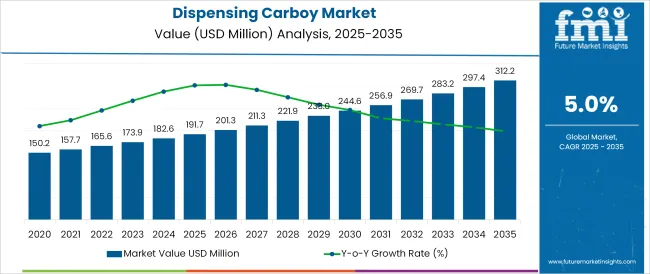

The Dispensing Carboy Market is estimated to be valued at USD 191.7 million in 2025 and is projected to reach USD 312.2 million by 2035, registering a compound annual growth rate (CAGR) of 5.0% over the forecast period.

The dispensing carboy market is experiencing steady growth due to increasing applications in fluid storage, chemical transfer, and sterile dispensing within regulated industries. As laboratory protocols, pharmaceutical manufacturing, and biomedical research expand, there is a rising need for containers that ensure precise, leak-proof liquid handling and compatibility with a range of reagents.

Manufacturers are innovating with autoclavable materials, ergonomic designs, and spigot-integrated formats to enhance user convenience and safety. Growth is further supported by environmental and operational preferences for reusable, durable containers that reduce spillage, evaporation, and waste. In emerging regions, improvements in healthcare infrastructure and research capabilities are encouraging the adoption of dispensing carboys for cleanroom and clinical applications.

Additionally, evolving standards around traceability, calibration, and chemical compatibility are pushing suppliers to develop smarter and modular container systems aligned with modern laboratory practices.

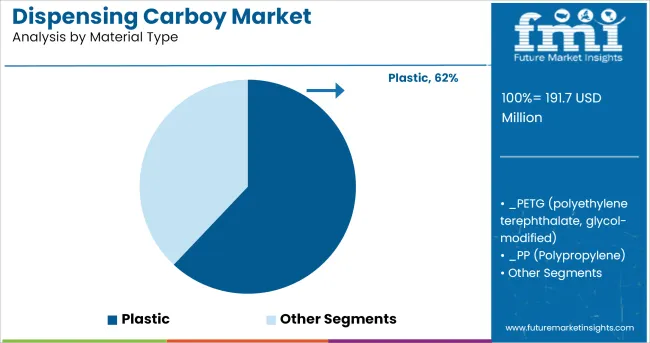

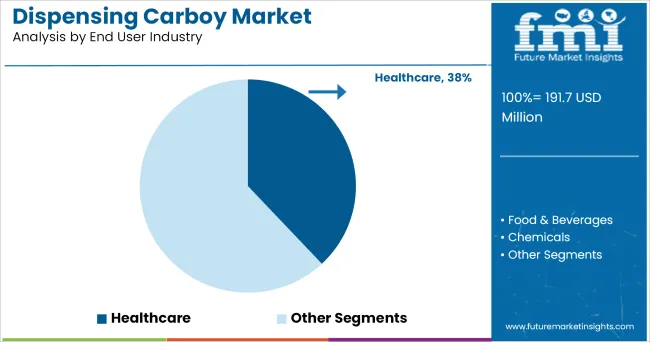

The market is segmented by Material Type and End User Industry and region. By Material Type, the market is divided into Plastic, PETG (polyethylene terephthalate, glycol-modified), PP (Polypropylene), PE (Polyethylene), Polycarbonate, and Glass. In terms of End User Industry, the market is classified into Healthcare, Food & Beverages, Chemicals, and Others.

Regionally, the market is classified into North America, Latin America, Western Europe, Eastern Europe, Balkan & Baltic Countries, Russia & Belarus, Central Asia, East Asia, South Asia & Pacific, and the Middle East & Africa.

Plastic dispensing carboys are expected to account for 62.0% of the market revenue in 2025, making it the dominant material type in this category. This leadership is being attributed to the superior chemical resistance, lightweight nature, and cost-efficiency of plastic materials such as polypropylene and high-density polyethylene.

These plastics offer durability in both sterile and non-sterile environments, supporting extended usage cycles without compromising structural integrity. Plastic carboys are also compatible with sterilization methods such as autoclaving and gamma irradiation, making them well-suited for pharmaceutical, laboratory, and clinical workflows.

The ease of molding allows for the integration of ergonomic handles, graduated markings, and spigot systems, further enhancing operational efficiency. Additionally, the recyclability and reduced environmental footprint of plastic variants align with sustainability goals, reinforcing their continued preference across industries seeking a balance between performance, compliance, and lifecycle cost.

The healthcare sector is projected to hold a 38.0% share of the dispensing carboy market in 2025, emerging as the leading end-user industry. This dominance is being driven by stringent requirements for sterile fluid handling in hospitals, diagnostic laboratories, and pharmaceutical manufacturing facilities.

Dispensing carboys are widely used in the preparation, storage, and transfer of reagents, media, and sterile solutions, where hygiene and contamination control are critical. Their role in supporting infection prevention protocols, accurate dosing, and compliance with healthcare standards such as USP and cGMP is essential to their continued adoption.

The growth of clinical research, biotechnology labs, and compounding pharmacies has also contributed to the increased demand for precision containers that meet cleanroom specifications. With rising investment in healthcare infrastructure and the global expansion of diagnostics and vaccine production, dispensing carboys are expected to remain a key component in fluid management systems.

Consistent advancements in the technology and increasing demand of research and experiments in laboratories and chemical industries have resulted into the surge of dispensing and storing liquids. Dispensing carboys are used to store medicated fluids in a bulk in order to resist it from getting contaminated.

Dispensing carboys are able to be autoclaved, can withstand certain levels of cold, heat or chemical interactions and are widely used to preserve and store medicinal liquids which are deployed in a range of pharmaceutical applications and are also used to add shelf life of the chemical contained.

The dispensing carboy market is witnessing a significant growth particularly in glass material, because inorganic nature of glass makes these carboys highly resistant to chemicals and other reactive substances. Furthermore, as the dispensing carboys are available in a variety of capacities depending upon requirement, the demand of the dispensing carboy in the market will continue to increase.

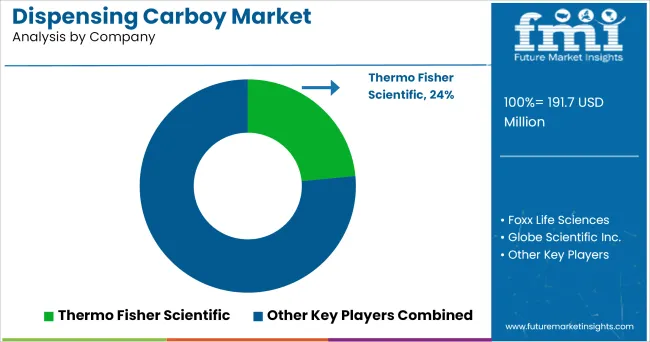

Presently, there are various players which are operating in the dispensing carboy market, producing customized dispensing carboys to cater to the increasing demand from different end-use industries, giving manufacturers a good opportunity to enter the market.

The dispensing carboys are principally used for transporting and storing liquids, often chemicals, solvents or deionized water. Heavy demand from laboratories, has driven the dispensing carboys growth.

With opaque exteriors to block ultraviolet light and great chemical resistance, the dispensing carboys store large quantities of liquids and are autoclavable for easy sterilization.

Dispensing carboys feature indented hand grips on the bottom for easy pouring & carrying, with large handles and the strong, space-saving design combines moulded-in graduations in litres and gallons. All these characteristics are expected to propel the growth of dispensing carboy in the market.

The major problem associated with plastics is that it pollutes the planet and damage the environment at every step in their lifecycle. Recycling only delays plastic's inevitable purpose to a landfill or the ocean.

With the increasing literacy rate and awareness in people regarding environmental degradation due to plastics, end-user preference is moving towards the adoption of eco-friendly and safe packaging solutions. Therefore, the dispensing carboy market growth is expected to be hampered during the forecast period.

The dispensing carboys are durable, cost effective, and reusable and has airtight lids which offers complete secure packaging solution. The dispensing carboy is widely used in the beverage industry for the fermentation of beverages such as cider, wine, beer, mead, and perry.

The robust design of dispensing carboy with airtight fitting and a fermentation lock inhibits bacteria and oxygen from penetrating during the fermentation process. Furthermore, high demand from the beverage industry is unlocking several opportunities for the dispensing carboys manufacturers in the near future.

Due to the numerous benefits of plastic, end-users are highly demanding plastic dispensing carboys. The light in weight characteristic of plastic gives it the preferred option in situations where heavy-duty storing equipment isn't easily obtainable and mobility is a requirement. An empty glass dispensing carboy can still be tough to manoeuvre, whereas plastic dispensing carboys can be handled with ease.

More modularity is provided by the plastic dispensing carboys, as compared to the glass as one could simply drill a hole, and add plugs, or any other functionality without discrediting the integrity of the material. Additionally, if a dispensing carboy is not made with a BPA-Free material, it can alter the taste and prompt potential health risks if any liquid stored is intended for consumption like wine or beer.

Several manufacturers are focusing on the new design of plastic dispensing carboys tap at the bottom and handles at the side which grants adaptability to end-users while handling and transporting the stocked liquid.

Various manufacturers are coming up with certain innovations and are modifying the dispensing carboys to increase sales. For instance, Dnyalon Labware is manufacturing heavy-walled plastic dispensing carboys with customized capacities.

Other manufacturers are widening the neck of the dispensing carboy to simplify cleaning and to enable faster pouring. The largemouth on the dispensing carboy implies trivial fluid transfer, without the necessity for funnels.

Asia Pacific region is likely to witness a huge rise in dispensing carboy usage due to rapid penetration and expansion of food and beverage industry in India, China and other emerging nations. Furthermore, high production capabilities and easy raw material availability is anticipated to increase the sales of dispensing carboy, making India and China to have an important market for dispensing carboy.

The global dispensing carboy market is estimated to be valued at USD 191.7 million in 2025.

The market size for the dispensing carboy market is projected to reach USD 312.2 million by 2035.

The dispensing carboy market is expected to grow at a 5.0% CAGR between 2025 and 2035.

The key product types in dispensing carboy market are plastic, petg (polyethylene terephthalate, glycol-modified), pp (polypropylene), PE (polyethylene), polycarbonate and glass.

In terms of end user industry, healthcare segment to command 38.0% share in the dispensing carboy market in 2025.

Our Research Products

The "Full Research Suite" delivers actionable market intel, deep dives on markets or technologies, so clients act faster, cut risk, and unlock growth.

The Leaderboard benchmarks and ranks top vendors, classifying them as Established Leaders, Leading Challengers, or Disruptors & Challengers.

Locates where complements amplify value and substitutes erode it, forecasting net impact by horizon

We deliver granular, decision-grade intel: market sizing, 5-year forecasts, pricing, adoption, usage, revenue, and operational KPIs—plus competitor tracking, regulation, and value chains—across 60 countries broadly.

Spot the shifts before they hit your P&L. We track inflection points, adoption curves, pricing moves, and ecosystem plays to show where demand is heading, why it is changing, and what to do next across high-growth markets and disruptive tech

Real-time reads of user behavior. We track shifting priorities, perceptions of today’s and next-gen services, and provider experience, then pace how fast tech moves from trial to adoption, blending buyer, consumer, and channel inputs with social signals (#WhySwitch, #UX).

Partner with our analyst team to build a custom report designed around your business priorities. From analysing market trends to assessing competitors or crafting bespoke datasets, we tailor insights to your needs.

Supplier Intelligence

Discovery & Profiling

Capacity & Footprint

Performance & Risk

Compliance & Governance

Commercial Readiness

Who Supplies Whom

Scorecards & Shortlists

Playbooks & Docs

Category Intelligence

Definition & Scope

Demand & Use Cases

Cost Drivers

Market Structure

Supply Chain Map

Trade & Policy

Operating Norms

Deliverables

Buyer Intelligence

Account Basics

Spend & Scope

Procurement Model

Vendor Requirements

Terms & Policies

Entry Strategy

Pain Points & Triggers

Outputs

Pricing Analysis

Benchmarks

Trends

Should-Cost

Indexation

Landed Cost

Commercial Terms

Deliverables

Brand Analysis

Positioning & Value Prop

Share & Presence

Customer Evidence

Go-to-Market

Digital & Reputation

Compliance & Trust

KPIs & Gaps

Outputs

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Market Share Breakdown of Dispensing Carboy Providers

Dispensing System Market Size and Share Forecast Outlook 2025 to 2035

Dispensing Robots Market Size and Share Forecast Outlook 2025 to 2035

Dispensing Guns Market Size and Share Forecast Outlook 2025 to 2035

Dispensing Trays Market Size, Share & Forecast 2025 to 2035

Dispensing Caps Market Growth - Demand & Forecast 2025 to 2035

Key Players & Market Share in the Dispensing Spout Industry

Dispensing Spout Market by Cap & Pump Type from 2024 to 2034

Dispensing Jug Market

Dispensing Tap Market

Dispensing Sprayers Market

Beer Dispensing Machine Market Trends - Growth, Demand & Analysis 2025 to 2035

Fluid Dispensing Equipment Market Size and Share Forecast Outlook 2025 to 2035

Twist Dispensing Closures Market Size and Share Forecast Outlook 2025 to 2035

Pouch Dispensing Fitment Market

Hinged Dispensing Caps Market Size and Share Forecast Outlook 2025 to 2035

Competitive Landscape of Hinged Dispensing Caps Providers

Spouted Dispensing Closures Market

Product Dispensing Machinery Market

Aerosol Dispensing Systems Market

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA