This is largely due to the demand for sterilization solution for the healthcare and pharmaceutical and lab industry, globally the autoclaving trays market, is set to observe significant expansion in the period between 2025 and 2035. The individual method of sterilization is autoclaving, and trays are used in this operation; this method that promotes sterilization is widely adopted across multiple sectors as a necessity to create effective infection control and achieve regulatory compliance.

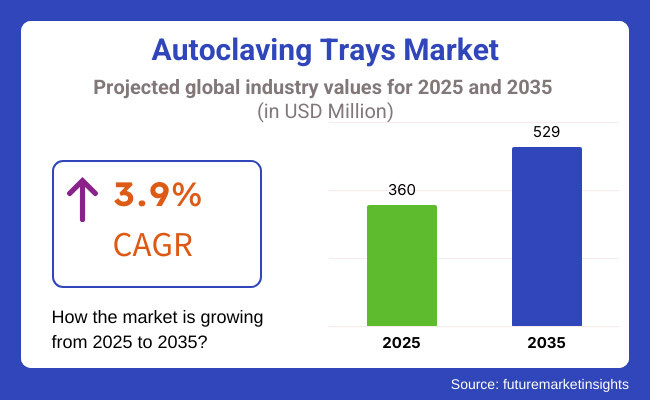

The forecast period is expected to be 3.9% CAGR growth until 2035, resulting in projected revenue of approximately USD 529 Million by the end of 2035 and is further expected to reach USD 360 Million in 2025. The increase in these industries was driven by factors such as the rising cost of healthcare, tighter sterilization regulations and advances in autoclaving materials such as heat-resistant plastic and steel.

The North America autoclaving trays market is projected to have a considerable share on the account of strict infection control regulations, rapid adoption of advanced sterilization techniques and an advanced healthcare infrastructure in this region. The USA remains a driving innovator, and hospitals, and research and pharmaceutical establishments, seek durable, efficient, and effective autoclaving solutions.

A key market is Europe, with strong healthcare policies, an increasing spending on medical device sterilization, and a focus on regulatory compliance contributing to this. Advanced autoclaving trays with structure corrosion and chemical attack resistance are being pioneered by countries inclusive of Germany, France, and the UK.

The Asia-Pacific region is anticipated to grow at the highest rate, driven by an advancing healthcare industry, growing awareness towards infection control, and increasing expenditures as medical research. China, India, and Japan are rapidly purchasing autoclaving trays for use in hospitals, clinics, and research laboratories.

Regional analysis of the autoclaving trays market includes Latin America, the Middle East & Africa. Market growth in these areas is also being fuelled by rising governmental and healthcare institution investment in infection control measures.

Challenge

High Manufacturing Costs and Material Constraints

High manufacturing cost along with the availability of suitable materials is some of the challenges of Autoclaving Trays Market. Manufacturers need to use advanced materials such as high-grade stainless steel or advanced polymers that can sustain repeated sterilization cycles to manufacture high-quality, durable trays, driving up production costs.

Regulatory and Compliance Challenges

Medical and lab trays for use in the autoclaving need to be of a specific regulatory standard to comply with sterility and safety. Each region you sell in may have its own compliance requirements, which can be tedious and tedious and cumbersome for manufacturers trying to break into new territories.

Opportunity

Advancements in Material Innovation

Development of new heat-resistant and antimicrobial materials are opportunities for the growth of the market. High durability polymer trays have been developed to be lightweight and durable, and new coatings for metal trays are also available to improve longevity and lower the overall cost of your trays.

Expansion of Healthcare and Laboratory Applications

The autoclaving trays market is witnessing growth and is expected to grow owing to the increasing need for sterilization solutions in hospitals, research laboratories, pharmaceutical industries, etc. As hospitals and clinics focus on infection control, the demand for effective and dependable sterilization trays is on the r

The Autoclaving Trays Market has grown steadily from 2020 to 2024, driven by the increasing awareness of infection control measures, the need for stringent sterilization protocols, and the expanding healthcare infrastructure across regions.

Manufacturers are highly focused on improving durability of tray and compliance with regulatory standards. However, higher costs and supply chain disruption affected the market. The response of companies has been to invest in innovation in materials and optimize production processes.

With the progress of antimicrobial coatings, sustainability in material, intelligent insight of sterilization tracing, the market is going to transform too heavily between the years 2025 and 2035. Digital integration like RFID-enabled trays for tracking sterilization cycles will improve both efficiency and compliance maintenance. The move towards tray materials that are sustainable and recyclable will also be in line with latest global environmental agendas.

Market Shifts: A Comparative Analysis 2020 to 2024 vs. 2025 to 2035

| Market Shift | 2020 to 2024 Trends |

|---|---|

| Regulatory Landscape | Strict adherence to sterilization norms and medical device regulations |

| Material Innovation | Heat-resistant polymers and coated metal trays development |

| Industry Adoption | Use in hospitals, research labs and pharmaceutical companies |

| Supply Chain and Distribution | Reliance on legacy manufacturing and supply chains |

| Market Competition | Presence of well-established vendors and increasing competition from vendors |

| Market Growth Drivers | Increased demand for infection control solutions, growing investments in healthcare |

| Sustainability and Energy Efficiency | Initial emphasis on durability and reusable designs |

| Integration of Digital Technologies | Limited adoption of tracking and monitoring tools |

| Future of Sterilization Equipment | Traditional sterilization trays and manual tracking |

| Market Shift | 2025 to 2035 Projections |

|---|---|

| Regulatory Landscape | Enhanced global standardization and digital compliance tracking |

| Material Innovation | Adoption of antimicrobial, lightweight, and eco-friendly materials |

| Industry Adoption | Expansion into biotech, veterinary, and food processing industries |

| Supply Chain and Distribution | Growth of localized production, automated manufacturing, and 3D printing technologies |

| Market Competition | Rise of customized and niche product offerings, along with AI-driven quality control |

| Market Growth Drivers | Technological advancements in sterilization, sustainability initiatives, and digital integration |

| Sustainability and Energy Efficiency | Large-scale adoption of recyclable, biodegradable, and energy-efficient sterilization solutions |

| Integration of Digital Technologies | Expansion of RFID-enabled trays, AI-driven sterilization tracking, and IoT-based inventory management |

| Future of Sterilization Equipment | Development of smart sterilization solutions, automated compliance monitoring, and predictive maintenance |

North America North America autoclaving trays market is growing at a faster pace due to increase in need for dependable sterilization in healthcare industries, high sterilization regulations, and improvement in medical trays materials. The need for infection control pushes the market growth towards optimal.

| Region | CAGR (2025 to 2035) |

|---|---|

| United States | 4.1% |

UK market is seeing wide acceptance of sterilization protocols by more hospitals, laboratories and pharmaceutical sector. Government interventions to encourage hygiene and safety in medical environments are predominantly driving the growth of the market.

| Region | CAGR (2025 to 2035) |

|---|---|

| United Kingdom | 3.7% |

the autoclaving trays in Tods demand in the European Union is gradually expanding as a result of the stringent application of healthcare norms, and developing interest in sterilization created infrastructure, and incremental advancement in medical research establishments.

| Region | CAGR (2025 to 2035) |

|---|---|

| European Union | 3.8% |

South Korea autoclaving trays market is witnessing growth due to rapid developments in the healthcare infrastructure, high preference for advanced sterilization equipment and increased awareness regarding hospital-acquired infections.

| Region | CAGR (2025 to 2035) |

|---|---|

| South Korea | 4.0% |

The global demand for autoclaving trays is anticipated to grow at a healthy rate owing to an increasing requirement for sterilized equipment and tools across medical, pharmaceutical, and laboratory sectors along with continuous advancements in tray material and designs.

Global CAGR (2025 to 2035): 3.9%

Furthermore, the sterilization and infection control awareness is increasing among the medical and laboratory professionals, which is expected to drive the growth of Autoclaving Trays market in the coming years.

Autoclaved trays (possessing high temperature and steam pressure resistance) are of the utmost importance for maintaining the sterility of surgical instruments, laboratory utensils and medical equipment. These trays are standard in hospitals, clinics, labs, surgical centers, and even ambulances, helping maintain sanitation and safety.

Rising prevalence of hospital-acquired infections (HAIs) and increasing demand for sterility will fuel the demand for these trays. That is why the entire global healthcare industry is shying away from improper sterilization processes in order to prevent contamination and protect patients.

Improvements in tray design, along with new materials like corrosion-cutting stainless steel and heat-stable plastics, also contribute to greater durability and efficiency in autoclave operations. In addition, Growth of global health/autoclaving trays hotels market is expected to witness high growth in the future owing to increased investment in healthcare infrastructure, laboratory research, and medical technology all over the world.

In addition, climate change is becoming a more pressing issue for the pharmaceutical market as producers seek out eco-friendly and reusable tray options that lessen medical waste and manifest a commitment to environmental stewardship.

Based on product type, plastic trays are the main type of trays in the market owing to their light weight, economic value, and durability. Sold throughout the medical community for efficient sterilization of instruments. Due to their chemical resistance, ease of use, and low price, they are the material we encounter in almost every healthcare rig.

Finally, recent progress in manufactures of plastic, including high-temperature- resistant polymers, have also enhanced their fitness for multiple autoclaving cycles. Similarly, such trays come in similar sizes and designs, to suit the sterilization requirements in different types of hospitals, laboratories, and surgical centers.

Factors like an upsurge in infection control and the widespread use of disposable medical supplies are fueling the growth in the market for plastic autoclaving trays over the years. Even with manufacturers turning towards biodegradable and recyclable plastics to cater to environmental regulations and meet the requirements of minimizing medical waste in healthcare businesses, the healthcare world is getting more attention to sustainability.

Stainless steel trays are also getting popularity because of its high strength, reuse, and excellent corrosion resistance. Specifically, these trays enjoy wide use in controlled environments, such as high-precision surgical procedures and lab environments where sterility is key. Hygiene: They are non-porous and do not harbour bacteria, making them a sensible source of hygiene.

Stainless steel trays also resist degradation from repeated high-temperature autoclaving, providing increased longevity and cost-effectiveness. These reusable Steris trays are a strong investment for a healthcare facility that requires frequent and consistent sterilization. The trays are becoming a staple in advanced medical facilities and research institutions that require longevity and contamination prevention.

Based on application, the largest segment of the autoclaving trays market is expected from hospitals and laboratories that demand stringent sterilization practices to avoid infections and contamination. Increase in surgical, diagnostic tests, and research activities need reliable sterilization solutions, driving the market for autoclaving trays.

Hospitals use them to keep surgical instruments sterile and patient safe; labs use them to keep research free from contamination. Ongoing growth of healthcare facilities, increasing health care spending around the world, and technological developments in sterilization processes are also supplementing the growth of the market.

Furthermore, the increasing approach towards infection control practices and implementation of stringent healthcare regulations globally is expected to drive the growth. There is also an emerging role for sustainability, with a growing emphasis on durable reusable and environmentally-friendly sterilization solutions.

So, to sum it all up, for many industries and businesses, autoclaving will continue to play a vital role in maintaining high standards of hygiene; and, autoclaving trays, an even more significant one.

The autoclaving trays market is experiencing steady growth due to increasing demand for sterile medical equipment, advancements in healthcare infrastructure, and the rising adoption of infection control measures. Key drivers include innovations in heat-resistant materials, the growing need for surgical instrument sterilization, and regulatory compliance in healthcare and laboratory settings.

Market Share Analysis by Key Players & Manufacturers

| Company/Organization Name | Estimated Market Share (%) |

|---|---|

| Thermo Fisher Scientific | 20-25% |

| Medline Industries | 15-20% |

| Bel-Art (SP Science ware) | 12-16% |

| Aesculap (B. Braun) | 8-12% |

| Aseptico | 5-9% |

| Other Manufacturers | 30-40% |

| Company/Organization Name | Key Offerings/Activities |

|---|---|

| Thermo Fisher Scientific | High-quality, autoclavable trays designed for laboratory and clinical sterilization applications. |

| Medline Industries | Durable and reusable autoclaving trays for medical and surgical instrument sterilization. |

| Bel-Art (SP Scienceware) | Autoclaving trays made from heat-resistant polymers and designed for laboratory use. |

| Aesculap (B. Braun) | Stainless steel sterilization trays with advanced protection for surgical tools. |

| Aseptico | Custom-designed autoclave trays for dental and surgical sterilization procedures. |

Key Market Insights

Thermo Fisher Scientific (20-25%)

Thermo Fisher's high-end autoclaving trays--which can withstand high temperature and are compatible for lab use--keep them ahead in the market.

Medline Industries (15-20%)

These autoclavable trays are HO of min. Autoclavable Trays (available for sterile industries) when these are In contact with medical instruments, they ensure contents are cleaned effectively.

Bel-Art (SP Scienceware) (12-16%)

Bel-Art offers trays that are autoclavable and made of polymers for your laboratory and research needs.

Aesculap (B. Braun) (8-12%)

Sterilization Trays from Aesculap are made of high-grade stainless steel and designed to autoclave surgical instruments.

Aseptico (5-9%)

Aseptico offers specialized autoclave trays for sterilization of dental and medical instruments.

Other Key Players (30-40% Combined)

The autoclaving trays market is witnessing a surge as various manufacturers and suppliers contribute towards the increasing availability of autoclaving trays such as:

The overall market size for Autoclaving Trays Market was USD 360 Million in 2025.

The Autoclaving Trays Market is expected to reach USD 529 Million in 2035.

The demand for the Autoclaving Trays Market will grow due to the rising emphasis on infection control and sterilization across healthcare facilities. Plastic trays are gaining popularity for their cost-effectiveness and disposability, while stainless steel trays are preferred for durability and repeated use. Hospitals, surgical centers, and laboratories will drive demand, fueled by increasing surgical procedures and R&D activities. Clinics and ambulances will also contribute due to expanding mobile healthcare services. Additionally, innovations in materials and strict sterilization regulations will further propel market growth during the forecast period.

The top 5 countries which drives the development of Autoclaving Trays Market are USA, European Union, Japan, South Korea and UK.

Plastics Trays demand supplier to command significant share over the assessment period.

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

ESD Trays Market Size and Share Forecast Outlook 2025 to 2035

Lab Trays Market Size and Share Forecast Outlook 2025 to 2035

Meat Trays Market Analysis - Size and Share Forecast Outlook 2025 to 2035

Key Companies & Market Share in the Food Trays Sector

CPET Trays Market

Sieve Trays Market Size and Share Forecast Outlook 2025 to 2035

Pharma Trays Market Size, Share & Forecast 2025 to 2035

Correx Trays Market

Insert Trays Market

Syringe Trays Market

PET Food Trays Market Size and Share Forecast Outlook 2025 to 2035

Assembly Trays Market Size and Share Forecast Outlook 2025 to 2035

Market Share Breakdown of Assembly Trays Manufacturers

Bakeable Trays Market

Cardboard Trays Market Size, Share & Forecast 2025 to 2035

Fibreglass Trays Market Size and Share Forecast Outlook 2025 to 2035

Dispensing Trays Market Size, Share & Forecast 2025 to 2035

Trach Care Trays Market

Key Companies & Market Share in the Containment Trays Sector

Compartment Trays Market

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA