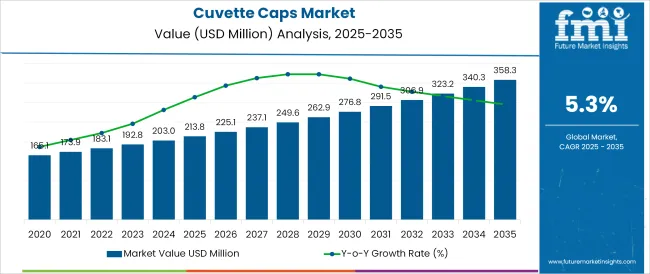

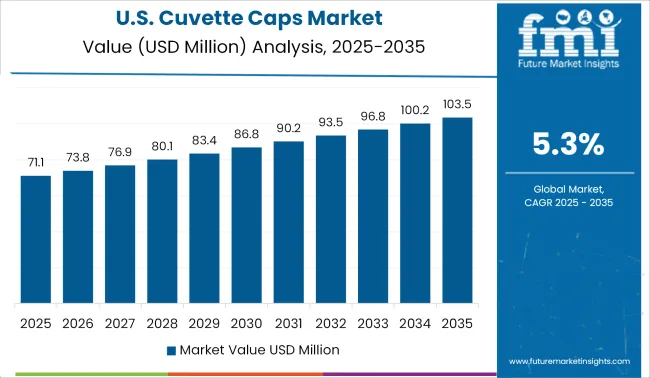

The Cuvette Caps Market is estimated to be valued at USD 213.8 million in 2025 and is projected to reach USD 358.3 million by 2035, registering a compound annual growth rate (CAGR) of 5.3% over the forecast period.

The cuvette caps market is gaining momentum due to increasing demand for secure, contamination-resistant closures in analytical testing, clinical diagnostics, and life sciences research. As laboratories continue to prioritize accuracy and reproducibility in sample handling, the use of cuvette caps has become integral to maintaining sample integrity during transport, storage, and spectrophotometric analysis.

Advancements in materials science and micro-molding technologies are enabling manufacturers to deliver precision-fit caps with superior chemical resistance, transparency, and sealing reliability. Additionally, rising adoption of automation and robotics in laboratories is driving the need for standardized, automation-compatible cap formats.

The growing emphasis on cross-contamination prevention, especially in molecular diagnostics and pharmaceutical testing, is further enhancing the relevance of high-quality cuvette caps. Looking ahead, increasing investments in biopharma R&D, expansion of diagnostic testing infrastructure, and global focus on lab efficiency are expected to support sustained growth in this market.

The market is segmented by Material Type, Product Type, and Shape and region. By Material Type, the market is divided into Polyethylene, Polypropylene, Polytetrafluoroethylene, Glass, Quartz, and Others. In terms of Product Type, the market is classified into Disposable, Reusable, Screw Cuvette Caps, and Stoppered Cuvettes.

Based on Shape, the market is segmented into Round and Square. Regionally, the market is classified into North America, Latin America, Western Europe, Eastern Europe, Balkan & Baltic Countries, Russia & Belarus, Central Asia, East Asia, South Asia & Pacific, and the Middle East & Africa.

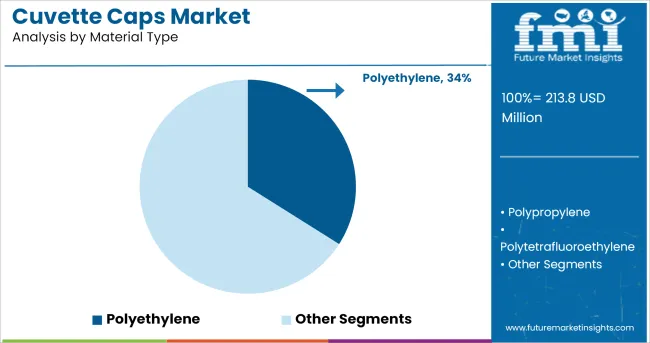

Polyethylene is expected to account for 34.0% of the total revenue share in the cuvette caps market in 2025, positioning it as the leading material type segment. This dominance is being driven by polyethylene’s strong chemical resistance, lightweight profile, and cost-effectiveness, which make it ideal for disposable and high-volume applications in laboratories.

The material’s flexibility and durability under varying storage conditions ensure reliable sealing without compromising sample integrity. Furthermore, polyethylene’s compatibility with automated dispensing and capping systems has increased its usage in high-throughput lab environments.

Its inert nature reduces the risk of sample interaction, which is especially important in sensitive spectrophotometric and biochemical assays. The recyclability of polyethylene also aligns with sustainability efforts in research institutions and commercial labs, reinforcing its preference across a broad range of applications.

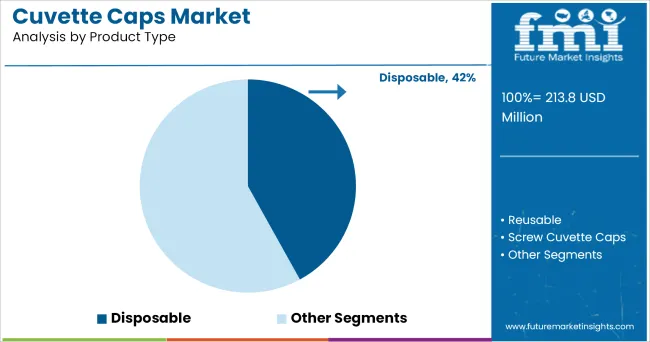

Disposable cuvette caps are projected to hold 42.0% of the market revenue in 2025, making them the dominant product type segment. This growth is being fueled by the rising demand for single-use laboratory components to minimize cross-contamination, improve workflow efficiency, and reduce the need for sterilization.

Disposable caps offer convenience and consistent performance in repetitive testing scenarios, especially in clinical diagnostics, environmental monitoring, and pharmaceutical quality control. Their cost-effectiveness and compliance with regulatory hygiene standards make them a preferred choice for labs operating under strict quality assurance protocols.

As lab automation scales and sample throughput increases, disposable cuvette caps are enabling faster turnaround times and reducing labor-intensive cleaning processes. The segment's growth is further supported by increased demand from decentralized and point-of-care testing setups, where ease of use and sterility are paramount.

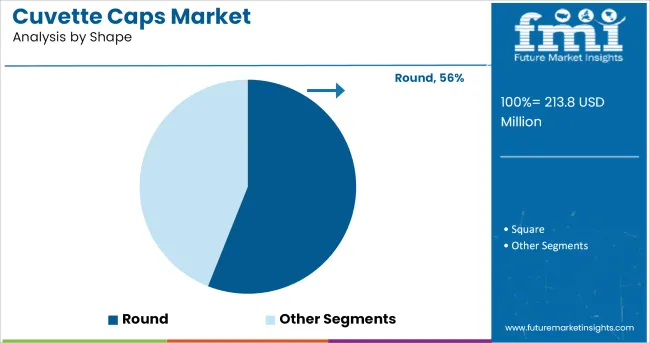

The round shape segment is anticipated to lead with 56.0% of the market revenue share in 2025, reflecting its widespread adoption across standard cuvette geometries. The dominance of round caps is attributed to their universal fit, secure sealing properties, and ease of integration with automated systems.

Round caps ensure uniform application of pressure, which is critical in maintaining airtight seals during transport and high-speed testing procedures. Their compatibility with most spectrophotometers and cuvette designs enhances their utility in academic, clinical, and industrial laboratories.

Additionally, the ergonomic benefits of round caps such as simplified handling and reduced alignment time have made them the standard choice for technicians in fast-paced lab settings. As manufacturers focus on optimizing cap performance and dimensional consistency, round-shaped designs continue to offer the best balance between usability, performance, and cost-effectiveness.

Cuvette caps are a type of protective caps which are tight and acts as a reliable seal on the top of the cuvette while protecting the top edge from scratches or damage while storage. They are commonly made from polyethylene in the standard cuvette sizes which are then autoclaved.

The flexible fins present on the cuvette caps allow for a tight fit to the cap which helps in preventing damage to the cuvette. In the cuvette screw cap, the threading on the top of the glass cuvette acts in an extraordinary sealing which then tightly seals the cuvette with no loss of solvent or an aqueous solution from the cuvette.

Cuvette caps not only protect the sample or the solution from spills or loss but also protect the air-sensitive samples by preventing the contamination and evaporation of the sample.

The disposable polyethylene cuvette caps for polystyrene (PS) and Poly-methyl methacrylate (PMMA) cuvettes are acting as an extraordinary solution while performing the Ultra-violet (UV) spectroscopy for various aqueous solutions and samples. These cuvette caps along with the disposable cuvettes are suitable for the photometric measurements of DNA, RNA, and proteins in the suitable UV range which can result in giving accurate results.

Also, the disposable caps avoid the contamination of the sample or the solution while performing the spectroscopy. Coloured cuvette caps are also useful in easy identification and labelling of the sample or the solution as compared to the transparent or colourless cuvette caps.

PTFE cuvette caps are the basic type of cuvette cap which are majorly used in the covering of the cuvette and are the least expensive. On the other hand, the PTFE cuvette caps have also a high risk of sample or solution loss while opening the cuvette for spectroscopy.

The PTFE cuvette caps can also result in the contamination and evaporation of the sample by frequent handling and opening of the cuvettes. The cuvette screw caps provide an excellent air-tight seal to the solutions and samples especially those who are air-sensitive. These cuvette caps allow injecting a sample into the cuvette while still keeping the seal airtight.

While performing the spectroscopy procedure numerous times with the same cuvette cap, the cuvette cap is susceptible to wear out and needs to be replaced. Also, the cuvette screw caps require constant cleaning and sterilizing with the alcohol-based solvent (95% ethanol) which is challenging for each reading of the spectroscopy which is time-consuming when compared to the disposable cuvette caps.

The following global key players such as

Key Asian players manufacturing cuvette caps

The manufacturers involved in the production of the cuvette caps are involved in the innovation and development of the spectrophotometer and the cuvettes to enhance the compatibility with the cuvette caps. Also, the invention of new technologies while making the use of the cuvette caps is useful in dissolving the solid sample in the cuvette.

The majority of the key players manufacturing cuvette caps have their presence in the USA which is the key factor driving the cuvette caps market growth. Also, the majority of the pharmaceutical and healthcare companies are pre-dominantly emphasizing research & development activities while the development of new products is acting as a boon towards the growth of the cuvette caps market.

The increasing demand for cuvette caps from pharmaceutical companies and laboratory testing is bolstering the market growth for the cuvette caps market.

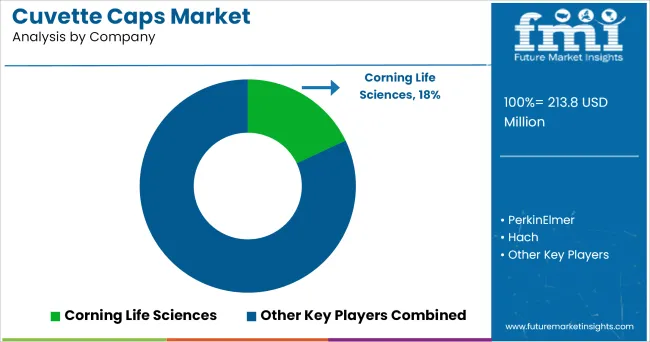

The global cuvette caps market is estimated to be valued at USD 213.8 million in 2025.

The market size for the cuvette caps market is projected to reach USD 358.3 million by 2035.

The cuvette caps market is expected to grow at a 5.3% CAGR between 2025 and 2035.

The key product types in cuvette caps market are polyethylene, polypropylene, polytetrafluoroethylene, glass, quartz and others.

In terms of product type, disposable segment to command 42.0% share in the cuvette caps market in 2025.

Our Research Products

The "Full Research Suite" delivers actionable market intel, deep dives on markets or technologies, so clients act faster, cut risk, and unlock growth.

The Leaderboard benchmarks and ranks top vendors, classifying them as Established Leaders, Leading Challengers, or Disruptors & Challengers.

Locates where complements amplify value and substitutes erode it, forecasting net impact by horizon

We deliver granular, decision-grade intel: market sizing, 5-year forecasts, pricing, adoption, usage, revenue, and operational KPIs—plus competitor tracking, regulation, and value chains—across 60 countries broadly.

Spot the shifts before they hit your P&L. We track inflection points, adoption curves, pricing moves, and ecosystem plays to show where demand is heading, why it is changing, and what to do next across high-growth markets and disruptive tech

Real-time reads of user behavior. We track shifting priorities, perceptions of today’s and next-gen services, and provider experience, then pace how fast tech moves from trial to adoption, blending buyer, consumer, and channel inputs with social signals (#WhySwitch, #UX).

Partner with our analyst team to build a custom report designed around your business priorities. From analysing market trends to assessing competitors or crafting bespoke datasets, we tailor insights to your needs.

Supplier Intelligence

Discovery & Profiling

Capacity & Footprint

Performance & Risk

Compliance & Governance

Commercial Readiness

Who Supplies Whom

Scorecards & Shortlists

Playbooks & Docs

Category Intelligence

Definition & Scope

Demand & Use Cases

Cost Drivers

Market Structure

Supply Chain Map

Trade & Policy

Operating Norms

Deliverables

Buyer Intelligence

Account Basics

Spend & Scope

Procurement Model

Vendor Requirements

Terms & Policies

Entry Strategy

Pain Points & Triggers

Outputs

Pricing Analysis

Benchmarks

Trends

Should-Cost

Indexation

Landed Cost

Commercial Terms

Deliverables

Brand Analysis

Positioning & Value Prop

Share & Presence

Customer Evidence

Go-to-Market

Digital & Reputation

Compliance & Trust

KPIs & Gaps

Outputs

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Understanding Cuvette Caps Market Share Trends

Capsule Vision Inspection Solution Market Size and Share Forecast Outlook 2025 to 2035

Capsule Filling Machines Market Size and Share Forecast Outlook 2025 to 2035

Capsule Hotels Market Size and Share Forecast Outlook 2025 to 2035

Capsule Endoscope and Workstations Market - Growth & Demand 2025 to 2035

Market Share Breakdown of Capsule Filling Machine Manufacturers

Market Share Breakdown of Caps and Closure Market

Competitive Breakdown of Capsaicin Manufacturers

Capsule Coffee Machines Market

Capsular Tension Rings Market

Encapsulated Flavors Market Size and Share Forecast Outlook 2025 to 2035

Encapsulated Zinc Feed Market Analysis - Size and Share Forecast Outlook 2025 to 2035

Encapsulated Lactic Acid Market Analysis by Application, Nature, Form, and Region from 2025 to 2035

Encapsulated Flavors and Fragrances Market Analysis by Product Type, Technology, Wall Material, End-use, Encapsulated Form, Process, and Region through 2035

Encapsulated Sodium Bicarbonate Market Trends - Growth & Industry Forecast 2025 to 2035

Encapsulant Material for PV Module Market Growth – Trends & Forecast 2024-2034

Encapsulant Market Growth – Trends & Forecast 2024-2034

Encapsulated Citric Acid Market

Encapsulated Salt Market

Encapsulated Caffeine Market

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA