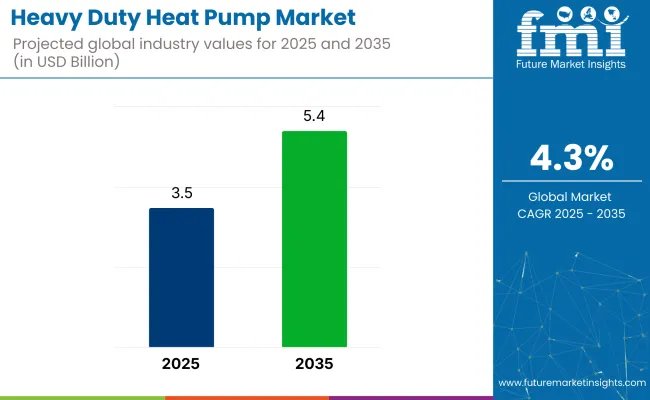

The heavy duty heat pump market is poised for steady expansion over the coming decade, underpinned by rising demand for industrial decarbonization, energy efficiency, and renewable heating solutions. In 2025, the market is projected to be valued at USD 3.5 billion, and it is expected to grow to USD 5.4 billion by 2035, registering a compound annual growth rate (CAGR) of 4.3% during the forecast period.

| Metric | Value |

|---|---|

| Industry Size (2025E) | USD 3.5 billion |

| Industry Value (2035F) | USD 5.4 billion |

| CAGR (2025 to 2035) | 4.3% |

Key driving factors include increasing industrial electrification, stringent environmental regulations, and the adoption of clean energy technologies across sectors such as manufacturing, food processing, chemicals, and district heating.

The market for heavy-duty heat pumps is changing, with the global movement towards industrial sustainability at the forefront of this transformation. The predominant trend impelling the market is the incorporation of heat pumps in industrial energy systems for process heating and cooling, replacing fossil-fuel-based boilers. New innovative high temperature heat pumps that can deliver temperatures exceeding 100°C are expanding application opportunities across industrial sectors.

Regulatory support through subsidies and carbon pricing mechanisms from governments, is also helping to accelerate their adoption. Furthermore, advanced automation and smart control systems are allowing for improved operation and maintenance, making large-scale heavy-duty heat pumps both economical and dependable.

North American heavy-duty heat pump demand is motivated by an increased focus on industrial decarburization and energy efficiency, especially in the USA and Canada. The federal and state-level policies, including the Inflation Reduction Act, are incentivizing the industrial electrification and clean heating technologies that will play a critical role in reducing GHG emissions from industrial facilities and contributing to major industrial reductions by 2030. Mature markets are seeing an increase in upgrading old, inefficient heating systems to efficient heat pumps in food processing, pulp & paper and some commercial facilities.

Utilities and municipalities are also adopting heat pumps in district heating pilot projects. But the growth in the market is expected to be somewhat limited by regional differences in energy pricing and the cost of deployment upfront. Advancements in high-temperature systems and supportive carbon regulations are likely to further cement the market’s growth across North America.

Europe is the most mature and energetic market for heavy-duty heat pumps due to energizing climate policies and energy security worries. Germany, Sweden, Denmark and the Netherlands are among the countries moving swiftly to scale up the integration of heat pumps into industrial plants and district heating networks.

EU-wide carbon neutrality targets and directives such as the energy efficiency directive and repowered are driving investments in clean heat technologies. Flip a switch on high-temperature heat pumps to replace gas boilers for large-scale use regulatory frameworks, access to renewable electricity, and public funding mechanisms facilitate deployment. Europe is also ahead in engineering innovation and manufacturing potential, and serves as a real world center for the R&D and commercialization of solutions for heavy-duty heat pumps

Asia-Pacific is also the fastest-growing regional market for heavy-duty heat pumps due to accelerating energy transition, decarbonization targets, and industrialization in countries like China, Japan, South Korea, and Australia. China is at the forefront of industrial-scale installations backed by strong policy and highly localized manufacturing capabilities.

Japan is emphasizing high-efficiency systems for both district heating and commercial use, whereas South Korea is developing thermal electrification as part of intelligent energy infrastructures. Regional governments offer favorable incentives and the devices are being integrated into the national climate roadmaps.

Another key area of deployment are industrial clusters and smart cities. Retrofit and infrastructure availability remain challenges, but the increasing cost of energy and continued push toward sustainability is accelerating market momentum.

The Rest of the World, including Latin America, the Middle East, and Africa, has a small heavy-duty heat pump market but with substantial room for growth in the future. Renewable electricity growth in Latin America is paving the way, especially in Brazil and Chile, for adopting new clean thermal technologies in food processing and mining.

With increasing awareness regarding sustainability, the Middle East is meaning to explore heat pumps for energy-efficient cooling, and desalination systems. With electrification improving, Africa is slowly introducing these systems into urban infrastructure. The slow adoption due to high upfront cost, lack of awareness and limited policy frameworks. Climate finance, international cooperation, technology transfer is likely to unleash possibilities for growth in these regions.

High Capital Costs and Complex Installation

High upfront capital requirements for system purchase, installation, and integration with existing facility systems and operations represents one of the biggest barriers for heavy-duty heat pump adoption. These systems tend to be site specific, with heavy upfront costs associated with additional design work, permitting, and infrastructure modifications, particularly when the heat pump is based on ground or water source systems.

Retrofitting existing facilities to accommodate heat pumps can be a technically complex task, involving re-engineering of legacy thermal systems and specialized engineering expertise. The high cost and complexity continue to slow widespread adoption in cost-competitive segments of the industrial sector, with limited standardized designs and scalable installation models.

Limited Awareness and Skilled Workforce Shortage

Another key challenge is the limited awareness of the opportunities and capabilities of heavy-duty heat pumps within industry stakeholders. Many decision-makers being more comfortable with traditional fossil fuel-based systems and lacking knowledge of the operational reliability and performance of large heat pumps, particularly in the case of high-temperature applications.

This perception gap is also exacerbated by a scarcity of professionals trained in the design, installation, and maintenance of industrial-grade heat pump systems. Specialized technicians and engineers are a rare breed, making deployment difficult in emerging markets where technical training infrastructure is limited.

These challenge is multifaceted, requiring a concerted focus on education, workforce development, and outreach with industry players to ensure participants have the trust and the capability throughout the value chain.

Technological Advancements in High-Temperature Heat Pumps

High-temperature heavy-duty heat pumps offer a major growth area, reaching industries where fossil-fuelled boilers have been the norm for temperatures above 100°C. Advancement in refrigerants, compressor design and system integration mean modern heat pumps can serve chemical processing, textiles, food and beverage and paper sectors, providing the required temperatures.

These advances not only enable a wider range of applications but also improve the efficiency of the systems and reduce their lifecycle costs. High-temperature capabilities enable thermal process electrification as demand for decarbonization continues to grow across various industries actively pursuing decarbonization targets and revised operational emissions. Ongoing R&D and demonstration projects, along with government-sponsored pilot programs, are likely to speed advanced heat pump technology deployment across the global industrial landscape.

Integration with Renewable Energy and Waste Heat Recovery

There is a strong coupled potential between heavy-duty heat pumps and renewable energy technologies (solar PV, wind) providing a pathway to 100% decarbonized heating. Heat pumps can generate low-emission thermal energy for industrial and district heating applications using electricity from renewables. Heat pumps are particularly effective at using otherwise wasted low-grade waste heat from industrial processes, data centers and wastewater treatment operations.

This dual capacity makes them critical for circular energy strategies and energy efficiency targets. Energy grids become greener and as carbon pricing mechanisms lock in, the ability to convert waste heat and renewable electricity to usable heat offers a scalable and sustainable pathway for further industrial transformation and energy optimization.

Between 2020 and 2024, the heavy-duty heat pump market witnessed a surge in adoption, mainly due to GHG reduction targets, energy efficiency policies, and increased demand for industrial heat pumps (IHP) in decarbonized heating and cooling applications. Countries in Europe and parts of the Asia-Pacific adopted climate action policies that prompt electrification of heating processes, leading to the widespread introduction of very high-capacity heat pumps, via commercial, district and industrial methods.

Looking ahead to 2025 to 2035, the market will become prehistoric for fast deployment with heat pumps ingrained in the wider smart energy infrastructure. The vast array of AI-powered energy management systems, escalating adoption of waste heat recovery practices, and robust sustainability requirements are anticipated to reshape performance benchmarks and alter market behaviors. This will make the way for the large-scale implementation of heavy-duty heat pumps worldwide through the electrification of thermal processes in high temperature industrial applications.

Comparative Market Analysis

| Market Shift | 2020 to 2024 |

|---|---|

| Regulatory Landscape | Early pilots of energy efficiency directives and incentives to install systems that heat with renewables. |

| Technological Advancements | Advanced compressor designs, low-GWP refrigerants, and modular system configurations. |

| Industry-Specific Demand | High adoption in food & beverage, chemicals, and district heating networks. |

| Sustainability & Circular Economy | Initial focus on reducing fossil fuel reliance and improving COP values. |

| Market Growth Drivers | Incentives under climate policy, increased awareness of lifecycle cost savings, and volatility in energy prices. |

| Market Shift | 2025 to 2035 |

|---|---|

| Regulatory Landscape | Emergence of carbon pricing mechanisms, stricter emissions compliance and mandatory heat electrification policies. |

| Technological Advancements | AI-driven predictive control systems, high-temperature heat pumps (>150°C), and integration with thermal storage. |

| Industry-Specific Demand | Growing data centers and industrial waste heat recovery; expansion in cement, steel, and paper industries |

| Sustainability & Circular Economy | Heat cycles with integrated industrial waste heat reuse, sustainable refrigerants, and net zero targets. |

| Market Growth Drivers | Demand for carbon neutrality, electrification of industrial heat, and integration into smart grid ecosystems. |

The heavy-duty heat pumps market in the United States is benefiting from key momentum drivers, including the decarbonization of industrial heating systems and stronger electrification trends across the manufacturing sector.

Federal clean energy programs are pushing industry towards sustainable thermal solutions as adopt energy efficiency mandates and incentives to increase. Demand from the food processing, chemical and paper sectors, where traditional boilers are being replaced with high-temperature heat pumps, is also driving growth. New opportunities are emerging with innovation in high-capacity systems and integration with smart energy grids.

| Country | CAGR (2025 to 2035) |

|---|---|

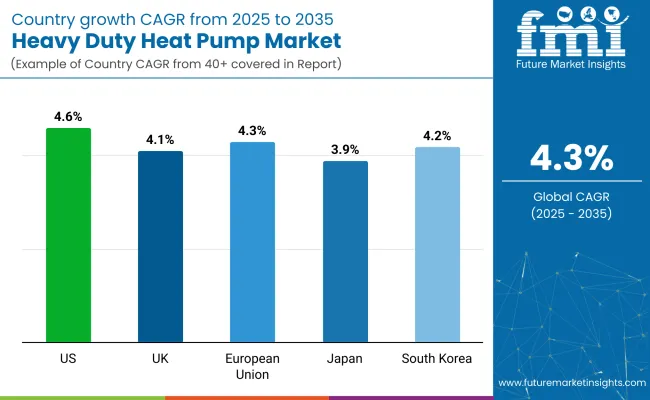

| United States | 4.6% |

UK market for heavy-duty heat pumps is growing in response to increasingly stringent carbon neutrality targets and government programmers such as the Industrial Energy Transformation Fund (IETF). Industry and commercial also look to electrified heat generation under net-zero strategies. Supportive regulatory policies, including restrictions on fossil fuel heating in new non-residential buildings after 2025, are driving demand. District heating and food manufacturing lead the sectors in adopting it. The market in the UK is anticipated to grow at a CAGR of 4.1% during the years 2025 and 2035.

| Country | CAGR (2025 to 2035) |

|---|---|

| United Kingdom | 4.1% |

EU taking the lead in moving towards low-emission industrial heating, the heavy-duty heat pumps market is very much favored. Policy tools such as the Green Deal and Repowered strategy are pushing industries to upgrade to clean thermal technologies589. Germany, France and the Netherlands are each making major investments in decarbonized district heating and electrified process heat. Accelerating adoption in industrial segments like chemicals, metallurgy and textiles, as carbon costs climb. EU market for heavy-duty heat pumps is projected to reach 4.3% CAGR during 2025 to 2035.

| Region | CAGR (2025 to 2035) |

|---|---|

| European Union | 4.3% |

Japan’s industrial heat pump market is growing in line with the push to go carbon neutral by 2050. The government is also supporting industrial decarbonization through the Green Innovation Fund and subsidies for energy-efficient equipment.

There has also been strong demand for heavy-duty heat pumps in sectors like electronics, steel and food processing that require high-temperature systems. Local manufacturers are also investing in R&D which yields compact and high performance units that are exported as well as sold for domestic use. Japan market is expected to achieve a CAGR of 3.9% from 2025 to 2035.

| Country | CAGR (2025 to 2035) |

|---|---|

| Japan | 3.9% |

South Korea industrial technology is also advancing, and the heavy-duty heat pumps market is growing as work continues to reduce dependence on fossil fuels. Aggressive climate policies, including the Korean New Deal and Green Growth Strategy, incentivize industries to transition towards electrified heating systems.

The semiconductor and chemical sectors are leading the way, as are government-backed smart factory programs. Rapid technological development in High-efficiency heat pump systems is reinforcing the market base.

Refrigeration is a major end-use application of heavy-duty heat pumps, accounting for more than a third of the market share in 20252035. The heavy-duty heat pumps market in South Korea is predicted to witness a CAGR of 4.2% through 2025 to 2035.

| Country | CAGR (2025 to 2035) |

|---|---|

| South Korea | 4.2% |

Air-water heat pumps hold a dominant share in the heavy duty segment due to their adaptability in commercial buildings, industrial facilities, and district heating systems. They draw heat from the ambient air and transfer it to a water-based system used for space heating or the production of hot water.

Thanks to wealth of these systems in Europe and East Asia where existing hydronic systems are retrofitted. In turns, government incentives for low-carbon heating technologies within frameworks such as the EU Green Deal drive up adoption. The development of high temperature air-water heat pump models broadened their application level in industrial processes and is expected to act as a key driver for market growth.

Ground source heat pumps have received considerable interest due to their high seasonal efficiency and nearly constant performance at varying outdoor temperatures [3]. These pumps are perfect for cold-climate countries including Northern Europe, Canada, and portions of the USA since they tap into the stable geothermal energy underground. While the upfront installation price can be significant, they're economical over the long haul with energy savings.

They also find increasing use in commercial buildings, schools and large-scale industrial heating applications. Regulatory support and zero-emission building mandates are driving much of the deployment, particularly in countries committed to deep decarbonization of the heating end-use sector.

Electrical heat pump was the most prominent type of power source segment accounting for majority of the total market share, and driven by global decarbonization efforts and heating electrification. The shift to electric-powered systems is becoming an even cleaner, more sustainable alternative to fossil-fuel alternatives as power grids integrate more renewables.

These pumps have very high efficiencies with COPs (Coefficient of Performance) typically above 3.0, and can be used in new construction as well as retrofit projects in urban and industrial applications. Adoption is led by Europe and the Asia-Pacific, driven by emissions regulations, carbon pricing and energy efficiency directives. Advances in technology are allowing electric pumps to provide higher output temperatures, unlocking their use in heavy duty industrial applications.

Gas-drive heat pumps are more prominent in regions where electrical infrastructure is limited or where natural gas is a cheaper fuel source than their electric equivalents. These systems are especially used in heavy-duty industrial applications or remote commercial areas, where there is a demand for reliability and commitment to delivering high-capacity heat.

They provide fuel flexibility and reduced operating costs where natural gas is plentiful. As environmental regulations are progressively tightening concerning fossil fuel utilization, hybrid arrangements and low-outflow burning technologies are making it feasible for these frameworks to remain important. Stable demand is seen in other markets such as Japan and the USA, where fossil fuel competitive energy systems and energy transitions are lagging.

The heavy-duty heat pump industry is on a growth trajectory, propelled by the rising demand for energy-efficient heating and cooling systems spanning the industrial and commercial spectrum. Important global contributors include (but are not limited to) Thermax Ltd, Star Refrigeration, GEA Group, MAN Energy Solutions, Oilon OY, Siemens Energy, and Johnson Controls.

These companies operate on new tech advancements, such as high-temperature heat pumps and combining with renewable energy resources to make it more efficient and sustainable. The market is also seeing trends such as the adoption of environmentally friendly refrigerants and the development of intelligent heat pump systems.

Market Share Analysis by Company

| Company Name | Estimated Market Share (%) |

|---|---|

| Thermax Ltd | 10-15% |

| Star Refrigeration | 8-12% |

| GEA Group | 7-10% |

| MAN Energy Solutions | 5-8% |

| Oilon OY | 4-6% |

| Other Companies | 50-60% |

| Company Name | Key Offerings/Activities |

|---|---|

| Thermax Ltd | Offers high-capacity heat pumps for industrial applications, focusing on energy efficiency and sustainability. |

| Star Refrigeration | Specializes in ammonia-based heat pump systems for large-scale refrigeration and heating applications. |

| GEA Group | Provides customized heat pump solutions for various industries, emphasizing high performance and reliability. |

| MAN Energy Solutions | Develops large-scale heat pump systems integrating renewable energy sources for district heating projects. |

| Oilon OY | Emphasize on industrial heat pumps with environmentally friendly refrigerants and high-temperature capabilities. |

Key Company Insights

Thermax Ltd

Thermax Ltd is a playing a significant role in the heavy-duty heat pump segment recognized nationally and internationally with its integrated sustainable energy and environment solutions. The company’s industrial heat pumps are aimed at sectors like chemicals, pharmaceuticals and food processing.

Thermax focuses on high energy efficiency, low carbon footprints, and lifecycle cost savings. It specializes in high-temperature applications and is aligned with waste heat recovery, a fast-growing segment in the decarbonization.

The firm has poured profuse investment into R&D in producing large-capacity heat pumps that are adaptable to retrofitting into the current infrastructure. Thermax is strategically lining itself up with global climate initiatives and policy frameworks focusing on industrial emissions reduction, assisted by a growing footprint in Asia, the Middle East and parts of Europe.

Star Refrigeration

Star Refrigeration is a UK leader in natural refrigerant systems, especially ammonia-based potent heat pumps. The company is pioneering with heat pumps for district heating, for food processing and for large-scale refrigeration. Star’s systems are designed to maximize reliability, efficiency, and minimal environmental footprint.

Their focus on CO₂ and ammonia refrigerants is a key differentiator in that they provide sustainable alternatives to synthetic refrigerants. Leveraging long-term system monitoring and performance optimization via its data analytics platform, Star delivers operational excellence. Its track record for engineering excellence and dedication to climate goals has earned it a coveted supplier position across Europe.” By expanding into new industrial verticals with significant local service networks and consistent investment in high-temperature applications, Star has been extending further across the EU and into the wider world.

GEA Group

GEA Group is a German engineering company that produces Heavy-Duty heat pumps that are tailored. In their systems, energy recovery is prioritized, reaching thermal outputs up to 90°C, suitable for challenging industrial requirements. GEA’s unique approach involves modular heat pump platforms, providing scalable and flexible solutions for multiple applications.

Early adopters of low-GWP refrigerants, where regulations allow. With a robust global supply chain and localized engineering support, GEA has the ability to respond quickly to activities with regional needs. The company is also progressively introducing tools for digital monitoring, predictive maintenance, etc. GEA’s commitment to performance, sustainability, and customer-centric engineering positions it well in the world’s transition toward low-carbon heating.

MAN Energy Solutions

MAN Energy Solutions is driving innovation in large-scale industrial and municipal heat pump systems, particularly in the context of energy transition and district heating. As part of the Volkswagen Group, MAN exploits engineering scale to offer heat pumps with outputs of greater than 50 MW. In Europe, it is a leader at the interface of heat pumps with renewable sources geothermal, wastewater, and seawater to provide district energy systems. Highly efficient compressors are used in MAN's Turbo series and it runs on eco-friendly refrigerants.

Recent update in Scandinavia and Germany refuse its crown in municipal decarbonization pathways. These systems often encompass real time monitoring and AI-driven control to optimize the load management. MAN is shaping the future of urban heating infrastructure with its focus on scale, reliability, and integration!

Oilon OY

Oilon OY is a Finnish energy technology company specializing in industrial heat pumps and OY burners. Its high-temperature heavy-duty heat pumps operate up to 120°C in applications in food processing, district heating, and paper. Brewing industry upgrades, including full attention to low-GWP refrigerants like CO₂ and propane, complement EU environmental incentives.

The company also makes heating pump units that are compact and modular, so they're better suited for industrial settings with space constraints. Oilon monitors its products throughout the lifecycle, and offers advanced automation and digital diagnostics for energy and performance optimization. Oilon is an increasingly international company operating in the Nordics and Asia-Pacific, continually investing in next generation systems focused on carbon neutrality. Their extensive thermal engineering expertise should provide them with durability over time.

In terms of Product Type, the industry is divided into Air-water Heat Pump, Air-air Heat Pump, Ground Source Heat Pump, Hybrid Heat Pump.

In terms of Power Source, the industry is divided into Electric, Gas Drive.

The report covers key regions, including North America, Latin America, Western Europe, Eastern Europe, East Asia, South Asia, and the Middle East and Africa (MEA).

The global Heavy Duty Heat Pump market is projected to reach USD 3.5 billion by the end of 2025.

The market is anticipated to grow at a CAGR of 4.3% over the forecast period.

By 2035, the Heavy Duty Heat Pump market is expected to reach USD 5.4 billion.

The Air-water Heat Pump segment is expected to dominate the market, due to its high energy efficiency, cost-effectiveness, easy installation, and widespread use in industrial, commercial, and district heating applications.

Key players in the Heavy Duty Heat Pump market include Thermax Ltd, Star Refrigeration, GEA Group, MAN Energy Solutions, Oilon OY.

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Heavy-Truck Composite Component Market Size and Share Forecast Outlook 2025 to 2035

Heavy Cordless Tools Market Analysis Size and Share Forecast Outlook 2025 to 2035

Heavy Haul Truck Market Analysis - Size, Share, and Forecast Outlook 2025 to 2035

Heavy Lifting Equipment Market Size and Share Forecast Outlook 2025 to 2035

Heavy Commercial Vehicle Eps Market Size and Share Forecast Outlook 2025 to 2035

Heavyweight Motorcycles Market Size and Share Forecast Outlook 2025 to 2035

Heavy Oil Cracking Catalyst Market Size and Share Forecast Outlook 2025 to 2035

Heavy Wall Bottles Market Size, Share & Forecast 2025 to 2035

Heavy Duty Pallet Rack Market Size and Share Forecast Outlook 2025 to 2035

Heavy Duty Corrugated Packaging Market Size and Share Forecast Outlook 2025 to 2035

Heavy-duty Truck AMT Transmission Market Size and Share Forecast Outlook 2025 to 2035

Heavy-duty Truck AMT Synchronizer Market Size and Share Forecast Outlook 2025 to 2035

Heavy-Duty Hydrogen Compressors Market Size and Share Forecast Outlook 2025 to 2035

Heavy Duty Bins Market Size and Share Forecast Outlook 2025 to 2035

Heavy Duty Pick Up Trucks Market Size and Share Forecast Outlook 2025 to 2035

Heavy Duty Gas Turbine Market Size and Share Forecast Outlook 2025 to 2035

Heavy Duty Vehicle Rental Market Size and Share Forecast Outlook 2025 to 2035

Heavy Duty Engine Market Size and Share Forecast Outlook 2025 to 2035

Heavy Duty Trucks Market Size and Share Forecast Outlook 2025 to 2035

Heavy Duty Paper Tags Market Insights – Growth & Demand 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA