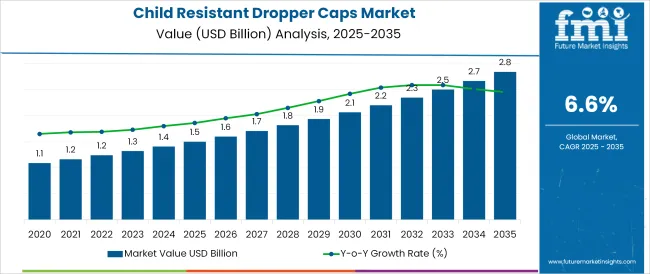

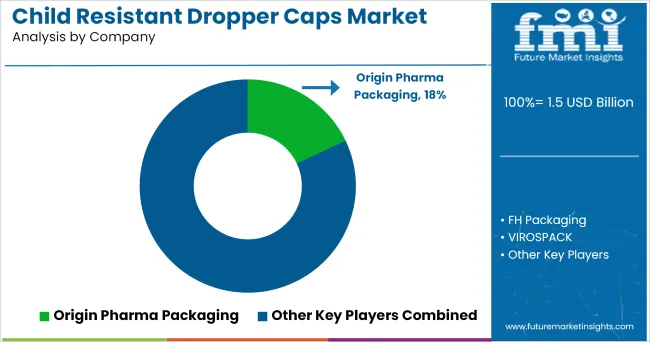

The Child Resistant Dropper Caps Market is estimated to be valued at USD 1.5 billion in 2025 and is projected to reach USD 2.8 billion by 2035, registering a compound annual growth rate (CAGR) of 6.6% over the forecast period.

The child resistant dropper caps market is demonstrating steady growth, fueled by increasing regulatory scrutiny around child safety and rising demand from the pharmaceutical, nutraceutical, and cosmetics sectors. Stringent safety standards have compelled manufacturers to adopt child-resistant designs while preserving convenience for adults, positioning these caps as an essential compliance component.

The growing awareness of accidental ingestion risks, particularly in households with young children, has further reinforced their necessity. Future market prospects are expected to benefit from advancements in ergonomic designs, material innovations aimed at sustainability, and greater adoption of premium packaging in high value liquid products.

Ongoing collaboration between packaging companies and end user industries is paving the way for innovation and expanding the use of these solutions into emerging applications, ensuring long term demand.

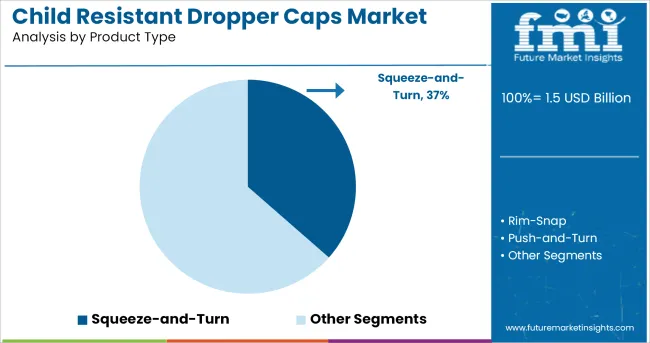

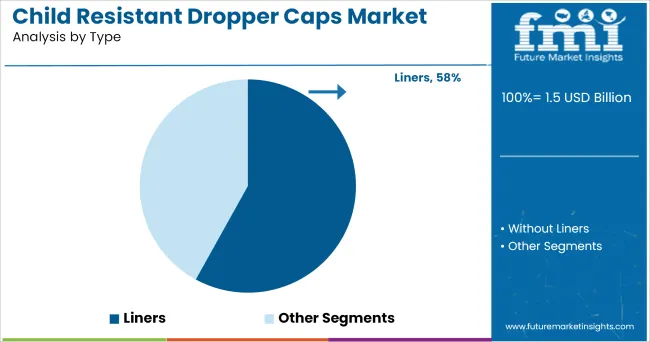

The market is segmented by Product Type, Type, Capacity, Neck Diameter, Material, and Sales Channel and region. By Product Type, the market is divided into Squeeze-and-Turn, Rim-Snap, Push-and-Turn, REL, and Squeeze-And-Pull. In terms of Type, the market is classified into Liners and Without Liners.

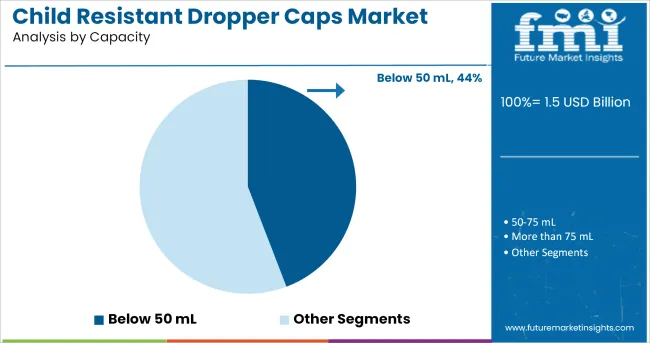

Based on Capacity, the market is segmented into Below 50 mL, 50-75 mL, and More than 75 mL. By Neck Diameter, the market is divided into 20-40 mm, Below 20 mm, 40-60 mm, and Above 60 mm. By Material, the market is segmented into PP (Polypropylene), LDPE (Low-density polyethylene), PE (Polyethylene), and PS (Polystyrene).

By Sales Channel, the market is segmented into Retail, Online Channel, and Others. Regionally, the market is classified into North America, Latin America, Western Europe, Eastern Europe, Balkan & Baltic Countries, Russia & Belarus, Central Asia, East Asia, South Asia & Pacific, and the Middle East & Africa.

When segmented by product type, the squeeze-and-turn segment is expected to command 36.5% of the total market revenue in 2025, securing its position as the leading product category. This leadership has been underpinned by the intuitive yet secure mechanism that balances child resistance with adult usability.

The design’s effectiveness in preventing unintended access, while remaining affordable to produce at scale, has made it a preferred choice among manufacturers. Ergonomic improvements and material enhancements have increased consumer acceptance, while its compatibility with a wide range of bottles and droppers has further boosted adoption.

This combination of compliance, cost efficiency, and consumer familiarity has reinforced the segment’s prominence in the market.

By type, the liners segment is projected to hold 58.0% of the market revenue share in 2025, establishing itself as the leading type segment. This dominance has been driven by its critical role in ensuring product integrity and tamper evidence alongside child resistance.

Liners provide an additional layer of protection by preventing leakage, maintaining product freshness, and enhancing overall safety features highly valued in regulated industries. The ability to customize liners for different liquid viscosities, bottle materials, and closure types has further cemented their widespread application.

Improvements in barrier materials and production technologies have enabled liners to deliver superior performance at competitive costs, which has strengthened their position as the segment of choice for many manufacturers.

When analyzed by capacity, the below 50 mL segment is expected to account for 44.2% of the market revenue in 2025, making it the top ranked capacity category. This leadership has been supported by the prevalence of small-dose liquid products in pharmaceuticals, essential oils, and specialty cosmetics where precise dosing and portability are critical.

The compact form factor aligns with regulatory mandates that emphasize secure closures for high potency formulations, many of which are packaged in smaller containers. Consumer demand for travel friendly and easy-to-store products has further boosted the preference for this capacity range.

Manufacturers’ focus on optimizing dropper functionality and ensuring reliable sealing in smaller bottles has contributed significantly to the segment’s strong performance and enduring appeal.

Dangerous drugs must be stored in the proper container to ensure the safety of children. Certain aspects of child-resistant packaging, or packaging that stops children from obtaining the contents within, enable adult’s access but prevent children from doing so.

Child-Resistant packaging equipment, such as dropper caps, are receiving more attention. Pharmaceutical packaging producers are increasingly focusing on child-resistant container types like droppers and caps. According to the European Child Safety Alliance, every year in Europe, 3,000 children under the age of 14 die from acute poisoning after acquiring access to pharmaceutical items.

Furthermore, according to the WHO, poisoning was responsible for 4% of global child injury deaths (0-17 years of age) in 2020. As a result, corporations are concentrating on the creation of child-resistant packaging, such as droppers caps. More advancements are projected to open up new growth potential for the global dropper caps market.

The advent of technology has accelerated the development of a less expensive and biodegradable replacement to the materials used in droppers and caps. Traditional plastic, such as PET, is a petroleum derivative, which makes it not only expensive but also increases greenhouse gas emissions.

Though bioplastics are more expensive than petroleum-based plastics, they can be made at lower temperatures with a steady supply of biomass, making them a viable material for developing environmentally responsible and cost-effective dropper caps.

Sugarcane ethanol has made a debut into the droppers and caps market as a formidable substitute for traditional plastics and an alternative to petroleum-derived plastics. Dropper caps made of bioplastics have a competitive advantage in terms of carbon emissions, and this might be considered as an environmentally friendly strategy for manufacturers.

The global child resistant dropper caps market is expected to rise steadily throughout the projected period, owing to an increase in demand for OTC (over-the-counter) pharmaceuticals. Increased knowledge of biodegradable solutions for droppers and caps is projected to promote this expansion.

The cosmetic packaging market has undergone slight modifications in trends during the last decade. With the rising popularity of essential oils and other cosmetics such as foundations and face tints, the demand for droppers has skyrocketed into the cosmetics business.

To find new growth opportunities, key industry players in the dropper and caps market are venturing into the cosmetics sector, particularly in the hair care, nail care, and skin care categories. With the cosmetics business focusing on usefulness, glamour, and practicality, new and visually appealing dropper bottles and caps are being viewed as a strategy for enticing customers and increasing sales.

Cosmetologists are adhering to the dictum of successful formula integration in various cosmetic goods, as well as their simple administration via dropper bottles, ensuring that the dropper market continues to expand and thrive.

Furthermore, because droppers allow users to manage the amount of cosmetic product they apply, cosmetics supplied in dropper bottles are becoming increasingly popular.

Furthermore, cosmetics manufacturers are taking use of the availability of diverse materials to create child resistant dropper caps, which is predicted to push the dropper caps market sales.

are some of the prominent players listed across the value chain of the child resistant dropper caps market.

Virospack's CRC and tamper-resistant solutions have taken the packaging market to next level. In June 2020, their safe droppers have received child-resistant certification from the Code of Federal Regulations. The development of the magnetic dropper with a magnetic seal is another notable progression in their unique techniques that has propelled them to the pinnacles of success.

The proprietary and unique sealing system is based on the magnetism of the four poles. This substitutes the standard screw-on method in a clever way. Virospack's inventions have turned the competitive scales in its favor and gain maximum market share in the child resistant dropper caps market.

To acquire broader coverage, the producers have streamlined their supply chain network with modern trade channels, pharmaceutical outlets, and an online channel. The market is moderately fragmented, with a large number of regional firms competing on the basis of low-cost child-resistant dropper caps.

The report is a compilation of first-hand information, qualitative and quantitative assessment by industry analysts, inputs from industry experts and industry participants across the value chain. The report provides in-depth analysis of parent market trends, macro-economic indicators and governing factors along with market attractiveness as per segments. The report also maps the qualitative impact of various market factors on market segments and geographies.

The global child resistant dropper caps market is estimated to be valued at USD 1.5 billion in 2025.

The market size for the child resistant dropper caps market is projected to reach USD 2.8 billion by 2035.

The child resistant dropper caps market is expected to grow at a 6.6% CAGR between 2025 and 2035.

The key product types in child resistant dropper caps market are squeeze-and-turn, rim-snap, push-and-turn, rel and squeeze-and-pull.

In terms of type, liners segment to command 58.0% share in the child resistant dropper caps market in 2025.

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Market Share Insights for Child Resistant Dropper Caps Manufacturers

Children Enteral Nutrition Market Size and Share Forecast Outlook 2025 to 2035

Child Safety Seats Market Growth - Trends & Forecast 2025 to 2035

Children’s Health Supplement Market Analysis by Product Type, Application and Age Group Through 2025 to 2035.

Children Mattress Market Product Type, Ingredient Type, Sales Channel, and Region - Trends, Growth & Forecast 2025 to 2035

Child resistant Zipper Market Size and Share Forecast Outlook 2025 to 2035

Child-Resistant Pumps Market Size and Share Forecast Outlook 2025 to 2035

Child Resistant Re-Closable Edible Bags Market Size and Share Forecast Outlook 2025 to 2035

Child-Resistant Foil Packaging Market Size and Share Forecast Outlook 2025 to 2035

Child Resistant Pouches Market Size and Share Forecast Outlook 2025 to 2035

Child Resistant Single Dose Pouches Market Size and Share Forecast Outlook 2025 to 2035

Child Resistant Pipette Closures Market Size and Share Forecast Outlook 2025 to 2035

Child Resistant Bottles Market Size and Forecast

Child Resistant Locking Pouches Market from 2025 to 2035

Child-Resistant Containers Market Trends & Demand 2025 to 2035

Competitive Landscape of Child Resistant Re-Closable Edible Bags Providers

Market Share Distribution Among Child-Resistant Pouches Manufacturers

Leading Providers & Market Share in Child-Resistant Foil Packaging

Market Share Distribution Among Child Resistant Pipette Closures Manufacturers

Child Resistant Bags Market

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA