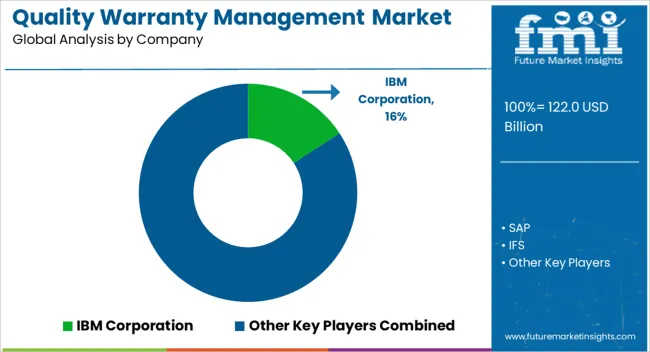

The Quality Warranty Management Market is estimated to be valued at USD 122.0 billion in 2025 and is projected to reach USD 472.6 billion by 2035, registering a compound annual growth rate (CAGR) of 14.5% over the forecast period.

| Metric | Value |

|---|---|

| Quality Warranty Management Market Estimated Value in (2025 E) | USD 122.0 billion |

| Quality Warranty Management Market Forecast Value in (2035 F) | USD 472.6 billion |

| Forecast CAGR (2025 to 2035) | 14.5% |

The quality warranty management market is witnessing consistent growth, supported by the increasing need for organizations to improve customer satisfaction, reduce operational inefficiencies, and comply with stringent industry regulations. Enterprises are increasingly adopting integrated quality management solutions to monitor product performance, manage warranty claims, and ensure regulatory compliance across global supply chains. Rising demand for predictive analytics, automation, and real-time reporting in quality processes is enhancing decision-making and helping businesses address issues before they escalate into significant warranty costs.

Investments in digital transformation initiatives, particularly in automotive, electronics, and manufacturing sectors, are further driving the deployment of advanced quality management systems. Cloud-based platforms and AI-enabled tools are improving the scalability and adaptability of solutions, enabling businesses to standardize processes across multiple regions and business units.

With customer-centric approaches gaining prominence, warranty management systems are evolving beyond compliance to become strategic enablers of brand trust and competitive advantage As industries face increasing product complexity and rising customer expectations, the market is expected to expand steadily, with a strong focus on data-driven quality assurance and customer engagement.

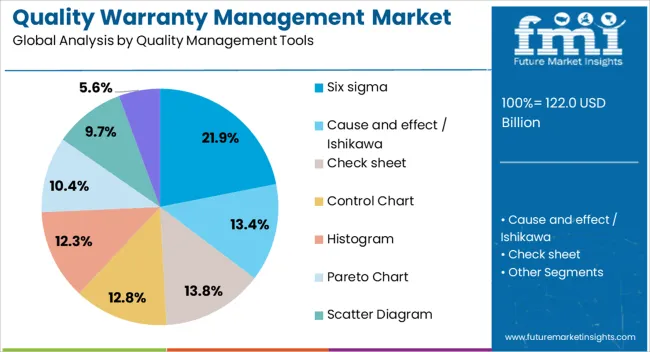

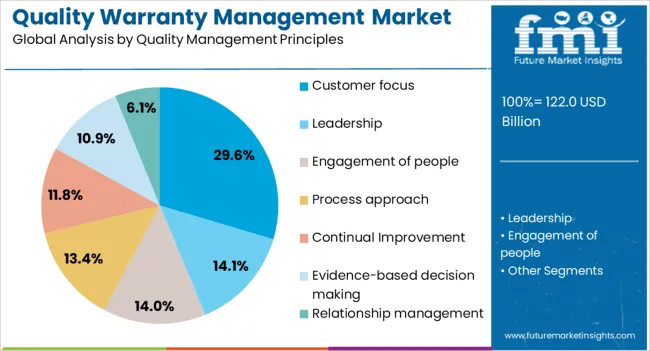

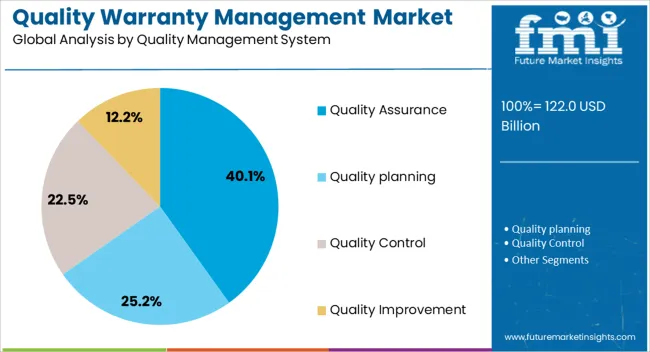

The quality warranty management market is segmented by quality management tools, quality management principles, quality management system, and geographic regions. By quality management tools, quality warranty management market is divided into Six sigma, Cause and effect / Ishikawa, Check sheet, Control Chart, Histogram, Pareto Chart, Scatter Diagram, and Stratification Diagram. In terms of quality management principles, quality warranty management market is classified into Customer focus, Leadership, Engagement of people, Process approach, Continual Improvement, Evidence-based decision making, and Relationship management. Based on quality management system, quality warranty management market is segmented into Quality Assurance, Quality planning, Quality Control, and Quality Improvement. Regionally, the quality warranty management industry is classified into North America, Latin America, Western Europe, Eastern Europe, Balkan & Baltic Countries, Russia & Belarus, Central Asia, East Asia, South Asia & Pacific, and the Middle East & Africa.

The six sigma subsegment is projected to account for 21.9% of the quality management tools category in the quality warranty management market revenue share in 2025, positioning it as the leading tool. Its dominance is being reinforced by its proven methodology in reducing process variation, improving efficiency, and driving defect-free outcomes across industries. Organizations continue to adopt six sigma frameworks to streamline production and service delivery, enabling cost reduction and enhancing customer satisfaction.

The structured approach to data-driven decision-making within six sigma provides measurable results that align with warranty reduction objectives. The scalability of six sigma tools across diverse functions such as manufacturing, supply chain, and service operations supports their widespread adoption.

Additionally, the integration of six sigma with digital platforms and analytics solutions is enabling faster identification of root causes and continuous process improvement As businesses focus on operational excellence and competitive differentiation, the six sigma framework is expected to remain a preferred tool, supporting sustained growth of this segment.

The customer focus subsegment is expected to represent 29.6% of the quality management principles category in the quality warranty management market revenue share in 2025, making it the most prominent principle. This leadership is being driven by the growing importance of customer-centric strategies that directly impact brand loyalty and long-term profitability. Organizations are prioritizing customer needs in product design, service delivery, and warranty management processes to strengthen their competitive positioning.

The principle of customer focus aligns closely with warranty management, as proactive engagement reduces claims, enhances satisfaction, and builds trust. Digital tools and feedback mechanisms are enabling real-time insights into customer expectations, allowing businesses to adapt faster to market changes.

Regulatory frameworks and industry certifications are also emphasizing customer-centric approaches, further reinforcing this principle’s adoption As companies expand globally, the ability to align products and services with evolving customer requirements is critical, ensuring that customer focus remains the cornerstone of quality management and a key driver of sustained growth in the market.

The quality assurance subsegment is anticipated to hold 40.1% of the quality management system category in the quality warranty management market revenue share in 2025, making it the dominant system. Its leadership is being explained by its central role in ensuring that processes, products, and services consistently meet predefined quality standards. Organizations are increasingly relying on quality assurance frameworks to prevent defects rather than simply detect them, thereby reducing warranty claims and associated costs.

This proactive approach aligns with the growing emphasis on operational efficiency and compliance with global quality regulations. The widespread implementation of quality assurance systems across manufacturing, healthcare, automotive, and consumer goods industries reflects their versatility and reliability.

Technological advancements such as AI-driven monitoring, automated inspections, and predictive analytics are further strengthening the role of quality assurance in warranty management As product complexity and regulatory requirements increase, businesses are prioritizing quality assurance systems to maintain consistency, enhance brand reputation, and drive customer trust, ensuring the continued dominance of this segment in the market.

Only when business marketers generate high-quality products rather than large quantities can they achieve success. It involves managing a product or service in the most effective way possible to consistently win over consumers and increase productivity for businesses and organizations. Therefore, key players deploy their specialist engineers at the supplier end of the supply chain, execute sample dock inspection and stock verification in the event of containment activities, diagnose the problem and contribute to rooting cause analysis, documentation, and team member training.

For issues with supplier quality, they also handle the right fulfilment of 8D papers and their real execution, which contributes to the quality warranty management market share. Inspection by a third party is always recommended since it is an objective technique to find defects before they become a problem.

The management of warranties from a quality perspective causes OEMs and Tier 1 suppliers a lot of trouble. Therefore, key players do a thorough examination of the warranty, trace it back to the suppliers and supplier processes, monitor remedial efforts using the 8D technique, and ultimately assist in lowering warranty claims. With a closed-loop digital system of record, key parties strive to assist the process and discrete manufacturers in meeting demanding industry and customer compliance.

Through in-line quality, transparent reporting, and straightforward audit monitoring, they guarantee predictable, repeatable quality delivery. Additionally, they adhere to the customer and industry laws with high-quality documentation that is instantly accessible digitally throughout the whole organization. These factors support the expansion of the global quality warranty management market size. Drive new and recurring business development, in addition, by performing on-time deliveries, enhancing supplier management, and raising customer satisfaction.

By integrating quality management into workflows and procedures, one can decrease quality loss, and the chance of warranty claims or product recalls while enhancing customer relations and brand reputation. The organization may access and exchange quality requirements and documents in real-time, owing to key participants. Additionally, they aid in the creation of process control plans that include thorough inspection instructions and digital check sheets that are directly linked to product standards, which drives the demand for quality warranty management. End users may keep an up-to-date list of compliance needs by managing and tracking documents like engineering and material specifications or recipes. And throughout processes, regulatory compliance (APQP, FSA, HACCP, FSMA, SQF) is simply enabled. OEMs rely on the dealer network to implement warranty schemes and account for work carried out.

A well-functioning warranty process can turn a warranty event into a business opportunity. By investigating expenditure, overspending can be avoided, processes can be streamlined, and customers' brand perceptions can be protected from damage. As a result, end users can improve control of dealer warranty invoicing processes through pre-payment approvals or post-payment audits or screening. Hence, global quality warranty management is likely to augment. Services offered by key players cover the entire automotive warranty control chain, such as warranty process, consulting and training, pre-authorization support, post-payment claim screening, consultative warranty reviews, and formalized warranty audits. In a similar manner, running and maintaining wind farms is expensive.

Any flaws that arise during the defined warranty term must be remedied by the manufacturer to guarantee wind turbines operate economically for as long as feasible. Key players are also implementing cutting-edge technology to simplify quality warranty administration. AI, for instance, is seen to have the greatest potential to change quality systems and move from reactive to proactive quality. Thus, by recommending categories, hazards, and reportability, as well as connecting complaints and other quality events, AI may be used to support decision-making. This is expected to skyrocket the adoption of quality warranty management. By identifying crucial component failures as soon as feasible so that warranty claims may be made, their end-of-warranty inspection services contribute to cost reduction. All these factors are anticipated to surge service demand and expand the global quality warranty management market size.

A happy customer to a greater extent leads more people to buy any item which has excellent quality. Increased quality concern issues, easy handling of complex processes, strict regulations of ISO, FDA, improved product quality, reduction in cost, increased customer satisfaction, defect reduction, increased market image drives the quality management market.

Initial introduction costs i.e training people with new changes in process can sometimes restraint the market for quality management market to grow.

The global quality management market can be divided into seven regions, namely North America, Latin America, Western Europe, Eastern Europe, Asia Pacific, Japan and Middle East and Africa.

North America, Japan and Europe stands apart in quality management market due to adoption of advanced quality tools and methodologies with high standard of living. Asia Pacific and Middle East are expected to grow eventually higher in forecast period as they emerging at a fast pace.

The report is a compilation of first-hand information, qualitative and quantitative assessment by industry analysts, inputs from industry experts and industry participants across the value chain. The report provides in-depth analysis of parent market trends, macro-economic indicators and governing factors along with market attractiveness as per segments. The report also maps the qualitative impact of various market factors on market segments and geographies.

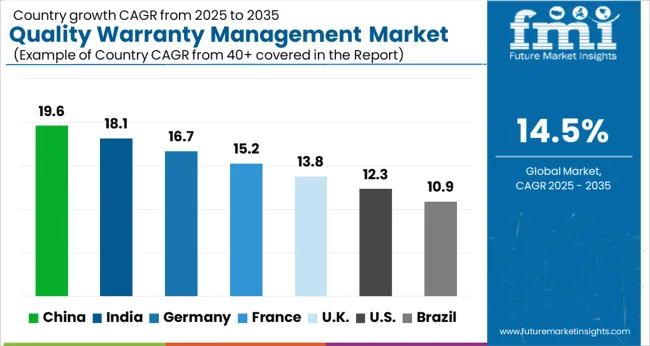

| Country | CAGR |

|---|---|

| China | 19.6% |

| India | 18.1% |

| Germany | 16.7% |

| France | 15.2% |

| UK | 13.8% |

| USA | 12.3% |

| Brazil | 10.9% |

The Quality Warranty Management Market is expected to register a CAGR of 14.5% during the forecast period, exhibiting varied country level momentum. China leads with the highest CAGR of 19.6%, followed by India at 18.1%. Developed markets such as Germany, France, and the UK continue to expand steadily, while the USA is likely to grow at consistent rates. Brazil posts the lowest CAGR at 10.9%, yet still underscores a broadly positive trajectory for the global Quality Warranty Management Market. In 2024, Germany held a dominant revenue in the Western Europe market and is expected to grow with a CAGR of 16.7%. The USA Quality Warranty Management Market is estimated to be valued at USD 44.6 billion in 2025 and is anticipated to reach a valuation of USD 142.5 billion by 2035. Sales are projected to rise at a CAGR of 12.3% over the forecast period between 2025 and 2035. While Japan and South Korea markets are estimated to be valued at USD 5.7 billion and USD 4.2 billion respectively in 2025.

| Item | Value |

|---|---|

| Quantitative Units | USD 122.0 Billion |

| Quality Management Tools | Six sigma, Cause and effect / Ishikawa, Check sheet, Control Chart, Histogram, Pareto Chart, Scatter Diagram, and Stratification Diagram |

| Quality Management Principles | Customer focus, Leadership, Engagement of people, Process approach, Continual Improvement, Evidence-based decision making, and Relationship management |

| Quality Management System | Quality Assurance, Quality planning, Quality Control, and Quality Improvement |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, Middle East & Africa |

| Country Covered | United States, Canada, Germany, France, United Kingdom, China, Japan, India, Brazil, South Africa |

| Key Companies Profiled | IBM Corporation, SAP, IFS, Tavant, Mize, Pegasystems Inc., PTC, Wipro Limited, Oracle Corporation, and Salesforce |

The global quality warranty management market is estimated to be valued at USD 122.0 billion in 2025.

The market size for the quality warranty management market is projected to reach USD 472.6 billion by 2035.

The quality warranty management market is expected to grow at a 14.5% CAGR between 2025 and 2035.

The key product types in quality warranty management market are six sigma, cause and effect / ishikawa, check sheet, control chart, histogram, pareto chart, scatter diagram and stratification diagram.

In terms of quality management principles, customer focus segment to command 29.6% share in the quality warranty management market in 2025.

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Quality Process Management Application Market Size and Share Forecast Outlook 2025 to 2035

Quality and Compliance Management Solution Market Forecast and Outlook 2025 to 2035

Air Quality Monitoring System Market Size and Share Forecast Outlook 2025 to 2035

Air Quality Monitoring Equipment Market Growth - Trends & Forecast 2025 to 2035

Air Quality Monitoring Software Market

Power Quality Equipment Market Size and Share Forecast Outlook 2025 to 2035

Power Quality Meter Market Size and Share Forecast Outlook 2025 to 2035

Water Quality Testing Equipment Market Growth – Trends & Forecast 2018-2027

Inline Quality Control Sensors Market

HVAC Air Quality Monitoring Market Size and Share Forecast Outlook 2025 to 2035

Analyzing Supplier Quality Management Applications Market Share

Supplier Quality Management Applications Market Outlook 2025 to 2035

Molecular Quality Controls Market Overview - Trends & Forecast 2025 to 2035

Indoor Air Quality Monitor Market Size and Share Forecast Outlook 2025 to 2035

Predictive Quality Assurance Equipment Market Size and Share Forecast Outlook 2025 to 2035

Rugged Air Quality Monitors Market Insights - Growth & Forecast 2025 to 2035

UK Supplier Quality Management Applications Market Analysis – Demand, Trends & Forecast 2025-2035

USA Supplier Quality Management Applications Market Insights – Trends, Demand & Growth 2025-2035

Portable Power Quality Meter Market Size and Share Forecast Outlook 2025 to 2035

Energy & Power Quality Meters Market Growth - Trends & Forecast through 2034

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA