The child resistant bottles market is projected to grow from USD 3.2 Billion in 2025 to USD 5.0 Billion by 2035, registering a CAGR of 4.6% during the forecast period. Sales in 2024 reached USD 3.0 Billion, reflecting steady demand across various sectors.

Growth has been driven by increasing applications in pharmaceuticals, chemicals, and household products, where child resistant bottles are essential for safety and compliance. The market's expansion is further supported by advancements in packaging technology and the rising demand for secure and user-friendly packaging solutions.

Innovations in closure types, such as push-and-turn and squeeze-and-turn mechanisms, are enhancing safety features, contributing to the market's growth.

Significant investments and expansions have been undertaken by key players in the child resistant bottles market. In March 2023, Berry Global launched Digi-Cap™ digital child-resistant closure is ideal for clinical trials, drug development, research and academic studies.

"This is a very advanced closure that provides extra benefits from the data it can amass, but it was important that it looked and felt the same for the patient so as not affect or influence their usage in any way,” said Berry Healthcare Business Development Director Chad Rice. “That is what makes our Digi-Cap™ so unique in that it matches our standard 38mm child resistant closures while incorporating this innovative technology.”

| Attributes | Key Insights |

|---|---|

| Estimated Size, 2025 | USD 3.2 billion |

| Projected Size, 2035 | USD 5.0 billion |

| Value-based CAGR (2025 to 2035) | 4.6% |

Environmental concerns and regulatory pressures have driven innovation in the child resistant bottles market. Sustainability and innovation have played pivotal roles in shaping the child resistant bottles market. The development of eco-friendly packaging solutions has been prioritized to meet environmental regulations and consumer preferences.

Advancements in bottle design have led to improved recyclability and reduced material usage, enhancing overall sustainability. Integration of smart features, such as tamper-evident seals and real-time tracking, has been implemented to ensure product safety and quality. These innovations have not only reduced the environmental footprint of packaging processes but have also opened new avenues for application in various industries.

The child resistant bottles market is expected to witness steady growth, driven by increasing demand in the pharmaceutical and household product sectors. Emerging markets in Asia-Pacific and Latin America are projected to offer significant growth opportunities due to rising consumer awareness and industrialization.

Strategic collaborations and investments in research and development are likely to foster product innovation and market expansion. As environmental concerns continue to influence consumer behavior, the adoption of eco-friendly child resistant bottles is expected to become a key differentiator in the industry.

The market is segmented based on material, capacity, closure type, end use, and region. By material, the market includes metal (stainless steel, aluminum), plastic (HDPE, LDPE, PET, PP), glass, and others. In terms of capacity, the market is categorized into up to 600 ml, 600 to 750 ml, 750 ml to 1,000 ml, 1,000 ml to 2,000 ml, and above 2,000 ml. By closure type, the market comprises screw caps, snap-lock caps, flip top caps, combination lock caps, push & turn caps, and others.

In terms of end use, the market includes pharmaceuticals, personal care, household chemicals, food & beverages, and others. Regionally, the market is analyzed across North America, Latin America, East Asia, South Asia & Pacific, Eastern Europe, Western Europe, Oceania, and the Middle East & Africa.

Plastic materials have been projected to hold 39.5% of the global child resistant bottles market share in 2025, owing to their light weight, cost-efficiency, and ease of molding into secure closure formats. Common resins such as HDPE, LDPE, PET, and PP have been utilized across pharmaceuticals, chemicals, and nutraceuticals.

Tamper-resistant and child-safe caps, including push-and-turn and squeeze-and-pull types, have been widely implemented in plastic bottle formats. These mechanisms have been standardized in regulatory frameworks, especially for controlled substances and over-the-counter medications.

Plastic bottles have allowed for barrier coatings, impact resistance, and transparency where required, along with compatibility with digital printing and labeling systems. Their suitability for small-volume dosages and liquid containment has further expanded their adoption across pediatric and geriatric markets.

With a growing shift toward mono-material recyclability and post-consumer resin (PCR) inclusion, plastic child-resistant bottles are being developed to meet sustainability mandates. The segment is expected to continue evolving with light weighting, smart tracking closures, and child-resistant certification advancements.

The pharmaceutical segment has been estimated to contribute 47.8% of the child resistant bottles market share in 2025, due to regulatory mandates and high reliance on safe primary packaging. Prescription drugs, over-the-counter analgesics, and pediatric formulations have all necessitated child-resistant packaging for accidental ingestion prevention.

Bottles with regulated opening systems have been mandated under national standards such as the USA Poison Prevention Packaging Act (PPPA) and similar frameworks in Europe and Asia. These packages have been designed to balance security with accessibility for elderly and disabled users.

Liquid medicines, tablets, and controlled substances have been packed in plastic or glass containers featuring CRC (child-resistant closure) caps. Multi-dose formats, tamper-evident seals, and dosage indicators have been integrated to reduce misuse and enhance patient compliance.

As pharmaceutical production continues expanding globally, especially in generics and pediatrics, the demand for child-resistant bottles is expected to remain high. Continuous innovation in closure mechanisms and material integrity will reinforce their use across primary pharmaceutical packaging formats.

The below table presents the expected CAGR for the global child resistant bottles market over several semi-annual periods spanning from 2025 to 2035. In the first half (H1) of the decade from 2024 to 2034, the business is predicted to surge at a CAGR of 4.5%, followed by a higher slight high growth rate of 4.7% in the second half (H2) of the same decade.

| Particular | Value CAGR |

|---|---|

| H1 | 4.5% (2024 to 2034) |

| H2 | 4.7% (2024 to 2034) |

| H1 | 4.2% (2025 to 2035) |

| H2 | 5.0% (2025 to 2035) |

Moving into the subsequent period, from H1 2024 to H2 2035, the CAGR is projected to decrease to 4.2% in the first half and increase to 5.0% in the second half. In the first half (H1) the market witnessed a decrease of 30 BPS while in the second half (H2), the market witnessed an increase of 30 BPS.

Growing Demand for Liquid Pharmaceuticals Drives Need for Child-Resistant Packaging

Liquid pharmaceuticals are highly in demand, particularly for pediatric and geriatric care patients. Most of these liquid medicines are syrups, oral suspensions, or tinctures and are prescribed to young children who cannot swallow a pill and elderly patients who have problems taking the solid forms.

This has led to demand for child-resistant packaging solutions that prevent accidental ingestion and thus ensure safety. Child-resistant bottles with screw caps or snap caps are some of the most effective means of creating barriers for children while making opening quite easy for adults. The importance of these bottles is in the pharmaceutical industry.

The safety features provided by the glass bottle help ensure compliance with such requirements as the Poison Prevention Packaging Act, hence minimizing poisoning incidences. This increase in the number of liquid pharmaceutical preparations used in the treatment of chronic conditions will provide ample market demand for the safe, tamper-proof user-friendly packaging.

Eco-Friendly Materials Drive Innovation in Sustainable Child-Resistant Bottle Packaging

As consumers increasingly demand products packed with eco-friendly materials, the manufacturers are growing highly interested in making child-resistant bottles that make use of recyclable material in their production process, including HDPE (High-Density Polyethylene) and PET (Polyethylene Terephthalate).

These are surely a sustainable alternative to some forms of traditional plastics, very highly recyclable, and not as harmful to the environment compared to non-recyclable forms. The use of sustainability is stronger in pharmaceutical and consumer chemicals.

Here, packaging plays a crucial role in both safety and environmental responsibility. Recyclable plastics are incorporated into child-resistant bottle designs, which ensures that the drugs are safe and does not add to plastic waste. This trend is forcing innovative packaging solutions to develop products that integrate child safety with environmental consciousness.

The recyclable child-resistant bottle is highly likely to be adopted in mass quantities that would prevent the degradation of the integrity and safety of these products while being implemented in more environmentally friendly ways across industries.

Balancing Safety and Accessibility Increases Complexity for Child-Resistant Bottles

Manufacturers face the challenge of designing multi-functional closures that are child-resistant but easy to open for elderly or disabled people. Even though child-resistant closures are crucial, they are often made almost impossible to open with mechanisms such as twisting or pressing motion.

However, elderly and disabled users, who might also have limited dexterity and strength, cannot so easily operate these mechanisms, thereby causing frustration and poor use. It requires intricate design solutions that would balance both factors, allow accessibility, yet maintain child resistance in these mechanisms.

Added complexity increases production costs because manufacturers have to invest in research and development for the creation of solutions that would meet both safety and usability standards. That deters some manufacturers from adopting child-resistant bottles because of high costs and the difficulties in design, especially where cost efficiency takes precedence in a market.

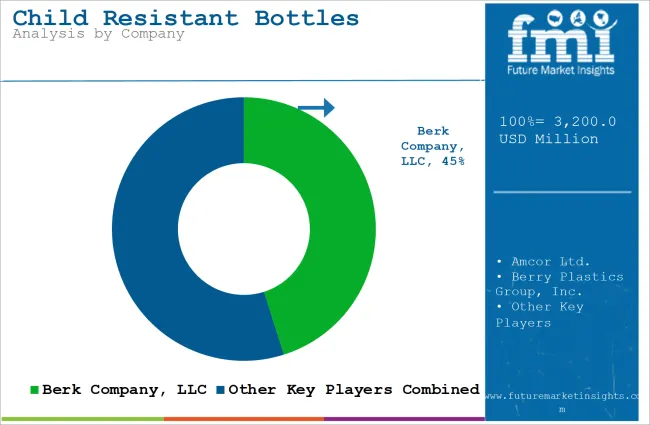

Tier 1 company leaders are characterized by high production technology and a wide product portfolio. These market leaders are distinguished by their extensive expertise in manufacturing and reconditioning across multiple packaging formats and a broad geographical reach, underpinned by a robust consumer base.

They provide a wide range of series including reconditioning, recycling, and manufacturing utilizing the latest technology and meeting the regulatory standards providing the highest quality. Prominent companies within Tier 1 include Amcor Ltd., Berry Plastics Group, Inc., Gerresheimer AG, Alpha Packaging, AptarGroup Inc.

Tier 2 companies are characterized by a strong presence overseas and strong market knowledge. These market players have good technology and ensure regulatory compliance but may not have advanced technology and wide global reach. Prominent companies in Tier 2 include Berk Company, LLC, Pretium Packaging Corp., Tim Plastics Inc., Comar LLC.

Tier 3 includes the majority of small-scale companies operating at the local presence and serving niche markets. These companies are notably oriented towards fulfilling local market demands and are consequently classified within the tier 3 share segment. T

hey are small-scale players and have limited geographical reach. Tier 3, within this context, is recognized as an unorganized market, denoting a sector characterized by a lack of extensive structure and formalization when compared to organized competitors.

The section below covers the industry analysis for the child resistant bottles market for different countries. Market demand analysis on key countries in several regions of the globe, including North America, Asia Pacific, Europe, and others, is provided. USA is anticipated to remain at the forefront in North America, with a CAGR of 4.2% through 2035. In South Asia & Pacific, India is projected to witness a CAGR of 5.7% by 2035.

| Countries | Value CAGR (2025 to 2035) |

|---|---|

| USA | 4.2% |

| Canada | 3.8% |

| Brazil | 4.6% |

| Argentina | 4.3% |

| Germany | 3.9% |

| China | 5.2% |

| India | 5.7% |

The primary growth promoter for USA child-resistant bottles in the pharmaceuticals market is the requirements of the pharmaceutical industry to package liquid medicines with secure packaging. Chronic conditions like diabetes, hypertension, and respiratory disorders are now more prevalent than before, leading to a massive prescription of liquid medicine. Most of the liquids are prescribed to children, elderly patients, and patients having difficulty swallowing solid pills, and thus requiring child-resistant packaging.

The USA Food and Drug Administration forces strict regulations under the Poison Prevention Packaging Act to require child-resistant packaging for such pharmaceuticals as certain medicines with a prescription order. Hence, pharmaceutical companies have to invest in advanced child-resistant bottle designs without compromising ease-of-use for patients.

This has led to the adoption of secure yet user-friendly closures, such as screw caps and snap caps, which will be necessary in preventing accidental ingestion while allowing the caregiver and patients to access it easily.

The regulatory pressure on the pharmaceutical packaging, especially that of the pediatric medications, is driving the market of child-resistant bottles in Germany. Emphasis on child safety in German laws, such as the Poison Prevention Packaging Act (PPPA), has created the demand for packaging solutions that prevent the accidental ingestion of medicines by children. Child-resistant bottles for liquids, including cough syrups and antibiotics, are also used in the pharmaceutical industry for high safety compliance.

In general, they feature security-closing bottles with screw caps or flip-top caps that are tamper-evident, child-resistant but accessible to adults. With the fast-growing demand from the youth section of the population for liquid pharmaceuticals, secured convenient packaging becomes one of the top drivers for the German market. This governmental regulatory environment, along with a greater awareness about child safety, is driving more demand for the use of child-resistant bottles within the pharmaceutical space.

Key players operating in the child resistant bottles market are investing in the development of innovative sustainable solutions and also entering into partnerships. Key child resistant bottles providers have also been acquiring smaller players to grow their presence to further penetrate the child resistant bottles market across multiple regions.

Recent Industry Developments in the Child Resistant Bottles Market

In November 2024, Amcor announced plans to acquire Berry Global for approximately USD 8.4 billion in stock. This merger aims to strengthen Amcor's position in the USA market and accelerate innovation in sustainable packaging solutions.

The global child resistant bottles industry is projected to witness CAGR of 4.6% between 2025 and 2035.

The global child resistant bottles industry stood at USD 3,097.8 million in 2024.

The global child resistant bottles industry is anticipated to reach USD 5,017.3 million by 2035 end.

South Asia & Pacific region is set to record the highest CAGR of 5.3% in the assessment period.

The key players operating in the global child resistant bottles industry include Berk Company, LLC, Amcor Ltd., Berry Plastics Group, Inc., Gerresheimer AG, Alpha Packaging, and AptarGroup Inc.

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

United States and Canada Child Resistant Bottles Market Size and Share Forecast Outlook 2025 to 2035

Children Enteral Nutrition Market Size and Share Forecast Outlook 2025 to 2035

Child Safety Seats Market Growth - Trends & Forecast 2025 to 2035

Children’s Health Supplement Market Analysis by Product Type, Application and Age Group Through 2025 to 2035.

Children Mattress Market Product Type, Ingredient Type, Sales Channel, and Region - Trends, Growth & Forecast 2025 to 2035

Child resistant Zipper Market Size and Share Forecast Outlook 2025 to 2035

Child-Resistant Pumps Market Size and Share Forecast Outlook 2025 to 2035

Child Resistant Re-Closable Edible Bags Market Size and Share Forecast Outlook 2025 to 2035

Child-Resistant Foil Packaging Market Size and Share Forecast Outlook 2025 to 2035

Child Resistant Pouches Market Size and Share Forecast Outlook 2025 to 2035

Child Resistant Single Dose Pouches Market Size and Share Forecast Outlook 2025 to 2035

Child Resistant Pipette Closures Market Size and Share Forecast Outlook 2025 to 2035

Child Resistant Dropper Caps Market Size and Share Forecast Outlook 2025 to 2035

Child Resistant Locking Pouches Market from 2025 to 2035

Child-Resistant Containers Market Trends & Demand 2025 to 2035

Competitive Landscape of Child Resistant Re-Closable Edible Bags Providers

Market Share Distribution Among Child-Resistant Pouches Manufacturers

Leading Providers & Market Share in Child-Resistant Foil Packaging

Market Share Insights for Child Resistant Dropper Caps Manufacturers

Market Share Distribution Among Child Resistant Pipette Closures Manufacturers

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA