Manufacturers in the direct thermal printing films market drive innovation by delivering efficient, high-quality, and sustainable labeling and printing solutions. They use advanced materials and designs to serve sectors such as retail, logistics, pharmaceuticals, and food packaging. By 2035, the global direct thermal printing films market will exceed USD 355.9 million, growing at a compound annual growth rate (CAGR) of 4.1%. Companies focus on eco-friendly innovations and cost-effective designs to meet shifting consumer and industry demands.

It further expands the market as businesses increasingly use direct thermal printing technology to get on-demand, durable, and cost-efficient labeling solutions. Advanced production techniques, such as recyclable films and enhanced durability, allow brands to meet their regulatory and environmental standards. The manufacturers work closely with industries for high-quality printing and performance.

| Attribute | Details |

|---|---|

| Projected Value by 2035 | USD 355.9 million |

| CAGR (2025 to 2035) | 4.1% |

Factors Driving the Market Growth

| Category | Market Share (%) |

|---|---|

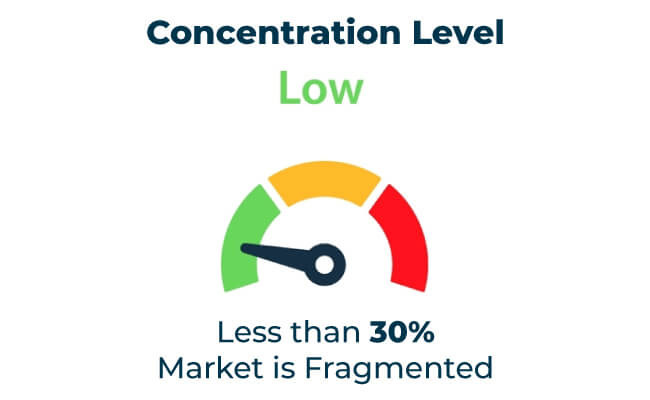

| Top 3 Players (Ricoh, Avery Dennison, Cosmo Films) | 16% |

| Rest of Top 5 Players (Mondi, UPM Raflatac) | 06% |

| Next 5 of Top 10 Players | 07% |

Type of Player & Industry Share

| Type of Player | Market Share (%) |

|---|---|

| Top 10 Players | 29% |

| Next 20 Players | 45% |

| Remaining Players | 26% |

Emerging markets in Asia-Pacific, Africa, and Latin America create significant export potential. Expanding logistics, retail, and e-commerce industries drive the demand for high-quality and cost-efficient labeling solutions. Global manufacturers capitalize on sustainability trends to tap into these markets.

| Region | North America |

|---|---|

| Market Share (%) | 30% |

| Key Drivers | Promotes sustainable printing solutions and high-quality labels. |

| Region | Europe |

|---|---|

| Market Share (%) | 35% |

| Key Drivers | Enforces recycling regulations and sustainable practices. |

| Region | Asia-Pacific |

|---|---|

| Market Share (%) | 25% |

| Key Drivers | Experiences rapid growth in e-commerce and retail sectors. |

| Region | Other Regions |

|---|---|

| Market Share (%) | 10% |

| Key Drivers | Expands demand for cost-efficient and durable labels. |

The direct thermal printing films market will grow by focusing on sustainability, advanced coatings, and innovative designs. Companies prioritizing recyclable materials and smart label integration will gain a competitive edge. Emerging markets and e-commerce growth will provide new revenue streams.

| Tier | Key Companies |

|---|---|

| Tier 1 | Ricoh, Avery Dennison, Cosmo Films |

| Tier 2 | Mondi, UPM Raflatac |

| Tier 3 | Smith & McLaurin, Appvion |

The direct thermal printing films market grows steadily due to the emphasis in industry trends on sustainability, convenience, and technology. Companies focused on friendly environmental practices, advanced coatings, and expanding emerging markets strengthen their positions in competition. Recycling advancement and growth in e-commerce open new opportunities for leaders in the market.

Appendix Key Definitions

Abbreviations

Methodology

This report integrates primary research, secondary data, and expert insights. Analysts validated findings through interviews with industry professionals and end-users. The methodology ensures a comprehensive and accurate market perspective.

The direct thermal printing films market encompasses the manufacturing and use of specialty films for direct thermal printing. These films are used by retail, logistics, food packaging, and pharmaceutical industries for durable, eco-friendly, and cost-effective labeling solutions.

Industries like retail, logistics, food packaging, and pharmaceuticals commonly use direct thermal printing films for labeling and tracking purposes.

Manufacturers use recyclable materials, eliminate ink ribbons, and optimize production processes to reduce waste and energy consumption.

Challenges include high initial investment costs, maintaining label durability in harsh conditions, and navigating diverse global regulatory standards.

Europe and Asia-Pacific lead the market due to strict sustainability regulations and growing e-commerce sectors.

E-commerce drives demand for durable and high-quality shipping labels, accelerating the adoption of direct thermal printing films

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Competitive Breakdown of Top Coated Direct Thermal Printing Films Providers

Direct Operated Poppet Valve Market Forecast and Outlook 2025 to 2035

Direct Burial Fiber Optic Cable Market Size and Share Forecast Outlook 2025 to 2035

Directed Energy Weapons Market Size and Share Forecast Outlook 2025 to 2035

Direct To Chip Liquid Cooling Market Size and Share Forecast Outlook 2025 to 2035

Direct Write Semiconductor Market Size and Share Forecast Outlook 2025 to 2035

Direct Oral Anticoagulants Market Size and Share Forecast Outlook 2025 to 2035

Direct-to-Shape Inkjet Printer Market Size, Growth, and Forecast 2025 to 2035

Directed Energy-Based Surgical Systems Market Growth – Forecast 2025 to 2035

Direct-to-Consumer Genetic Testing Market Analysis - Trends & Outlook 2025 to 2035

Direct Drive Wind Turbine Market Growth - Trends & Forecast 2025 to 2035

Direct Reduced Iron Market Growth – Trends & Forecast 2024-2034

Directional Drilling Service Market Growth – Trends & Forecast 2024-2034

Direct Methanol Fuel Cell Market Growth – Trends & Forecast 2024-2034

Directional Luminaire Market

Direct-To-Consumer Test Market

Direct-Fed Microbial Products Market

Direct-acting Antiviral Medicines Market

Assessing Direct-to-shape Inkjet Printer Market Share & Industry Trends

Direct to Garment Printing Market Size and Share Forecast Outlook 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA