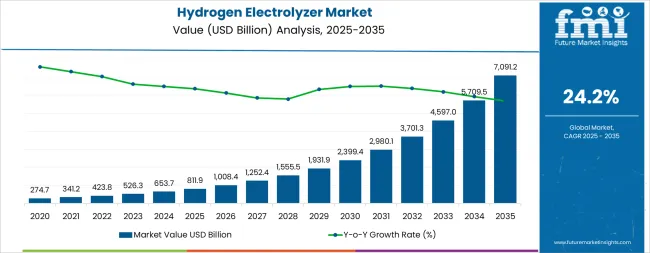

The global hydrogen electrolyzer market is valued at USD 811.9 million in 2025 and is slated to reach USD 7.1 billion by 2035, recording an absolute increase of USD 6.3 billion over the forecast period. This translates into a total growth of 773%, with the market forecast to expand at a compound annual growth rate (CAGR) of 24.2% between 2025 and 2035. The overall market size is expected to grow by nearly 8.7X during the same period, supported by increasing global decarbonization efforts, growing green hydrogen infrastructure development, and rising adoption of renewable-powered electrolysis technologies across diverse industrial applications.

Between 2025 and 2030, the hydrogen electrolyzer market is projected to expand from USD 811.9 million to USD 2.4 billion, resulting in a value increase of USD 1.6 billion, which represents 25.4% of the total forecast growth for the decade. This phase of development will be shaped by increasing clean energy transitions, rising green hydrogen project deployments, and growing adoption of PEM electrolyzer solutions in power-to-gas and energy applications. Equipment manufacturers are expanding their production capabilities to address the growing demand for efficient hydrogen production solutions and enhanced operational scalability.

| Metric | Value |

|---|---|

| Estimated Value (2025E) | USD 811.9 million |

| Forecast Value (2035F) | USD 7.1 billion |

| Forecast CAGR (2025 to 2035) | 24.2% |

From 2030 to 2035, the market is forecast to grow from USD 2.4 billion to USD 7.1 billion, adding another USD 4.7 billion, which constitutes 74.6% of the overall ten-year expansion. This period is expected to be characterized by the expansion of large-scale electrolyzer systems, the integration of gigawatt-level hydrogen projects, and the development of advanced power-to-gas technologies for industrial facilities. The growing adoption of clean energy programs and renewable integration initiatives will drive demand for hydrogen electrolyzers with enhanced operational efficiency and reduced production costs.

Between 2020 and 2024, the hydrogen electrolyzer market experienced rapid growth at a 20.3% CAGR, driven by increasing awareness of hydrogen as clean energy carrier demand and growing recognition of electrolyzers as essential equipment for decarbonization, renewable energy storage, and industrial hydrogen production operations. The market developed as industries recognized the potential for green hydrogen to enhance energy security while reducing carbon emissions and improving energy system flexibility. Technological advancement in PEM technologies and alkaline systems began emphasizing the critical importance of maintaining operational efficiency and cost optimization in hydrogen production systems.

Market expansion is being supported by the increasing global decarbonization efforts and the corresponding need for clean hydrogen production equipment that can maintain operational reliability and energy conversion efficiency while supporting diverse renewable energy applications across various industrial environments. Modern energy companies are increasingly focused on implementing electrolyzer solutions that can reduce carbon emissions, minimize energy costs, and provide consistent performance in green hydrogen production operations. Hydrogen electrolyzers' proven ability to deliver enhanced energy conversion efficiency, reliable hydrogen production capabilities, and versatile renewable energy applications make them essential equipment for contemporary clean energy operations and industrial decarbonization solutions.

The growing emphasis on renewable energy integration and operational efficiency is driving demand for hydrogen electrolyzers that can support high-capacity production, reduce energy conversion losses, and enable efficient power-to-gas operations across varying renewable energy configurations. Energy operators' preference for equipment that combines reliability with operational efficiency and cost-effectiveness is creating opportunities for innovative electrolyzer implementations. The rising influence of climate regulations and clean energy technologies is also contributing to increased adoption of hydrogen electrolyzers that can provide advanced operational control without compromising performance or energy conversion optimization.

The hydrogen electrolyzer market is poised for robust growth and transformation. As energy companies and industries across both developed and emerging markets seek clean hydrogen production equipment that is efficient, reliable, automated, and climate-compliant, electrolyzer systems are gaining prominence not just as operational equipment but as strategic infrastructure for operational efficiency, energy security reliability, decarbonization enhancement, and renewable energy optimization.

Rising clean energy transitions and industrial decarbonization in North America, Western Europe, and East Asia amplify demand, while manufacturers are picking up on innovations in PEM technologies and high-capacity applications.

Pathways like PEM electrolyzer adoption, power-to-gas integration, and advanced hydrogen production technologies promise strong margin uplift, especially in developed markets. Geographic expansion and application diversification will capture volume, particularly where renewable energy is growing or industrial infrastructure requires decarbonization. Climate pressures around emission reduction, energy security, and performance enhancement give structural support.

The market is segmented by product type, capacity, outlet pressure, end use, and region. By product type, the market is divided into proton exchange membrane (PEM) electrolyzer, alkaline electrolyzer, and solid oxide electrolyzer. By capacity, it covers low (≤150 kW), medium (150-400 kW, 400-750 kW, 750 kW-1 MW), and high (1-10 MW, 10-20 MW, above 20 MW). By outlet pressure, it is segmented into low (≤10 bar), medium (10-40 bar), and high (>40 bar). By end use, it covers ammonia, methanol, refining/hydrocarbon, electronics, energy, power to gas, transport, pharma & biotech, food & beverages, and others. Regionally, the market is divided into North America, Latin America, Western Europe, Eastern Europe, South Asia Pacific, East Asia, and Middle East & Africa.

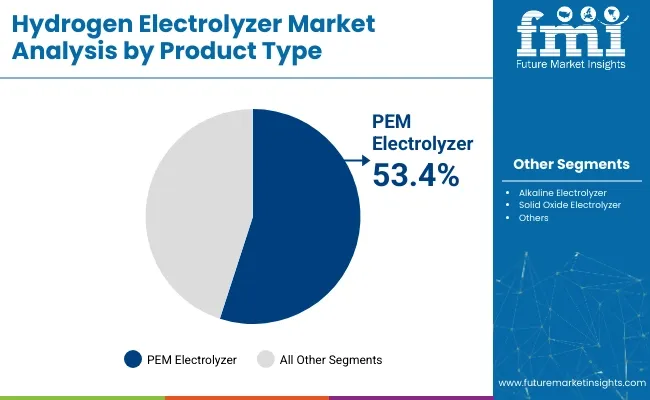

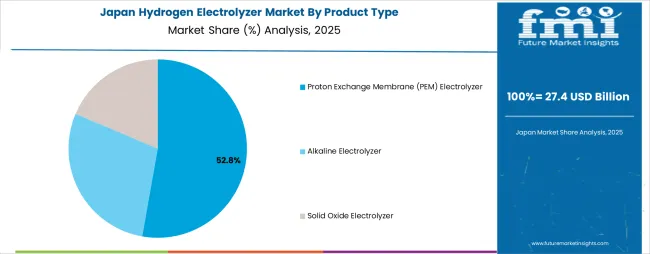

The proton exchange membrane (PEM) electrolyzer segment is projected to account for 53.4% of the hydrogen electrolyzer market in 2025, reaffirming its position as the leading product type category. Energy operators and industrial companies increasingly utilize PEM electrolyzers for their proven reliability, high efficiency capabilities, and cost-effectiveness in hydrogen production applications across renewable energy systems, industrial processes, and power-to-gas applications. PEM electrolyzer technology's established operational procedures and consistent performance output directly address the energy requirements for reliable hydrogen production and operational efficiency in diverse renewable energy environments.

This product type segment forms the foundation of current clean hydrogen production operations, as it represents the technology with the greatest operational flexibility and established performance infrastructure across multiple applications and energy scenarios. Operator investments in enhanced PEM systems and operational optimization continue to strengthen adoption among energy companies and industrial manufacturers. With operators prioritizing operational reliability and equipment availability, PEM electrolyzers align with both operational efficiency objectives and cost management requirements, making them the central component of comprehensive hydrogen production strategies.

Low pressure (≤10 bar) is projected to represent 62.8% of hydrogen electrolyzer demand in 2025, underscoring its critical role as the primary outlet pressure for electrolyzer systems and hydrogen production operations. Energy operators prefer low pressure electrolyzers for their efficiency, reliability, and ability to handle diverse applications while supporting operational flexibility and system integration requirements. Positioned as essential equipment for modern hydrogen production operations, low pressure systems offer both operational advantages and performance benefits.

The segment is supported by continuous innovation in electrolyzer system development and the growing availability of specialized pressure configurations that enable efficient hydrogen production with enhanced operational capabilities. Energy companies are investing in system optimization to support large-scale operations and production delivery. As hydrogen demand becomes more prevalent and operational efficiency requirements increase, low pressure systems will continue to dominate the outlet pressure market while supporting advanced system utilization and energy operational strategies.

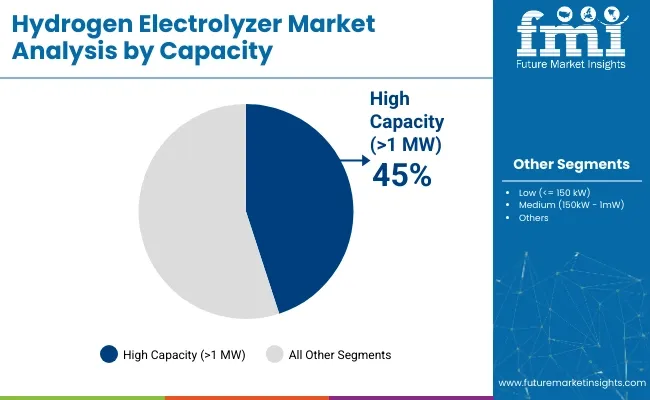

High capacity electrolyzers (>1 MW) are projected to experience strong growth with a CAGR of 7.1% from 2025 to 2035, driven by increasing demand for large-scale hydrogen production in industrial, energy, and power-to-gas applications. This capacity segment represents 45.0% market share and provides optimal operating conditions for many industrial systems, offering enhanced scaling benefits and operational efficiency while supporting diverse energy requirements and production configurations.

The segment is supported by continuous innovation in large-scale electrolyzer development and the growing availability of specialized high-capacity configurations that enable efficient hydrogen production with enhanced operational capabilities. Additionally, industrial operators are investing in high-capacity optimization to support gigawatt-scale operations and production performance delivery. As renewable energy integration becomes more prevalent and operational efficiency requirements increase, the high-capacity segment will continue to drive market growth while supporting advanced system utilization and industrial operational strategies.

Power to gas is projected to represent the fastest-growing application with a CAGR of 8.2% from 2025 to 2035, while accounting for 34% market share, underscoring its critical role as the primary growth driver of electrolyzer demand for renewable energy integration and grid balancing operations. Energy operators prefer power-to-gas applications for their efficiency, reliability, and ability to handle renewable energy storage while supporting grid operations and energy system requirements. Positioned as essential applications for modern energy operations, power-to-gas systems offer both operational advantages and performance benefits.

The segment is supported by continuous innovation in renewable energy integration and the growing availability of specialized electrolyzer configurations that enable efficient energy conversion with enhanced grid capabilities. Additionally, energy companies are investing in power-to-gas optimization to support large-scale operations and renewable energy delivery. As renewable energy becomes more prevalent and grid efficiency requirements increase, power to gas will continue to drive the application market while supporting advanced system utilization and energy operational strategies.

The hydrogen electrolyzer market is advancing rapidly due to increasing decarbonization efforts and growing adoption of clean energy infrastructure that provides enhanced hydrogen production capabilities and renewable energy integration reliability across diverse industrial applications. However, the market faces challenges, including high equipment capital costs, specialized infrastructure requirements, and varying operational requirements across different energy environments. Innovation in PEM technologies and high-capacity systems continues to influence equipment development and market expansion patterns.

The growing expansion of clean energy projects and renewable energy development is enabling electrolyzer manufacturers to develop hydrogen production systems that provide superior operational efficiency, enhanced energy conversion capabilities, and reliable performance in high-demand energy environments. Advanced electrolyzer systems provide improved operational capacity while allowing more effective hydrogen production and consistent performance delivery across various applications and energy requirements. Manufacturers are increasingly recognizing the competitive advantages of modern electrolyzer capabilities for operational efficiency and energy productivity positioning.

Modern hydrogen electrolyzer manufacturers are incorporating PEM technologies and high-capacity production systems to enhance operational efficiency, reduce energy conversion losses, and ensure consistent performance delivery to energy operators. These technologies improve production reliability while enabling new applications, including automated power-to-gas and advanced grid integration solutions. Advanced technology integration also allows manufacturers to support premium equipment positioning and operational optimization beyond traditional hydrogen production equipment supply.

| Country | CAGR (2025-2035) |

|---|---|

| USA | 20.9% |

| Japan | 21.0% |

| UK | 20.4% |

| Germany | 16.2% |

| France | 20.4% |

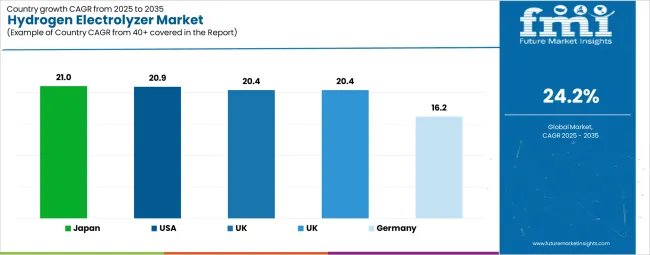

The hydrogen electrolyzer market is experiencing exceptional growth globally, with Japan leading at a 21% CAGR through 2035, driven by extensive government funding programs, advanced hydrogen technology investments, and significant adoption of clean hydrogen production solutions. USA follows at 20.9%, supported by federal policy initiatives, clean energy investments, and growing adoption of electrolyzer technologies. UK and France show growth at 20.4%, emphasizing hydrogen strategy implementation and renewable energy integration capabilities. Germany records 16.2%, focusing on industrial decarbonization and green hydrogen infrastructure development.

The report covers an in-depth analysis of top-performing countries are highlighted below.

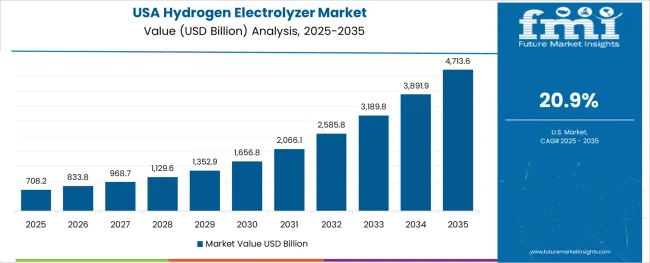

Revenue from hydrogen electrolyzers in the USA is projected to exhibit exceptional growth with a CAGR of 20.9% through 2035, driven by extensive federal clean energy programs and rapidly growing adoption of PEM electrolyzer solutions supported by the Inflation Reduction Act and Department of Energy initiatives. The country's comprehensive energy infrastructure and increasing investment in advanced electrolyzer technologies are creating substantial demand for efficient hydrogen production solutions. Major energy companies and industrial facilities are establishing comprehensive electrolyzer systems to serve both domestic operations and export requirements.

Revenue from hydrogen electrolyzers in Japan is expanding at a CAGR of 21.0%, supported by the country's substantial government funding initiatives, extensive clean energy infrastructure development, and increasing adoption of advanced electrolyzer systems. The country's comprehensive hydrogen strategy and growing clean energy demand are driving advanced production capabilities. Government agencies and energy companies are establishing extensive electrolyzer operations to address the growing demand for efficient hydrogen production and energy security.

Revenue from hydrogen electrolyzers in the UK is growing at a CAGR of 20.4%, driven by expanding hydrogen strategy implementation, increasing renewable energy integration requirements, and growing investment in clean energy enhancement. The country's established energy infrastructure and emphasis on decarbonization optimization are supporting demand for advanced electrolyzer technologies across major energy markets. Energy operators and industrial companies are establishing comprehensive electrolyzer programs to serve both domestic energy needs and technology export requirements.

Revenue from hydrogen electrolyzers in Germany is expanding at a CAGR of 16.2%, supported by the country's industrial decarbonization programs, growing clean energy demand, and increasing investment in hydrogen infrastructure development. Germany's established industrial sector and emphasis on green hydrogen production are driving demand for reliable electrolyzer technologies across major industrial markets. Manufacturing operators and energy facilities are establishing electrolyzer partnerships to serve both domestic industrial development and operational efficiency markets.

Revenue from hydrogen electrolyzers in France is expanding at a CAGR of 20.4%, supported by the country's national hydrogen strategy programs, growing renewable energy demand, and increasing investment in technology development. France's established energy sector and emphasis on clean hydrogen advancement are driving demand for innovative electrolyzer technologies across major energy markets. Energy companies and industrial operators are establishing technology partnerships to serve both domestic energy expansion and operational efficiency requirements.

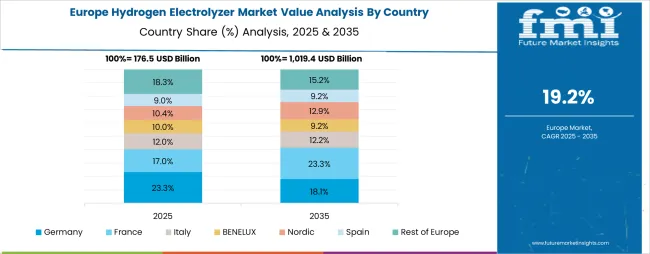

The hydrogen electrolyzer market in Europe is projected to grow from USD 240.0 million in 2025 to USD 2.1 billion by 2035, registering a CAGR of 24.0% over the forecast period. Germany is expected to maintain its leadership position with a 35.2% market share in 2025, increasing to 36.8% by 2035, supported by its advanced industrial infrastructure, comprehensive decarbonization programs, and major hydrogen facilities serving European and international markets.

United Kingdom follows with a 22.1% share in 2025, projected to ease to 21.3% by 2035, driven by hydrogen strategy implementation, renewable energy integration initiatives, and established energy capabilities, but facing challenges from competitive pressures and investment constraints. France holds a 18.7% share in 2025, expected to decline to 18.2% by 2035, supported by national hydrogen strategy upgrades and clean energy requirements but facing challenges from technology optimization and investment uncertainties.

Netherlands commands a 12.8% share in 2025, projected to reach 13.1% by 2035, while Denmark accounts for 8.2% in 2025, expected to reach 8.6% by 2035. The Rest of Europe region, including Nordic countries, Eastern European markets, Italy, Spain, and other European countries, is anticipated to gain momentum, expanding its collective share from 3.0% to 2.0% by 2035, attributed to increasing hydrogen development across Nordic countries and growing clean energy modernization across various European markets implementing infrastructure upgrade programs.

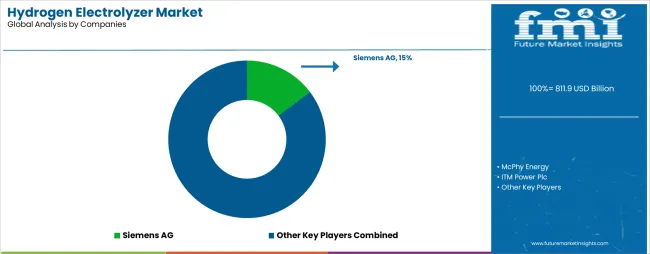

The hydrogen electrolyzer market is characterized by competition among established energy equipment manufacturers, specialized electrolyzer technology providers, and integrated clean energy system companies. Companies are investing in advanced PEM electrolyzer research, high-capacity system development, operational efficiency enhancement, and comprehensive technology portfolios to deliver efficient, reliable, and climate-compliant hydrogen electrolyzer solutions. Innovation in PEM systems, alkaline technologies, and solid oxide integration is central to strengthening market position and competitive advantage.

Siemens AG leads the market with a strong presence, offering comprehensive hydrogen electrolyzer solutions and energy systems with a focus on reliability and operational efficiency for industrial applications. McPhy Energy provides extensive electrolyzer portfolios with an emphasis on innovation, customization, and aftermarket support services. ITM Power delivers specialized PEM electrolyzer systems with a focus on renewable energy integration and regional adaptability. Tianjin Mainland Hydrogen Equipment specializes in advanced electrolyzer technologies with emphasis on industrial and energy applications. Gaztransport & Technigaz focuses on electrolyzer solutions with emphasis on high-capacity applications and operational excellence. Giner Inc. offers comprehensive electrolyzer equipment with emphasis on technology innovation and manufacturing performance. GreenHydrogen Systems provides diverse electrolyzer solutions with regional market leadership and cost-effective production capabilities.

| Items | Values |

|---|---|

| Quantitative Units (2025) | USD 811.9 million |

| Product Type | Proton Exchange Membrane (PEM) Electrolyzer, Alkaline Electrolyzer, Solid Oxide Electrolyzer |

| Capacity | Low (≤150 kW), Medium (150-400 kW, 400-750 kW, 750 kW-1 MW), High (1-10 MW, 10-20 MW, Above 20 MW) |

| Outlet Pressure | Low (≤10 Bar), Medium (10-40 Bar), High (>40 Bar) |

| End Use | Ammonia, Methanol, Refining/Hydrocarbon, Electronics, Energy, Power to Gas, Transport, Pharma & Biotech, Food & Beverages, Others |

| Regions Covered | North America, Latin America, Western Europe, Eastern Europe, South Asia Pacific, East Asia, Middle East & Africa |

| Countries Covered | United States, Canada, Germany, United Kingdom, France, China, Japan, Brazil, India and 15+ countries |

| Key Companies Profiled | Siemens AG, McPhy Energy, ITM Power, Tianjin Mainland Hydrogen Equipment, Gaztransport & Technigaz, Giner Inc., and GreenHydrogen Systems |

| Additional Attributes | Electrolyzer sales by product type and capacity category, regional demand trends, competitive landscape, technological advancements in PEM systems, high-capacity development, operational efficiency innovation, and performance enhancement optimization |

The global hydrogen electrolyzer market is estimated to be valued at USD 811.9 billion in 2025.

The market size for the hydrogen electrolyzer market is projected to reach USD 7,091.2 billion by 2035.

The hydrogen electrolyzer market is expected to grow at a 24.2% CAGR between 2025 and 2035.

The key product types in hydrogen electrolyzer market are proton exchange membrane (pem) electrolyzer, alkaline electrolyzer and solid oxide electrolyzer.

In terms of capacity, low (≤150 kw) segment to command 62.8% share in the hydrogen electrolyzer market in 2025.

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

USA Hydrogen Electrolyzer Market Growth - Trends & Forecast 2025 to 2035

Hydrogenated Dimer Acid Market Size and Share Forecast Outlook 2025 to 2035

Hydrogen Fluoride Gas Detection Market Size and Share Forecast Outlook 2025 to 2035

Hydrogen Storage Tanks and Transportation Market Size and Share Forecast Outlook 2025 to 2035

Hydrogen Refueling Station Market Size and Share Forecast Outlook 2025 to 2035

Hydrogen Aircraft Market Size and Share Forecast Outlook 2025 to 2035

Hydrogen Peroxide Market Size and Share Forecast Outlook 2025 to 2035

Hydrogen Fuel Cell Vehicle Market Size and Share Forecast Outlook 2025 to 2035

Hydrogen Pipeline Market Size and Share Forecast Outlook 2025 to 2035

Hydrogen Generator Market Size and Share Forecast Outlook 2025 to 2035

Hydrogen Energy Storage Market Size and Share Forecast Outlook 2025 to 2035

Hydrogen Combustion Engine Market Size and Share Forecast Outlook 2025 to 2035

Hydrogen Storage Tanks Market Size and Share Forecast Outlook 2025 to 2035

Hydrogen Hubs Market Size and Share Forecast Outlook 2025 to 2035

Hydrogen Buses Market Growth – Trends & Forecast 2025 to 2035

Hydrogen Truck Market Growth – Trends & Forecast 2024 to 2034

Hydrogen Detection Market Growth & Outlook 2024-2034

Hydrogen Storage Tank Market Growth – Trends & Forecast 2024-2034

Hydrogen Fueling Station Market Growth – Trends & Forecast 2024-2034

Hydrogenated Palm Oil Market

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA