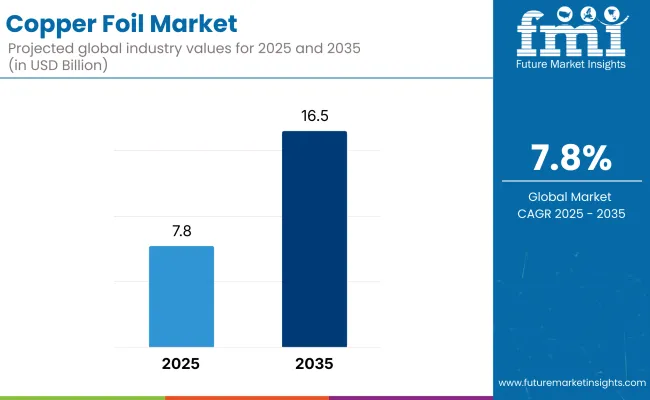

The global copper foil market is estimated at USD 7.8 billion in 2025 and is expected to attain USD 16.5 billion by 2035, reflecting a CAGR of 7.8% over the forecast period. This growth is primarily driven by increased demand in EV batteries, electronics, and renewable energy sectors.

Printed circuit boards (PCBs) are anticipated to be a promising segment in the market, owing to the proliferation of smart devices and high-speed computing systems. The Asia-Pacific region, particularly China, Japan, and South Korea, is expected to showcase significant potential, driven by strong production bases and increasing demand in electronics and EV industries.

In 2024, global copper foil capacity was reported at 2.4 million metric tons, with China accounting for 80% of this capacity. Specifically, lithium battery copper foil capacity stood at 1.4 million metric tons, while electronic circuit copper foil capacity was 985,000 metric tons.

The International Energy Agency (IEA) has highlighted a potential 30% shortfall in copper supply by 2035 if corrective actions are not taken. This underscores the need for governments to support new mining and refining initiatives, encourage recycling, and diversify sources to prevent future supply bottlenecks. China's dominance in copper refining, processing over 70% of the world's supply, exacerbates the risk of supply bottlenecks. This concentration heightens vulnerability to supply shocks, potentially leading to significant price volatility.

IEA Executive Director Fatih Birol emphasizes the necessity for governments to support new mining and refining initiatives, encourage recycling, and diversify sources to mitigate these risks. The IEA's Global Critical Minerals Outlook 2025 underscores the urgency of strategic cooperation and investment to ensure a stable transition to sustainable energy.

Sustainability practices are gaining traction, with market players integrating green production processes to meet environmental regulations. This focus on sustainable manufacturing is shaping the industry's growth landscape and aligning with global environmental goals.

Technological advancements in ultra-thin and electrodeposited copper foil manufacturing are enhancing product quality and expanding application scopes. These innovations are crucial for meeting the evolving demands of next-generation applications in electronics and energy storage.

PCBs now represent one of the fastest-growing segments of the copper foil marketplace, providing critically important conductive pathways in a wide variety of electronic products, including consumer electronics, industrial equipment, and automotive systems. Unlike traditional wiring, copper foil for PCBs enable smaller, lighter, and more efficient circuit designs that facilitates miniaturization and better performance.

3D's high speed and high-frequency electronic devices continue to operate, and the preferred material is copper foil because it provides the reliability, longevity, and excellent electrical performance that manufacturers are demanding. Flex and rigid-flex PCBs have strengthened Y-O-Y market momentum with ultra-thin copper foil, multilayer PCBs, and are sluicing from integrated automation, aerospace electronics and smartphones, wearables.

Introduction of advanced copper foil manufacturing processes, particularly electrodeposition and rolled annealing process, helps to improve uptake utensils due to high accuracy, better adhesive, and superior etching properties of PCB applications. Creating sustainable copper foil production technologies including low emission electrodeposition, use of reclaimed copper and lead free processing has greatly enhanced the market growth, boosting sustainability and regulation compliance for electronics manufacturers.

The grades of high-purity copper foil with enhanced conductivity, surface smoothness, and higher resistance to corrosion have bolstered the market growth, as they are compatible with future electronic devices. The PCB industry faces opportunities and challenges, including benefits of electrical performance, miniaturization, and long life, while raw copper prices have fluctuated, regulatory pressures relating to electronic waste are increasing, and supply chain issues are affecting both semiconductor and PCB manufacturing efforts.

However, recent breakthroughs in Nano-structured copper foils, AI-enabled PCB design automation and additive manufacturing of the boards themselves are improving efficiency, performance, and sustainability, and manufacturers are ensuring future growth for copper foil in PCB manufacturing globally.

Battery producers have achieved widespread market acceptance, especially in the electric vehicle (EV), including renewable energy and consumer electronics as they start to employ high performance copper foils to increase energy density and conductivity. Copper foil acts as an anode current collector unlike any conventional battery materials, which ensures high electron flow, lower resistance, and higher energy density.

The rising demand for lithium-ion and solid-state batteries which use ultra-thin copper foils to enable higher charge-discharge rates is yielding new usage in battery manufacturing, as manufacturers aim to boost battery life and performance. According to research, the use of high-purity copper foils (over 60%) by lithium-ion battery manufacturers ensures a steady demand for Foil grade copper.

Examples of one of high-energy-density battery technologies, such as adhesive properties of thin, light-weight copper foils, which have been proved by testing led to considerable improvement in market demand to ensure optimized performance in electric vehicles (EVs), grid storage and portable electronics.

This adoption has been further accelerated with the use of next-generation copper foils including nanostructured surfaces, graphene coatings, and high-temperature resistance ensuring much greater conductivity and stability within any high operating conditions.

Maximizing market growth, battery recycling programs with sustainable copper foil recovery technologies and closed-loop material supply have also been established, alongside environmental sustainability and resource efficiency in energy storage applications.

The emergence of ultra-thin copper foils with roll-to-roll production facilities, increased mechanical strength, and improved electrochemical stability has further strengthened the market growth based on enhanced efficiency and lifespan for advanced battery technologies.

Having the advantages of energy efficiency, conductivity and longevity, the battery industry faces challenges from supply chain risks in copper mining, high production costs of ultra-thin foils and regulatory requirements on battery disposal and material sustainability.

However, emerging technologies with AI-based battery service diagnostics and production of 3D-printed copper anodes as well as hybrid material integration in anode micromorphology are progressing efficiency, safety and environmental metrics and underpinning growth of copper foil in the global battery value chains.

Due to its advanced thermal conductivity, corrosion resistance, and lifespan in heating, ventilation, air conditioning (HVAC), refrigeration equipment, and industrial cooling systems, the heat exchangers market regimented becoming one of the most used applications for copper foil. Against the backdrop of traditional aluminum based systems, copper foil heat exchangers provide greater heat transfer efficiency, longer service life and system reliability.

Growing demand for high-efficiency heat exchange technologies such as microchannel copper foil structures, optimized surface coatings, and novel fin structures are supporting adoption in residential, commercial, and industrial markets ensuring solid market demand.

Although this segment is interesting due to strong thermal performance, long lifespan, and system efficiency, it will face challenges from volatility of raw material prices, energy-intensive manufacturing processes, and increasing competitive pressure from non-traditional thermal management materials.

However, emerging technologies such as nanostructured copper coatings, AI-based thermal optimization and hybrid lightweight metal composites are contributing to improved efficiency, reduction in costs and sustainability, ensuring further market growth for copper foil to be utilized in heat exchanger applications worldwide.

As market adoption within the electrical equipment sector is reached due to adoption from power grid operators, transformer manufacturers and high-voltage cable manufacturers who incentivize copper foils in their respective applications for electrical conductivity performance, energy efficiency and mechanical flexibility, this segment offers a robust opportunity for future growth. Compared to traditional conductors, copper foil allows for tighter layer stacking, better insulation, and lower energy loss in power transfer field.

Demand for high-purity copper foils used in energy-efficient transformers with higher conductivity and reduced electromagnetic losses has increased their usage in power distribution systems to provide optimal energy transmission and lower carbon emissions.

While electrical equipment industry has the advantages of electrical efficiency, flexibility, and durability, its disadvantages include increasingly stricter regulatory requirements on energy efficiency, high initial cost of producing cost-effective copper foil using high scenarios technology, as well as substitution of conductive materials.

However, artificial intelligence-leaning power grid monitoring, smart transformer technologies, and recyclable copper foil applications that are on the horizon will help to improve efficiency, cost effectiveness, and sustainability, ensuring that copper foil used in electrical equipment will continue to grow across the world.

Because of the highly developed electronics, automotive, and renewable energy sectors of the region, North America is a value-based market for copper foil. United States and Canada are a major consumers of copper foil in printed circuit boards (PCBs), Lithium-Ion batteries and electromagnetic shielding. High-purity copper foil consumption has been heavily driven by increasing adoption of electric vehicles (EVs) and technological advancements in energy storage systems.

In addition, the shift toward alternative energy solutions like solar and wind power is creating demand for copper foil in power transmission and energy storage applications. However, volatile raw material prices and trade policies driven by geopolitics can shape market dynamics and require manufacturers to develop successful sourcing and manufacturing strategies.

Europe commands a large portion of the copper foil market as the continent’s focus continues to draw more towards renewable energy, electric mobility and advanced electronics production. Germany, France and the United Kingdom collectively make up a significant portion of copper foil consumption, particularly in the manufacture of batteries for electric cars and power grids.

European Union policies aimed at reducing carbon emissions have sped up the shift toward clean energy technology that is driving up demand for copper foil that is used in solar panels, wind turbines and electric vehicle battery technologies. Copper foil finds application not only in the region's aerospace sector but also in the industrial automation sector owing to its high conductivity and lightweight properties.

Despite stringent environmental legislation over metal processing and mining, recycling drives have increasingly incentivized companies to invest in greener copper-smelting processes.

The Asia-Pacific region will be the fastest-growing market of copper foil mainly due to rapid growth in the electronics, automotive, and renewable energy sectors in China, Japan, South Korea, and India. The world's largest producer and consumer of copper foil.

China dominates the market with its massive electronics manufacturing base and deep supply chain. Japan and South Korea lead the technology in lithium-ion batteries, also increasing the demand for high-grade copper foil applied in battery electrodes. The deepening penetration of 5G technology and high-performance computing equipment has also stimulated copper foil usage in advanced circuit board manufacturing.

In spite of the robust market potential, the region is challenged by environmental issues and volatile raw material prices. Governments are proactively encouraging cleaner production processes and recycling technologies to reduce resource depletion and pollution issues.

Challenge

Volatility in Raw Material Prices and Supply Chain Disruptions

Uneven demand for copper globally, mining policies, and trade restrains causing inductions on copper prices because which suspends market opportunities are few of the major challenges for the copper foil market segment.

Disruptions to supply chains, especially in the sourcing and transport of raw materials, can create higher costs and production delays for manufacturers. Trade wars and legal policies involved in the import/export of materials could also influence the supply and pricing of copper foil, making it difficult for these companies to sustain steady production volumes.

Opportunity

Expansion of Electric Vehicle and Renewable Energy Markets

The copper foil market has a significant growth opportunity from rapid growth in the electric vehicle and renewable energy markets. With governments worldwide pushing people to embrace EVs and green energy solutions, the look for lithium-ion batteries and high-power electrical components is growing.

Copper foil is also a key material in the energy transition, used in battery anodes, solar panels and high-end electronics. The evolution of ultra-thin and high-strength copper foil technologies also opens up new possibilities in the adoption of flexible electronics, the 5G infrastructure and next-generation computing devices, thus amplifying market opportunities.

Between 2020 and 2024, the copper foil market witnessed substantial growth, driven by the increasing demand for electric vehicles (EVs), printed circuit boards (PCBs), and renewable energy applications. The rise in consumer electronics and the expansion of 5G infrastructure fueled demand for high-performance copper foils with enhanced conductivity and durability. Additionally, the surge in lithium-ion battery production for EVs contributed to the growing consumption of electrodeposited copper foils.

Between 2025 and 2035, the copper foil market will undergo transformative changes driven by advancements in energy storage, miniaturized electronics, and next-generation telecommunication networks. The emergence of solid-state batteries and graphene-enhanced copper foils will revolutionize energy storage applications, significantly improving battery efficiency, lifespan, and charging speed.

Future copper foil production will focus on sustainability, with closed-loop recycling systems, bioleaching technologies, and low-carbon refining methods becoming industry standards. AI-driven process optimization will enhance yield efficiency, while block chain-based supply chain tracking will improve transparency and compliance with environmental regulations.

Market Shifts: A Comparative Analysis (2020 to 2024 vs. 2025 to 2035)

| Market Shift | 2020 to 2024 |

|---|---|

| Regulatory Landscape | Tighter environmental regulations, emission control laws, and mining standards for sustainability. |

| Technological Advancements | Ultra-thin copper foils, AI-driven quality control, and high-frequency PCB-compatible foils. |

| Industry Applications | EV batteries, printed circuit boards, renewable energy, and 5G infrastructure. |

| Adoption of Smart Equipment | AI-based foil defect detection, automated material processing, and precision rolling techniques. |

| Sustainability & Cost Efficiency | Low-emission refining techniques, copper recycling initiatives, and reduced energy consumption in production. |

| Data Analytics & Predictive Modeling | AI-enhanced quality monitoring, cloud-integrated production tracking, and real-time defect analysis. |

| Production & Supply Chain Dynamics | COVID-19-related disruptions, raw material price fluctuations, and increased demand for EV-related copper foils. |

| Market Growth Drivers | EV adoption, consumer electronics, and high-speed data transmission-driven growth. |

| Market Shift | 2025 to 2035 |

|---|---|

| Regulatory Landscape | Compliance monitoring through AI, block chain traceability of materials, and net-zero carbon emissions requirements. |

| Technological Advancements | Graphene-enhanced copper foils, solid-state battery foil technology, and nanostructured conductive films. |

| Industry Applications | Growth into solid-state batteries, 6G communication networks, flexible hybrid electronics, and electric aviation. |

| Adoption of Smart Equipment | Real-time AI-driven defect prevention, smart foil customization for application-specific performance, and encrypted semiconductor foil manufacturing. |

| Sustainability & Cost Efficiency | Circular economy-driven copper foil production, bioleaching-based refining, and zero-waste copper extraction. |

| Data Analytics & Predictive Modeling | Quantum-enhanced conductivity simulation, decentralized AI-driven production optimization, and block chain-secured supply chains. |

| Production & Supply Chain Dynamics | AI-optimized supply chains, decentralized copper foil manufacturing using precision deposition, and block chain-enabled material authentication. |

| Market Growth Drivers | AI-fueled energy storage innovations, next-generation communication technologies, and growth of smart wearables and electric aviation. |

The USA copper foil market is experiencing robust growth with growing demand from the electronics, automotive, and renewable energy industries. The fast growth of the electric vehicle (EV) market is fueling demand for high-performance copper foils used in lithium-ion batteries and circuit boards.

Moreover, the expansion of 5G technology is also driving demand for copper foil used in printed circuit boards (PCBs). The solar energy market is also a major driver; as copper foil is extensively used in photovoltaic applications. With continued innovations in flexible electronics and intelligent devices, the industry is in line for consistent growth.

| Country | CAGR (2025 to 2035) |

|---|---|

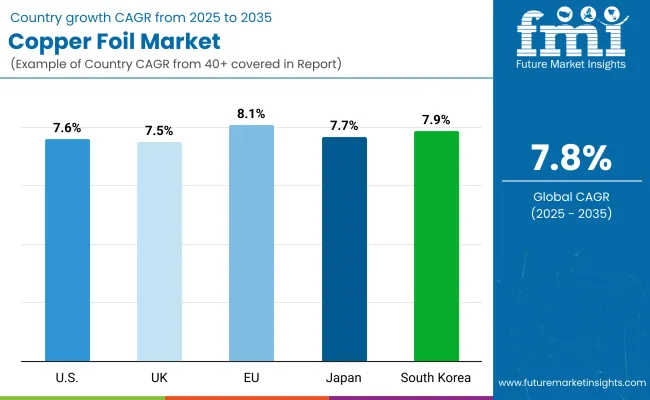

| USA | 7.6% |

One of the biggest drivers of the UK copper foil industry is the increase in its application in renewable energy systems, automotive, and electronics production. Growing Deployment Targets for Carbon Targets Paneled Demand for Copper Foils in Electric Vehicles Batteries and Energy Storage Systems.

The rise of 5G and intelligent connected solutions is also driving market growth, as copper foil is used to manufacture PCBs. Also, Lightweight Copper Material for electronic shielding and high-frequency applications are being used in aerospace & defense sectors which are fueling the market growth.

| Country | CAGR (2025 to 2035) |

|---|---|

| UK | 7.5% |

Demand in electric vehicles, renewable energy and electronics is strongly driving growth in the European copper foil market. Alongside this roadmap, the EU’s ambitious plan for the implementation of clean energy has accelerated investment related to solar panels, energy storage systems and efficient power grids all reliant on copper foil.

Copper anode foils are in growing demand in the likes of top-tier automakers in Germany, France, and the Netherlands. Additionally, the rise of 5G networks and AI computing systems is further propelling the market, as copper foil is vital in high-frequency circuits and heat management systems.

| Region | CAGR (2025 to 2035) |

|---|---|

| European Union | 8.1% |

Japan's market for copper foil is expanding due to the country's semiconductor industry, electric vehicle growth and electronics miniaturization. The country is a leader in high-performance lithium-ion batteries, which ultra-thin copper foils are needed for. Demand for flexible circuits based on copper foil is also being driven by Japan's telecommunications and robotics industries.

In addition, research and development of next-generation PCB technologies for AI computing, quantum electronics and high-speed processor technologies are further aiding the market growth. A second contributing cause echoes the trend toward lightweight, high-conductivity materials in aviation and automotive applications.

| Country | CAGR (2025 to 2035) |

|---|---|

| Japan | 7.7% |

The copper foil market in South Korea is booming due to its strong production base for electronics and semiconductors. Leading battery manufacturers, including LG Energy Solution and Samsung SDI, are the largest users of copper foils in both EV batteries and energy storage products. Another factor driving demand for copper foil is the booming 5G infrastructure, which is contributing to a surge in the use of high-frequency PCBs.

In addition, raising investments in flexible electronics, OLED displays, and wearable technology is also fueling the market opportunities. The government driven localization for key material manufacture is also establishing local copper foil manufacturing capabilities.

| Country | CAGR (2025 to 2035) |

|---|---|

| South Korea | 7.9% |

The Copper Foil Market is experiencing significant growth, driven by increasing demand in the electronics, automotive, and energy storage sectors. Copper foil, widely used in printed circuit boards (PCBs), lithium-ion batteries, and electromagnetic shielding applications, has become an essential material in emerging technologies such as electric vehicles (EVs) and renewable energy storage systems.

Rising investments in high-performance electronic devices and sustainability initiatives are further fueling market expansion. Leading companies are focusing on expanding production capacity, improving foil conductivity, and innovating ultra-thin copper foils for advanced applications.

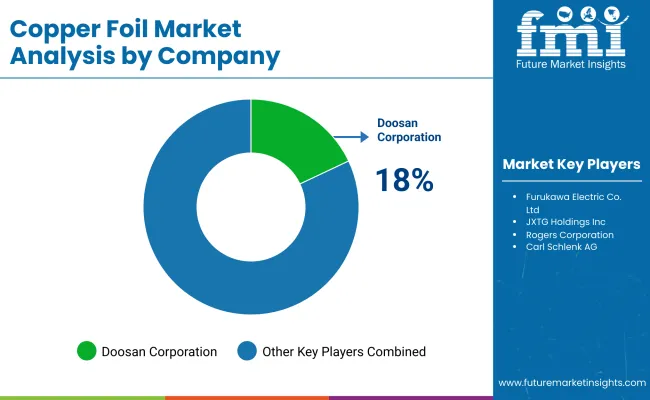

Market Share Analysis by Company

| Company Name | Estimated Market Share (%) |

|---|---|

| Doosan Corporation | 18-23% |

| Furukawa Electric Co. Ltd. | 15-20% |

| JXTG Holdings Inc. | 12-16% |

| Mitsui Mining & Smelting Co. Ltd. | 10-14% |

| Rogers Corporation | 8-12% |

| Carl Schlenk AG | 6-10% |

| Other Companies (combined) | 15-20% |

| Company Name | Key Offerings/Activities |

|---|---|

| Doosan Corporation | Develops high-performance copper foils for lithium-ion batteries and PCBs. |

| Furukawa Electric Co. Ltd. | Produces ultra-thin, high-conductivity copper foils for advanced electronics. |

| JXTG Holdings Inc. | Produces copper foil solutions for automotive, energy storage, and industrial uses. |

| Mitsui Mining & Smelting Co. Ltd. | Manufactures high-purity electrodeposited copper foils for PCB and battery uses. |

| Rogers Corporation | Focuses on high-reliability copper foils for RF applications and flexible electronics. |

| Carl Schlenk AG | Supplies precision-rolled copper foils for industrial and electronic uses. |

Key Company Insights

Doosan Corporation (18-23%)

A dominant player in the copper foil market, Doosan Corporation focuses on high-performance foils for lithium-ion batteries, electric vehicles, and PCB applications. The company has been expanding production capacity to cater to the rising demand for EV battery materials.

Furukawa Electric Co. Ltd. (15-20%)

Furukawa Electric is known for ultra-thin, high-conductivity copper foils for high-tech electronics and telecom industries. The company invests heavily in R&D to enhance product performance.

JXTG Holdings Inc. (12-16%)

A major player in copper refining and foil manufacturing, JXTG Holdings provides copper foils used in the automotive, energy storage and industrial segments. The company is focusing its mining and smelting businesses to make a quality raw material.

Mitsui Mining & Smelting Co. Ltd. (10-14%)

Mitsui Mining & Smelting also specializes in ultra-high purity electrodeposited copper foils, used by PCB and lithium-ion battery manufacturers. The company has been expanding its global presence to meet demand.

Rogers Corporation (8-12%)

Rogers Corporation also provides copper foils for high-frequency and RF applications including telecommunications and aerospace. The group is also developing flexible copper foil solutions for next-generation electronics.

Carl Schlenk AG (6-10%)

A leading supplier of precision-rolled copper foils, Carl Schlenk AG serves industrial and electronic applications. The company emphasizes innovation in thin and flexible copper foil technologies.

Other Key Players (15-20% Combined)

The copper foil market is also supported by regional and emerging companies, including:

The overall market size for copper foil market was USD 7.8 billion in 2025.

The copper foil market is expected to reach USD 16.5 billion in 2035.

The rising demand across multiple industries, particularly in electronics, batteries, and electrical applications fuels Copper Foil Market during the forecast period.

The top 5 countries which drives the development of Copper Foil Market are USA, UK, Europe Union, Japan and South Korea.

On the basis of application, heat exchangers to command significant share over the forecast period.

Table 1: Global Market Value (US$ Million) Forecast by Region, 2018 to 2033

Table 2: Global Market Volume (Tons) Forecast by Region, 2018 to 2033

Table 3: Global Market Value (US$ Million) Forecast by Product Type, 2018 to 2033

Table 4: Global Market Volume (Tons) Forecast by Product Type, 2018 to 2033

Table 5: Global Market Value (US$ Million) Forecast by Application, 2018 to 2033

Table 6: Global Market Volume (Tons) Forecast by Application, 2018 to 2033

Table 7: Global Market Value (US$ Million) Forecast by Thickness, 2018 to 2033

Table 8: Global Market Volume (Tons) Forecast by Thickness, 2018 to 2033

Table 9: North America Market Value (US$ Million) Forecast by Country, 2018 to 2033

Table 10: North America Market Volume (Tons) Forecast by Country, 2018 to 2033

Table 11: North America Market Value (US$ Million) Forecast by Product Type, 2018 to 2033

Table 12: North America Market Volume (Tons) Forecast by Product Type, 2018 to 2033

Table 13: North America Market Value (US$ Million) Forecast by Application, 2018 to 2033

Table 14: North America Market Volume (Tons) Forecast by Application, 2018 to 2033

Table 15: North America Market Value (US$ Million) Forecast by Thickness, 2018 to 2033

Table 16: North America Market Volume (Tons) Forecast by Thickness, 2018 to 2033

Table 17: Latin America Market Value (US$ Million) Forecast by Country, 2018 to 2033

Table 18: Latin America Market Volume (Tons) Forecast by Country, 2018 to 2033

Table 19: Latin America Market Value (US$ Million) Forecast by Product Type, 2018 to 2033

Table 20: Latin America Market Volume (Tons) Forecast by Product Type, 2018 to 2033

Table 21: Latin America Market Value (US$ Million) Forecast by Application, 2018 to 2033

Table 22: Latin America Market Volume (Tons) Forecast by Application, 2018 to 2033

Table 23: Latin America Market Value (US$ Million) Forecast by Thickness, 2018 to 2033

Table 24: Latin America Market Volume (Tons) Forecast by Thickness, 2018 to 2033

Table 25: Europe Market Value (US$ Million) Forecast by Country, 2018 to 2033

Table 26: Europe Market Volume (Tons) Forecast by Country, 2018 to 2033

Table 27: Europe Market Value (US$ Million) Forecast by Product Type, 2018 to 2033

Table 28: Europe Market Volume (Tons) Forecast by Product Type, 2018 to 2033

Table 29: Europe Market Value (US$ Million) Forecast by Application, 2018 to 2033

Table 30: Europe Market Volume (Tons) Forecast by Application, 2018 to 2033

Table 31: Europe Market Value (US$ Million) Forecast by Thickness, 2018 to 2033

Table 32: Europe Market Volume (Tons) Forecast by Thickness, 2018 to 2033

Table 33: Asia Pacific Market Value (US$ Million) Forecast by Country, 2018 to 2033

Table 34: Asia Pacific Market Volume (Tons) Forecast by Country, 2018 to 2033

Table 35: Asia Pacific Market Value (US$ Million) Forecast by Product Type, 2018 to 2033

Table 36: Asia Pacific Market Volume (Tons) Forecast by Product Type, 2018 to 2033

Table 37: Asia Pacific Market Value (US$ Million) Forecast by Application, 2018 to 2033

Table 38: Asia Pacific Market Volume (Tons) Forecast by Application, 2018 to 2033

Table 39: Asia Pacific Market Value (US$ Million) Forecast by Thickness, 2018 to 2033

Table 40: Asia Pacific Market Volume (Tons) Forecast by Thickness, 2018 to 2033

Table 41: MEA Market Value (US$ Million) Forecast by Country, 2018 to 2033

Table 42: MEA Market Volume (Tons) Forecast by Country, 2018 to 2033

Table 43: MEA Market Value (US$ Million) Forecast by Product Type, 2018 to 2033

Table 44: MEA Market Volume (Tons) Forecast by Product Type, 2018 to 2033

Table 45: MEA Market Value (US$ Million) Forecast by Application, 2018 to 2033

Table 46: MEA Market Volume (Tons) Forecast by Application, 2018 to 2033

Table 47: MEA Market Value (US$ Million) Forecast by Thickness, 2018 to 2033

Table 48: MEA Market Volume (Tons) Forecast by Thickness, 2018 to 2033

Figure 1: Global Market Value (US$ Million) by Product Type, 2023 to 2033

Figure 2: Global Market Value (US$ Million) by Application, 2023 to 2033

Figure 3: Global Market Value (US$ Million) by Thickness, 2023 to 2033

Figure 4: Global Market Value (US$ Million) by Region, 2023 to 2033

Figure 5: Global Market Value (US$ Million) Analysis by Region, 2018 to 2033

Figure 6: Global Market Volume (Tons) Analysis by Region, 2018 to 2033

Figure 7: Global Market Value Share (%) and BPS Analysis by Region, 2023 to 2033

Figure 8: Global Market Y-o-Y Growth (%) Projections by Region, 2023 to 2033

Figure 9: Global Market Value (US$ Million) Analysis by Product Type, 2018 to 2033

Figure 10: Global Market Volume (Tons) Analysis by Product Type, 2018 to 2033

Figure 11: Global Market Value Share (%) and BPS Analysis by Product Type, 2023 to 2033

Figure 12: Global Market Y-o-Y Growth (%) Projections by Product Type, 2023 to 2033

Figure 13: Global Market Value (US$ Million) Analysis by Application, 2018 to 2033

Figure 14: Global Market Volume (Tons) Analysis by Application, 2018 to 2033

Figure 15: Global Market Value Share (%) and BPS Analysis by Application, 2023 to 2033

Figure 16: Global Market Y-o-Y Growth (%) Projections by Application, 2023 to 2033

Figure 17: Global Market Value (US$ Million) Analysis by Thickness, 2018 to 2033

Figure 18: Global Market Volume (Tons) Analysis by Thickness, 2018 to 2033

Figure 19: Global Market Value Share (%) and BPS Analysis by Thickness, 2023 to 2033

Figure 20: Global Market Y-o-Y Growth (%) Projections by Thickness, 2023 to 2033

Figure 21: Global Market Attractiveness by Product Type, 2023 to 2033

Figure 22: Global Market Attractiveness by Application, 2023 to 2033

Figure 23: Global Market Attractiveness by Thickness, 2023 to 2033

Figure 24: Global Market Attractiveness by Region, 2023 to 2033

Figure 25: North America Market Value (US$ Million) by Product Type, 2023 to 2033

Figure 26: North America Market Value (US$ Million) by Application, 2023 to 2033

Figure 27: North America Market Value (US$ Million) by Thickness, 2023 to 2033

Figure 28: North America Market Value (US$ Million) by Country, 2023 to 2033

Figure 29: North America Market Value (US$ Million) Analysis by Country, 2018 to 2033

Figure 30: North America Market Volume (Tons) Analysis by Country, 2018 to 2033

Figure 31: North America Market Value Share (%) and BPS Analysis by Country, 2023 to 2033

Figure 32: North America Market Y-o-Y Growth (%) Projections by Country, 2023 to 2033

Figure 33: North America Market Value (US$ Million) Analysis by Product Type, 2018 to 2033

Figure 34: North America Market Volume (Tons) Analysis by Product Type, 2018 to 2033

Figure 35: North America Market Value Share (%) and BPS Analysis by Product Type, 2023 to 2033

Figure 36: North America Market Y-o-Y Growth (%) Projections by Product Type, 2023 to 2033

Figure 37: North America Market Value (US$ Million) Analysis by Application, 2018 to 2033

Figure 38: North America Market Volume (Tons) Analysis by Application, 2018 to 2033

Figure 39: North America Market Value Share (%) and BPS Analysis by Application, 2023 to 2033

Figure 40: North America Market Y-o-Y Growth (%) Projections by Application, 2023 to 2033

Figure 41: North America Market Value (US$ Million) Analysis by Thickness, 2018 to 2033

Figure 42: North America Market Volume (Tons) Analysis by Thickness, 2018 to 2033

Figure 43: North America Market Value Share (%) and BPS Analysis by Thickness, 2023 to 2033

Figure 44: North America Market Y-o-Y Growth (%) Projections by Thickness, 2023 to 2033

Figure 45: North America Market Attractiveness by Product Type, 2023 to 2033

Figure 46: North America Market Attractiveness by Application, 2023 to 2033

Figure 47: North America Market Attractiveness by Thickness, 2023 to 2033

Figure 48: North America Market Attractiveness by Country, 2023 to 2033

Figure 49: Latin America Market Value (US$ Million) by Product Type, 2023 to 2033

Figure 50: Latin America Market Value (US$ Million) by Application, 2023 to 2033

Figure 51: Latin America Market Value (US$ Million) by Thickness, 2023 to 2033

Figure 52: Latin America Market Value (US$ Million) by Country, 2023 to 2033

Figure 53: Latin America Market Value (US$ Million) Analysis by Country, 2018 to 2033

Figure 54: Latin America Market Volume (Tons) Analysis by Country, 2018 to 2033

Figure 55: Latin America Market Value Share (%) and BPS Analysis by Country, 2023 to 2033

Figure 56: Latin America Market Y-o-Y Growth (%) Projections by Country, 2023 to 2033

Figure 57: Latin America Market Value (US$ Million) Analysis by Product Type, 2018 to 2033

Figure 58: Latin America Market Volume (Tons) Analysis by Product Type, 2018 to 2033

Figure 59: Latin America Market Value Share (%) and BPS Analysis by Product Type, 2023 to 2033

Figure 60: Latin America Market Y-o-Y Growth (%) Projections by Product Type, 2023 to 2033

Figure 61: Latin America Market Value (US$ Million) Analysis by Application, 2018 to 2033

Figure 62: Latin America Market Volume (Tons) Analysis by Application, 2018 to 2033

Figure 63: Latin America Market Value Share (%) and BPS Analysis by Application, 2023 to 2033

Figure 64: Latin America Market Y-o-Y Growth (%) Projections by Application, 2023 to 2033

Figure 65: Latin America Market Value (US$ Million) Analysis by Thickness, 2018 to 2033

Figure 66: Latin America Market Volume (Tons) Analysis by Thickness, 2018 to 2033

Figure 67: Latin America Market Value Share (%) and BPS Analysis by Thickness, 2023 to 2033

Figure 68: Latin America Market Y-o-Y Growth (%) Projections by Thickness, 2023 to 2033

Figure 69: Latin America Market Attractiveness by Product Type, 2023 to 2033

Figure 70: Latin America Market Attractiveness by Application, 2023 to 2033

Figure 71: Latin America Market Attractiveness by Thickness, 2023 to 2033

Figure 72: Latin America Market Attractiveness by Country, 2023 to 2033

Figure 73: Europe Market Value (US$ Million) by Product Type, 2023 to 2033

Figure 74: Europe Market Value (US$ Million) by Application, 2023 to 2033

Figure 75: Europe Market Value (US$ Million) by Thickness, 2023 to 2033

Figure 76: Europe Market Value (US$ Million) by Country, 2023 to 2033

Figure 77: Europe Market Value (US$ Million) Analysis by Country, 2018 to 2033

Figure 78: Europe Market Volume (Tons) Analysis by Country, 2018 to 2033

Figure 79: Europe Market Value Share (%) and BPS Analysis by Country, 2023 to 2033

Figure 80: Europe Market Y-o-Y Growth (%) Projections by Country, 2023 to 2033

Figure 81: Europe Market Value (US$ Million) Analysis by Product Type, 2018 to 2033

Figure 82: Europe Market Volume (Tons) Analysis by Product Type, 2018 to 2033

Figure 83: Europe Market Value Share (%) and BPS Analysis by Product Type, 2023 to 2033

Figure 84: Europe Market Y-o-Y Growth (%) Projections by Product Type, 2023 to 2033

Figure 85: Europe Market Value (US$ Million) Analysis by Application, 2018 to 2033

Figure 86: Europe Market Volume (Tons) Analysis by Application, 2018 to 2033

Figure 87: Europe Market Value Share (%) and BPS Analysis by Application, 2023 to 2033

Figure 88: Europe Market Y-o-Y Growth (%) Projections by Application, 2023 to 2033

Figure 89: Europe Market Value (US$ Million) Analysis by Thickness, 2018 to 2033

Figure 90: Europe Market Volume (Tons) Analysis by Thickness, 2018 to 2033

Figure 91: Europe Market Value Share (%) and BPS Analysis by Thickness, 2023 to 2033

Figure 92: Europe Market Y-o-Y Growth (%) Projections by Thickness, 2023 to 2033

Figure 93: Europe Market Attractiveness by Product Type, 2023 to 2033

Figure 94: Europe Market Attractiveness by Application, 2023 to 2033

Figure 95: Europe Market Attractiveness by Thickness, 2023 to 2033

Figure 96: Europe Market Attractiveness by Country, 2023 to 2033

Figure 97: Asia Pacific Market Value (US$ Million) by Product Type, 2023 to 2033

Figure 98: Asia Pacific Market Value (US$ Million) by Application, 2023 to 2033

Figure 99: Asia Pacific Market Value (US$ Million) by Thickness, 2023 to 2033

Figure 100: Asia Pacific Market Value (US$ Million) by Country, 2023 to 2033

Figure 101: Asia Pacific Market Value (US$ Million) Analysis by Country, 2018 to 2033

Figure 102: Asia Pacific Market Volume (Tons) Analysis by Country, 2018 to 2033

Figure 103: Asia Pacific Market Value Share (%) and BPS Analysis by Country, 2023 to 2033

Figure 104: Asia Pacific Market Y-o-Y Growth (%) Projections by Country, 2023 to 2033

Figure 105: Asia Pacific Market Value (US$ Million) Analysis by Product Type, 2018 to 2033

Figure 106: Asia Pacific Market Volume (Tons) Analysis by Product Type, 2018 to 2033

Figure 107: Asia Pacific Market Value Share (%) and BPS Analysis by Product Type, 2023 to 2033

Figure 108: Asia Pacific Market Y-o-Y Growth (%) Projections by Product Type, 2023 to 2033

Figure 109: Asia Pacific Market Value (US$ Million) Analysis by Application, 2018 to 2033

Figure 110: Asia Pacific Market Volume (Tons) Analysis by Application, 2018 to 2033

Figure 111: Asia Pacific Market Value Share (%) and BPS Analysis by Application, 2023 to 2033

Figure 112: Asia Pacific Market Y-o-Y Growth (%) Projections by Application, 2023 to 2033

Figure 113: Asia Pacific Market Value (US$ Million) Analysis by Thickness, 2018 to 2033

Figure 114: Asia Pacific Market Volume (Tons) Analysis by Thickness, 2018 to 2033

Figure 115: Asia Pacific Market Value Share (%) and BPS Analysis by Thickness, 2023 to 2033

Figure 116: Asia Pacific Market Y-o-Y Growth (%) Projections by Thickness, 2023 to 2033

Figure 117: Asia Pacific Market Attractiveness by Product Type, 2023 to 2033

Figure 118: Asia Pacific Market Attractiveness by Application, 2023 to 2033

Figure 119: Asia Pacific Market Attractiveness by Thickness, 2023 to 2033

Figure 120: Asia Pacific Market Attractiveness by Country, 2023 to 2033

Figure 121: MEA Market Value (US$ Million) by Product Type, 2023 to 2033

Figure 122: MEA Market Value (US$ Million) by Application, 2023 to 2033

Figure 123: MEA Market Value (US$ Million) by Thickness, 2023 to 2033

Figure 124: MEA Market Value (US$ Million) by Country, 2023 to 2033

Figure 125: MEA Market Value (US$ Million) Analysis by Country, 2018 to 2033

Figure 126: MEA Market Volume (Tons) Analysis by Country, 2018 to 2033

Figure 127: MEA Market Value Share (%) and BPS Analysis by Country, 2023 to 2033

Figure 128: MEA Market Y-o-Y Growth (%) Projections by Country, 2023 to 2033

Figure 129: MEA Market Value (US$ Million) Analysis by Product Type, 2018 to 2033

Figure 130: MEA Market Volume (Tons) Analysis by Product Type, 2018 to 2033

Figure 131: MEA Market Value Share (%) and BPS Analysis by Product Type, 2023 to 2033

Figure 132: MEA Market Y-o-Y Growth (%) Projections by Product Type, 2023 to 2033

Figure 133: MEA Market Value (US$ Million) Analysis by Application, 2018 to 2033

Figure 134: MEA Market Volume (Tons) Analysis by Application, 2018 to 2033

Figure 135: MEA Market Value Share (%) and BPS Analysis by Application, 2023 to 2033

Figure 136: MEA Market Y-o-Y Growth (%) Projections by Application, 2023 to 2033

Figure 137: MEA Market Value (US$ Million) Analysis by Thickness, 2018 to 2033

Figure 138: MEA Market Volume (Tons) Analysis by Thickness, 2018 to 2033

Figure 139: MEA Market Value Share (%) and BPS Analysis by Thickness, 2023 to 2033

Figure 140: MEA Market Y-o-Y Growth (%) Projections by Thickness, 2023 to 2033

Figure 141: MEA Market Attractiveness by Product Type, 2023 to 2033

Figure 142: MEA Market Attractiveness by Application, 2023 to 2033

Figure 143: MEA Market Attractiveness by Thickness, 2023 to 2033

Figure 144: MEA Market Attractiveness by Country, 2023 to 2033

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Copper Foil Rolling Mill Market Forecast and Outlook 2025 to 2035

Copper and Aluminum Welding Bar Market Size and Share Forecast Outlook 2025 to 2035

Copper Pipes and Tubes Market Size and Share Forecast Outlook 2025 to 2035

Copper Chromite Black Pigment Market Size and Share Forecast Outlook 2025 to 2035

Copper Cabling Systems Market Size and Share Forecast Outlook 2025 to 2035

Copper Bismuth Catalyst Market Size and Share Forecast Outlook 2025 to 2035

Copper and Brass Flat Products Market Size and Share Forecast Outlook 2025 to 2035

Copper Oxychloride Market Size and Share Forecast Outlook 2025 to 2035

Copper and Copper Alloy Scrap and Recycling Market Size and Share Forecast Outlook 2025 to 2035

Copper Fungicides Market Size and Share Forecast Outlook 2025 to 2035

Copper Tube Market Size and Share Forecast Outlook 2025 to 2035

Copper Coated Film Market Insights & Industry Trends 2024-2034

Copper Azoles Market

Structural Copper Wire Market Size and Share Forecast Outlook 2025 to 2035

Oxygen-free Copper Market Size and Share Forecast Outlook 2025 to 2035

USA and Canada Copper Market Insights - Demand, Size & Industry Trends 2025 to 2035

Chromium Zirconium Copper Rod Market Size and Share Forecast Outlook 2025 to 2035

High Frequency High Speed Copper Clad Laminate CCL Market Size and Share Forecast Outlook 2025 to 2035

Foil Embossing Machine Market Size and Share Forecast Outlook 2025 to 2035

Foil Pouch Packaging Market Size and Share Forecast Outlook 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA