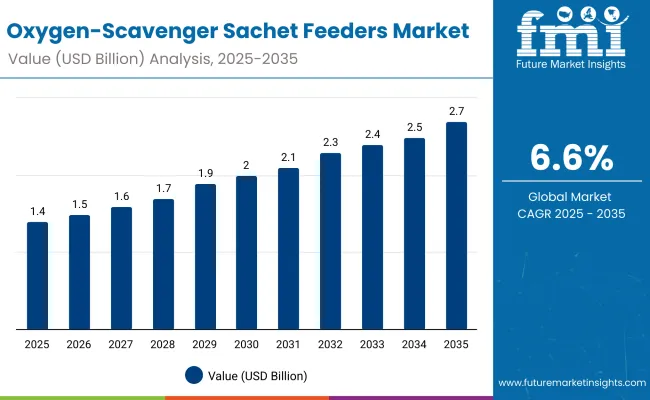

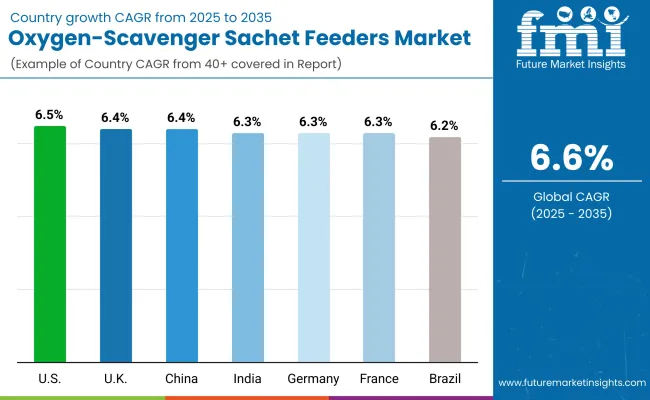

The global Oxygen-Scavenger Sachet Feeders Market will grow from USD 1.4 billion in 2025 to USD 2.7 billion by 2035 at a CAGR of 6.6 %. Market growth is supported by increasing demand for active packaging in food preservation, pharmaceuticals, and electronics.

Rotary feeders offer continuous operation and high placement accuracy, ensuring uniform sachet dispensing. Between 2025 and 2030, automation upgrades and clean-room compliant feeding systems will accelerate adoption. Asia-Pacific will lead global expansion due to high food-processing capacity and government incentives for food-safety innovation.

Between 2020 and 2024, rising consumer focus on freshness and food safety spurred adoption of oxygen-scavenging sachets in sealed packaging. Manufacturers transitioned from chemical-based absorbers to eco-friendly iron and enzyme formulations. By 2035, the market will reach USD 2.7 billion, driven by advanced filling technologies and automated multi-lane feeders. Asia-Pacific will dominate with extensive food & pharma packaging expansion, while North America will focus on precision systems for medical and nutraceutical products.

| Metric | Value |

|---|---|

| Estimated Value in (2025E) | USD 1.4 billion |

| Forecast Value in (2035F) | USD 2.7 billion |

| Forecast CAGR (2025 to 2035) | 6.6% |

Growth is driven by heightened demand for extended shelf-life packaging across food, healthcare, and electronics sectors. Automatic sachet feeders improve production efficiency, maintain product sterility, and reduce manual contamination risk. Innovations in biodegradable sachet materials and clean-room automation further enhance system adoption worldwide.

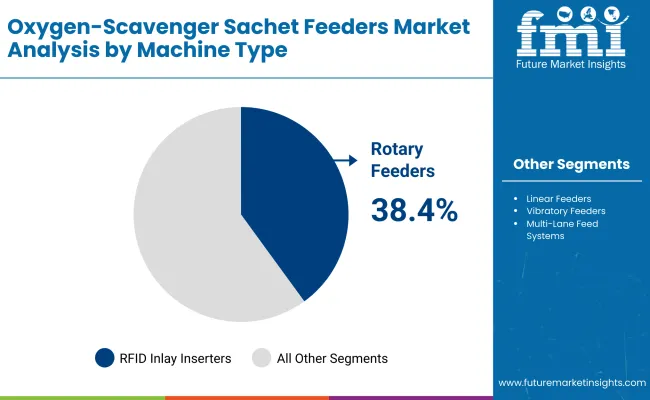

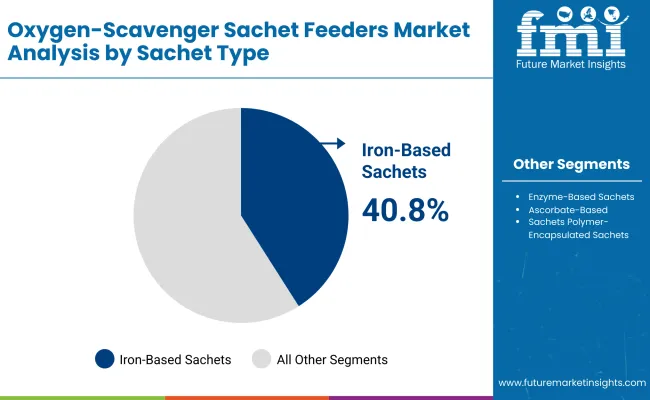

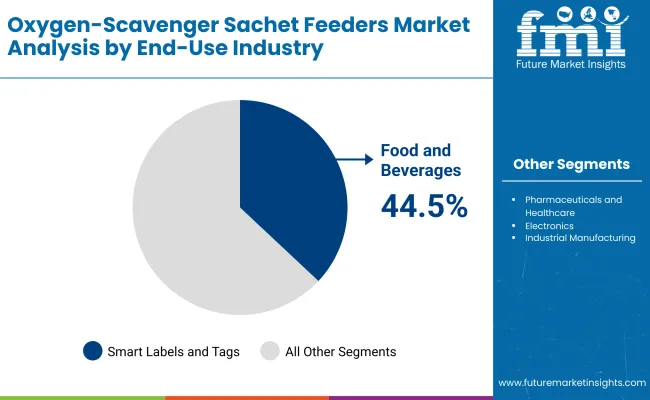

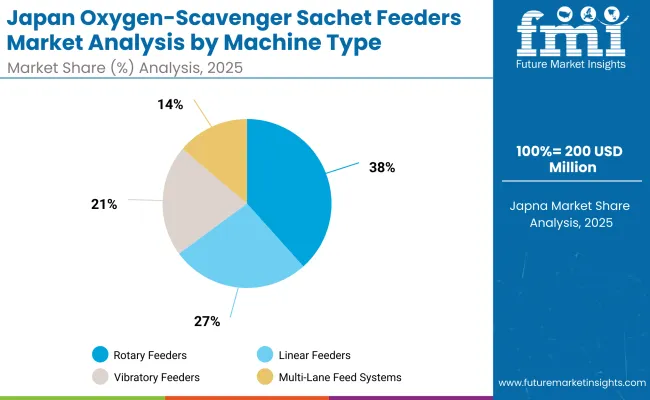

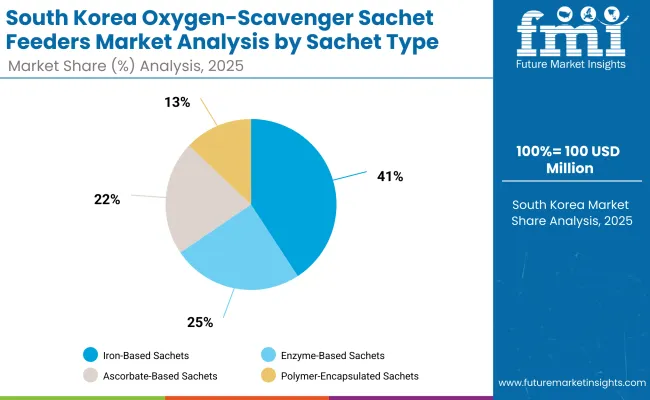

The market is segmented by machine type, sachet type, end-use industry, and region. Machine types include rotary, linear, vibratory, and multi-lane feed systems. Sachet types encompass iron-based, enzyme-based, ascorbate-based, and polymer-encapsulated formats. End-use industries comprise food & beverages, pharmaceuticals & healthcare, electronics, and industrial manufacturing. Geographically, the market covers North America, Europe, Asia-Pacific, Latin America, and the Middle East & Africa.

Rotary feeders are projected to hold 38.4% of the market in 2025, driven by their ability to deliver continuous sachet feeding at high speeds. Their precision rotary motion ensures accurate placement and consistent flow for mass production lines in food, pharmaceutical, and electronics packaging.

Manufacturers value their low maintenance, compact design, and ability to handle varying sachet sizes. Integration with automated filling and sealing systems enhances overall productivity. As packaging lines evolve toward continuous, high-throughput operations, rotary feeders remain the dominant machine type.

Iron-based sachets are expected to represent 40.8% of the market in 2025, supported by their reliability, low cost, and effectiveness in oxygen absorption. They are widely used to protect moisture- and oxidation-sensitive goods such as dried foods, pharmaceuticals, and supplements.

Their simple chemistry, long shelf life, and compatibility with recyclable packaging reinforce adoption across industries. Continuous innovation in miniaturized sachet formats enhances usability in compact packs. As sustainability and freshness preservation align, iron-based sachets remain the industry standard for oxygen scavenging.

The food and beverage sector is projected to command 44.5% of the market in 2025, as oxygen-scavenging technologies become integral to maintaining freshness and quality in packaged goods. These sachets prevent spoilage, color changes, and microbial growth in snacks, baked goods, and ready-to-eat items.

Retailers and manufacturers are adopting automated sachet feeding systems to improve production efficiency and product consistency. With consumer preference for preservative-free foods growing, oxygen-control packaging remains essential. The food and beverage industry continues to drive the largest end-use share through sustainable and active packaging adoption.

The market is driven by stringent food safety regulations and growing automation in high-speed packaging lines to enhance accuracy and hygiene. However, high equipment costs and limited compatibility with biodegradable films restrict widespread implementation. Opportunities emerge from bio-enzyme technologies and refillable sachet formats supporting sustainable packaging. Key trends include multi-lane feed module integration, IoT-enabled dispensing controls, and eco-friendly active packaging systems improving efficiency and environmental performance.

The global oxygen-scavenger sachet feeders market is expanding as demand for shelf-life extension, food preservation, and sterile pharmaceutical packaging continues to grow. Asia-Pacific dominates global manufacturing with advanced automation and large-scale sachet production facilities.

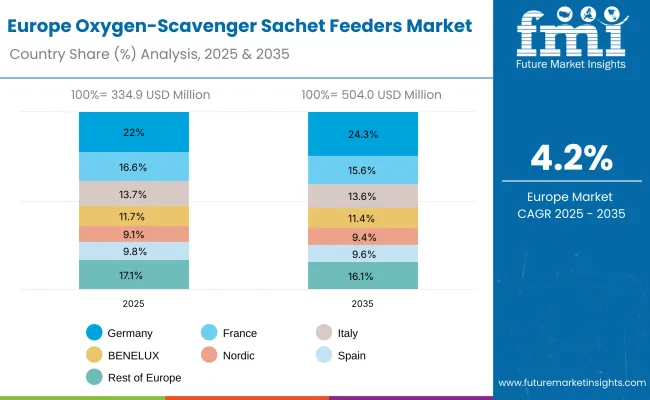

North America prioritizes FDA-compliant active packaging for medical and food sectors, while Europe leads innovation in sustainable oxygen-absorbing materials and high-precision feeder systems. Technological integration in rotary, multi-lane, and compact dispensing systems is accelerating adoption across food, nutraceutical, and pharmaceutical packaging lines.

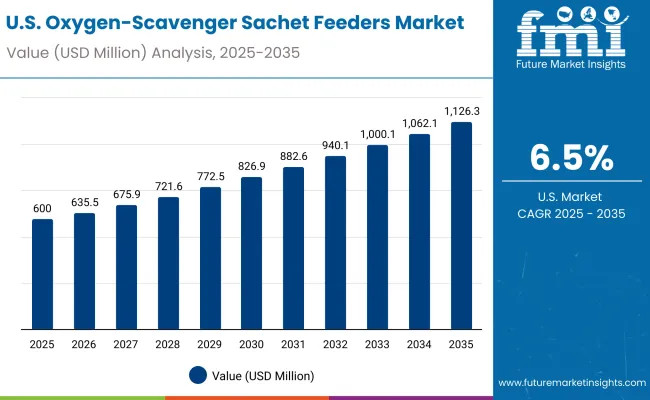

The USA will grow at 6.5% CAGR, driven by strong adoption of automated food and nutraceutical packaging lines. Rotary feeders are gaining traction in medical and sterile product handling. Growth in active packaging for fresh produce, pharmaceuticals, and supplements reflects increasing demand for extended shelf-life solutions. Enhanced compliance with FDA and ISO standards strengthens domestic manufacturing competitiveness.

Germany will expand at 6.3% CAGR, supported by innovation in enzyme-based oxygen-scavenging technologies. The nation’s strong engineering base fosters development of safe, energy-efficient sachet feeding equipment. Industrial automation across pharmaceutical facilities ensures compliance with EU regulations, while sustainability initiatives promote the shift toward biodegradable scavenger materials.

The UK will grow at 6.4% CAGR, emphasizing food-grade oxygen-control systems and sustainable packaging. Government-backed initiatives for packaging waste reduction enhance industry modernization. Strong adoption in high-value pharmaceutical packaging supports the nation’s growing biologics and medical export sectors. The use of recyclable active sachets continues to increase.

China will grow at 6.4% CAGR, supported by rapid automation in food processing andpackaging sectors. Domestic OEMs are expanding production of multi-lane sachet feeding systems for industrial-scale operations. Exports of iron-based oxygen absorbers and dispensing equipment are surging, establishing China as a global supply hub for active packaging technology.

India will grow at 6.3% CAGR, driven by expansion in ready-to-eat and instant food categories. Government initiatives promoting food safety automation and modern packaging infrastructure are accelerating technology adoption. Pharmaceutical manufacturers are increasingly deploying oxygen management systems to protect sensitive formulations and extend product stability.

Japan will grow at 7.0% CAGR, leading global innovation in enzyme-based and nano-coated oxygen-absorbing sachets. Compact automation solutions are optimized for precision medical and nutraceutical packaging. The country’s emphasis on high-quality, oxygen-free containers strengthens its leadership in sustainable and advanced active packaging solutions.

South Korea will lead with 7.1% CAGR, driven by the presence of smart sachet feeder manufacturers and advanced R&D capabilities. The development of polymer-encapsulated oxygen absorbers supports extended usability and safety. Export-oriented production of automated feeding systems for food and pharmaceutical applications continues to fuel national market growth.

Japan’s oxygen-scavenger sachet feeders market, valued at USD 200.0 million in 2025, is dominated by rotary feeders, holding a 37.1% share due to their superior speed and consistency in high-volume food and pharmaceutical packaging. Linear feeders ensure steady dosing for small-batch operations, while vibratory feeders offer precision handling of lightweight sachets. Multi-lane feed systems are gaining ground in flexible packaging automation.

South Korea’s oxygen-scavenger sachet feeders market, worth USD 100.0 million in 2025, is led by iron-based sachets, representing 42.7% share for their high oxygen absorption rate and long shelf-life protection. Enzyme-based sachets cater to eco-conscious packaging, while ascorbate-based variants serve moisture-sensitive goods. Polymer-encapsulated sachets are increasingly utilized for electronics and medical device packaging applications.

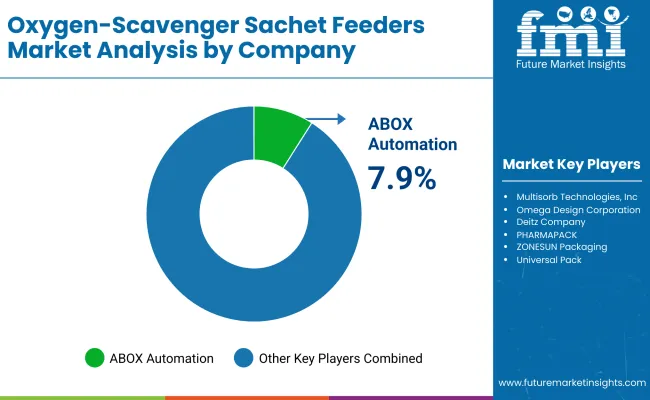

The market is moderately fragmented with key players including ABOX Automation, Multisorb Technologies Inc., Omega Design Corporation, Deitz Company, GTI Inc. (Golden-Tech International), PHARMAPACK, ZONESUN Packaging, Universal Pack, Matrix Packaging Machines, and Marchesini Group. Companies focus on robotic integration, precision feeding, and bio-based material compatibility.

Key Developments

| Item | Value |

|---|---|

| Quantitative Units | USD 1.4 Billion (2025 baseline) |

| By Machine Type | Rotary, Linear, Vibratory, Multi-Lane Feed Systems |

| By Sachet Type | Iron-Based, Enzyme-Based, Ascorbate-Based, Polymer-Encapsulated |

| By End-Use Industry | Food & Beverages, Pharmaceuticals & Healthcare, Electronics, Industrial |

| Key Companies Profiled | ABOX Automation, Multisorb Technologies Inc., Omega Design Corporation, Matrix Packaging Machines |

| Additional Attributes | Market driven by automation in active packaging and eco-sachet innovation |

The Oxygen-Scavenger Sachet Feeders Market is valued at USD 1.4 billion in 2025.

The Oxygen-Scavenger Sachet Feeders Market will reach USD 2.7 billion by 2035.

The market is projected to grow at a CAGR of 6.6 % during the forecast period.

Iron-Based Sachets lead the market with a 40.8 % share, owing to cost-effective and efficient oxygen absorption performance.

The Food and Beverage sector dominates with a 44.5 % share, driven by stringent packaging hygiene standards and longer shelf-life requirements.

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Sachet Packaging Machines Market Size and Share Forecast Outlook 2025 to 2035

Sachet Packaging Market Size and Share Forecast Outlook 2025 to 2035

Sachet Filler Market Analysis - Size, Share, & Forecast Outlook 2025 to 2035

Sachet Packaging Industry Analysis in Asia Pacific - Size, Share, and Forecast 2025 to 2035

Market Leaders & Share in the Sachet Packaging Machines Industry

Competitive Overview of Sachet Packaging Market Share

Sachet and Pouch Handling Systems Market

USA Sachet Packaging Market Report – Trends, Demand & Industry Outlook 2025-2035

Snap Sachets Market Size and Share Forecast Outlook 2025 to 2035

Market Share Breakdown of Snap Sachets Manufacturers

ASEAN Sachet Packaging Market Analysis – Size, Share & Forecast 2025-2035

Japan Sachet Packaging Market Outlook – Share, Growth & Forecast 2025-2035

Germany Sachet Packaging Market Trends – Size, Share & Growth 2025-2035

Sanitizer Sachet Market Size and Share Forecast Outlook 2025 to 2035

Key Companies & Market Share in Sanitizer Sachet Industry

Single Dose Sachet Market

Micro-Dosing Sachet Fillers Market Analysis - Size and Share Forecast Outlook 2025 to 2035

Asia Pacific Sachet Packaging Machines Market Size and Share Forecast Outlook 2025 to 2035

Aluminium Foil Sachet Market

Odor-Neutralizing Sachets Market Size and Share Forecast Outlook 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA