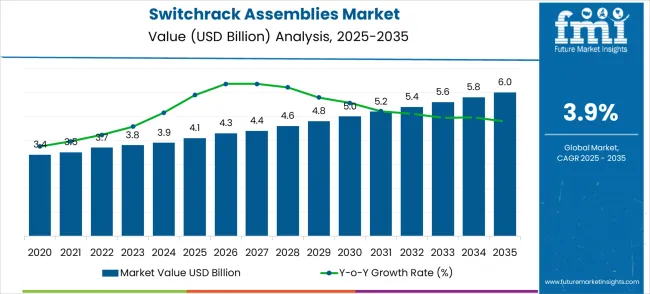

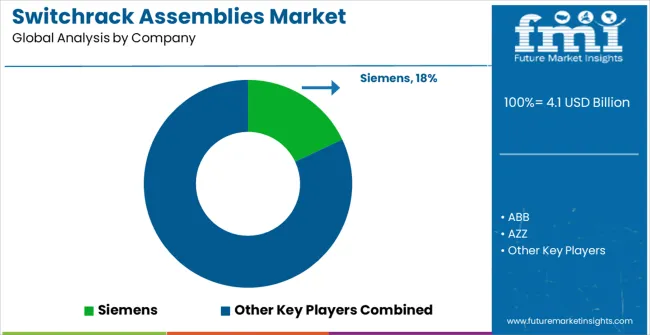

The Switchrack Assemblies Market is estimated to be valued at USD 4.1 billion in 2025 and is projected to reach USD 6.0 billion by 2035, registering a compound annual growth rate (CAGR) of 3.9% over the forecast period.

| Metric | Value |

|---|---|

| Switchrack Assemblies Market Estimated Value in (2025 E) | USD 4.1 billion |

| Switchrack Assemblies Market Forecast Value in (2035 F) | USD 6.0 billion |

| Forecast CAGR (2025 to 2035) | 3.9% |

Market expansion is being supported by the continuous growth of electrical infrastructure development across established and emerging markets and the corresponding need for organized mounting equipment that ensures optimal electrical system performance and operational safety. Modern electrical installations require sophisticated rack systems that can deliver precise equipment organization, reduced maintenance complexity, and enhanced safety characteristics while operating under diverse electrical configurations and environmental requirements. The superior structural capacity and accessibility characteristics of high-quality switchrack assemblies make them essential components in electrical installations where mounting performance directly impacts system reliability and maintenance efficiency.

The growing emphasis on electrical safety standards and maintenance accessibility enhancement is driving demand for advanced rack assemblies from certified manufacturers with proven track records of quality and reliability in electrical applications. Electrical contractors and facility operators are increasingly investing in premium switchrack assemblies that offer extended service life while maintaining consistent structural performance and system organization. Regulatory requirements and electrical standards are establishing performance benchmarks that favor high-quality mounting equipment with superior engineering properties and resistance to operational stresses.

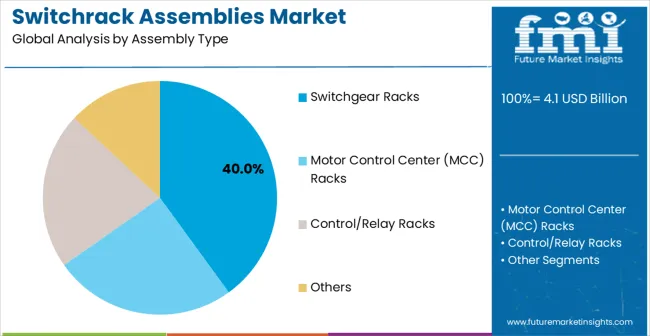

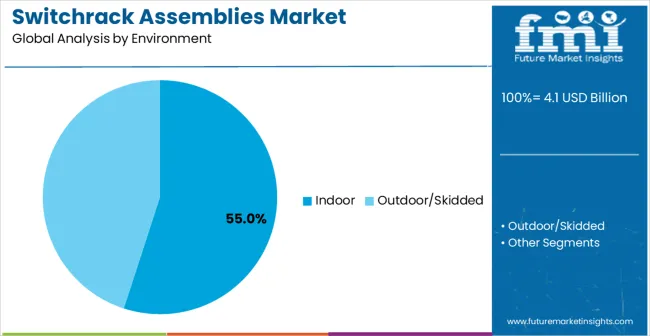

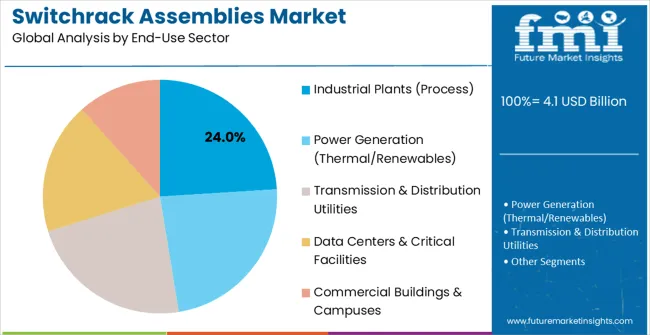

The switchrack assemblies market is segmented by assembly type, environment, end-use sector, and geographic regions. By assembly type, switchrack assemblies market is divided into Switchgear Racks, Motor Control Center (MCC) Racks, Control/Relay Racks, and Others. In terms of environment, switchrack assemblies market is classified into Indoor and Outdoor/Skidded. Based on end-use sector, switchrack assemblies market is segmented into Industrial Plants (Process), Power Generation (Thermal/Renewables), Transmission & Distribution Utilities, Data Centers & Critical Facilities, and Commercial Buildings & Campuses. Regionally, the switchrack assemblies industry is classified into North America, Latin America, Western Europe, Eastern Europe, Balkan & Baltic Countries, Russia & Belarus, Central Asia, East Asia, South Asia & Pacific, and the Middle East & Africa.

The market is segmented by assembly type, environment, end-use sector, voltage class, and region. By assembly type, the market is divided into switchgear racks, motor control center (MCC) racks, control/relay racks, and other configurations. Based on the environment, the market is categorized into indoor and outdoor/skidded segments. By end-use sector, the market includes power generation (thermal/renewables), transmission & distribution utilities, industrial plants (process), data centers & critical facilities, and commercial buildings & campuses. By voltage class, applications span low voltage (≤1 kV), medium voltage (1–36 kV), and high voltage (>36 kV). Regionally, the market is divided into North America, Europe, Asia-Pacific, Latin America, and the Middle East & Africa.

Switchgear Racks assembly configurations are projected to account for 40% of the switchrack assemblies market in 2025. This leading share is supported by the versatility and load-bearing capabilities of switchgear rack systems in power distribution applications and the widespread preference for standardized mounting solutions in utility and industrial facilities. Switchgear racks offer excellent structural stability and equipment compatibility, making them ideal for protective device mounting and challenging electrical environments where strength and operational reliability are essential. The segment benefits from technological advancements that have improved mounting flexibility, seismic resistance, and standardization requirements.

Modern switchgear racks incorporate advanced structural steel technologies, precision-engineered mounting components, and specialized configuration options that deliver exceptional load-bearing performance while maintaining simplicity of installation and compatibility under demanding electrical conditions. These innovations have significantly improved equipment organization while preserving compatibility with various switchgear manufacturers and reducing installation costs through enhanced standardization and reduced customization requirements. The utility sector particularly drives demand for switchgear rack solutions, as power distribution facilities require reliable mounting equipment that can meet stringent performance standards and safety requirements.

Indoor environment applications are expected to represent 55% of switch rack assembly demand in 2025. This significant share reflects the substantial volume of electrical installations housed within controlled environments globally and the need for organized mounting equipment that meets indoor installation requirements and accessibility standards. Indoor applications require consistent supplies of switchrack assemblies for electrical rooms, control houses, and industrial facilities across diverse operational environments and building configurations. The segment benefits from ongoing electrical infrastructure growth and increasing emphasis on equipment organization and maintenance accessibility in controlled environments.

Indoor environment applications demand exceptional equipment reliability to ensure consistent structural performance throughout operational periods while meeting stringent electrical safety standards and building code compliance requirements. These applications require switchrack assemblies that can withstand controlled environmental conditions, equipment loads, and long-term service under standard indoor conditions and maintenance schedules. The growing emphasis on building automation and centralized electrical distribution, particularly in commercial and industrial facilities requiring organized electrical infrastructure for optimal space utilization and maintenance access, drives consistent demand for high-quality indoor mounting equipment.

Industrial Plants (Process) are projected to account for 24% of the switchrack assemblies market in 2025. This substantial share is supported by the growing emphasis on industrial automation and the increasing need for organized electrical infrastructure that meets process industry requirements and safety standards. Industrial plant applications require robust and accessible mounting equipment that can perform across varying process conditions while maintaining operational reliability and regulatory compliance. The segment benefits from the increasing complexity of industrial electrical systems and growing investments in the modernization of manufacturing facilities.

Modern industrial plant applications demand switchrack assemblies that offer superior structural durability, reduced maintenance complexity, and enhanced equipment accessibility to support diverse process industry requirements and operational specifications. These facilities operate under demanding industrial conditions and safety regulations, requiring equipment that can adapt to different process environments while maintaining consistent performance and compliance standards. The growing emphasis on Industry 4.0 implementation and organized electrical infrastructure drives demand for industrial operators who can provide comprehensive mounting solutions with proven track records of operational reliability and safety compliance.

The switchrack assemblies market is advancing steadily due to continuing global electrical infrastructure growth and increasing recognition of organized mounting equipment reliability importance in operational safety and maintenance efficiency. However, the market faces challenges, including steel price volatility affecting equipment costs, varying electrical code requirements across regions, creating customization complexity, and manufacturing lead times for specialized configurations extending project timelines. Regional electrical standards and customization requirements continue to influence equipment design and market development patterns.

The growing deployment of modular assembly systems, standardized mounting configurations, and pre-engineered solutions is enabling superior installation efficiency and enhanced maintenance accessibility in switchrack assembly applications. Advanced modular systems and standardized integration provide enhanced organization capabilities, reduced installation complexity, and improved maintenance access compared to traditional custom-built mounting solutions. These innovations are particularly valuable for electrical infrastructure projects that require reliable equipment capable of meeting rapid installation schedules and demanding operational conditions.

Modern switchrack assembly manufacturers face challenges from steel price volatility and regional electrical code variations that create manufacturing complexity and project specification challenges. Integration of standardized designs, modular configurations, and compliance management systems creates opportunities for advanced mounting equipment that supports both high-performance electrical installation and cost optimization requirements. However, limited standardization among equipment manufacturers and custom mounting requirements continue to create compatibility challenges and extended engineering cycles for specialized applications.

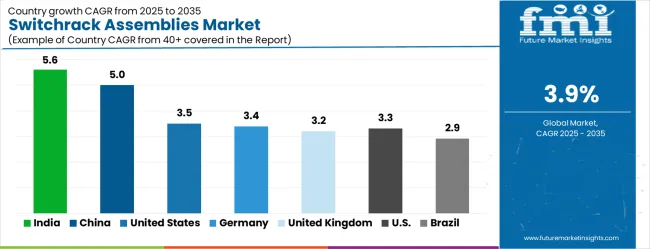

| Country | CAGR (2025-2035) |

|---|---|

| India | 5.6% |

| China | 5.0% |

| United States | 3.5% |

| Germany | 3.4% |

| United Kingdom | 3.2% |

The switchrack assemblies market is growing steadily, with India leading at a 5.6% CAGR through 2035, driven by expanding industrial infrastructure development, increasing power generation capacity expansion, and comprehensive electrical modernization programs supporting both domestic consumption and industrial growth. China follows at 5.0%, supported by extensive renewable energy installations, expanding industrial automation projects, and increasing focus on electrical safety standards serving domestic and regional markets. The United States records growth at 3.5%, emphasizing data center expansion, renewable energy integration, and operational excellence in critical facility applications. Germany shows steady growth at 3.4%, focusing on industrial facility modernization and renewable energy projects. The United Kingdom maintains expansion at 3.2%, supported by electrical infrastructure renewal and engineering excellence.

The report covers an in-depth analysis of 40+ countries; five top-performing countries are highlighted below.

Revenue from switchrack assemblies in India is projected to exhibit the highest growth rate with a CAGR of 5.6% through 2035, driven by expanding industrial infrastructure and comprehensive power generation capacity development, creating substantial opportunities for electrical mounting equipment suppliers across manufacturing facilities, power plants, and industrial automation sectors. The country's growing industrial manufacturing capacity and expanding electrical infrastructure projects are creating significant demand for both traditional structural and advanced modular mounting equipment. Major industrial companies and electrical contractors are establishing comprehensive local equipment procurement to support large-scale operations and meet growing demand for organized electrical mounting solutions.

Revenue from switchrack assemblies in China is expanding at a CAGR of 5.0%, supported by extensive renewable energy projects and comprehensive industrial automation development, creating sustained demand for reliable electrical mounting equipment across diverse infrastructure categories and industrial segments. The country's leadership in renewable energy development and expanding manufacturing capabilities is driving demand for mounting equipment that provides consistent performance while supporting cost-effective operational requirements. Switchrack assembly manufacturers are investing in local production facilities to support growing renewable energy operations and industrial automation demand.

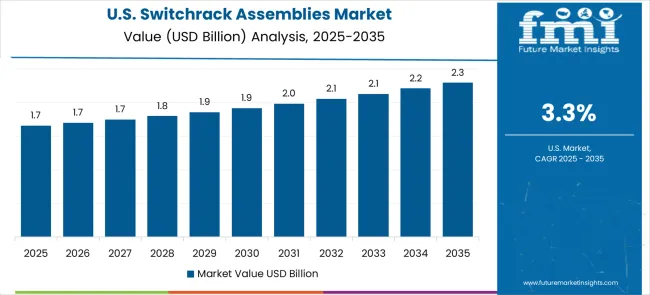

Demand for switchrack assemblies in the United States is projected to grow at a CAGR of 3.5%, supported by the country's leadership in data center construction and renewable energy integration, requiring sophisticated electrical mounting equipment for critical facility and utility operations. American electrical contractors are implementing high-quality mounting systems that support advanced electrical technologies, operational reliability, and comprehensive safety protocols. The market is characterized by a focus on operational excellence, equipment durability, and compliance with stringent electrical performance and safety standards.

Revenue from switchrack assemblies in Germany is growing at a CAGR of 3.4%, driven by industrial facility modernization programs and renewable energy project development, creating sustained opportunities for electrical mounting equipment suppliers serving both manufacturing facilities and utility installations. The country's advanced industrial sector and expanding renewable energy capabilities are creating demand for mounting equipment that supports diverse operational requirements while maintaining performance standards. Industrial facilities and utility operators are developing equipment procurement strategies to support operational efficiency and regulatory compliance.

Demand for switchrack assemblies in the United Kingdom is expanding at a CAGR of 3.2%, driven by electrical infrastructure renewal programs and commercial facility development, creating opportunities for electrical mounting equipment suppliers serving both utility and commercial sectors. The country's established electrical expertise and mature infrastructure markets are creating demand for high-quality mounting equipment that supports operational performance and regulatory standards. Equipment manufacturers and electrical contractors are maintaining comprehensive development capabilities to support diverse electrical requirements.

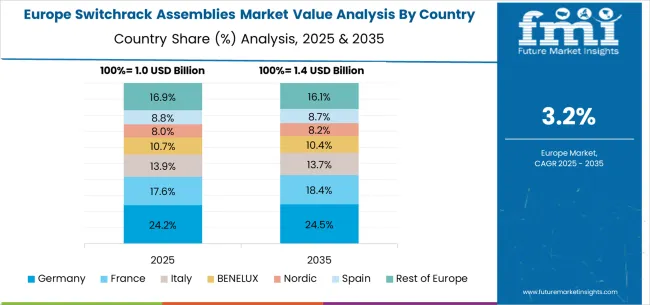

The switchrack assemblies market in Europe is projected to grow from USD 1.0 billion in 2025 to USD 1.4 billion by 2035, registering a CAGR of 3.4% over the forecast period. Germany is expected to maintain its leadership position with a 35.2% market share in 2025, remaining stable at 35.0% by 2035, supported by its advanced electrical equipment manufacturing sector, precision engineering capabilities, and comprehensive innovation expertise serving European and international electrical infrastructure markets.

The United Kingdom follows with a 22.8% share in 2025, projected to reach 23.1% by 2035, driven by electrical infrastructure modernization programs, advanced mounting technology development capabilities, and growing focus on operational efficiency solutions for premium electrical installations. France holds an 18.4% share in 2025, expected to maintain 18.2% by 2035, supported by industrial electrical infrastructure demand and advanced mounting technology applications, but facing challenges from market competition and economic considerations.

Italy commands a 12.6% share in 2025, projected to reach 12.8% by 2035, while Spain accounts for 7.3% in 2025, expected to reach 7.5% by 2035. The Netherlands maintains a 3.7% share in 2025, growing to 3.8% by 2035. The Rest of Europe region, including Nordic countries, Eastern Europe, Belgium, Switzerland, and Austria, is anticipated to hold 18.6% in 2025, declining slightly to 18.4% by 2035, attributed to mixed growth patterns with strong expansion in some Nordic electrical infrastructure markets balanced by moderate growth in smaller countries implementing electrical system modernization programs.

The switchrack assemblies market is defined by competition among established electrical infrastructure manufacturers, specialized mounting system providers, and emerging industrial technology firms. Companies are investing in advanced mounting technology, manufacturing process optimization, quality management systems, and global distribution capabilities to deliver reliable, efficient, and cost-effective electrical mounting equipment. Strategic partnerships, technological advancement, and geographic expansion are central to strengthening product portfolios and market presence.

ABB, operating globally, offers comprehensive electrical infrastructure mounting solutions with a focus on advanced technology, operational excellence, and electrical industry partnerships, maintaining a leading market position. Siemens provides specialized electrical mounting equipment with emphasis on engineering efficiency and operational reliability. Schneider Electric, a global electrical equipment specialist, delivers advanced mounting technologies with a focus on precision engineering and integrated electrical solutions. These leading companies demonstrate strong market presence through technological innovation and comprehensive service capabilities.

Established mounting equipment providers include Eaton, offering specialized electrical mounting solutions with a focus on operational performance and customer service excellence. Powell Industries delivers comprehensive mounting systems with emphasis on industrial applications and technical support. Rockwell Automation provides mounting equipment with a focus on motor control center integration and industrial automation applications. AZZ offers specialized mounting solutions with emphasis on utility applications and regional market development.

Emerging market participants include S&C Electric, offering specialized electrical mounting expertise, innovative technologies, and technical support across global and regional electrical infrastructure markets, focusing on advanced mounting capabilities and operational reliability solutions.

The switchrack assemblies market underpins electrical infrastructure efficiency enhancement, safety compliance optimization, maintenance accessibility improvement, and operational reliability. With electrical infrastructure growth, advancing mounting technologies, and increasing safety regulations, the sector must balance equipment quality, installation efficiency, and cost competitiveness. Coordinated contributions from governments, electrical associations, equipment manufacturers, electrical contractors, and investors will accelerate the transition toward advanced, reliable, and highly efficient electrical mounting systems.

| Items | Values |

|---|---|

| Quantitative Units | USD 4.1 Billion |

| Assembly Type | Switchgear Racks, Motor Control Center (MCC) Racks, Control/Relay Racks, Others |

| Environment | Indoor, Outdoor/Skidded |

| End-Use Sector | Power Generation (Thermal/Renewables), Transmission & Distribution Utilities, Industrial Plants (Process), Data Centers & Critical Facilities, Commercial Buildings & Campuses |

| Voltage Class | Low Voltage (≤1 kV), Medium Voltage (1–36 kV), High Voltage (>36 kV) |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, Middle East & Africa |

| Country Covered | United States, Canada, Germany, France, United Kingdom, China, Japan, India, Brazil, South Africa |

| Key Companies Profiled | ABB, AZZ, Eaton, Powell Industries, Rockwell Automation, S&C Electric, Schneider Electric, Siemens |

| Additional Attributes | Dollar sales by assembly type/voltage class, regional demand trends, competitive landscape, indoor vs. outdoor configuration preferences, electrical safety standard integration, modular design innovations, and prefabricated electrical building solutions driving infrastructure efficiency, safety compliance, and maintenance accessibility |

The global switchrack assemblies market is estimated to be valued at USD 4.1 billion in 2025.

The market size for the switchrack assemblies market is projected to reach USD 6.0 billion by 2035.

The switchrack assemblies market is expected to grow at a 3.9% CAGR between 2025 and 2035.

The key product types in switchrack assemblies market are switchgear racks, motor control center (mcc) racks, control/relay racks and others.

In terms of environment, indoor segment to command 55.0% share in the switchrack assemblies market in 2025.

The global switchrack assemblies market is estimated to be valued at USD 4.1 billion in 2025.

The market size for the switchrack assemblies market is projected to reach USD 6.0 billion by 2035.

The switchrack assemblies market is expected to grow at a 3.9% CAGR between 2025 and 2035.

The key product types in switchrack assemblies market are switchgear racks, motor control center (mcc) racks, control/relay racks and others.

In terms of environment, indoor segment to command 55.0% share in the switchrack assemblies market in 2025.

Explore Similar Insights

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA