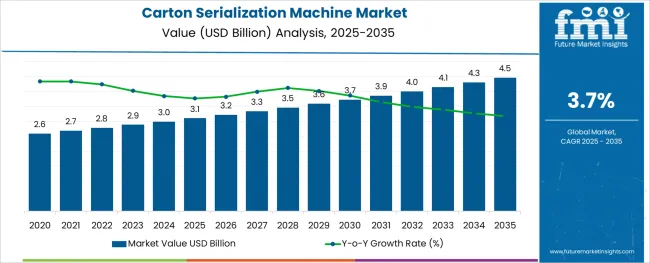

The Carton Serialization Machine Market is estimated to be valued at USD 3.1 billion in 2025 and is projected to reach USD 4.5 billion by 2035, registering a compound annual growth rate (CAGR) of 3.7% over the forecast period.

The carton serialization machine market is witnessing accelerated growth due to global mandates on product traceability, counterfeit prevention, and secure supply chain management. Serialization solutions are increasingly being adopted to enable item-level identification, improve inventory transparency, and ensure regulatory adherence, particularly in the pharmaceutical sector.

Advances in vision systems, data management software, and integration with enterprise resource planning (ERP) platforms are enhancing machine efficiency and compatibility with existing packaging lines. Automation trends and Industry 4.0 initiatives are also influencing procurement decisions, as manufacturers seek modular, scalable, and fully integrated serialization systems that reduce labor dependency and boost output precision.

Growth prospects are being further supported by the rise in cross-border trade of regulated products and increasing concerns over brand protection. Investment in flexible serialization platforms, capable of supporting multiple carton sizes and high-speed printing, is expected to continue shaping market expansion over the forecast period.

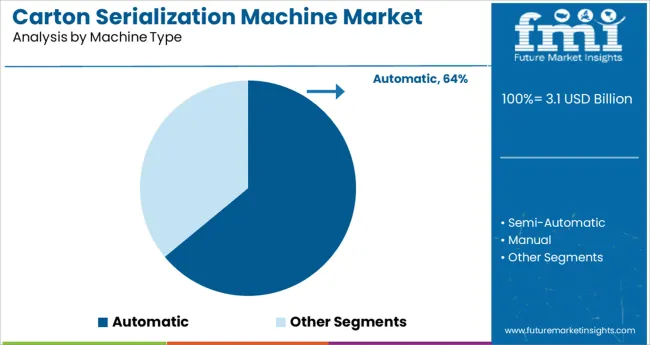

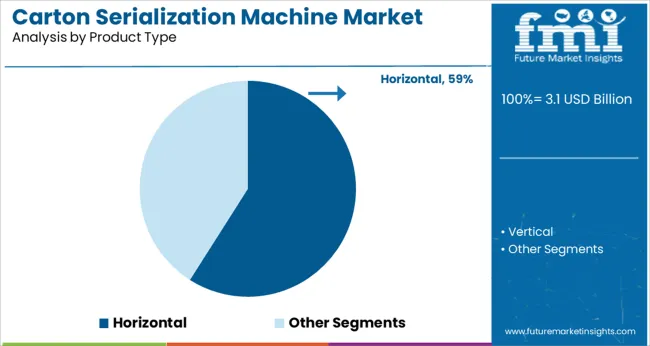

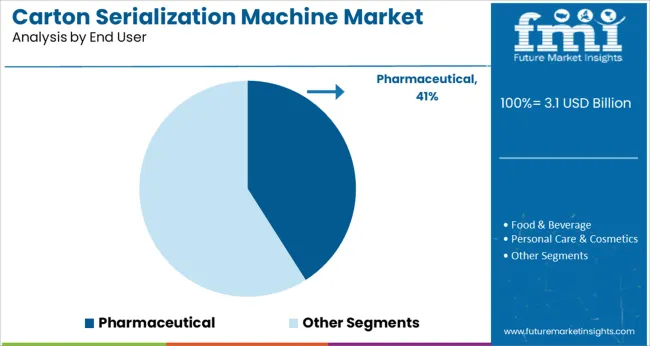

The market is segmented by Machine Type, Product Type, and End User and region. By Machine Type, the market is divided into Automatic, Semi-Automatic, and Manual. In terms of Product Type, the market is classified into Horizontal and Vertical. Based on End User, the market is segmented into Pharmaceutical, Food & Beverage, Personal Care & Cosmetics, and Others.

Regionally, the market is classified into North America, Latin America, Western Europe, Eastern Europe, Balkan & Baltic Countries, Russia & Belarus, Central Asia, East Asia, South Asia & Pacific, and the Middle East & Africa.

Automatic machines are projected to hold 64.0% of the total revenue share in the carton serialization machine market in 2025, establishing them as the leading segment. Their dominance is being supported by the increasing need for high-speed, hands-free serialization processes in regulated production environments.

Automatic machines ensure greater operational consistency, reduce human error, and support continuous packaging workflows—key factors in industries like pharmaceuticals, where data accuracy and uptime are critical. These systems are often integrated with real-time monitoring, label verification, and rejection mechanisms, enabling compliance with serialization laws such as DSCSA and FMD

The ability to seamlessly connect with upstream and downstream equipment in automated production lines reinforces their preference among large-scale manufacturers. As global traceability requirements tighten, automatic serialization machines are being prioritized for their efficiency, accuracy, and long-term scalability.

Horizontal serialization machines are expected to capture 59.0% of the market revenue in 2025, positioning them as the leading product type. This dominance is being driven by their suitability for high-speed, inline serialization processes where cartons are conveyed in a linear orientation.

Horizontal machines provide better control over carton flow, enabling precise code placement, inspection, and rejection within compact footprints. Their compatibility with existing cartoning lines has led to widespread adoption in industries that demand consistent throughput and minimal manual intervention.

Moreover, horizontal configurations support a variety of carton sizes and coding technologies, including thermal inkjet and laser printing. As manufacturers seek to balance space efficiency with automation, horizontal serialization units offer the optimal blend of flexibility, output reliability, and integration ease, making them the preferred choice in both legacy upgrades and new installations.

The pharmaceutical industry is anticipated to lead the carton serialization machine market with a 41.0% revenue share in 2025. This leadership is being shaped by stringent global mandates on product traceability, patient safety, and counterfeit prevention.

Regulatory frameworks such as the EU Falsified Medicines Directive and the USA Drug Supply Chain Security Act have made serialization a legal requirement, driving widespread implementation across pharmaceutical packaging operations. Carton serialization machines enable compliance by marking each unit with a unique identifier, ensuring supply chain visibility from manufacturing to point-of-sale. The industry’s strict demands for data integrity, print quality, and integration with validation systems have increased reliance on robust serialization technologies.

Additionally, the growing complexity of pharmaceutical distribution and rise in biologics and specialty drugs has further elevated the need for secure, automated serialization solutions tailored to pharma-specific packaging formats and operational requirements.

Carton serialization machine are used for labeling cartons with a proper serial number and the barcodes of the products present in the carton. There are various advantages of using carton serialization machines such as multiple country track and trace regulations. According to the height of the carton, it is equipped with a variable-speed control.

Carton serialization machine can print any type of data by using technologies such as inkjet, stereo, thermal, etc. There are various several features of carton serialization machine due to which every product that is present in the box gets a particular unique identity. This would be easier for the retailer and wholesaler to sell the goods at an appropriate price.

It can also inspect and reject visual defects like smudging color, missing & incorrect characters, and codes, etc.

Innovation such as integrated barcode and vision system is a key driver enhancing the global carton serialization machines market. Carton serialization has seen an increase in demand for the market because with the help of the serialization the products of a particular company can be distinguished very easily.

Barcode systems have an equal importance in the super market due to which the price of the product can be easily evaluated. Carton serialization machine majorly covers applications in pharmaceutical industries. Increasing trend for medicines and food items have risen the demand for carton which has resulted in increased sales of carton serialization machine.

In addition to, the major driver of carton serialization machine market includes growing demand for packaged food and beverages, pharmaceuticals industry which results in convenience in carrying and transportation of cartons. However, production cost for carton serialization machine are some of the factors which are restraining the market from its potential growth.

Furthermore, the market for carton serialization machine is hampered by stringent norms for installation from regional government across the globe.

The global carton serialization machines market can be divided into seven major regions which are as follows -

Europe and North America is considered as one of the largest markets for carton serialization machine due to the high selling of pharmaceutical products, industrial goods, etc. which need cartons for packaging. Europe and North America is considered as one of the major regions of markets for carton serialization machine followed by Asia-Pacific.

Asia Pacific region is expected to witness significant growth and is anticipated to have the highest CAGR for carton serialization machine market over the forecast period. Latin America and Middle-East & Africa region are expected to witness above average growth for carton serialization market over the forecast period.

A majority of Carton serialization machine is used in Europe and North America. However, China and India carton serialization machine manufacturers are looking to grab most of the opportunity offered in terms of revenue in this decade.

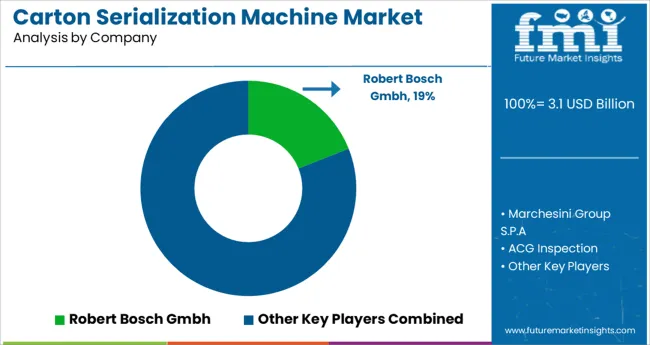

Few of the key players in carton serialization machine are Robert Bosch Gmbh, Marchesini group S.P.A, ACG Inspection, MGS Machine Serialization, Onelite Pharma, Softgroup limited, Omega design Corp, Atlantic Zeiser GmbH, Pineberry Manufacturing Inc., Optel Pharmaceutical, Christ Packing Systems GmbH & Co. KG etc.

The report is a compilation of first-hand information, qualitative and quantitative assessment by industry analysts, inputs from industry experts and industry participants across the value chain. The report provides in-depth analysis of parent market trends, macro-economic indicators and governing factors along with market attractiveness as per segments. The report also maps the qualitative impact of various market factors on market segments and geographies.

The global carton serialization machine market is estimated to be valued at USD 3.1 billion in 2025.

It is projected to reach USD 4.5 billion by 2035.

The market is expected to grow at a 3.7% CAGR between 2025 and 2035.

The key product types are automatic, semi-automatic and manual.

horizontal segment is expected to dominate with a 59.0% industry share in 2025.

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Carton Liners Market Size and Share Forecast Outlook 2025 to 2035

Carton Bottle Market Size and Share Forecast Outlook 2025 to 2035

Carton Display Market Size and Share Forecast Outlook 2025 to 2035

Market Share Breakdown of Carton Display Industry

Industry Share & Competitive Positioning in Carton Bottle Market

Carton Sealing Tape Market

Carton Sealer Market

Cartoning Machines Market from 2025 to 2035

Carton Sealer Machine Market Size and Share Forecast Outlook 2025 to 2035

Carton Form Fill Seal Machine Market

Carton Folding And Gluing Machine Market Size and Share Forecast Outlook 2025 to 2035

Egg Carton Market Size and Share Forecast Outlook 2025 to 2035

Industry Share Analysis for Egg Carton Manufacturers

Milk Carton Market Size and Share Forecast Outlook 2025 to 2035

Key Players & Market Share in the Brick Carton Packaging Industry

Brick Carton Packaging Market by Packaging Type from 2024 to 2034

Pizza Cartons Market

Dairy Carton Market

Liquid Carton Packaging Market Size and Share Forecast Outlook 2025 to 2035

Fluted Carton Trays Market Size, Share & Forecast 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA