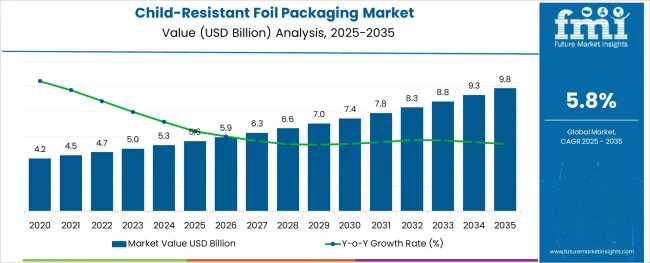

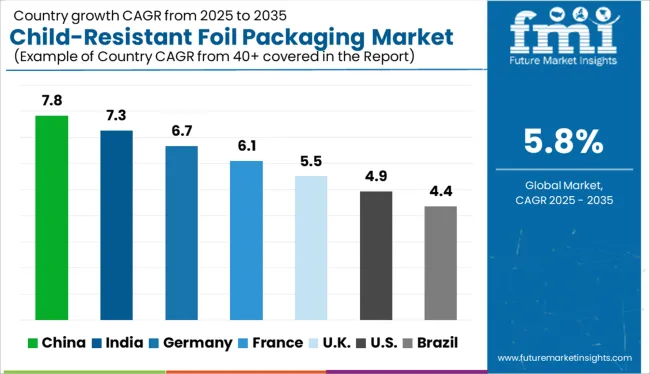

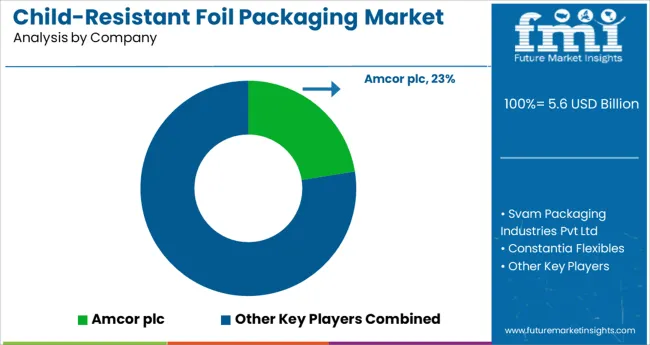

The Child-Resistant Foil Packaging Market is estimated to be valued at USD 5.6 billion in 2025 and is projected to reach USD 9.8 billion by 2035, registering a compound annual growth rate (CAGR) of 5.8% over the forecast period.

The child resistant foil packaging market is witnessing consistent growth as regulatory compliance, consumer safety awareness, and innovation in barrier materials drive adoption. Rising concerns over accidental ingestion of medications and hazardous substances by children have compelled manufacturers and regulators to enforce stricter packaging standards.

Advanced foil technologies offering tamper evidence and superior barrier properties are being increasingly adopted to meet these demands while ensuring product integrity. Growth is further supported by continuous investments in sustainable and recyclable foil solutions, aligning with broader environmental initiatives.

Future opportunities are expected to emerge from the expansion of pharmaceutical manufacturing, increasing over the counter drug consumption, and collaborations between packaging converters and healthcare brands to co-develop customized, user friendly formats. Ongoing material innovation and improved production efficiencies are paving the way for broader market penetration and higher compliance rates across industries.

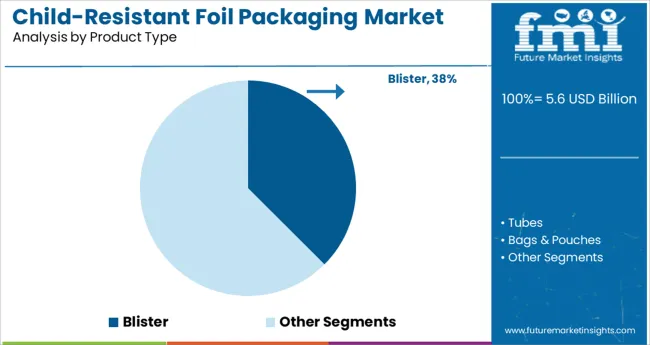

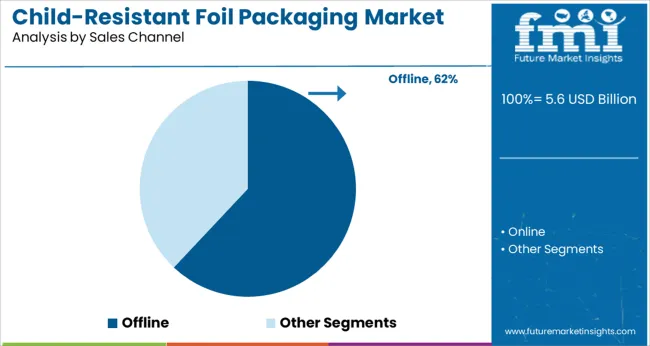

The market is segmented by Product Type, Sales Channel, and End Use Industry and region. By Product Type, the market is divided into Blister, Tubes, Bags & Pouches, and Others. In terms of Sales Channel, the market is classified into Offline and Online.

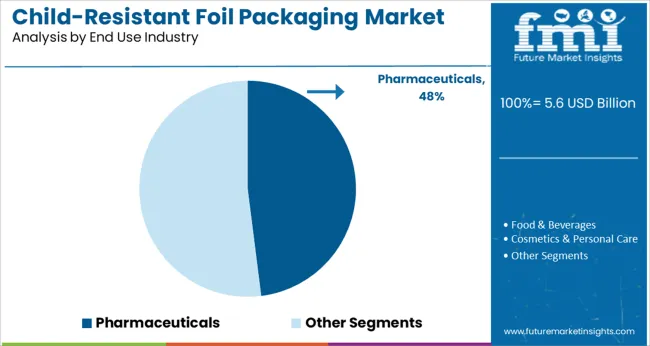

Based on End Use Industry, the market is segmented into Pharmaceuticals, Food & Beverages, Cosmetics & Personal Care, Home Care & Toiletries, Chemical & Fertilizers, Automotive, and Others (Tobacco, etc.). Regionally, the market is classified into North America, Latin America, Western Europe, Eastern Europe, Balkan & Baltic Countries, Russia & Belarus, Central Asia, East Asia, South Asia & Pacific, and the Middle East & Africa.

When segmented by product type the blister segment is anticipated to account for 37.5% of the market revenue in 2025 making it the leading product category. This leadership has been shaped by its proven ability to combine child resistance with ease of use for intended adults ensuring regulatory compliance without compromising accessibility.

The rigid structure and customizable cavity design of blisters have facilitated integration of multi layered foil laminates providing superior protection against moisture light and contamination. Additionally the scalability of blister production and compatibility with high speed filling lines have enhanced cost efficiency for large scale pharmaceutical and healthcare applications.

Manufacturers have also favored blisters for their ability to offer clear dosage visibility and branding opportunities reinforcing trust and convenience among end users. These attributes have solidified the segment’s dominance in markets where safety regulatory adherence and operational efficiency converge.

Segmented by sales channel the offline segment is projected to capture 62.0% of the market revenue in 2025 securing its position as the leading distribution route. This prominence has been driven by the entrenched networks of wholesalers distributors and retail pharmacies which continue to account for the majority of packaging procurement particularly in regulated industries.

Offline channels have enabled manufacturers to build strong relationships with pharmaceutical and healthcare buyers through direct engagement tailored service and assured supply chain continuity. Moreover the need for compliance verification and the complexity of custom specifications have favored in person transactions where technical consultations and quality inspections are more feasible.

The physical presence of suppliers and established contractual arrangements have also contributed to greater reliability and trust reinforcing the offline channel’s leadership amid growing demand for child resistant solutions.

When segmented by end use industry the pharmaceuticals sector is expected to hold 48.0% of the market revenue in 2025 maintaining its position as the primary driver of demand. This dominance has been underpinned by the industry’s stringent safety requirements to prevent accidental ingestion by children while preserving product efficacy and shelf life.

The proliferation of prescription and over the counter medications coupled with heightened regulatory enforcement has accelerated the adoption of compliant foil based packaging solutions in this sector. Pharmaceutical companies have increasingly prioritized child resistant packaging as part of their corporate responsibility and risk mitigation strategies ensuring patient safety and brand protection.

The sector’s scale of operations and commitment to innovation have facilitated rapid implementation of advanced barrier materials and secure closure technologies solidifying its leadership in shaping the evolution of child resistant foil packaging.

The global child-resistant foil packaging market witnessed a CAGR of 4.9% during the historic period with a market value of USD 5.6 Billion in 2025.

The child-resistant foil packaging is demanded the most by the pharmaceutical industries amid the threat of drug intoxication. Child-resistant foil packaging prevents children from consuming medicines or medical adhesives accidentally.

Child-resistant foil packaging is probably a concern with the pharmaceutical industry since pharmaceuticals may contain fatal ingredients which affect children very harshly. Child protective blisters are one of the protective medication packaging solutions.

Various end-users are demanding child-resistant packaging due to rising concerns about children’s safety. Blister packaging is used the most for the manufacturing of child-resistant foil packaging.

Its unique features and various characteristics make the product type the most preferable.

The geared-up pharmaceutical industry is projected to drive the demand for child-resistant foil packaging. Rising safety concerns against drug intoxication by children are preferring child-resistant pharmaceutical packaging solutions. Overall, the global child-resistant foil packaging market is anticipated to bolster at a faster pace during the forecast period.

The cases of drug intoxication are rising rapidly across the world. The major cases of drug intoxication are faced by children. Children are facing the fatal effects of drugs that they have consumed unintentionally.

The safety of children is a must while dealing with pharmaceutical products. The pharmaceutical industry requires safety packaging measures to cut down such intoxication cases.

The sensitive approach to children’s safety by the pharmaceutical industry created a stage for the child-resistant foil packaging market. Child-resistant foil packaging is the preferred option for manufacturing safe and secure packaging solutions in pharmaceuticals.

This child-resistant foil packaging plays a defensive role by keeping drugs out of the reach of children. The preference given to child-resistant packaging solutions for medication is pushing the child-resistant foil packaging market.

Based on the Product Type segment, the blister segment holds the major portion of the global child-resistant foil packaging market. The targeted segment is projected to hold around 63% of the market share of child-resistant foil packaging market by the end of 2035.

This is due to the enormous benefits obtained from blister packaging. Blister packaging format is used for pharmaceutical and nutraceutical drugs, as it is a lightweight protective packaging product type. A blister is better than plastic in blocking the light.

Thus, the benefits such as efficiency, low cost, and recyclability drive the blister segment in the global child-resistant foil packaging market.

The pharmaceutical end-use industry is the most lucrative segment in the end-use industry for the global child-resistant foil packaging market and is projected to offer an incremental growth opportunity of USD 1.6 Billion during the forecast period.

The global pharmaceutical landscape has undergone significant changes in the past few years. Post-covid, self-medication, and outpouring rise in demand for all types of drugs & medicines propelled the consumption of child-resistant foil packaging across the pharma industry.

Due to an increase in online orders, the usage of child-resistant foil packaging has been increased by small & medium-sized manufacturers, which indicates a meteoric rise in sales until 2035.

Indian Pharmaceutical industry has touched new heights after the pandemic hit the global market. The Indian pharmaceutical industry witnessed rapid growth and has produced vaccines and medicines in bulk.

The rising risk of drug intoxication or ingestion of fatal items is threatening the industry as well as the apex medical bodies. Children are the general victims of such drug intoxication cases. The prevention of accidental ingestion is essential.

India as a child-populous country has more threat of child drug intoxication. According to data collected from the World Bank, 25.8% of the total population of the country is between the age ranges of 0-14.

The data shows that the children population is quite high in the country. The growing pharmaceutical industry also raised concerns about children’s safety. Such a sensitive approach surges demand for child-resistant packaging solutions across the country and is anticipated to grow at 6.6% over the forecasted period.

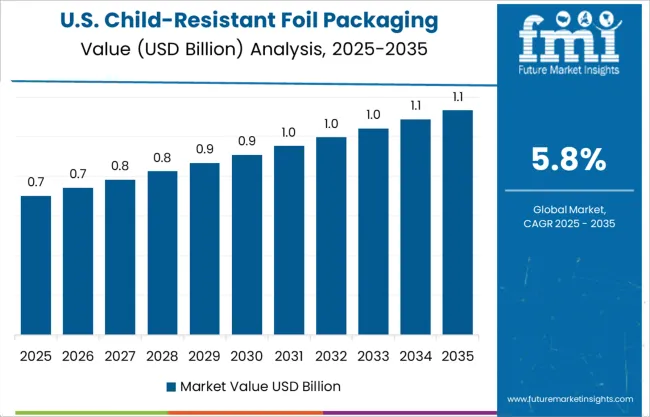

The USA is considered a developed market for child-resistant packaging. The country has made strict rules focusing on children’s safety and is sensible regarding the incidents that are happening due to negligence of packaging.

The country is also taking legislative steps against such casualness. Under the Federal Insecticide, Fungicide, and Rodenticide Act (FIFRA), section 25 (c) (3), the Environmental Protection Agency of the USA depicted criteria for safe and protected packaging of pharmaceuticals, fertilizers, and other chemicals to guard children against accidental ingestion and serious illness.

To prevent accidental ingestion of such drugs, the country has set standards for child-resistant foil packaging manufacturers.

The steps taken by the government towards safe and child-resistant packaging are helping child-resistant closure manufacturers to cater to the rising demand.

The upsurge in demand for child-resistant packaging across the country is expected to offer incremental opportunities worth USD 631 million over the next decade.

The various key market players are upgrading their technologies and are developing various child-resistant foil packaging solutions for safety aspects.

Different companies are following the market trends and producing high-end packaging solutions as per the requirements.

Some acquisitions and expansions are being done in order to capture the overall child-resistant foil packaging market. Some of these are under-

In September 2025, Amcor Plc’s innovative recyclable blister packaging solutions are awarded by the Association of Plastic Recyclers.

This innovative and eco-friendly initiative by the packaging giant strengthened its recognition in the pharmaceutical packaging solution market and has developed steady demand growth for packaging solutions.

| Attribute | Details |

|---|---|

| Growth Rate | CAGR of 5.8% from 2025 to 2035 |

| Base Year for Estimation | 2025 |

| Historical Data | 2020 to 2025 |

| Forecast Period | 2025 to 2035 |

| Quantitative Units | Revenue in billion, Volume in Units, and CAGR from 2025 to 2035 |

| Report Coverage | Revenue Forecast, Volume Forecast, Company Ranking, Competitive Landscape, Growth Factors, Trends, and Pricing Analysis |

| Segments Covered | Product Type, Sales Channel, End Use Industry, Region |

| Regions Covered | North America; Latin America; Europe; East Asia; South Asia; Middle East and Africa; Oceania |

| Key Countries Covered | USA, Canada, Mexico, Brazil, Germany, United Kingdom, France, Italy, Spain, Russia, China, Japan, India, GCC countries, Australia |

| Key Companies Profiled | Amcor plc; Svam Packaging Industries Pvt Ltd; Constantia Flexibles; Oliver Healthcare Packaging; Bilcare Research; Wiicare; Sonoco Products Company; Klockner Pentaplast Group; Rohrer Corporation; IMPAK Corporation; ePac Flexible Packaging; PPC Flexible Packaging LLC; Hi-Tech Pharmaceuticals, Inc.; ProAmpac LLC |

| Customization & Pricing | Available upon Request |

The global child-resistant foil packaging market is estimated to be valued at USD 5.6 billion in 2025.

It is projected to reach USD 9.8 billion by 2035.

The market is expected to grow at a 5.8% CAGR between 2025 and 2035.

The key product types are blister, tubes, bags & pouches and others.

offline segment is expected to dominate with a 62.0% industry share in 2025.

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Leading Providers & Market Share in Child-Resistant Foil Packaging

Foil Embossing Machine Market Size and Share Forecast Outlook 2025 to 2035

Foil Laminates Market Size and Share Forecast Outlook 2025 to 2035

Market Positioning & Share in the Foil Laminates Sector

Market Share Breakdown of Foil Labels Manufacturers

Foil Labels Market Analysis by Metal Foils & Polymer-Based Foils Through 2035

Foil Tapes Market

Foil Zipper Bags Market

Foil Pouch Packaging Market Size and Share Forecast Outlook 2025 to 2035

Multi-foil Rotor Market Analysis - Size, Share, and Forecast Outlook 2025 to 2035

Evaluating Metal Foil Tapes Market Share & Provider Insights

Copper Foil Rolling Mill Market Forecast and Outlook 2025 to 2035

Coding Foils & Tapes Market Size and Share Forecast Outlook 2025 to 2035

Inline Foil Punch and Seal Machines Market Size and Share Forecast Outlook 2025 to 2035

Copper Foil Market Growth - Trends & Forecast 2025 to 2035

Market Share Insights of Coding Foils & Tapes Providers

Tipping Foils Market Size and Share Forecast Outlook 2025 to 2035

Understanding Market Share Trends in the Tipping Foils Industry

Lidding Foil Market

Aluminum Foil Peel-Off Ends Maker Market Size and Share Forecast Outlook 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA