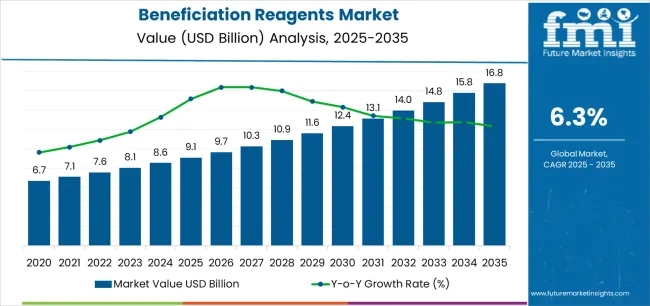

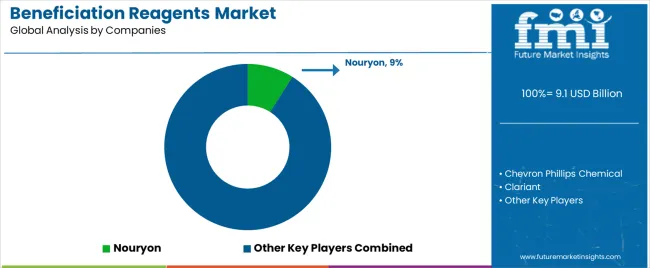

The beneficiation reagents market enters a decade of measured expansion that will transform mineral processing and extraction capabilities across mining operations, ore processing facilities, and metallurgical applications. The market's progression from USD 9.1 billion in 2025 to USD 16.8 billion by 2035 represents controlled growth, reflecting the accelerated adoption of flotation technologies and mineral separation advancement across mining projects, processing operations, and industrial applications worldwide.

The first half of the decade (2025-2030) will witness the market climbing from USD 9.1 billion to approximately USD 12.3 billion, adding USD 3.2 billion in value, which constitutes 47% of the total forecast growth period. This phase will be characterized by the continued adoption of advanced flotation systems over conventional separation methods, driven by increasing ore complexity and the growing need for efficient extraction solutions in mining and processing applications globally. Enhanced reagent formulation capabilities and automated dosing systems will become standard expectations rather than premium options.

The latter half (2030-2035) will witness continued growth from USD 12.3 billion to USD 16.7 billion, representing an addition of USD 4.4 billion or 53% of the decade's expansion. This period will be defined by mass market penetration of specialized collector formulations, integration with comprehensive process control platforms, and seamless compatibility with existing mineral processing infrastructure. The market trajectory signals fundamental shifts in how mining operators approach mineral separation and recovery operations, with participants positioned to benefit from growing demand across multiple application segments and product categories.

Beneficiation reagent operations encompass sophisticated chemical formulation systems coordinating collector, frother, and modifier applications across diverse mineral separation and flotation processes. Xanthate collectors provide enhanced mineral selectivity through chemical bonding mechanisms enabling precise separation of valuable minerals from gangue materials. Concentration ranges typically vary from 10 to 500 grams per ton of ore processed, offering efficient performance across different mineral compositions and processing conditions.

Non-ferrous metal applications drive primary reagent demand through requirements for copper, zinc, lead, and nickel extraction from complex ore bodies requiring selective flotation processes. Multi-stage flotation systems utilize sequential reagent additions to achieve progressive mineral concentration while maintaining separation efficiency. Advanced collector formulations enable differential flotation of similar minerals through pH control and surface chemistry modification.

Ferrous metal applications include iron ore beneficiation, where reverse flotation removes silicate impurities while concentrating iron-bearing minerals. Phosphate and potash mining operations require specialized collector formulations to separate valuable minerals from clay and carbonate contaminants. Industrial mineral processing encompasses talc, fluorite, and barite separation requiring tailored reagent programs for optimal grade and recovery performance.

| Period | Primary Revenue Buckets | Share | Notes |

|---|---|---|---|

| Today | Xanthate formulations | 35% | Collector-driven, selective flotation |

| Dithiophosphate applications | 25% | Secondary collectors, complex ores | |

| Frother systems | 20% | Foam stability, process optimization | |

| Other specialty reagents | 20% | Custom formulations, niche applications | |

| Non-ferrous metal processing | 40% | Primary application segment | |

| Ferrous metal processing | 35% | Secondary application segment | |

| Future (3-5 yrs) | Advanced xanthate systems | 38-42% | Formulation enhancement, selectivity gains |

| Enhanced dithiophosphate solutions | 22-28% | Process optimization, application expansion | |

| Integrated frother platforms | 18-22% | Stability improvement, efficiency gains | |

| Specialized reagent formulations | 15-20% | Custom applications, process innovation | |

| Expanded non-ferrous systems | 42-48% | Market expansion, technology integration | |

| Optimized ferrous platforms | 32-38% | Process improvement, efficiency enhancement | |

| Digital monitoring systems | 3-5% | IoT integration, process optimization |

| Metric | Value |

|---|---|

| Market Value (2025) | USD 9.1 billion |

| Market Forecast (2035) | USD 16.7 billion |

| Growth Rate | 6.3% CAGR |

| Leading Product | Xanthate Segment |

| Primary Application | Non-ferrous Metals |

The market demonstrates strong fundamentals with xanthate formulations capturing a dominant share through reliable flotation capabilities and separation optimization. Non-ferrous metal applications drive primary demand, supported by increasing ore complexity and operational efficiency development. Geographic expansion remains concentrated in developed mining regions with established processing infrastructure, while emerging economies show accelerating adoption rates driven by mining modernization initiatives and rising mineral processing standards.

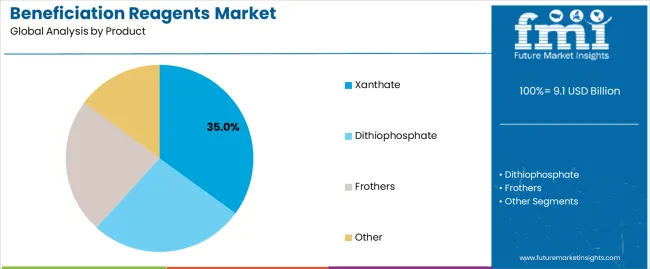

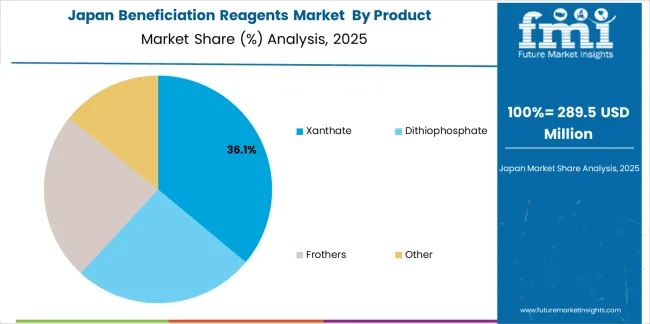

Primary Classification: The market segments by product into xanthate (35%), dithiophosphate (25%), frothers (20%), and others (20%), representing the evolution from basic flotation methods to specialized reagent solutions for comprehensive mineral processing optimization.

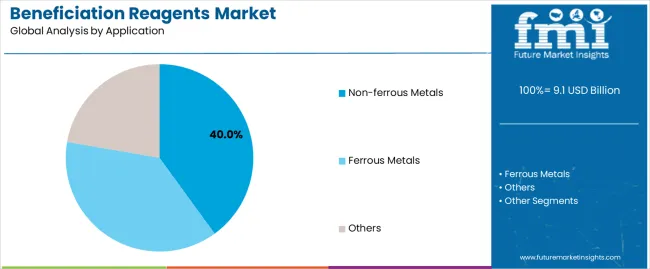

Secondary Classification: Application segmentation divides the market into non-ferrous metals (40%) and ferrous metals (35%) and others (25%) systems, reflecting distinct requirements for processing efficiency, mineral selectivity, and flotation performance standards.

The segmentation structure reveals technology progression from standard flotation methods toward specialized reagent applications with enhanced separation consistency and performance capabilities, while application diversity spans from copper-lead-zinc processing to iron ore beneficiation requiring precise chemical solutions.

Market Position: Xanthate collectors command the leading position in the beneficiation reagents market with 35% market share through advanced flotation features, including superior selectivity characteristics, operational efficiency, and separation optimization that enable mining operators to achieve optimal recovery across diverse mineral processing applications.

Value Drivers: The segment benefits from operator preference for reliable collector systems that provide consistent separation characteristics, reduced process complexity, and operational efficiency optimization without requiring significant infrastructure modifications. Advanced chemical features enable automated dosing systems, performance monitoring, and integration with existing flotation equipment, where operational performance and recovery optimization represent critical operator requirements.

Competitive Advantages: Xanthate collectors differentiate through proven operational reliability, consistent separation characteristics, and integration with automated process control systems that enhance flotation effectiveness while maintaining optimal recovery standards for diverse mineral processing applications.

Key market characteristics:

Dithiophosphate collectors maintain a 25% market position in the beneficiation reagents market due to their enhanced selectivity properties and complex ore application characteristics. These systems appeal to operations requiring specialized performance with premium positioning for challenging separation applications. Market growth is driven by complex ore segment expansion, emphasizing selective flotation solutions and operational efficiency through optimized chemical designs.

Frother applications capture 20% market share through comprehensive foam stability requirements in flotation operations, process optimization, and mineral processing applications requiring reliable foam systems capable of operating with various collector formulations while providing effective process stability and performance capabilities.

Market Context: Non-ferrous metal applications demonstrate market leadership in the beneficiation reagents market with 40% share due to widespread adoption of flotation processing systems and increasing focus on operational cost efficiency, mineral processing optimization, and applications that maximize recovery while maintaining grade standards.

Appeal Factors: Mining operators prioritize processing consistency, operational efficiency, and integration with existing mineral processing infrastructure that enables coordinated flotation operations across multiple ore types. The segment benefits from substantial processing investment and modernization programs that emphasize the acquisition of advanced reagent systems for recovery optimization and processing efficiency applications.

Growth Drivers: Mining facility expansion programs incorporate advanced reagent systems as standard processing equipment for flotation operations, while ore complexity growth increases demand for consistent separation capabilities that comply with recovery standards and minimize processing complexity.

Application dynamics include:

Ferrous metal applications capture 35% market share through comprehensive processing requirements in iron ore beneficiation, steel industry feed preparation, and mineral processing operations. These operations demand reliable reagent systems capable of handling large-scale processing while providing effective separation management and operational performance capabilities.

Other applications account for 25% market share, including phosphate processing, industrial minerals, and specialized flotation requirements for operational optimization and mineral accessibility.

| Category | Factor | Impact | Why It Matters |

|---|---|---|---|

| Driver | Mining industry expansion & ore complexity growth (processing requirements, grade optimization) | ★★★★★ | Large-scale mining operations require efficient, reliable separation solutions with consistent performance and recovery optimization across flotation applications. |

| Driver | Technology advancement & process automation (flotation efficiency, automated dosing) | ★★★★★ | Drives demand for intelligent reagent solutions and high-performance separation capabilities; suppliers providing automated systems gain competitive advantage. |

| Driver | Environmental compliance & process optimization (waste reduction, recovery improvement) | ★★★★☆ | Mining operations need compliant processing solutions; demand for efficient formulations expanding addressable market segments. |

| Restraint | Raw material costs & supply chain complexity (chemical availability, price volatility) | ★★★★☆ | Small mining operations face cost pressure; increases price sensitivity and affects reagent availability in cost-sensitive markets. |

| Restraint | Alternative processing competition & technology substitution | ★★★☆☆ | Cost-focused applications face challenges with technology selection and processing requirements, limiting adoption in price-sensitive segments. |

| Trend | Digital process monitoring & smart flotation (connected processing systems) | ★★★★★ | Growing demand for intelligent processing solutions; digital integration becomes core value proposition in advanced mining segments. |

| Trend | Asian market expansion & regional mining growth | ★★★★☆ | Regional processing development drives demand for localized reagent solutions; regional capabilities drive competition toward localization. |

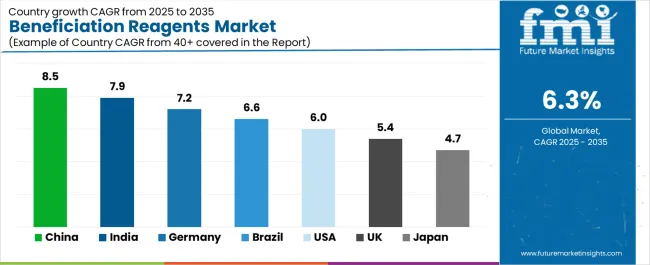

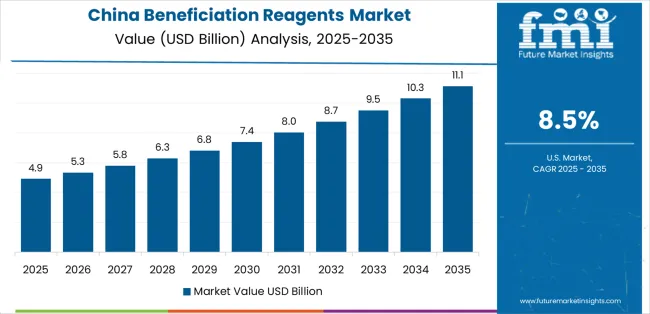

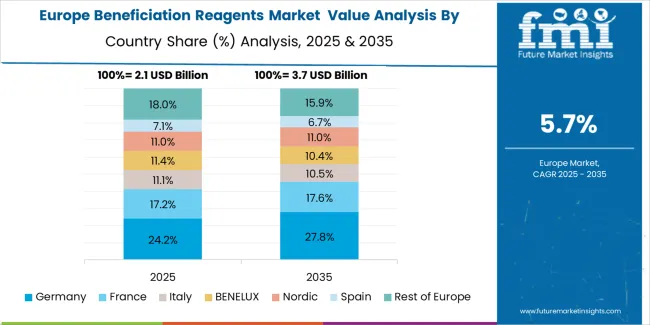

The beneficiation reagents market demonstrates varied regional dynamics with growth leaders including China (8.5% growth rate) and India (7.9% growth rate) driving expansion through mining initiatives and mineral processing capacity development. Steady Performers encompass Germany (7.2% growth rate), Brazil (6.6% growth rate), and USA (6.0% growth rate), benefiting from established mining industries and advanced processing adoption. Mature Markets feature UK (5.4% growth rate) and Japan (4.7% growth rate), where processing technology advancement and environmental requirements support consistent growth patterns.

Regional synthesis reveals East Asian and South Asian markets leading adoption through mining expansion and processing development, while Western countries maintain steady expansion supported by technology advancement and regulatory requirements. Emerging markets show strong growth driven by mining applications and facility modernization trends.

| Region/Country | 2025-2035 Growth | How to win | What to watch out |

|---|---|---|---|

| China | 8.5% | Lead with high-volume processing systems | Environmental regulations; processing complexity |

| India | 7.9% | Focus on cost-effective reagent solutions | Infrastructure challenges; supply availability |

| Germany | 7.2% | Premium quality positioning | Over-specification; regulatory compliance |

| Brazil | 6.6% | Provide comprehensive mining solutions | Economic stability; processing requirements |

| USA | 6.0% | Offer regulatory-compliant applications | Environmental regulations; technology requirements |

| UK | 5.4% | Premium efficiency positioning | Market maturity; processing costs |

| Japan | 4.7% | Premium technology positioning | Technology precision; market maturity |

China establishes fastest market growth through aggressive mining programs and comprehensive mineral processing capacity development, integrating advanced beneficiation reagents as standard components in copper, iron ore, and rare earth processing facilities. The country's 8.5% growth rate reflects government initiatives promoting mining modernization and processing development capabilities that mandate the use of efficient separation systems in mineral processing facilities. Growth concentrates in major mining regions, including Shanxi, Inner Mongolia, and Sichuan, where processing technology development showcases integrated reagent systems that appeal to operators seeking advanced separation optimization capabilities and operational mining applications.

Chinese reagent manufacturers are developing cost-effective chemical solutions that combine domestic production advantages with advanced formulation features, including automated supply systems and enhanced performance capabilities. Distribution channels through mining suppliers and processing service distributors expand market access, while government support for mining development supports adoption across diverse operator segments.

Strategic Market Indicators:

In Rajasthan, Odisha, and Chhattisgarh states, mining facilities and processing operations are implementing advanced beneficiation reagents as standard chemicals for facility optimization and operational processing enhancement, driven by increasing government mining investment and mineral processing modernization programs that emphasize the importance of separation capabilities. The market holds a 7.9% growth rate, supported by government mining initiatives and processing infrastructure development programs that promote advanced reagent systems for mining facilities.

Indian operators are adopting chemical systems that provide consistent operational performance and environmental compliance features, appealing in mining regions where facility efficiency and processing standards represent critical operational requirements. Market expansion benefits from growing mineral processing capabilities and technology integration agreements that enable domestic production of advanced reagent systems for mining applications.

Germany's advanced mining technology market demonstrates sophisticated reagent integration with documented operational effectiveness in premium processing applications and modern facility installations through integration with existing quality systems and mining infrastructure. The country maintains a 7.2% growth rate, leveraging traditional chemical expertise and precision systems integration in reagent technology. Mining centers, including North Rhine-Westphalia, Bavaria, and Lower Saxony, showcase premium installations where reagent systems integrate with traditional quality platforms and modern facility management systems to optimize processing operations and maintain mining quality profiles.

German chemical companies prioritize reagent precision and quality consistency in flotation development, creating demand for premium systems with advanced features, including performance monitoring and automated chemical systems. The market benefits from established chemical infrastructure and commitment to mining standards that provide long-term operational benefits and compliance with traditional quality processing methods.

Brazil establishes comprehensive mining development through extensive mineral processing programs and established mining infrastructure, integrating beneficiation reagents across iron ore facilities and base metal processing applications. The country's 6.6% growth rate reflects mature mining industry relationships and established chemical adoption that supports widespread use of reagent systems in processing facilities and mining-compliant operations. Growth concentrates in major mining regions, including Minas Gerais, Pará, and Goiás, where mining technology showcases mature chemical deployment that appeals to operators seeking proven processing capabilities and operational efficiency applications.

Brazilian mining companies leverage established supply networks and comprehensive technical capabilities, including formulation programs and technical support that create customer relationships and operational advantages. The market benefits from mature mining standards and environmental requirements that support reagent system use while supporting technology advancement and operational optimization.

USA establishes regulatory-compliant market development through comprehensive mining programs and established environmental infrastructure, integrating beneficiation reagents across copper, gold, and iron ore processing applications. The country's 6.0% growth rate reflects mature mining industry relationships and established chemical adoption that supports widespread use of reagent systems in processing facilities and environmentally-compliant operations. Growth concentrates in major mining centers, including Nevada, Arizona, and Montana, where mining technology showcases mature reagent deployment that appeals to operators seeking proven environmental capabilities and operational efficiency applications.

American chemical companies leverage established distribution networks and comprehensive regulatory capabilities, including compliance programs and technical support that create customer relationships and operational advantages. The market benefits from mature environmental standards and EPA requirements that support reagent system use while supporting technology advancement and operational optimization.

UK establishes premium efficiency development through advanced mining programs and established processing infrastructure, integrating beneficiation reagent systems across mineral processing facilities and specialty applications. The country's 5.4% growth rate reflects established mining industry relationships and advanced chemical adoption that supports widespread use of reagent systems in processing facilities and efficiency-oriented operations. Growth concentrates in processing centers, including Scotland, Wales, and Northern England, where mining technology showcases mature chemical deployment that appeals to operators seeking proven efficiency capabilities and operational optimization applications.

British chemical companies leverage established technical networks and comprehensive efficiency capabilities, including optimization programs and technical support that create customer relationships and operational advantages. The market benefits from established processing standards and environmental requirements that support reagent system use while supporting technology advancement and operational optimization.

Japan's advanced mining technology market demonstrates sophisticated beneficiation reagent integration with documented operational effectiveness in premium processing applications and modern facility installations through integration with existing efficiency systems and mining infrastructure. The country maintains a 4.7% growth rate, leveraging traditional efficiency expertise and precision systems integration in reagent technology. Processing centers, including Hokkaido, Tohoku, and Kyushu, showcase premium installations where reagent systems integrate with traditional efficiency platforms and modern facility management systems to optimize processing operations and maintain mining efficiency profiles.

Japanese chemical companies prioritize reagent precision and efficiency consistency in flotation development, creating demand for premium systems with advanced features, including efficiency monitoring and automated reagent systems. The market benefits from established efficiency infrastructure and commitment to processing standards that provide long-term operational benefits and compliance with traditional quality mining methods.

The European beneficiation reagents market is projected to represent a significant portion of global consumption, with strong regional distribution across major mining economies. Germany is expected to maintain its leadership position with USD 1.2 billion in 2025, accounting for substantial European market share, supported by its advanced chemical infrastructure and major processing centers.

United Kingdom follows with USD 850.0 million, representing significant European market share in 2025, driven by comprehensive mining programs and reagent technology development initiatives. France holds USD 650.0 million through specialized processing applications and environmental compliance requirements. Italy commands USD 520.0 million, while Spain accounts for USD 420.0 million in 2025. The rest of Europe region maintains USD 1.1 billion, attributed to increasing reagent system adoption in Nordic countries and emerging mining facilities implementing processing modernization programs.

| Stakeholder | What they actually control | Typical strengths | Typical blind spots |

|---|---|---|---|

| Global platforms | Supply networks, broad chemical portfolios, production facilities | Proven reliability, multi-region support, comprehensive service | Technology refresh cycles; customer lock-in dependency |

| Technology innovators | R&D capabilities; advanced formulations; digital interfaces | Latest technology first; attractive ROI on specialized applications | Service density outside core regions; customization complexity |

| Regional specialists | Local sourcing, fast delivery, nearby technical support | "Close to site" support; pragmatic pricing; local regulations | Technology gaps; talent retention in chemical engineering |

| Application-focused ecosystems | Industry expertise, technical support, specialized solutions | Lowest application variation; comprehensive industry support | Scaling costs if overpromised; technology obsolescence |

| Service specialists | Process programs, chemical supply, technical training | Win service-intensive applications; flexible support | Scalability limitations; narrow market focus |

| Items | Values |

|---|---|

| Quantitative Units (2025) | USD 9.1 billion |

| Product | Xanthate, Dithiophosphate, Frothers, Other |

| Application | Non-ferrous Metals, Ferrous Metals, Others |

| Regions Covered | East Asia, Western Europe, South Asia Pacific, North America, Latin America, Middle East & Africa |

| Countries Covered | China, Germany, United States, Japan, India, Brazil, United Kingdom, and 25+ additional countries |

| Key Companies Profiled | Nouryon, Chevron Phillips Chemical, Clariant, Syensqo, Ecolab, Evonik, BASF, Kao Chemicals, Yantai Humon Group |

| Additional Attributes | Dollar sales by product and application categories, regional adoption trends across East Asia, Western Europe, and South Asia Pacific, competitive landscape with chemical suppliers and service providers, operator preferences for processing consistency and operational reliability, integration with mining platforms and facility monitoring systems, innovations in reagent technology and formulation enhancement, and development of advanced beneficiation solutions with enhanced performance and processing optimization capabilities. |

The global beneficiation reagents market is estimated to be valued at USD 9.1 billion in 2025.

The market size for the beneficiation reagents market is projected to reach USD 16.8 billion by 2035.

The beneficiation reagents market is expected to grow at a 6.3% CAGR between 2025 and 2035.

The key product types in beneficiation reagents market are xanthate, dithiophosphate, frothers and other.

In terms of application, non-ferrous metals segment to command 40.0% share in the beneficiation reagents market in 2025.

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Eco-friendly Beneficiation Reagents Market Size and Share Forecast Outlook 2025 to 2035

Eco-friendly Precious Metal Beneficiation Reagents Market Forecast and Outlook 2025 to 2035

Non-eco-friendly Precious Metal Beneficiation Reagents Market Forecast and Outlook 2025 to 2035

Grignard Reagents Market Demand & Trends 2022 to 2032

Flotation Reagents Market Size and Share Forecast Outlook 2025 to 2035

Myoglobin Reagents Market

Sequencing Reagents Market

Fructosamine Reagents Market

Lipase Testing Reagents Market Size and Share Forecast Outlook 2025 to 2035

Electrophoresis Reagents Market Size and Share Forecast Outlook 2025 to 2035

Urinary Protein Reagents Market

Magnesium Testing Reagents Market

Hematology Analyzer And Reagents Market

Total Iron-Binding Capacity Reagents Market

Molecular Biology Enzymes, Kits & Reagents Market Trends and Forecast 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA