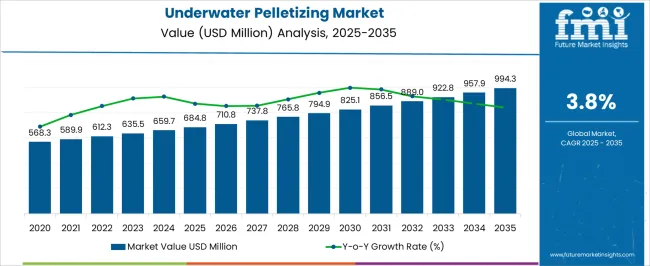

The underwater pelletizing market is projected to grow from USD 684.8 million in 2025 to USD 994.3 million by 2035, generating an absolute dollar opportunity of USD 309.5 million over the forecast period. This growth is supported by a CAGR of 3.8%, driven by increasing demand for high-quality pellets in plastic, polymer, and recycling industries. In the first five-year phase (2025–2030), the market is expected to grow from USD 684.8 million to USD 843.2 million, adding USD 158.4 million, which accounts for 51.2% of the total incremental growth. This growth is driven by the expansion of the plastics industry and increased use of underwater pelletizing in high-demand sectors such as packaging and automotive.

The second phase (2030–2035) will contribute USD 151.1 million, representing 48.8% of the total growth, reflecting stronger momentum as advanced pelletizing systems become widely adopted in emerging markets and industries. Annual increments will rise from USD 25 million in early years to USD 40 million by 2035, signaling growth driven by innovations in polymer production and higher efficiency requirements. Manufacturers focusing on energy-efficient, cost-effective, and customizable pelletizing systems will capture the largest share of this USD 309.5 million opportunity.

| Metric | Value |

|---|---|

| Underwater Pelletizing Market Estimated Value in (2025 E) | USD 684.8 million |

| Underwater Pelletizing Market Forecast Value in (2035 F) | USD 994.3 million |

| Forecast CAGR (2025 to 2035) | 3.8% |

The Underwater Pelletizing market is exhibiting robust growth driven by increasing demand for precision-controlled polymer processing systems across various manufacturing environments. The current market scenario reflects a growing shift toward advanced pelletizing technologies that ensure uniform size, reduced waste, and high production efficiency.

Factors such as the rising need for high-quality thermoplastics in automotive, packaging, and consumer goods have played a key role in the market's expansion. Investments in modernizing plastic processing plants and the continuous push for energy-efficient and low-maintenance systems are further supporting market advancement.

The future outlook remains positive as automation and digitization trends continue to evolve, offering enhanced control, traceability, and adaptability in production workflows As global industries place greater emphasis on material consistency, operational uptime, and sustainable processing, underwater pelletizing systems are expected to gain broader acceptance, positioning the market for continued growth.

The underwater pelletizing market is segmented by type, production capacity, level of automation, material type, application, end-use industry, distribution channel, and geographic regions. By type, the underwater pelletizing market is divided into underwater pelletizers and strand pelletizers. In terms of production capacity, the underwater pelletizing market is classified into 500 kg/hr to 5000 kg/hr, up to 100 kg/hr, 100 kg/hr to 500 kg/hr, and More than 5000 kg/hr. Based on level of automation of the underwater pelletizing market is segmented into Fully automatic, Manual, and Semi-automatic.

By material type, the underwater pelletizing market is segmented into Commodity plastics, Plastics Engineering, High-performance polymers, Bioplastics, Elastomers and thermoplastic elastomers (TPEs), and Additive masterbatch and fillers. The application of the underwater pelletizing market is segmented into Plastics and polymers manufacturing, Textile and fiber production, Food packaging, Recycling and waste management, Compounding and masterbatch production, and Others. By end-use industry, the underwater pelletizing market is segmented into Automotive, Textile, Pharmaceutical, Construction, Electronics, and Others. The distribution channel of the underwater pelletizing market is segmented into Direct and Indirect. Regionally, the underwater pelletizing industry is classified into North America, Latin America, Western Europe, Eastern Europe, Balkan & Baltic Countries, Russia & Belarus, Central Asia, East Asia, South Asia & Pacific, and the Middle East & Africa.

The underwater pelletizer type is projected to contribute 58.3% of the market revenue in 2025, making it the leading segment by type. This dominant share is being supported by the widespread use of underwater pelletizing systems in high-throughput plastic processing applications where uniform pellet formation is critical.

The ability to operate under continuous flow conditions with minimal thermal degradation has made this type a preferred choice among large-scale producers. Moreover, the flexibility to handle a wide range of polymer types and the compatibility with automated cutting and cooling systems have enhanced its adoption.

The segment's growth is further reinforced by increasing investments in infrastructure upgrades, particularly in regions focused on high-capacity polymer output. As manufacturers seek systems that offer high efficiency, product uniformity, and reduced downtime, the underwater pelletizer segment is expected to maintain its leadership position in the market.

The 500 kg/hr to 5000 kg/hr production capacity range is anticipated to hold 36.7% of the market share in 2025. This share is being attributed to the growing demand for medium to high output capacity systems that can support both flexible production volumes and scalable plant operations.

This capacity range aligns well with the needs of mid-sized manufacturers looking to balance operational efficiency with capital investment. The segment has gained traction due to its suitability for a wide variety of resin types and processing needs, providing the right combination of output speed and energy optimization.

Additionally, systems within this capacity bracket are often equipped with advanced controls and automation-ready designs, making them ideal for facilities transitioning to smart manufacturing. As polymer demand continues to rise across industries such as automotive, construction, and packaging, this production range is expected to remain in high demand.

The fully automatic level of automation is projected to account for 49.5% of the market revenue in 2025, emerging as the most preferred configuration. This share is being driven by the growing industry preference for systems that minimize manual intervention while maximizing consistency, safety, and throughput.

Fully automatic systems enable real-time monitoring, precise process control, and reduced labor dependency, which are critical factors in high-volume manufacturing environments. The adoption of such systems is also being supported by the need to reduce operational errors and material waste while improving plant efficiency.

The integration of smart sensors, programmable logic controllers, and centralized control units has made fully automatic underwater pelletizing systems an attractive investment for producers aiming to achieve long-term operational stability. As the manufacturing sector continues to advance toward Industry 4.0 standards, the fully automatic segment is expected to witness sustained growth in adoption and investment.

The underwater pelletizing market is driven by rising demand for efficient, high-quality plastic pelletizing solutions, particularly in the plastic production and recycling sectors. Opportunities in expanding industries and trends toward energy-efficient systems are reshaping the market. However, high initial costs and complex maintenance remain significant challenges. By 2025, overcoming these barriers with cost-effective, energy-efficient, and easy-to-maintain solutions will be key for continued market growth.

The underwater pelletizing market is growing due to the increasing demand for efficient and high-quality plastic pelletizing solutions in industries like polymers, chemicals, and packaging. Underwater pelletizing offers superior pellet size control and is ideal for producing high-performance plastic products. As industries continue to focus on improving product quality and process efficiency, demand for underwater pelletizing systems will rise. By 2025, this demand will continue to grow as manufacturers seek to improve their operational efficiency and output consistency.

Opportunities in the underwater pelletizing market are increasing with the expansion of plastic production and recycling industries. As global demand for plastics continues to rise, manufacturers are turning to advanced pelletizing systems for greater production efficiency. Additionally, the growing focus on recycling and reusing plastics is driving the need for advanced pelletizing solutions to convert recycled plastic into high-quality pellets for new applications. By 2025, the market will see significant growth driven by these sectors.

Emerging trends in the underwater pelletizing market include the growing demand for energy-efficient and compact pelletizing systems. As manufacturers strive to reduce energy consumption and operational costs, they are adopting systems that offer lower energy usage and reduced space requirements. Compact pelletizing systems are especially sought after in industries with limited space. By 2025, energy-efficient designs will continue to dominate the market, as businesses look for ways to improve cost-effectiveness and sustainability in their production processes.

Despite growth, challenges related to high initial investment and complex maintenance persist in the underwater pelletizing market. The installation of advanced underwater pelletizing systems requires substantial capital investment, which can be a barrier for small and medium-sized businesses. Additionally, these systems often require skilled technicians for maintenance and repair, leading to higher operational costs. By 2025, addressing these challenges through cost-effective solutions and improved ease of maintenance will be crucial for wider adoption in various industries.

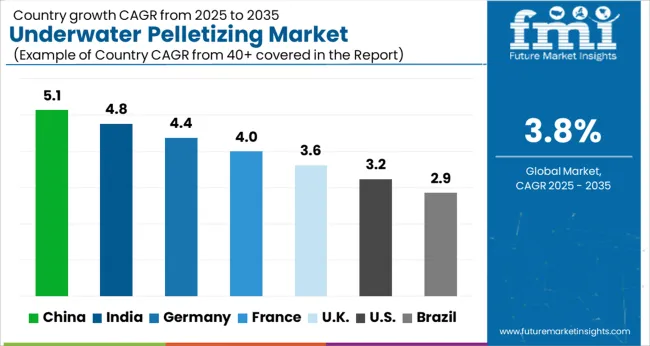

The global underwater pelletizing market is projected to grow at a 3.8% CAGR from 2025 to 2035. China leads with a growth rate of 5.1%, followed by India at 4.8%, and Germany at 4.4%. The United Kingdom records a growth rate of 3.6%, while the United States shows the slowest growth at 3.2%. These varying growth rates are driven by factors such as increasing demand for high-quality plastic pellets, the growing use of underwater pelletizing in the plastics industry, and rising environmental awareness. Emerging markets like China and India are experiencing higher growth due to expanding industrial sectors, increasing plastic production, and advancements in recycling technologies, while more mature markets like the USA and the UK see steady growth driven by technological innovations and the increasing demand for sustainable and efficient production methods. This report includes insights on 40+ countries; the top markets are shown here for reference.

The underwater pelletizing market in China is growing rapidly, with a projected CAGR of 5.1%. China’s expanding industrial base, particularly in the plastics and manufacturing sectors, is driving the demand for efficient and high-quality underwater pelletizing systems. The country’s growing focus on sustainable production methods, coupled with its increasing plastic production and recycling initiatives, is contributing significantly to market growth. Additionally, China’s push towards adopting advanced technology in plastic manufacturing and the government’s focus on environmental sustainability further accelerate the adoption of underwater pelletizing systems.

The underwater pelletizing market in India is projected to grow at a CAGR of 4.8%. India’s growing plastics production, coupled with the increasing demand for high-quality plastic pellets in various industrial applications, is driving the adoption of underwater pelletizing systems. The country’s expanding industrial base, along with its focus on improving production efficiency and sustainability, further contributes to market growth. Additionally, the government’s initiatives to promote recycling and reduce plastic waste in India are accelerating the demand for advanced and efficient pelletizing systems in the country.

The underwater pelletizing market in Germany is projected to grow at a CAGR of 4.4%. Germany’s strong industrial base, especially in the automotive, packaging, and consumer goods sectors, is driving steady demand for efficient and high-quality underwater pelletizing systems. The country’s focus on sustainability, energy efficiency, and technological advancements in plastics manufacturing further boosts market growth. Additionally, Germany’s leadership in environmental policies and its commitment to reducing plastic waste and improving recycling processes contribute to the steady adoption of underwater pelletizing systems.

The underwater pelletizing market in the United Kingdom is projected to grow at a CAGR of 3.6%. The UK’s increasing demand for high-quality plastic pellets, particularly in packaging and consumer goods, is driving steady growth in the underwater pelletizing market. The country’s growing emphasis on sustainable and efficient manufacturing processes, as well as the increasing adoption of recycling technologies, supports the demand for advanced pelletizing systems. Additionally, the UK’s regulatory frameworks promoting environmental sustainability and reducing plastic waste further accelerate the adoption of underwater pelletizing systems.

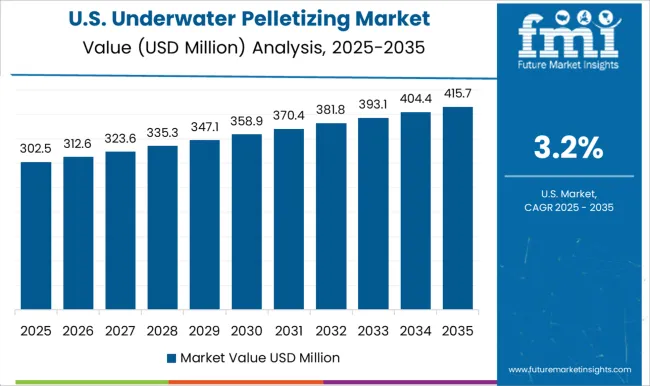

The underwater pelletizing market in the United States is expected to grow at a CAGR of 3.2%. The USA market remains steady, driven by the increasing demand for plastic pellets in various industrial sectors, including automotive, packaging, and consumer goods. The country’s focus on improving the efficiency of plastic production processes and reducing environmental impact contributes to the market’s steady growth. Additionally, the increasing adoption of recycling technologies and government regulations promoting sustainability and waste reduction are further fueling the demand for underwater pelletizing systems in the USA

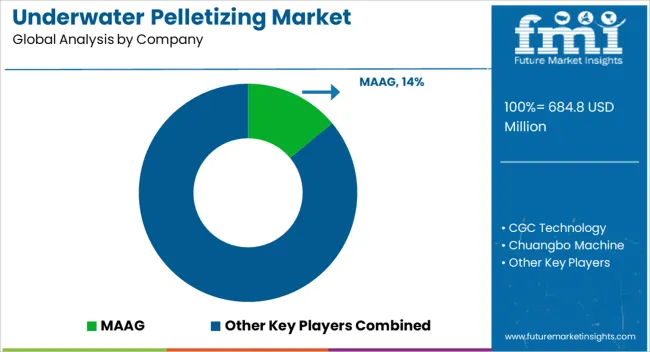

The underwater pelletizing market is dominated by MAAG, which leads with its highly efficient underwater pelletizing systems used in plastic processing and the production of pellets for various industries, including automotive, packaging, and recycling. MAAG’s dominance is supported by its advanced technology, global presence, and strong customer base across multiple sectors. Key players such as Coperion, CGC Technology, and Farrel Pomini maintain significant market shares by offering robust underwater pelletizing solutions that ensure high throughput, precise pellet size, and energy efficiency in the extrusion process. These companies focus on enhancing system durability, increasing production speeds, and reducing operational costs in pellet production.

Emerging players like Chuangbo Machine, Cowell Extrusion, and USEON are expanding their market presence by offering specialized underwater pelletizing equipment tailored for niche applications such as engineering plastics, biodegradable plastics, and medical devices. Their strategies include improving pellet quality, enhancing system integration, and focusing on eco-friendly and cost-effective solutions. Market growth is driven by the increasing demand for high-quality, sustainable plastic pellets, rising recycling activities, and the expansion of plastics manufacturing worldwide. Innovations in automation, advanced cooling systems, and integration with smart manufacturing technologies are expected to continue shaping competitive dynamics and fuel further growth in the global underwater pelletizing market.

| Item | Value |

|---|---|

| Quantitative Units | USD 684.8 Million |

| Type | Underwater pelletizer and Strand pelletizer |

| Production Capacity | 500 kg/hr to 5000 kg/hr, Up to 100 kg/hr, 100 kg/hr to 500 kg/hr, and More than 5000 kg/hr |

| Level of Automation | Fully automatic, Manual, and Semi-automatic |

| Material Type | Commodity plastics, Plastics Engineering, High-performance polymers, Bioplastics, Elastomers and thermoplastic elastomers (TPEs), and Additive masterbatch and fillers |

| Application | Plastics and polymers manufacturing, Textile and fiber production, Food packaging, Recycling and waste management, Compounding and masterbatch production, and Others |

| End Use Industry | Automotive, Textile, Pharmaceutical, Construction, Electronics, and Others |

| Distribution Channel | Direct and Indirect |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, Middle East & Africa |

| Country Covered | United States, Canada, Germany, France, United Kingdom, China, Japan, India, Brazil, South Africa |

| Key Companies Profiled | MAAG, CGC Technology, Chuangbo Machine, Coperion, Cowell Extrusion, Cowin Extrusion, Crown Machine, ECON, Farrel Pomini, Neoplast, Nordson, Prime Margo Machines, USEON, Wuxi Huachen, and Xinda |

| Additional Attributes | Dollar sales by pelletizer type and application, demand dynamics across plastic processing, recycling, and pharmaceutical sectors, regional trends in underwater pelletizing adoption, innovation in pelletizing efficiency and material recovery technologies, impact of regulatory standards on environmental impact and product quality, and emerging use cases in biodegradable plastics and sustainable manufacturing. |

The global underwater pelletizing market is estimated to be valued at USD 684.8 million in 2025.

The market size for the underwater pelletizing market is projected to reach USD 994.3 million by 2035.

The underwater pelletizing market is expected to grow at a 3.8% CAGR between 2025 and 2035.

The key product types in underwater pelletizing market are underwater pelletizer and strand pelletizer.

In terms of production capacity, 500 kg/hr to 5000 kg/hr segment to command 36.7% share in the underwater pelletizing market in 2025.

Our Research Products

The "Full Research Suite" delivers actionable market intel, deep dives on markets or technologies, so clients act faster, cut risk, and unlock growth.

The Leaderboard benchmarks and ranks top vendors, classifying them as Established Leaders, Leading Challengers, or Disruptors & Challengers.

Locates where complements amplify value and substitutes erode it, forecasting net impact by horizon

We deliver granular, decision-grade intel: market sizing, 5-year forecasts, pricing, adoption, usage, revenue, and operational KPIs—plus competitor tracking, regulation, and value chains—across 60 countries broadly.

Spot the shifts before they hit your P&L. We track inflection points, adoption curves, pricing moves, and ecosystem plays to show where demand is heading, why it is changing, and what to do next across high-growth markets and disruptive tech

Real-time reads of user behavior. We track shifting priorities, perceptions of today’s and next-gen services, and provider experience, then pace how fast tech moves from trial to adoption, blending buyer, consumer, and channel inputs with social signals (#WhySwitch, #UX).

Partner with our analyst team to build a custom report designed around your business priorities. From analysing market trends to assessing competitors or crafting bespoke datasets, we tailor insights to your needs.

Supplier Intelligence

Discovery & Profiling

Capacity & Footprint

Performance & Risk

Compliance & Governance

Commercial Readiness

Who Supplies Whom

Scorecards & Shortlists

Playbooks & Docs

Category Intelligence

Definition & Scope

Demand & Use Cases

Cost Drivers

Market Structure

Supply Chain Map

Trade & Policy

Operating Norms

Deliverables

Buyer Intelligence

Account Basics

Spend & Scope

Procurement Model

Vendor Requirements

Terms & Policies

Entry Strategy

Pain Points & Triggers

Outputs

Pricing Analysis

Benchmarks

Trends

Should-Cost

Indexation

Landed Cost

Commercial Terms

Deliverables

Brand Analysis

Positioning & Value Prop

Share & Presence

Customer Evidence

Go-to-Market

Digital & Reputation

Compliance & Trust

KPIs & Gaps

Outputs

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Underwater Light Market Size and Share Forecast Outlook 2025 to 2035

Underwater Hotel Market Forecast and Outlook 2025 to 2035

Underwater Welding Consumable Market Size and Share Forecast Outlook 2025 to 2035

Underwater Modems Market Size and Share Forecast Outlook 2025 to 2035

Underwater Bikes Market Size and Share Forecast Outlook 2025 to 2035

Underwater Connectors Market Size and Share Forecast Outlook 2025 to 2035

Underwater Camera Market Size and Share Forecast Outlook 2025 to 2035

Underwater Acoustic Communication Market Growth - Trends & Forecast 2025 to 2035

Underwater Welding Equipment Market Growth – Trends & Forecast 2024-2034

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA