The market for structure directing agents (SDAs) is focused on the use of chemical compounds that serve to assist in the formation of porous structures, particularly zeolites, mesoporous structures and metal-organic frameworks (MOFs). These agents play a vital role in controlling pore size, pore shape, and pore order in catalysis, adsorption, separation processes, and pharmaceutical synthesis.

Increasing demand for zeolites in petrochemical refining, increasing use of nanostructured materials, and technological advances in the field of green chemical synthesis are other factors propelling the market. In addition, the market is gaining momentum by the growing use for gas separation, carbon capture, and drug delivery applications.

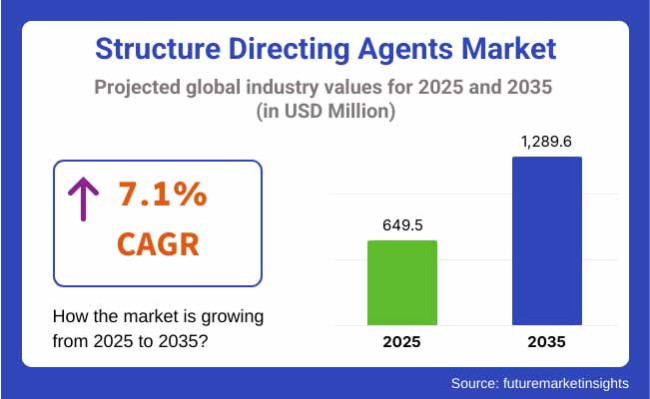

In 2025, the global structure directing agents market is projected to reach approximately USD 649.5 million, with expectations to grow to around USD 1,289.6 million by 2035, reflecting a Compound Annual Growth Rate (CAGR) of 7.1% during the forecast period.

The projected CAGR highlights the growing use of SDAs in energy-saving catalysis, increasing demand for SDAs in chemical manufacturing for high-performance materials, and an upsurge in bio-based and sustainable structure directing agents. In addition, applications in the fields of environmental remediation and water treatment are expected to continue propelling market growth.

North America hold a significant share in the structure directing agents market, driven by solid demand for zeolites in refining, increasing R&D expenditure for next generation materials, and established chemical and pharmaceutical industries.

Petrochemical and environmental applications of SDAs remain heavily weighted to the United States and Canada, along with ongoing work on custom-pore-structure materials for adsorption and catalysis. The market is also being facilitated by government support for green chemistry and carbon capture technology.

The major driving nations of this region include Germany, France, and the UK, contributing towards traditional zeolite-based catalytic processes and high-end material studies. Growing environmentally friendly practice policies in the European Union, to control emission and promote the use of clean energy is anticipated to drive up the demand for SDAs in industrial waste treatment and adsorption. In addition, development in nanomaterials and pharmaceutical innovations stimulates sector growth across region.

Among regions, the structure directing agents market is expected to grow at the highest rate in the Asia-Pacific region owing to increase in industrialization coupled with expanding petrochemical production, and growing usage of advanced materials in pharmaceuticals and water treatment in the countries like China, India, Japan, and South Korea.

Market demand is driven by the growing usage of zeolites within refinery operations in the region, increasing government focus on pollution control, and burgeoning applications of nanomaterials. In addition, such factors as rising preference for customized SDAs in special chemical synthesis are also expected to boost demand for market.

Challenges

High Production Costs and Limited Availability of Raw Materials

The manufacturing process and industry challenges are also accounted for in the report. Special organic and inorganic SDAs will be needed for zeolites, mesoporous materials, and metal-organic frameworks (MOFs), which are expensive and difficult to obtain chemicals. Tighter environmental regulations of chemical synthesis and emissions are squeezing production costs as well as compliance for producers.

Opportunities

Growth in Catalysis, Renewable Energy, and Nanotechnology Applications

Increasing applications of SDA in the synthesis of advanced materials, green chemistry, and nanotechnology drives the growth of the market. However, bio-based SDAs, artificial intelligence-driven materials design, and sustainable zeolite synthesis all enhance efficiency while minimizing ecological impacts. In addition, the advent of SDAs in areas such as fuel cell technology, CO₂ capture, and novel drug delivery systems is providing additional market opportunities.

Between the period 2020 to 2024, supply chain disruption, regulatory constraints were also impediments while little innovation in green SDAs hampered sustainable market growth.

The market will graze towards bio-based, AI-optimized, and high-performance SDA formulations by 2025 to 2035. Greener SDA for green chemical synthesis, AI-driven molecular modelling for precise materials design, advanced SDA for next-gen nanomaterials will revolutionize industry applications. Additionally, governmental policies that promote renewable energy material and CO₂-reducing catalytic procedures will further enhance the adoption of SDAs in sustainable technologies.

Market Shifts: A Comparative Analysis 2020 to 2024 vs. 2025 to 2035

| Market Shift | 2020 to 2024 Trends |

|---|---|

| Regulatory Landscape | Compliance with REACH, EPA, and chemical safety standards |

| Technology Innovations | Growth in organic SDAs for zeolite and nonporous material synthesis |

| Market Adoption | Demand for zeolites, mesoporous materials, and MOFs for catalysis and separation processes |

| Sustainability Trends | Shift toward low-impact SDA synthesis and improved recycling methods |

| Market Competition | Dominated by chemical and material science firms (BASF, Clariant, Zeolyst, ExxonMobil, Chemiewerk Bad Köstritz, PQ Corporation, Tosoh Corporation) |

| Consumer Trends | Demand for efficient catalysts, petrochemical refining, and high-performance adsorbents |

| Market Shift | 2025 to 2035 Projections |

|---|---|

| Regulatory Landscape | Stricter environmental mandates on SDA production, AI-optimized material design, and biodegradable SDAs |

| Technology Innovations | Advancements in AI-driven molecular design, sustainable bio-based SDAs, and quantum computing-assisted material engineering |

| Market Adoption | Expansion into renewable energy, carbon capture, and drug delivery applications |

| Sustainability Trends | Large-scale adoption of biodegradable SDAs, bio-derived templating agents, and CO₂-neutral material production |

| Market Competition | Rise of AI-powered material startups, sustainable SDA innovators, and biotech-based material synthesis firms |

| Consumer Trends | Growth in green chemistry applications, AI-designed SDAs, and bio-inspired nanomaterials |

Directing agent market in the USA - chemical supplier, producer, or manufacturer industrial's excess demand increasing use of structure-directing agents (SDAs) in zeolite synthesis and nanomaterial formation is anticipated to propel the market.

Also driving market growth are major chemical industries and thousands of dollars’ worth of investment in advanced material research. Increasing need for high-performance catalysts in refining and petrochemical sectors is further stimulating the market demand.

| Country | CAGR (2025 to 2035) |

|---|---|

| USA | 7.4% |

UK structure directing agents market is influenced by increasing investments in nanotechnology, sustainable catalysts, and advanced material science. The SDAs is growing in the pharmaceutical formulation and industrial application.

The market trends are defined by the government policies to support green chemistry and the development of sustainable materials. In addition, partnerships between academic institutions and chemical manufacturers are driving innovation in zeolite catalysts and structure-directing agents.

| Country | CAGR (2025 to 2035) |

|---|---|

| UK | 6.9% |

The EU structure directing agents market is gradually thriving, due to an increasing applications in chemical synthesis, biopharmaceutical production, and energy-efficient catalysis. Tight regulations from the EU on sustainable and green chemical processes are shaping market trends.

Germany, the Netherlands, and France are key markets, showing strong demand for SDAs in water treatment, gas separation technologies, and industrial catalysis. Additionally, growth of the market is driven by advancement of porous material engineering and zeolite utilization.

| Region | CAGR (2025 to 2035) |

|---|---|

| EU | 6.8% |

Japan has a highly developed chemical research, development of nanotechnology, and increased demand for high-purity catalysts, The Structure Directing Agents market in Japan is expected to flourish in the years to come. Increase of amelioration of SDAs in specialty chemicals and petrochemical refining is supporting the market expansion.

The growing application of sustainable and bio-based structure-directing agents and supporting government policies pertaining to green chemistry are additionally driving the market growth. Japan's supremacy in advanced material science is helping the market as well.

| Country | CAGR (2025 to 2035) |

|---|---|

| Japan | 7.1% |

The South Korea structure directing agents market is experiencing robust growth with increasing investments in the chemical, semiconductor, and industrial catalyst sectors. The need for SDAs in producing high-performance zeolites and electronic materials is growing.

Market trends are influenced by government endeavors in nanotechnology research and green chemical processes. In addition, the growth of the market is attributed to the advancing SDA formulations into pharmaceutical and environmental applications.

| Country | CAGR (2025 to 2035) |

|---|---|

| South Korea | 7.0% |

Organic structure directing agents (OSDAs) help achieve precise and controlled structures in zeolites, catalysts, and high-performance adsorbents, directing the formation of microporous and mesoporous materials. The agents consist largely of (amine, quaternary ammonium salts, and organic surfactants) which function that in the self-assembly of crystalline structures.

Control of pore size, framework topology, and chemical functionality are among the significant drivers of the organic SDA during zeolite synthesis. Catalyst producers and material scientists rely primarily on organic structure-directing agents (OSDAs) to synthesize customized molecular sieves with enhanced adsorption and catalytic activities, which lead to increased efficiency in chemical processing and separation technologies.

Organic SDAs are also widely used in green chemistry and sustainable synthesis processes with a reduced environmental risk and a lower usage of harmful solvents. Researchers extensively study organic templates that are biodegradable and have low-energy synthesis pathways, as these are promising candidates for higher environmental sustainability along with lower regulatory hurdles.

Despite the advantages of organic SDA synthesis, it is pricier and poses a risk of thermal decomposition, which has further led manufacturers to develop hybrid templating methods for synthesis, recyclable organic directing agents and solvent-free synthesis processes, which would enhance cost-effective scalability of the process.

This concept is gradually spreading to the synthesis of crystalline materials and one of the more appealing alternatives to conventional organic structure directing agents (OSDAs) for industrial and high-temperature applications is inorganic structure directing agents (ISDAs). Including alkali metals, metal oxides, and silicate compounds, these agents can serve as accurate guides during the process of thermally stable and chemically durable framework development.

Their high structural stability and ability to form rigid, robust crystalline networks make inorganic SDAs one of the primary reasons for demand among structural debtors. ISDAs are used in diverse industries, including petrochemical refining, gas separation and semiconductor manufacturing, to develop robust zeolites and synthetic crystalline material, superior materials performance under harsh working conditions.

Moreover, inorganic SDAs play a significant role in the synthesis of electronic materials, where they help in facilitating the homogeneous growth of crystals and defect-free lattice structures. It is mainly because most of the research in this area is focused on complex modular inorganic SDA systems, co-templating nano-scale incorporation, and high-yield crystallisation processes affording control over crystalline architecture and material homogeneity.

Although appealing, the use of inorganic SDA is limited and confined to template removal problems with a narrow range of available frameworks, motivating manufacturers to explore synergistic SDA systems, multi-component directing agents, and AI-enhanced material design to ensure increased responsiveness and broader application opportunities.

Zeolites represent one of the largest application fields of template materials because such microporous alum inosilicate compounds are essential catalysts, adsorbents, and ion-exchangers for numerous industries. Silanes diradicals as Slit directs the formation of high fidelity pore architecture to ensure outstanding selectivity and effective use of zeolites.

The adoption of SDA ranks among the primary drivers in the production of zeolite synthesis using SDA in petrochemical refining and molecular sieving applications. Refineries, chemical producers, and eco-engineering companies at their core, underpinned through catalytic cracking, hydrocarbon isomerization, and the purification of air, offer enhanced operational efficiency while optimizing resource utilization in practice.

Zeolite catalysts are also vital for the production of greener fuels and emissions control by enabling reduced carbon footprints in industry. Various approaches are being pursued by researchers including utilization of bio-derived zeolite templates, AI-aided catalyst design, and innovative mesoporous architectures to ensure enhanced catalytic activity and sustainability.

While beneficial, the synthesis of zeolites requires extensive control over crystal growth and framework stability, motivating producers to develop hybrid organic-inorganic SDAs, rapid-crystallization methods, and continuous flow synthesis methods that ensure superior process efficiency and mass production.

Crystalline materials are widely used in electronic devices, high-performance optics, and batteries with significant material properties tailored for specific industries. SDAs permit controlled crystallization growth, phase stability, and lattice-structure defects without faults, ensuring greater function of material and accuracy of application.

One of the major factors driving SDA demand in crystalline materials applications and significance for semiconductor production as well as photovoltaic devices and nanostructured materials synthesis. Many manufacturers of electronic components heavily rely on SDA-facilitated crystal engineering to develop ultra-pure silicon, gallium nitride, and perovskite assemblies that include highly conductive, optically transparent, and mechanically effective materials.

Furthermore, SDAs are of great importance in battery science and energy storage technology, which undertakes controllable lithium-ion diffusion, and enhances charge retention and cycle life of advanced battery materials. A majority of scientists make sure that SDA is included in crystal structure prediction, and enhances AI, machine-learning powered material discovery, and SDA-assisted hybrid synthesis to provide enhanced material innovation and technological progress.

2D crystal material synthesis with SDAs is beneficial nevertheless they require a high degree of purity and defect free operation, thus prompting manufacturers to explore AI-optimized material modelling, automated monitoring of crystal growth, and scalable thin-film deposition techniques for improved production reliability and commercial viability.

Growing demand for zeolites, catalysts, and advanced materials in petrochemicals, pharmaceuticals, and chemical production are driving the growth of the structure directing agents (SDA) market. SDAs play a critical role in determining the configuration of microporous materials such as zeolite for catalytic and adsorptive application. Driven by rising refinery operations, demand for greener catalytic processes, and innovations in mater.

Market Share Analysis by Key Players

| Company/Organization Name | Estimated Market Share (%) |

|---|---|

| BASF SE | 18-22% |

| Clariant AG | 14-18% |

| Zeolyst International | 12-16% |

| Albemarle Corporation | 10-14% |

| Tosoh Corporation | 8-12% |

| Others | 26-32% |

| Company/Organization Name | Key Offerings/Activities |

|---|---|

| BASF SE | Produces SDAs for zeolite synthesis in petrochemical and chemical catalysis. |

| Clariant AG | Specializes in template molecules for the controlled synthesis of structured materials. |

| Zeolyst International | Develops SDAs for custom-designed zeolites used in refining and separation processes. |

| Albemarle Corporation | Manufactures high-performance SDAs for fluid catalytic cracking (FCC) applications. |

| Tosoh Corporation | Provides SDAs for industrial and specialty zeolites used in adsorption and ion exchange. |

Key Market Insights

BASF SE (18-22%)

BASF leads the structure directing agents market, supplying high-purity SDAs for industrial catalysis and petrochemical refining.

Clariant AG (14-18%)

Clariant specializes in custom SDA solutions, enabling zeolite production for adsorption and catalytic processes.

Zeolyst International (12-16%)

Zeolyst focuses on tailored SDA formulations for high-performance catalyst materials in refining and chemical separation.

Albemarle Corporation (10-14%)

Albemarle provides SDAs optimized for FCC catalysts, improving petroleum refining efficiency.

Tosoh Corporation (8-12%)

Tosoh develops industrial-grade SDAs, supporting synthetic zeolite production for environmental and energy applications.

Other Key Players (26-32% Combined)

Several emerging players and specialty chemical companies are expanding the SDA market with innovative formulations and high-performance materials, including:

The overall market size for structure directing agents market was USD 649.5 million in 2025.

The structure directing agents market is expected to reach USD 1,289.6 million in 2035.

Expanding applications in catalysis and material synthesis, increasing demand for zeolites in petrochemical and detergent industries, and advancements in nanotechnology will drive market growth.

The top 5 countries which drives the development of Structure directing agents market are USA, European Union, Japan, South Korea and UK

Crystalline materials expected to grow to command significant share over the assessment period.

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Structured Cabling Market Size and Share Forecast Outlook 2025 to 2035

Structure Tester Market Size and Share Forecast Outlook 2025 to 2035

Structured Data Management Software Market Size and Share Forecast Outlook 2025 to 2035

Evaluating Structured Product Label Management Market Share

Structured Product Label Management Market Outlook 2025-2035

UK Structured Product Label Management Market Insights – Trends, Growth & Forecast 2025-2035

Aerostructure Market Size and Share Forecast Outlook 2025 to 2035

USA Structured Product Label Management Market Analysis – Size, Trends & Industry Outlook 2025-2035

Aero Structure Equipment Market

Japan Structured Product Label Management Market Outlook – Size, Share & Innovations 2025-2035

5G Infrastructure Market Size and Share Forecast Outlook 2025 to 2035

Germany Structured Product Label Management Market Report – Trends, Demand & Forecast 2025-2035

IT Infrastructure Management Tools Market

Cloud Infrastructure Entitlement Management Market Report – Trends & Forecast 2024-2034

Cloud Infrastructure-As-A-Service Market

Virtual Infrastructure Manager Market Size and Share Forecast Outlook 2025 to 2035

Hosting Infrastructure Services Market Analysis - Size Share and Forecast Outlook 2025 to 2035

Managed Infrastructure Services Market Analysis by Solution, Application, and Region Through 2035

Carrier Infrastructure in Telecom Applications Market - Forecast 2025 to 2035

Cloud IT Infrastructure Hardware Market Size and Share Forecast Outlook 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA