where the top three companies collectively hold around 45–52% of global market share, driven by strong technological capabilities, extensive production facilities, and established relationships with major end-use industries such as cosmetics, pharmaceuticals, and food packaging. The leading company, Essel Propack Limited, commands 25% of the market share, supported by its diverse portfolio of laminated tube products and a robust global presence. Competition is centered on tube customization, barrier properties, printing capabilities, and sustainable material offerings rather than price alone.

Market leaders such as Essel Propack Limited, Albéa Group, and Huhtamaki Oyj maintain their competitive edge through advanced tube production technologies, offering high-quality laminated tubes that provide superior protection and ease of use for cosmetics, personal care, and pharmaceutical packaging. These companies emphasize material flexibility, product design, and sustainable practices to meet the growing demand for eco-friendly packaging solutions.

Challenger companies such as Montebello Packaging, CCL Industries Inc., and Hoffmann Neopac AG differentiate through their expertise in specialized tube designs and custom solutions for niche markets, including luxury cosmetics and pharmaceutical packaging.

Additional competition arises from regional players like Tubex Holding GmbH, Linhardt GmbH & Co. KG, Sonoco Products Company, and IntraPac International Corporation, which focus on local production, cost-effective solutions, and responsive customer service to serve growing demand in emerging markets.

| Items | Values |

|---|---|

| Quantitative Units (2025) | USD 2.8 billion |

| Tube Capacity | Below 50ml, 50-100ml, 100-150ml, Above 150ml |

| Layer Structure | 3-layer, 5-layer, 7-layer, Others |

| End-Use Application | Cosmetics & Personal Care, Pharmaceuticals, Oral Care, Food & Beverages, Others |

| Material Type | Polyethylene-Based Laminates, Aluminum-Barrier Laminates, EVOH-Barrier Laminates, Others |

| Closure Type | Flip-Top Caps, Screw Caps, Nozzle Caps, Others |

| Regions Covered | North America, Europe, East Asia, South Asia & Pacific, Latin America, Middle East & Africa |

| Countries Covered | United States, Canada, United Kingdom, Germany, France, China, Japan, South Korea, India, Brazil, Australia and 40+ countries |

| Key Companies Profiled | Essel Propack Limited, Albéa Group, Huhtamaki Oyj, Montebello Packaging, CCL Industries Inc., Hoffmann Neopac AG, Tubex Holding GmbH, Linhardt GmbH & Co. KG, Sonoco Products Company, IntraPac International Corporation |

| Additional Attributes | Dollar sales by tube capacity and application category, regional demand trends, competitive landscape, technological advancements in lamination systems, barrier layer development, printing equipment innovation, and supply chain integration |

The global laminated tubes market is estimated to be valued at USD 2.8 billion in 2025.

The market size for the laminated tubes market is projected to reach USD 5.2 billion by 2035.

The laminated tubes market is expected to grow at a 6.4% CAGR between 2025 and 2035.

The key product types in laminated tubes market are below 50ml, 50-100ml, 100-150ml and above 150ml.

In terms of end-use application, cosmetics & personal care segment to command 52.3% share in the laminated tubes market in 2025.

Our Research Products

The "Full Research Suite" delivers actionable market intel, deep dives on markets or technologies, so clients act faster, cut risk, and unlock growth.

The Leaderboard benchmarks and ranks top vendors, classifying them as Established Leaders, Leading Challengers, or Disruptors & Challengers.

Locates where complements amplify value and substitutes erode it, forecasting net impact by horizon

We deliver granular, decision-grade intel: market sizing, 5-year forecasts, pricing, adoption, usage, revenue, and operational KPIs—plus competitor tracking, regulation, and value chains—across 60 countries broadly.

Spot the shifts before they hit your P&L. We track inflection points, adoption curves, pricing moves, and ecosystem plays to show where demand is heading, why it is changing, and what to do next across high-growth markets and disruptive tech

Real-time reads of user behavior. We track shifting priorities, perceptions of today’s and next-gen services, and provider experience, then pace how fast tech moves from trial to adoption, blending buyer, consumer, and channel inputs with social signals (#WhySwitch, #UX).

Partner with our analyst team to build a custom report designed around your business priorities. From analysing market trends to assessing competitors or crafting bespoke datasets, we tailor insights to your needs.

Supplier Intelligence

Discovery & Profiling

Capacity & Footprint

Performance & Risk

Compliance & Governance

Commercial Readiness

Who Supplies Whom

Scorecards & Shortlists

Playbooks & Docs

Category Intelligence

Definition & Scope

Demand & Use Cases

Cost Drivers

Market Structure

Supply Chain Map

Trade & Policy

Operating Norms

Deliverables

Buyer Intelligence

Account Basics

Spend & Scope

Procurement Model

Vendor Requirements

Terms & Policies

Entry Strategy

Pain Points & Triggers

Outputs

Pricing Analysis

Benchmarks

Trends

Should-Cost

Indexation

Landed Cost

Commercial Terms

Deliverables

Brand Analysis

Positioning & Value Prop

Share & Presence

Customer Evidence

Go-to-Market

Digital & Reputation

Compliance & Trust

KPIs & Gaps

Outputs

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Market Share Breakdown of Laminated Tubes Manufacturers

Laminated Busbar Market Forecast and Outlook 2025 to 2035

Laminated Glass Market Size and Share Forecast Outlook 2025 to 2035

Laminated Labels Market Size and Share Forecast Outlook 2025 to 2035

Laminated Tube Closure Market from 2025 to 2035

U.S. Laminated Tube Market Trends & Demand Forecast 2024-2034

Laminated Woven PP Bags Market

Tubes, Bottles and Tottles Market

Cryotubes Market

BOPP Laminated Woven Sacks Market Size and Share Forecast Outlook 2025 to 2035

Pump Tubes Market Size and Share Forecast Outlook 2025 to 2035

Silk Laminated Paper Market Analysis - Size, Share, and Forecast Outlook 2025 to 2035

Litho Laminated Cartons Market Size and Share Forecast Outlook 2025 to 2035

Paper Tubes & Core Industry Analysis in United States Trends, Size, and Forecast for 2025-2035

Key Companies & Market Share in Paper Tubes Industry

Paper Tubes Market Growth & Industry Insights 2021-2031

Litho Laminated Packaging Market from 2025 to 2035

Cross Laminated Timber Market

Lotion Tubes Market Size and Share Forecast Outlook 2025 to 2035

Bubble Tubes Market Size and Share Forecast Outlook 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA