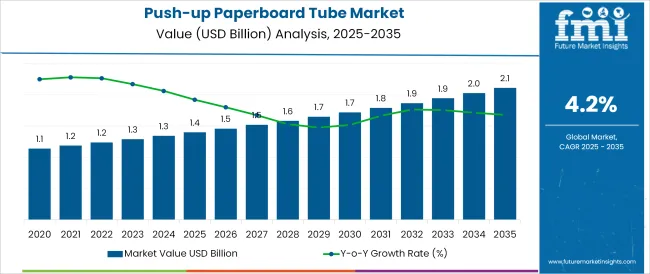

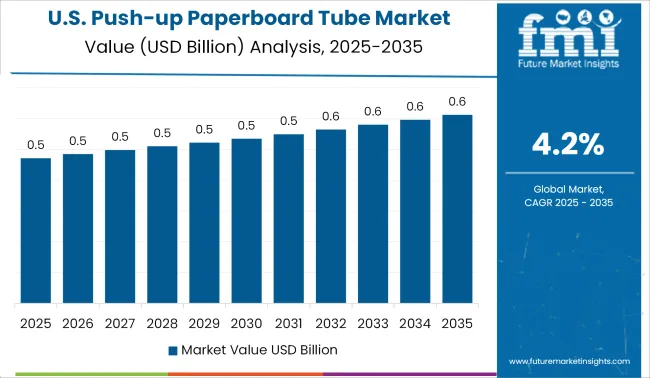

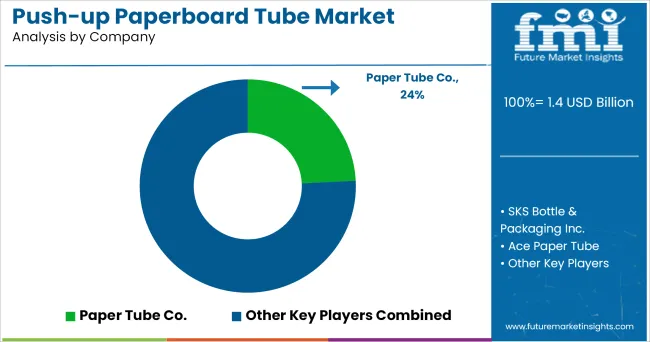

The Push-up Paperboard Tube Market is estimated to be valued at USD 1.4 billion in 2025 and is projected to reach USD 2.1 billion by 2035, registering a compound annual growth rate (CAGR) of 4.2% over the forecast period.

The push‑up paperboard tube market is experiencing robust growth fueled by growing consumer preference for sustainable, premium packaging across personal care, food, and beverage sectors. Eco-conscious brands are prioritizing recyclable and fiber-based materials to replace plastic alternatives.

Technological advancements in high-barrier coatings, precision forming, and automated tube-filling machinery are enabling functional, eye-catching packaging with secure push‑up mechanisms. Meanwhile, sustainability regulations especially in Europe and North America are reinforcing adoption of paperboard tubes. The market outlook remains positive as manufacturers continue to innovate with compostable liners, premium finishes, and efficient production methods.

Brands benefit from the tubes’ convenience, reusability, and shelf presence, and they leverage these attributes to support product differentiation in retail and direct‑to‑consumer channels. Overall, push‑up paperboard tubes are becoming a strategic packaging choice that aligns with environmental goals, brand aesthetics, and consumer demand for convenience.

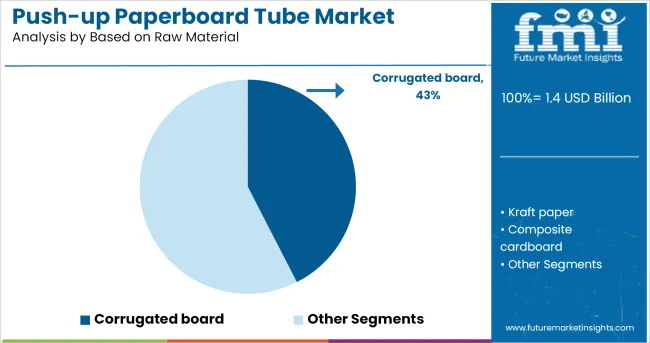

It is observed that corrugated board accounts for 42.5% of the market share within raw material classification. This prominence is attributed to its structural strength, cost-effectiveness, and ease of sourcing.

Corrugated board has been favored due to its ability to support sturdy push-up mechanisms and withstand repeated handling, which ensures product protection and performance. Additionally, the material offers superior printability and branding potential, facilitating high-quality graphics and consumer engagement.

Supply chain efficiencies and availability of recycled fiber content have also enabled sustainable cost optimization. The cumulative effect of durability, visual appeal, and eco-friendly sourcing has positioned corrugated board as the leading raw material choice in push-up tube production.

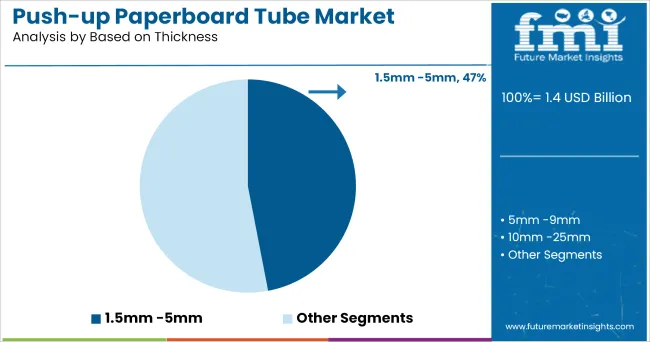

It is noted that tubes within the 1.5 mm to 5 mm wall thickness range hold 47.0% of market share. This segment’s leadership is supported by its ideal balance between rigidity and material economy.

This thickness range provides sufficient structural integrity to support push-up functionality while minimizing waste and reducing material costs. It enables manufacturers to optimize tube weight without compromising shelf performance or user experience.

Additionally, such tubes are compatible with standard filling lines and automated machinery, allowing for efficient high-speed production. These combined benefits of performance, cost savings, and process compatibility have made the 1.5 mm–5 mm thickness range the preferred choice among manufacturers and brands.

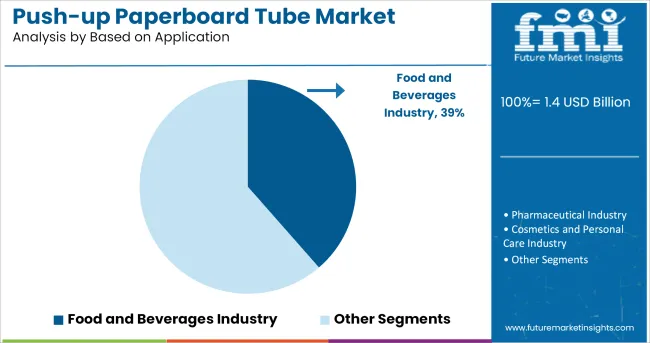

It is recognized that the food and beverages industry segment holds 38.6% of total market share. This leadership has been driven by increasing demand for eco-conscious, convenient, and premium packaging formats for items such as nutritional powders, confectionery, and ready-to-drink pods.

Push‑up paperboard tubes offer airtightness and portability, enhancing product freshness and consumer ease of use. Furthermore, industry regulations around food safety and packaging sustainability have supported the adoption of fiber-based tubes.

The visual appeal of printed, branded tubes has also enabled stronger retail presence, especially in gifting and on-shelf merchandising. As a result, push‑up tubes have become a favored solution within food and beverage packaging, integrating functional performance with environmental integrity.

Push-up paperboard tubes are highly in demand as a convenient packaging solution that provides quality protection to various items like jewellery, cosmetics, paintings and others. Apart from protection and preservation, these push-up paper tubes enhance the image of the product by the attractive packaging solution.

Push-up paperboard tube packaging has a wide application for products that need complete protection against moisture. It is very efficient in resisting heat and pressure and thus considered a safe packaging solution.

One of the key factors for increased demand is that these push-up paperboard tubes are biodegradable and it is easy to recycle. The rise in demand for environment-friendly products among the manufacturers as well as consumers will boost the push-up paperboard tube market to a great extent. These paperboard tubes are cost-effective though it provide numerous benefits to the consumers.

Push-up paperboard tubes are efficient in saving space so it is widely used for packaging of electrical and packing tape, aluminum foil, cellophane wrap, films, fabric, foam, labels, disposable paper products, ribbon and other products. The manufacturers nowadays prefer such packaging for their product promotion activity through digital printing on the push-up paperboard tube which is trending in the market.

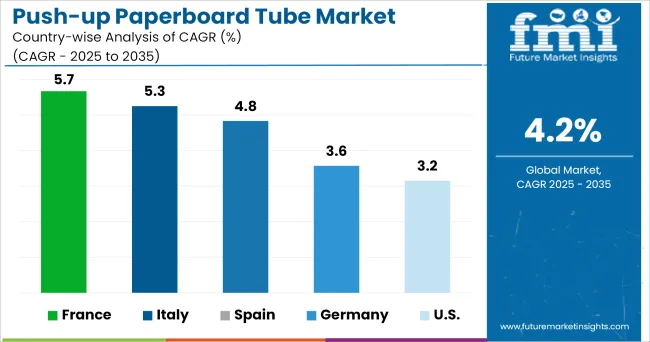

North American push-up paperboard tube market is anticipated to have a significant growth in the forecasted period because in this region manufacturers prefer to pay more for an efficient packaging solution that would not only protect their product but also enhance the product appeal among the consumers.

The European market has a growth opportunity in the push-up paperboard tube market as the government is planning to ban hazardous packaging materials like plastics for environmental protection. Thus manufacturers are shifting towards environment-friendly packaging solutions such as push-up paperboard tubes that has low carbon footprints and provides safe packaging solutions.

Some key manufacturers operating the business in the push-up paperboard tube market globally includes

The report is a compilation of first-hand information, qualitative and quantitative assessment by industry analysts, inputs from industry experts and industry participants across the value chain. The report provides an in-depth analysis of parent market trends, macro-economic indicators and governing factors along with market attractiveness as per segments. The report also maps the qualitative impact of various market factors on market segments and geographies.

The global push-up paperboard tube market is estimated to be valued at USD 1.4 billion in 2025.

The market size for the push-up paperboard tube market is projected to reach USD 2.1 billion by 2035.

The push-up paperboard tube market is expected to grow at a 4.2% CAGR between 2025 and 2035.

The key product types in push-up paperboard tube market are corrugated board, kraft paper and composite cardboard.

In terms of based on thickness, 1.5mm -5mm segment to command 47.0% share in the push-up paperboard tube market in 2025.

Our Research Products

The "Full Research Suite" delivers actionable market intel, deep dives on markets or technologies, so clients act faster, cut risk, and unlock growth.

The Leaderboard benchmarks and ranks top vendors, classifying them as Established Leaders, Leading Challengers, or Disruptors & Challengers.

Locates where complements amplify value and substitutes erode it, forecasting net impact by horizon

We deliver granular, decision-grade intel: market sizing, 5-year forecasts, pricing, adoption, usage, revenue, and operational KPIs—plus competitor tracking, regulation, and value chains—across 60 countries broadly.

Spot the shifts before they hit your P&L. We track inflection points, adoption curves, pricing moves, and ecosystem plays to show where demand is heading, why it is changing, and what to do next across high-growth markets and disruptive tech

Real-time reads of user behavior. We track shifting priorities, perceptions of today’s and next-gen services, and provider experience, then pace how fast tech moves from trial to adoption, blending buyer, consumer, and channel inputs with social signals (#WhySwitch, #UX).

Partner with our analyst team to build a custom report designed around your business priorities. From analysing market trends to assessing competitors or crafting bespoke datasets, we tailor insights to your needs.

Supplier Intelligence

Discovery & Profiling

Capacity & Footprint

Performance & Risk

Compliance & Governance

Commercial Readiness

Who Supplies Whom

Scorecards & Shortlists

Playbooks & Docs

Category Intelligence

Definition & Scope

Demand & Use Cases

Cost Drivers

Market Structure

Supply Chain Map

Trade & Policy

Operating Norms

Deliverables

Buyer Intelligence

Account Basics

Spend & Scope

Procurement Model

Vendor Requirements

Terms & Policies

Entry Strategy

Pain Points & Triggers

Outputs

Pricing Analysis

Benchmarks

Trends

Should-Cost

Indexation

Landed Cost

Commercial Terms

Deliverables

Brand Analysis

Positioning & Value Prop

Share & Presence

Customer Evidence

Go-to-Market

Digital & Reputation

Compliance & Trust

KPIs & Gaps

Outputs

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Industry Share & Competitive Positioning in Push-up Paperboard Tube Market

Paperboard Partition Market Size and Share Forecast Outlook 2025 to 2035

Tube and Core Market Size and Share Forecast Outlook 2025 to 2035

Tube Tester Market Size and Share Forecast Outlook 2025 to 2035

Tube Rotator Market Size and Share Forecast Outlook 2025 to 2035

Tuberculosis Therapeutics Market Size and Share Forecast Outlook 2025 to 2035

Tube Laminating Films Market Size and Share Forecast Outlook 2025 to 2035

Tube Filling Machine Market Size and Share Forecast Outlook 2025 to 2035

Paperboard Packaging Market Size and Share Forecast Outlook 2025 to 2035

Tube Ice Machine Market Size and Share Forecast Outlook 2025 to 2035

Tube Closures Market Size and Share Forecast Outlook 2025 to 2035

Tube Sealing Machines Market Analysis by Tube type, Technology type, End User, and Region through 2025 to 2035

Paperboard Mailer Market Growth - Demand & Forecast 2025 to 2035

Tuberculous Meningitis Treatment Market - Demand & Innovations 2025 to 2035

Tube Feeding Formula Market Analysis by Product Type, Form, End User, Primary Condition and Distribution Channel Through 2035

Market Share Distribution Among Tube Filling Machine Manufacturers

Competitive Breakdown of Tube Sealing Machines Providers

Breaking Down Market Share in Tube Laminating Films

Competitive Overview of Tube and Core Market Share

Paperboard Tray Market Growth - Trends & Forecast 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA