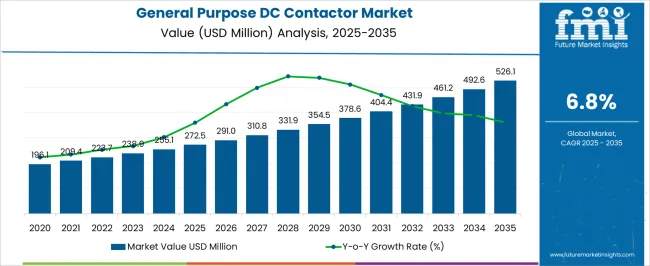

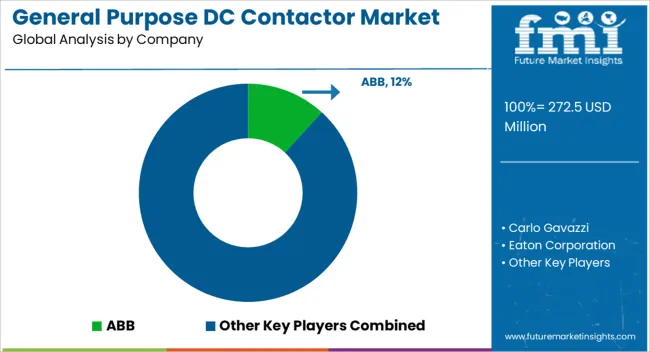

The general purpose DC contactor market stands at USD 272.5 million in 2025 and is expected to reach USD 526.1 million by 2035, growing at a CAGR of 6.8%, with a multiplying factor of about 1.93x. Long-term value accumulation curve analysis illustrates how incremental market value builds over the decade, highlighting periods of stronger adoption and revenue contribution.

In the early phase, from 2025 to 2028, value accumulation is gradual as adoption is largely driven by replacement of legacy DC contactors and integration in standard industrial applications, including power distribution, automation, and automotive systems. This phase establishes the baseline for sustained market expansion. Between 2028 and 2032, the accumulation curve steepens as demand increases across emerging applications such as renewable energy systems, electric vehicles, and smart grid infrastructure. Technological improvements in contactor durability, compact design, and higher load capacity contribute to faster uptake, enhancing market value significantly during this period. From 2032 to 2035, accumulation continues steadily as mature regions consolidate adoption and growth in emerging regions accelerates, supported by industrial modernization and expanding energy infrastructure.

The long-term value accumulation curve demonstrates that market growth is cumulative and dynamic, with early adoption setting the stage for later acceleration, while technological advancement and diversification of applications sustain value creation throughout the forecast period.

| Metric | Value |

|---|---|

| General Purpose DC Contactor Market Estimated Value in (2025 E) | USD 272.5 million |

| General Purpose DC Contactor Market Forecast Value in (2035 F) | USD 526.1 million |

| Forecast CAGR (2025 to 2035) | 6.8% |

The general purpose DC contactor market is influenced by multiple upstream sectors. Industrial equipment manufacturers account for approximately 36%, integrating DC contactors into machinery and automation systems. Automotive and electric vehicle OEMs contribute around 28%, using contactors in battery management, motor control, and power distribution units. Renewable energy equipment producers represent roughly 17%, deploying contactors in solar, wind, and energy storage systems. Rail and transport system manufacturers hold close to 11%, incorporating contactors in traction and signaling equipment. Component and supplier network providers make up the remaining 8%, supplying auxiliary parts, control modules, and replacement components. The market is growing as DC contactors are increasingly integrated into electrified systems. Automotive and EV applications now account for over 32% of new installations, driven by the expansion of battery-electric vehicles and hybrid platforms.

Industrial automation and renewable energy installations are adopting compact and energy-efficient contactors, reducing power losses by 8–10%. Advancements in solid-state and hybrid DC contactors are improving switching reliability and lifespan by 12–15%. Remote monitoring and predictive maintenance solutions are being implemented to minimize downtime and enhance operational safety. Demand for modular and easy-to-install contactors is rising, particularly in industrial and transportation sectors.

The general purpose DC contactor market is expanding steadily, driven by the rising adoption of DC-based power systems across transportation, renewable energy, and industrial applications. Industry publications and manufacturer announcements have pointed to growing demand from electric mobility and energy storage sectors, where DC contactors are essential for controlling high-voltage circuits safely.

Advancements in contactor design, such as arc suppression technologies and compact high-current models, have improved operational efficiency and reliability. Regulatory support for clean transportation and renewable integration has further accelerated adoption, particularly in markets transitioning to electric fleets and smart grid infrastructure.

Additionally, ongoing investments in charging station networks and off-grid power systems are boosting requirements for robust, long-life DC contactors. The market outlook remains positive as manufacturers focus on improving thermal performance, reducing maintenance needs, and integrating intelligent monitoring capabilities, ensuring compatibility with next-generation electric and hybrid systems.

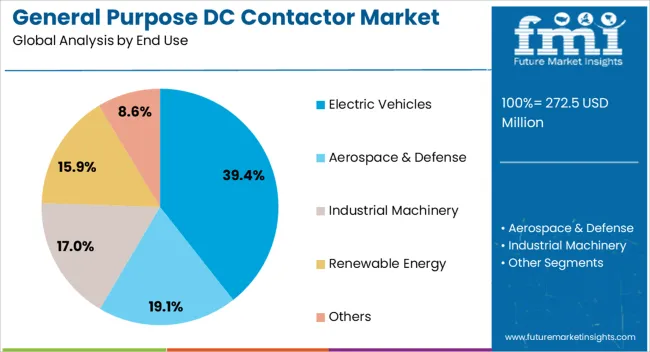

The general purpose DC contactor market is segmented by end use, and geographic regions. By end use, general purpose DC contactor market is divided into Electric Vehicles, Aerospace & Defense, Industrial Machinery, Renewable Energy, and Others. Regionally, the general purpose DC contactor industry is classified into North America, Latin America, Western Europe, Eastern Europe, Balkan & Baltic Countries, Russia & Belarus, Central Asia, East Asia, South Asia & Pacific, and the Middle East & Africa.

The electric vehicles segment is projected to account for 39.4% of the general purpose DC contactor market revenue in 2025, maintaining its lead due to the rapid global shift toward electrified transportation. Growth in this segment has been fueled by the critical role DC contactors play in managing battery connections, protecting circuits, and enabling safe power transfer within high-voltage EV systems.

Automotive engineering reports have highlighted the need for contactors that can handle frequent switching cycles, high current loads, and fault protection in compact spaces, aligning with modern EV design requirements. Government incentives for EV purchases, coupled with stricter emissions regulations, have intensified production volumes and increased demand for reliable contactor solutions.

Furthermore, expanding electric bus, truck, and two-wheeler markets have diversified the application base within the EV category. As advancements in solid-state switching and contact material technology improve efficiency and durability, the electric vehicles segment is expected to retain its dominant position in the market, supported by sustained growth in global EV adoption.

The general purpose DC contactor market is expanding due to increasing demand for efficient electrical switching in industrial, automotive, and renewable energy applications. These contactors provide reliable control of DC circuits, ensuring safety, reducing downtime, and improving energy efficiency.

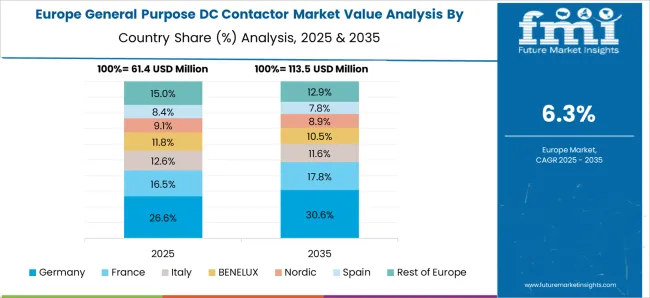

Adoption is strong in automotive electric drive systems, industrial machinery, and solar and energy storage solutions. Technological advancements in compact designs, high-current capacity, and durability enhance operational performance. Asia Pacific leads growth due to expanding manufacturing and renewable energy infrastructure, while Europe and North America focus on industrial automation and electric vehicle applications.

The rise of electric vehicles and renewable energy systems is a major driver of DC contactor demand. Automotive applications require reliable switching for traction batteries, motor controllers, and charging systems. Renewable energy systems, including solar inverters and energy storage solutions, rely on DC contactors for efficient energy management. Industrial machinery, material handling equipment, and battery backup systems also adopt contactors to ensure operational continuity and safety. Enhanced reliability, longer lifespan, and high-current handling support broader adoption. Increasing electrification and industrial automation are further driving the demand for general purpose DC contactors globally.

Advanced DC contactor designs with higher current ratings, compact sizes, and integrated monitoring features are creating growth opportunities. These innovations allow seamless integration into EV battery packs, energy storage systems, and industrial control panels. Enhanced electrical durability and thermal management improve operational safety and reliability. Manufacturers focusing on high-performance, modular, and scalable contactors are positioned to meet growing industry requirements. Increasing demand for energy-efficient components, robust switching solutions, and space-saving designs drives adoption across automotive, renewable energy, and industrial applications.

Integration of DC contactors with IoT-enabled monitoring and smart control systems is an emerging trend. Real-time status monitoring, predictive maintenance, and remote control enhance operational efficiency and reduce downtime. Smart contactors enable automated energy management in renewable energy systems, electric vehicles, and industrial equipment. Emerging designs also support faster switching, enhanced safety, and reduced energy losses. The integration of intelligent features supports broader adoption in commercial, industrial, and automotive sectors, enabling predictive maintenance and energy optimization, while improving safety and system reliability.

High production costs and the need for compliance with international safety standards are primary challenges. DC contactors require precise engineering, high-quality materials, and rigorous testing to ensure reliability under high-current and high-voltage conditions. Differences in standards across regions can increase complexity for global manufacturers. Companies investing in scalable designs, quality assurance, and compliance management are better positioned to overcome these barriers. Maintaining performance, safety, and cost-effectiveness is critical to sustain adoption and remain competitive in the global general purpose DC contactor market.

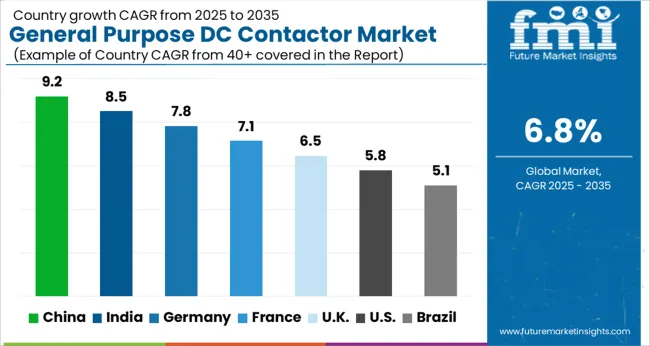

| Country | CAGR |

|---|---|

| China | 9.2% |

| India | 8.5% |

| Germany | 7.8% |

| France | 7.1% |

| UK | 6.5% |

| USA | 5.8% |

| Brazil | 5.1% |

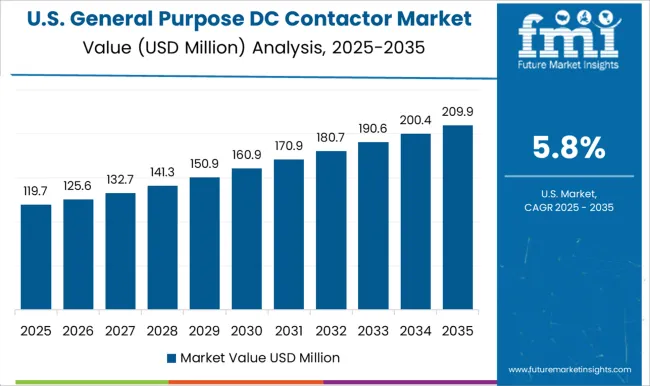

The general purpose DC contactor market is growing at a global CAGR of 6.8% from 2025 to 2035, supported by increasing industrial automation, electrical infrastructure upgrades, and demand for reliable switching solutions. China leads with a CAGR of 9.2%, +35% above the global benchmark, driven by BRICS-backed industrial expansion, widespread adoption in manufacturing facilities, and rising demand for power distribution systems. India follows at 8.5%, +25% over the global average, reflecting strong growth in electrical equipment manufacturing and expansion of industrial automation. Germany records 7.8%, +15% above the global CAGR, shaped by OECD-supported innovation in electrical components and integration in advanced industrial applications. The United Kingdom posts 6.5%, slightly below the global rate, influenced by selective upgrades in industrial infrastructure. The United States stands at 5.8%, −15% under the global benchmark, reflecting mature electrical systems and steady demand from industrial and commercial sectors.

China is growing at a CAGR of 9.2%, 2.4% above the global CAGR of 6.8%, driven by strong demand from electric vehicles, renewable energy systems, and industrial automation sectors. Domestic manufacturers are scaling production of high-performance DC contactors with improved current handling, safety, and durability. Increasing adoption of EV charging stations, solar inverters, and industrial control systems supports market expansion. Strategic partnerships between component suppliers and OEMs enhance technology integration and supply chain efficiency. Rising investments in smart grid infrastructure and industrial automation further fuel demand. China’s focus on advanced electrical components and export potential strengthens its position in the global DC contactor market.

India is recording a CAGR of 8.5%, 1.7% above the global CAGR, supported by adoption in EVs, industrial automation, and renewable energy systems. Manufacturers are increasing production of durable, high-current DC contactors to meet domestic and export requirements. Investments in electric mobility infrastructure and solar power plants are driving demand. Partnerships with global component suppliers ensure advanced technology transfer and faster market penetration. Rising industrial electrification and demand for reliable power switching devices strengthen adoption. India’s focus on smart manufacturing and industrial automation positions it as a significant growth market in the Asia-Pacific region.

Germany is growing at a CAGR of 7.8%, 1.0% above the global CAGR, driven by automotive, industrial, and renewable energy applications. High-quality DC contactors are used in electric vehicles, industrial control systems, and solar inverters. Strong R&D infrastructure and industrial collaborations support innovation in durability, performance, and safety. Export of specialized contactors for automotive and industrial applications maintains steady growth. Germany’s focus on precision engineering, industrial automation, and sustainable energy solutions ensures market stability and moderate expansion above global benchmarks.

The United Kingdom is expanding at a CAGR of 6.5%, slightly below the global CAGR of 6.8%, reflecting moderate adoption. DC contactors are mainly used in renewable energy systems, EVs, and industrial applications. Adoption is supported by imports of advanced components from Europe and Asia. Industrial electrification and energy storage projects are supporting incremental demand. Investments in R&D and technology partnerships enhance product efficiency, durability, and compliance with local standards. Gradual growth in smart grid and renewable power systems ensures steady expansion of DC contactor adoption.

The United States is progressing at a CAGR of 5.8%, 1.0% below the global CAGR of 6.8%, reflecting slower growth due to a mature industrial and automotive market. Adoption is driven by EVs, industrial automation, and renewable energy applications. Domestic manufacturers focus on high-performance contactors with improved current handling and safety features. Imports of advanced DC contactors from Europe and Asia supplement production. Growth is sustained by industrial electrification, renewable power projects, and rising EV adoption, though overall expansion remains below global benchmarks due to market maturity.

The general purpose DC contactor market is driven by manufacturers providing reliable switching solutions for industrial, transportation, renewable energy, and automation applications. ABB is assumed to be the leading player, offering a portfolio of DC contactors engineered for high-current capacity, long service life, and precise electrical switching. Carlo Gavazzi and Eaton Corporation maintain strong positions through compact, modular contactors designed for control panels, battery systems, and motor drives.

Fuji Electric and GEYA Electrical Equipment Supply provide scalable solutions with enhanced thermal management, mechanical endurance, and compatibility with industrial control systems. K.A. Schmersal GmbH & Co. KG and LOVATO Electric S.p.A. focus on safety-compliant contactors with performance optimization for machinery and automation applications. LS ELECTRIC, L&T, Mitsubishi Electric Corporation, and Panasonic Corporation strengthen the market through energy-efficient designs, technical support, and global service networks. Rockwell Automation and Siemens emphasize integration with programmable logic controllers and automation platforms, while Sensata Technologies, Inc., Schneider Electric, Schaltbau, Toshiba International Corporation, and TE Connectivity offer durable, high-performance contactors for heavy-duty industrial and transportation systems. Product brochures highlight switching capacity, coil voltage options, electrical endurance, contact resistance, and mechanical reliability. Features such as high operational cycles, compact design, low maintenance requirements, and rapid response times are emphasized. Technical documentation, installation guidelines, and application notes ensure seamless integration into electrical panels, battery systems, and automated processes.

| Item | Value |

|---|---|

| Quantitative Units | USD 272.5 Million |

| End Use | Electric Vehicles, Aerospace & Defense, Industrial Machinery, Renewable Energy, and Others |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, Middle East & Africa |

| Country Covered | United States, Canada, Germany, France, United Kingdom, China, Japan, India, Brazil, South Africa |

| Key Companies Profiled | ABB, Carlo Gavazzi, Eaton Corporation, Fuji Electric, GEYA Electrical Equipment Supply, K.A. Schmersal GmbH & Co. KG, LOVATO Electric S.p.A., LS ELECTRIC, L&T, Mitsubishi Electric Corporation, Panasonic Corporation, Rockwell Automation, Siemens, Sensata Technologies, Inc., Schneider Electric, Schaltbau, Toshiba International Corporation, and TE Connectivity |

| Additional Attributes | Dollar sales by contactor type and voltage rating, demand dynamics across industrial machinery, power distribution, and transportation applications, regional trends across North America, Europe, and Asia-Pacific, innovation in compact designs, high-current handling, and smart monitoring features, environmental impact of energy efficiency and material recyclability, and emerging use cases in electric vehicles, renewable energy systems, and automated industrial equipment. |

The global general purpose DC contactor market is estimated to be valued at USD 272.5 million in 2025.

The market size for the general purpose DC contactor market is projected to reach USD 526.1 million by 2035.

The general purpose DC contactor market is expected to grow at a 6.8% CAGR between 2025 and 2035.

The key product types in general purpose DC contactor market are electric vehicles, aerospace & defense, industrial machinery, renewable energy and others.

In terms of , segment to command 0.0% share in the general purpose DC contactor market in 2025.

Our Research Products

The "Full Research Suite" delivers actionable market intel, deep dives on markets or technologies, so clients act faster, cut risk, and unlock growth.

The Leaderboard benchmarks and ranks top vendors, classifying them as Established Leaders, Leading Challengers, or Disruptors & Challengers.

Locates where complements amplify value and substitutes erode it, forecasting net impact by horizon

We deliver granular, decision-grade intel: market sizing, 5-year forecasts, pricing, adoption, usage, revenue, and operational KPIs—plus competitor tracking, regulation, and value chains—across 60 countries broadly.

Spot the shifts before they hit your P&L. We track inflection points, adoption curves, pricing moves, and ecosystem plays to show where demand is heading, why it is changing, and what to do next across high-growth markets and disruptive tech

Real-time reads of user behavior. We track shifting priorities, perceptions of today’s and next-gen services, and provider experience, then pace how fast tech moves from trial to adoption, blending buyer, consumer, and channel inputs with social signals (#WhySwitch, #UX).

Partner with our analyst team to build a custom report designed around your business priorities. From analysing market trends to assessing competitors or crafting bespoke datasets, we tailor insights to your needs.

Supplier Intelligence

Discovery & Profiling

Capacity & Footprint

Performance & Risk

Compliance & Governance

Commercial Readiness

Who Supplies Whom

Scorecards & Shortlists

Playbooks & Docs

Category Intelligence

Definition & Scope

Demand & Use Cases

Cost Drivers

Market Structure

Supply Chain Map

Trade & Policy

Operating Norms

Deliverables

Buyer Intelligence

Account Basics

Spend & Scope

Procurement Model

Vendor Requirements

Terms & Policies

Entry Strategy

Pain Points & Triggers

Outputs

Pricing Analysis

Benchmarks

Trends

Should-Cost

Indexation

Landed Cost

Commercial Terms

Deliverables

Brand Analysis

Positioning & Value Prop

Share & Presence

Customer Evidence

Go-to-Market

Digital & Reputation

Compliance & Trust

KPIs & Gaps

Outputs

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

General Intelligent Decision-Making Service Market Size and Share Forecast Outlook 2025 to 2035

General Equipment Rental Services Market Size and Share Forecast Outlook 2025 to 2035

General Surgery Devices Market Insights – Demand and Growth Forecast 2025 to 2035

Generalized Anxiety Disorder Treatment Market Insights by Drug Class, Therapies, Distribution Channel, and Region 2035

Generalized Myasthenia Gravis Management Market - Growth & Treatment Advances 2025 to 2035

General Anesthesia Drugs Market Insights – Trends & Forecast 2025 to 2035

General Purpose Electronic Test and Measurement Instruments Market Analysis and Forecast by Product, End Use, and Region Through 2035

Purpose-built Backup Appliance (PBBA) Market Size and Share Forecast Outlook 2025 to 2035

Repurposed Human Immunosuppressants Market Size and Share Forecast Outlook 2025 to 2035

On Purpose Technologies Market Growth - Trends & Forecast 2025 to 2035

Multipurpose Goods Vehicle Market Size and Share Forecast Outlook 2025 to 2035

Special Purpose Needles Market Analysis – Growth & Forecast 2025 to 2035

Special-Purpose Analog-to-Digital Converters (ADCs) Market Forecast and Outlook 2025 to 2035

Riding Multi-Purpose Lawn Mower Market Size and Share Forecast Outlook 2025 to 2035

Demand for Multipurpose Goods Vehicle in UK Size and Share Forecast Outlook 2025 to 2035

All Electric Multipurpose Goods Vehicle Market Forecast and Outlook 2025 to 2035

Demand for All Electric Multipurpose Goods Vehicle in USA Size and Share Forecast Outlook 2025 to 2035

Contactor Market Size and Share Forecast Outlook 2025 to 2035

Contactor-based Transfer Switch Market Size and Share Forecast Outlook 2025 to 2035

Train Contactor Market - Growth & Demand 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA