The global capsule vision inspection solution market is projected to reach USD 2,178.9 million by 2035, recording an absolute increase of USD 1,050.4 million over the forecast period. The market is valued at USD 1,128.5 million in 2025 and is set to rise at a CAGR of 6.8% during the assessment period. The overall market size is expected to grow by nearly 1.9 times during the same period, supported by increasing demand for pharmaceutical quality assurance and consumer safety worldwide, driving demand for automated inspection systems and increasing investments in manufacturing automation and regulatory compliance programs globally.

Between 2025 and 2030, the capsule vision inspection solution market is projected to expand from USD 1,128.5 million to USD 1,568.1 million, resulting in a value increase of USD 439.6 million, which represents 41.8% of the total forecast growth for the decade. This phase of development will be shaped by rising demand for defect detection and quality control automation, product innovation in artificial intelligence-powered inspection algorithms and high-resolution imaging systems, as well as expanding integration with pharmaceutical manufacturing execution systems and serialization infrastructure. Companies are establishing competitive positions through investment in deep learning capabilities, multi-spectrum imaging technologies, and strategic market expansion across pharmaceutical manufacturing, nutraceutical production, and cosmeceutical capsule applications.

From 2030 to 2035, the market is forecast to grow from USD 1,568.1 million to USD 2,178.9 million, adding another USD 610.8 million, which constitutes 58.2% of the overall ten-year expansion. This period is expected to be characterized by the expansion of specialized inspection systems, including 360-degree defect detection platforms and integrated packaging line solutions tailored for specific capsule types and production environments, strategic collaborations between vision system manufacturers and pharmaceutical equipment suppliers, and an enhanced focus on predictive quality analytics and zero-defect manufacturing. The growing emphasis on pharmaceutical serialization and track-and-trace requirements will drive demand for advanced, connected capsule vision inspection solution systems across diverse manufacturing applications. High capital investment requirements and system integration complexity may pose challenges to market expansion.

| Metric | Value |

|---|---|

| Market Value (2025) | USD 1,128.5 million |

| Market Forecast Value (2035) | USD 2,178.9 million |

| Forecast CAGR (2025-2035) | 6.8% |

The capsule vision inspection solution market grows by enabling pharmaceutical manufacturers to achieve comprehensive quality control and eliminate defective products while meeting stringent regulatory compliance requirements. Pharmaceutical companies face mounting pressure to ensure product quality and consumer safety, with capsule vision inspection systems typically detecting 99.9% of defects including cracks, dents, color variations, and contamination that manual inspection cannot reliably identify, making these automated solutions essential for good manufacturing practice compliance and brand protection. The pharmaceutical industry's need for consistent quality verification creates demand for advanced vision systems that inspect 100% of production output at high speeds exceeding 300,000 capsules per hour, ensuring comprehensive defect detection without production bottleneck creation.

Government initiatives promoting pharmaceutical quality standards and patient safety regulations drive adoption in drug manufacturing facilities, dietary supplement production, and cosmeceutical capsule operations, where defect prevention has direct impacts on consumer health and regulatory compliance. The global shift toward pharmaceutical automation and Industry 4.0 implementation accelerates vision inspection system demand as manufacturers integrate quality control data with manufacturing execution systems enabling real-time process optimization and predictive quality management. Contract manufacturing organization expansion creates sustained capital investment in inspection infrastructure supporting multi-client production requiring validated quality systems.

Pharmaceutical serialization requirements and track-and-trace mandates drive system adoption, with vision inspection platforms integrating barcode verification and aggregation capabilities supporting regulatory compliance across global markets. Nutraceutical industry growth particularly in vitamins, probiotics, and herbal supplements packaged in capsule form creates expanding application scope beyond pharmaceutical products. High capital costs ranging from USD 100,000 to USD 500,000 per inspection line and technical expertise requirements for system programming and maintenance may limit adoption rates among smaller manufacturers and developing market facilities with constrained budgets and limited engineering resources.

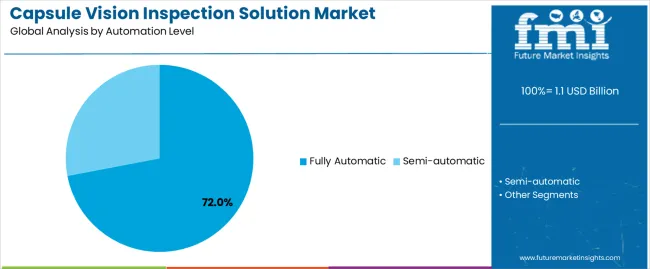

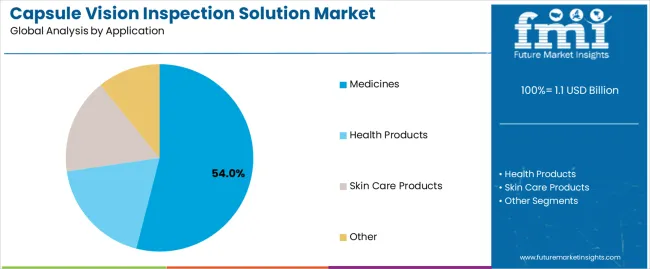

The market is segmented by automation level, application, and region. By automation level, the market is divided into semi-automatic and fully automatic. Based on application, the market is categorized into medicines, health products, skin care products, and other. Regionally, the market is divided into Asia Pacific, Europe, North America, Latin America, and Middle East & Africa.

The fully automatic segment represents the dominant force in the capsule vision inspection solution market, capturing approximately 72.0% of total market share in 2025. This advanced category encompasses integrated systems featuring automatic capsule feeding, multi-camera inspection stations, automatic rejection mechanisms, and data management platforms, delivering comprehensive inspection with minimal operator intervention. The fully automatic segment's market leadership stems from its superior throughput capabilities processing 200,000-400,000 capsules per hour, consistent inspection quality eliminating human error and fatigue factors, and comprehensive data logging supporting regulatory validation and process optimization.

The semi-automatic segment maintains a substantial 28.0% market share, serving smaller production volumes through operator-assisted systems requiring manual capsule loading or rejection verification while providing automated defect detection at accessible price points. Key advantages driving the fully automatic segment include production efficiency supporting high-volume manufacturing operations with minimal labor requirements, quality consistency achieving uniform inspection standards across all shifts and production batches eliminating operator variability, regulatory compliance providing documented inspection records and validation protocols supporting FDA and international regulatory requirements, and total cost optimization reducing per-unit inspection costs through high-speed operation and labor elimination justifying capital investment through operational savings over 3-5 year equipment lifecycles.

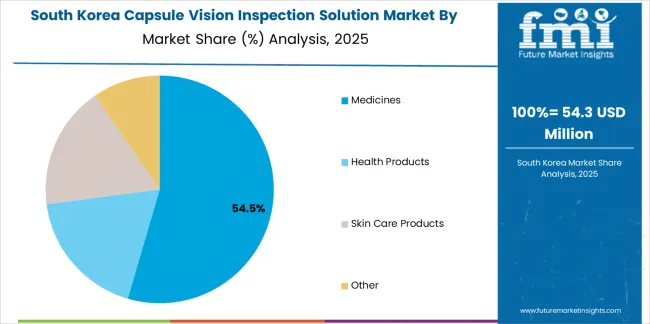

Medicines applications dominate the capsule vision inspection solution market with approximately 54.0% market share in 2025, reflecting the critical importance of pharmaceutical quality control and the stringent regulatory requirements governing drug manufacturing. The segment's market leadership is reinforced by widespread adoption across prescription drug manufacturing, over-the-counter medication production, and generic pharmaceutical operations requiring comprehensive defect detection supporting patient safety and regulatory compliance.

The health products segment represents 26.0% market share through specialized applications including dietary supplements, vitamins, probiotics, and herbal products where quality assurance supports brand reputation and consumer confidence despite less stringent regulatory oversight than pharmaceutical drugs. Skin care products account for 12.0% market share, encompassing cosmeceutical capsules including collagen supplements, skincare actives, and beauty products increasingly packaged in capsule format. Other represents 8.0% market share, covering veterinary medicines, agricultural capsules, and specialty applications. Key market dynamics supporting application preferences include pharmaceutical emphasis on regulatory compliance driving validated inspection system requirements, health products focus on quality consistency supporting premium positioning and consumer trust, growing nutraceutical market expansion creating sustained demand for inspection capabilities across diverse supplement categories, and regulatory convergence globally implementing stricter quality standards for dietary supplements and health products driving inspection system adoption beyond traditional pharmaceutical manufacturing.

The market is driven by three concrete demand factors tied to quality assurance and manufacturing efficiency. First, pharmaceutical quality regulations create increasing requirements for comprehensive inspection documentation, with FDA and EMA regulations requiring validated inspection processes and documented quality control for all manufactured units, necessitating automated systems providing complete inspection records supporting regulatory submissions and audit compliance. Second, production efficiency demands drive automation adoption, with manual inspection capable of examining only 30-50 capsules per minute compared to automated systems processing 5,000-7,000 capsules per minute, enabling manufacturers to achieve required throughput without proportional labor cost increases. Third, contract manufacturing growth accelerates system investment, with contract manufacturing organizations serving multiple clients requiring flexible inspection capabilities and validated systems supporting diverse product portfolios and regulatory requirements across pharmaceutical, nutraceutical, and cosmeceutical applications.

Market restraints include high capital investment affecting adoption decisions, particularly for mid-sized manufacturers where complete inspection line costs exceeding USD 300,000 represent significant capital allocation requiring multi-year return on investment justification competing with other facility upgrade priorities. System integration complexity poses implementation challenges, as vision inspection systems require coordination with capsule filling equipment, packaging lines, and manufacturing execution systems necessitating specialized engineering expertise and extended validation timelines potentially disrupting production during installation. False rejection rates impact operational efficiency, as overly sensitive inspection parameters generate false positives requiring manual verification and potentially discarding acceptable product, while insufficiently sensitive settings risk releasing defective capsules creating quality failures and regulatory exposure requiring careful system calibration and ongoing optimization.

Key trends indicate accelerated adoption in Asia-Pacific markets, particularly China and India, where pharmaceutical manufacturing expansion and contract manufacturing organization growth drive demand for automated quality control infrastructure supporting export markets and domestic regulatory compliance. Technology advancement trends toward artificial intelligence and deep learning algorithms improving defect detection accuracy, multi-spectral imaging including infrared and ultraviolet inspection detecting defects invisible to standard cameras, and predictive analytics identifying production process issues before defect rates increase are transforming quality control approaches. Integration with Industry 4.0 platforms enables real-time quality monitoring, automated process adjustments based on inspection data, and predictive maintenance preventing system downtime. The market thesis could face disruption if pharmaceutical manufacturing shifts toward continuous processing and real-time release testing fundamentally alter quality control workflows, potentially requiring integrated inline inspection rather than separate vision inspection stations while maintaining demand for defect detection capabilities throughout production processes.

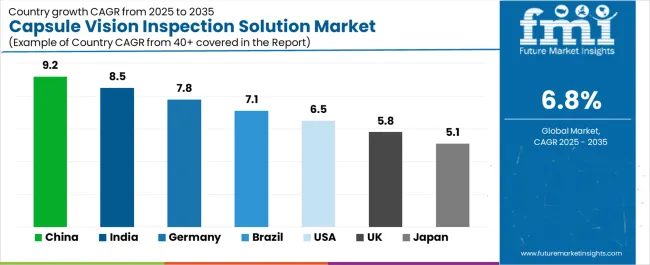

| Country | CAGR (2025-2035) |

|---|---|

| China | 9.2% |

| India | 8.5% |

| Germany | 7.8% |

| Brazil | 7.1% |

| USA | 6.5% |

| UK | 5.8% |

| Japan | 5.1% |

The capsule vision inspection solution market is gaining momentum worldwide, with China taking the lead thanks to aggressive pharmaceutical manufacturing expansion and comprehensive quality infrastructure development. Close behind, India benefits from contract manufacturing organization growth and increasing regulatory compliance requirements, positioning itself as a strategic growth hub in the Asia-Pacific region. Germany shows strong advancement, where pharmaceutical industry excellence and precision engineering capabilities strengthen demand for advanced inspection technologies. Brazil demonstrates robust growth through pharmaceutical industry modernization and expanding generic drug manufacturing, signaling continued investment in quality control infrastructure. The USA maintains solid expansion through pharmaceutical innovation leadership and comprehensive regulatory oversight, while the UK records consistent progress driven by pharmaceutical manufacturing presence and quality assurance emphasis. Meanwhile, Japan stands out for its precision manufacturing culture and comprehensive pharmaceutical quality standards. Together, China and India anchor the global expansion story, while established markets build stability and diversity into the market's growth path.

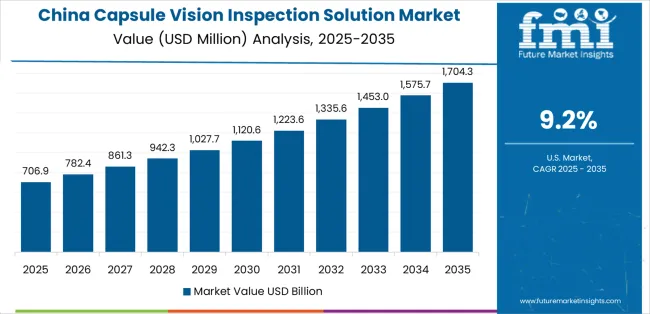

China demonstrates the strongest growth potential in the Capsule Vision Inspection Solution Market with a CAGR of 9.2% through 2035. The country's leadership position stems from comprehensive pharmaceutical manufacturing capacity expansion, intensive contract manufacturing organization development, and aggressive quality standard implementation driving adoption of automated inspection technologies. Growth is concentrated in major pharmaceutical clusters, including Jiangsu, Zhejiang, Shandong, and Guangdong provinces, where pharmaceutical manufacturers and contract production organizations are implementing vision inspection systems for export quality compliance and domestic regulatory requirements. Distribution channels through pharmaceutical equipment suppliers, automation system integrators, and direct manufacturer relationships expand deployment across capsule production facilities. The country's pharmaceutical industry upgrade initiatives provide policy support for manufacturing automation and quality system enhancement, including incentives for advanced equipment adoption.

Key market factors include pharmaceutical production intensity with comprehensive capacity expansion in generic drugs and contract manufacturing creating extensive inspection infrastructure requirements, export market compliance driving quality system investment supporting European and North American regulatory requirements, domestic manufacturing capabilities providing cost-competitive vision system production and integration services, and regulatory alignment with international standards through China Food and Drug Administration modernization creating favorable conditions for automated quality control adoption.

In Hyderabad, Ahmedabad, Mumbai, and Bangalore regions, the adoption of capsule vision inspection solutions is accelerating across pharmaceutical manufacturing facilities, contract manufacturing organizations, and nutraceutical production plants, driven by export market growth and domestic regulatory enhancement. The market demonstrates strong growth momentum with a CAGR of 8.5% through 2035, linked to comprehensive pharmaceutical manufacturing expansion and increasing focus on quality infrastructure development. Indian pharmaceutical manufacturers are implementing automated inspection systems and validation protocols to support USA FDA and European Medicines Agency compliance while meeting domestic quality standards for growing pharmaceutical production. The country's position as global generic drug supplier and contract manufacturing hub creates sustained demand for quality control infrastructure, while expanding nutraceutical sector drives adoption beyond traditional pharmaceutical applications.

Leading pharmaceutical development regions, including Telangana, Gujarat, Maharashtra, and Karnataka, driving capsule vision inspection solution adoption with facility modernization programs and regulatory compliance initiatives. Technology partnerships with international equipment manufacturers accelerate deployment with validation support and technical training addressing regulatory requirements. Market development through contract manufacturing organization expansion creates demand for flexible inspection capabilities supporting diverse client requirements, while pharmaceutical export growth necessitates quality systems meeting international regulatory standards.

Germany's advanced pharmaceutical sector demonstrates sophisticated implementation of capsule vision inspection solutions, with documented integration achieving comprehensive quality control in high-volume manufacturing facilities producing pharmaceuticals and nutraceuticals. The country's pharmaceutical infrastructure in major regions, including Bavaria, North Rhine-Westphalia, Hesse, and Baden-Württemberg, showcases deployment of advanced vision systems supporting pharmaceutical manufacturing excellence and regulatory compliance leadership. German pharmaceutical manufacturers emphasize quality assurance and process validation, creating demand for reliable inspection solutions that support GMP compliance and facilitate regulatory inspections. The market maintains strong growth through focus on pharmaceutical innovation and manufacturing automation, with a CAGR of 7.8% through 2035.

Key development areas include pharmaceutical manufacturing excellence supporting comprehensive quality control programs and systematic defect prevention strategies, engineering expertise among automation specialists and pharmaceutical engineers enabling sophisticated system implementation and optimization, strategic partnerships between pharmaceutical companies and equipment manufacturers supporting custom solution development for specialized applications, and integration of Industry 4.0 concepts including artificial intelligence, predictive analytics, and manufacturing execution system connectivity enhancing quality control effectiveness.

Brazil's developing pharmaceutical sector demonstrates increasing implementation of capsule vision inspection solutions, with industry modernization and quality standard enhancement driving demand for automated quality control technologies. The market shows solid potential with a CAGR of 7.1% through 2035, driven by pharmaceutical manufacturing growth and healthcare infrastructure improvement across major industrial regions, including São Paulo, Rio de Janeiro, Minas Gerais, and Paraná. Brazilian pharmaceutical manufacturers are adopting automated inspection systems for compliance with ANVISA regulatory requirements, particularly in export-oriented manufacturing requiring international quality standards. Technology deployment channels through pharmaceutical equipment distributors and automation system integrators expand coverage across pharmaceutical and nutraceutical production facilities.

Leading market segments include pharmaceutical manufacturing facilities implementing GMP-compliant production capabilities, contract manufacturing organizations serving international clients requiring validated inspection processes, and nutraceutical producers adopting quality control systems supporting premium market positioning. Technology partnerships with international equipment manufacturers provide access to proven systems and technical support for installation and validation programs, while growing pharmaceutical exports create demand for quality infrastructure meeting destination market regulatory requirements.

The USA market demonstrates comprehensive implementation of capsule vision inspection solutions based on extensive pharmaceutical manufacturing infrastructure and stringent regulatory oversight. The country shows solid potential with a CAGR of 6.5% through 2035, driven by pharmaceutical innovation leadership, contract manufacturing organization presence, and FDA regulatory requirements across major pharmaceutical centers, including New Jersey, Pennsylvania, North Carolina, and California. American pharmaceutical manufacturers are adopting advanced vision inspection solutions for FDA compliance, quality by design implementation, and continuous manufacturing initiatives requiring integrated quality control. Technology deployment channels through specialized pharmaceutical equipment suppliers and automation integrators provide comprehensive implementation support.

Leading market segments include branded pharmaceutical manufacturing requiring validated inspection supporting drug approvals, generic drug facilities implementing comprehensive quality control meeting FDA requirements, and contract manufacturing organizations serving diverse clients with flexible inspection capabilities. Technology innovation through domestic vision system manufacturers advances artificial intelligence capabilities, multi-spectral imaging, and predictive quality analytics, while FDA guidance supporting pharmaceutical automation and data integrity creates clear regulatory pathways for advanced inspection system implementation.

The United Kingdom's capsule vision inspection solution market demonstrates focused implementation across pharmaceutical manufacturing facilities and contract production organizations, with documented adoption supporting comprehensive quality assurance programs and regulatory compliance. The country maintains steady growth momentum with a CAGR of 5.8% through 2035, driven by pharmaceutical industry presence and quality system emphasis. Major pharmaceutical centers, including Cambridge, Oxford, London, and Manchester, showcase deployment of advanced inspection systems supporting pharmaceutical manufacturing and contract production operations.

Key market characteristics include pharmaceutical manufacturing presence creating demand for quality control infrastructure supporting MHRA regulatory compliance, contract manufacturing organizations requiring validated inspection systems serving international clients, quality assurance emphasis through comprehensive validation and documentation programs, and technology partnerships between pharmaceutical companies and inspection system providers supporting continuous quality improvement initiatives.

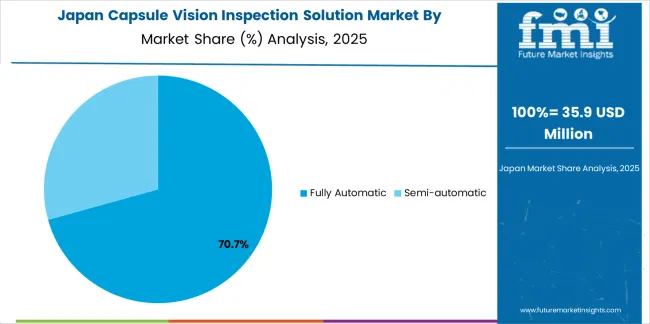

Japan's capsule vision inspection solution market demonstrates mature implementation focused on pharmaceutical manufacturing quality and precision automation integration, with documented deployment achieving superior defect detection through systematic validation and meticulous operational protocols. The country maintains steady growth through commitment to pharmaceutical excellence and quality culture, with a CAGR of 5.1% through 2035, driven by comprehensive regulatory requirements and precision manufacturing expertise. Major pharmaceutical regions, including Tokyo, Osaka, Aichi, and Fukuoka, showcase sophisticated inspection system deployment integrated with comprehensive manufacturing quality systems.

Key market characteristics include pharmaceutical manufacturing precision supporting thorough validation and systematic quality control across capsule production facilities, quality culture emphasis driving comprehensive defect prevention and continuous improvement programs, technology partnerships between pharmaceutical companies and domestic equipment manufacturers ensuring system reliability and technical support, and regulatory compliance excellence through PMDA guidance and industry quality standards supporting validated inspection implementation.

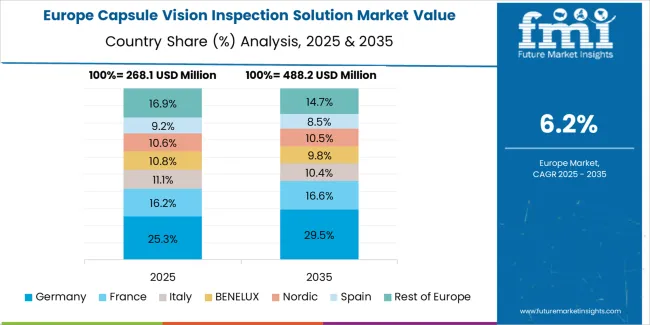

The capsule vision inspection solution market in Europe is projected to grow from USD 403.3 million in 2025 to USD 680.4 million by 2035, registering a CAGR of 5.4% over the forecast period. Germany is expected to maintain its leadership position with a 28.5% market share in 2025, declining slightly to 28.2% by 2035, supported by its pharmaceutical manufacturing excellence and major production centers, including Bavaria, North Rhine-Westphalia, and Hesse regions.

The United Kingdom follows with a 18.5% share in 2025, projected to reach 18.2% by 2035, driven by pharmaceutical industry presence and contract manufacturing capabilities. France holds a 16.8% share in 2025, expected to reach 17.0% by 2035, backed by pharmaceutical industry strength and quality assurance programs. Italy commands a 13.2% share in both 2025 and 2035, driven by pharmaceutical manufacturing and nutraceutical production. Switzerland accounts for 10.5% in 2025, rising to 10.7% by 2035 on pharmaceutical industry concentration and quality standards. Spain maintains 6.8% in 2025, reaching 7.0% by 2035 on pharmaceutical production growth. The Rest of Europe region is anticipated to hold 5.7% in 2025, expanding to 6.7% by 2035, attributed to increasing capsule vision inspection solution adoption in Nordic countries and emerging Central & Eastern European pharmaceutical manufacturing development.

The Japanese capsule vision inspection solution market demonstrates a mature and precision-focused landscape, characterized by sophisticated integration of fully automatic systems with existing pharmaceutical manufacturing infrastructure across major pharmaceutical companies, contract manufacturing organizations, and nutraceutical producers. Japan's emphasis on pharmaceutical quality and manufacturing excellence drives demand for reliable inspection solutions that support comprehensive validation protocols and maintain consistent performance through systematic maintenance programs. The market benefits from strong partnerships between pharmaceutical manufacturers and equipment suppliers including domestic automation companies, creating comprehensive service ecosystems that prioritize system reliability and technical support programs. Pharmaceutical centers in Tokyo Metropolitan Area, Kansai region, Chubu region, and other major production areas showcase advanced inspection implementations where systems achieve validated defect detection through precise parameter control and thorough qualification studies.

The South Korean capsule vision inspection solution market is characterized by growing pharmaceutical manufacturing sector, with companies maintaining increasing system deployments through comprehensive facility modernization and quality infrastructure enhancement supporting export manufacturing capabilities. The market demonstrates increasing focus on automated inspection technologies and comprehensive validation programs, as Korean pharmaceutical manufacturers increasingly demand reliable systems supporting international regulatory compliance for export markets including United States, Europe, and Japan. Domestic pharmaceutical companies are expanding manufacturing capabilities through technology partnerships with international equipment manufacturers, implementing validated inspection systems supporting regulatory approvals for domestic and export markets. The competitive landscape shows increasing collaboration between pharmaceutical manufacturers and inspection system providers, creating integrated quality control approaches combining equipment supply with validation support and ongoing technical assistance ensuring sustained system performance.

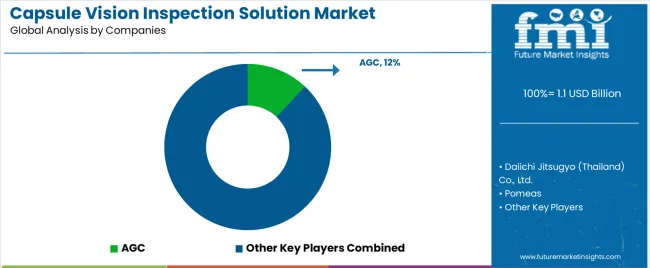

The capsule vision inspection solution market features approximately 25-30 meaningful players with moderate concentration, where the top three companies control roughly 30-35% of global market share through established technology portfolios and comprehensive pharmaceutical industry relationships. Competition centers on detection accuracy, system reliability, and validation support quality rather than price competition alone. AGC leads with approximately 12.0% market share through its comprehensive pharmaceutical equipment portfolio including advanced vision inspection systems.

Market leaders include AGC, Cognex, and Syntegon, which maintain competitive advantages through extensive machine vision expertise, proven pharmaceutical application experience, and global service networks spanning pharmaceutical manufacturing markets, creating reliability and support advantages with quality-focused pharmaceutical customers. These companies leverage research and development capabilities in artificial intelligence algorithms, multi-spectral imaging technologies, and ongoing validation support relationships to defend market positions while expanding into emerging markets and specialized applications including nutraceutical and cosmeceutical capsule inspection.

Challengers encompass Daiichi Jitsugyo (Thailand) Co., Ltd., OPTEL, and FSI Technologies, which compete through specialized solutions and strong regional presence in key pharmaceutical manufacturing markets. Technology specialists, including Pomeas, Proditec, and Sensum, focus on specific inspection technologies or market segments, offering differentiated capabilities in optical design, software algorithms, and custom integration services.

Regional players including Fitow, Angshi Intelligence (Shenzhen) Co., Ltd., Wuxi Jingzhi Vision Technology Co., Ltd., Knapp, and Enclony create competitive pressure through localized manufacturing and responsive technical support, particularly in high-growth Asian markets where domestic manufacturers provide cost-competitive solutions adapted to local production requirements. Market dynamics favor companies that combine proven detection performance with comprehensive validation documentation, responsive technical support, and ongoing system optimization capabilities addressing the complete implementation lifecycle from initial specification through installation, qualification, and routine operation supporting sustained pharmaceutical manufacturing quality assurance programs.

Capsule vision inspection solutions represent critical quality assurance technologies that enable pharmaceutical manufacturers to achieve 99.9% defect detection at production speeds exceeding 300,000 capsules per hour, delivering comprehensive quality control with automated operation eliminating human error and supporting regulatory compliance in demanding pharmaceutical manufacturing applications. With the market projected to grow from USD 1,128.5 million in 2025 to USD 2,178.9 million by 2035 at a 6.8% CAGR, these inspection systems offer compelling advantages - quality assurance, regulatory compliance, and operational efficiency - making them essential for medicines manufacturing, health products production, and pharmaceutical operations requiring validated defect detection supporting patient safety and brand protection objectives. Scaling market adoption and technology advancement requires coordinated action across regulatory frameworks, quality standards, equipment manufacturers, pharmaceutical companies, and manufacturing automation expertise.

How Governments Could Spur Local Production and Adoption?

Pharmaceutical Quality Standards should establish clear requirements for capsule inspection validation, develop harmonized international standards reducing redundant qualification efforts, and create guidance documents for automated inspection system qualification supporting regulatory compliance. Research & Innovation Funding must support development of advanced detection algorithms improving accuracy and reducing false rejections, fund comparative studies establishing inspection system performance benchmarks, and invest in artificial intelligence research enhancing defect classification and process optimization capabilities. Manufacturing Support needs to provide incentives for pharmaceutical equipment manufacturing including vision inspection systems, support domestic production capabilities reducing import dependencies, and establish technology transfer programs enabling developing countries to access advanced quality control technologies.

Regulatory Harmonization should create mutual recognition agreements for equipment qualification between regulatory authorities, establish common validation protocols reducing qualification burden for manufacturers operating globally, and develop digital submission standards enabling efficient regulatory review of inspection system documentation. Workforce Development must establish technical training programs for pharmaceutical engineers on vision system implementation and validation, develop certification programs validating competencies in automated inspection system operation, and support maintenance training ensuring sustained system performance throughout equipment lifecycle.

How Industry Bodies Could Support Market Development?

Validation Standards should define standardized protocols for capsule inspection system qualification, establish performance criteria ensuring minimum detection capabilities across defect types, and create documentation templates supporting regulatory submission requirements. Technical Guidelines must develop best practices for system installation and integration with pharmaceutical production lines, establish maintenance protocols ensuring sustained performance and regulatory compliance, and create troubleshooting resources supporting effective system utilization and optimization.

Quality Benchmarking needs to establish industry metrics for detection accuracy and false rejection rates, develop reporting frameworks documenting inspection program effectiveness, and create peer learning networks enabling knowledge sharing across pharmaceutical manufacturers implementing similar technologies. Application Standards should develop guidelines for appropriate inspection parameters across different capsule types and production speeds, establish calibration protocols ensuring measurement accuracy, and create defect classification systems standardizing quality assessment approaches supporting industry-wide quality improvement.

How OEMs and Technology Players Could Strengthen the Ecosystem?

Advanced Detection Technology should develop next-generation imaging systems with enhanced resolution and multi-spectral capabilities, create artificial intelligence algorithms improving defect classification accuracy and reducing false rejections, and implement deep learning systems enabling automated parameter optimization based on production data. System Integration must ensure seamless connectivity with pharmaceutical manufacturing execution systems and packaging equipment, develop standardized communication protocols supporting interoperability, and create modular designs enabling capacity scaling and capability upgrades without complete system replacement.

Validation Support needs to provide comprehensive qualification protocols and documentation packages supporting regulatory submissions, offer on-site validation assistance ensuring successful system qualification, and develop ongoing compliance programs supporting periodic revalidation requirements. User Training should establish comprehensive operator training programs covering system operation and basic troubleshooting, provide maintenance training ensuring sustained system performance, and create online resources including video tutorials and application guides supporting effective system utilization throughout equipment lifecycle.

How Suppliers Could Navigate the Shift?

Application-Focused Solutions should develop pharmaceutical-optimized systems emphasizing validation documentation and GMP compliance, create health products configurations addressing nutraceutical and supplement manufacturing requirements, and offer flexible platforms supporting diverse capsule types and production environments with solutions optimized for each application's specific quality and regulatory requirements. Geographic Expansion must establish service networks in high-growth markets like China and India ensuring local technical support availability, while maintaining comprehensive spare parts inventory and technical expertise in established markets like USA and Europe supporting rapid response to customer requirements.

Technology Differentiation should invest in proprietary detection algorithms providing superior accuracy and reduced false rejection rates, develop advanced imaging technologies detecting defects invisible to conventional systems, and create predictive analytics capabilities identifying process issues before defect rates increase. Partnership Models need to develop long-term relationships with pharmaceutical manufacturers through equipment leasing programs, establish performance guarantee agreements demonstrating confidence in system capabilities, and create integrated service offerings combining equipment supply with validation support, operator training, and ongoing technical assistance ensuring customer success.

How Investors and Financial Enablers Could Unlock Value?

Vision System Manufacturing should finance established manufacturers for capacity expansion, algorithm development programs, and international market entry supporting growing demand in pharmaceutical and health products markets. Service Infrastructure must provide capital for establishing regional service centers, spare parts inventory, and technical training facilities ensuring comprehensive customer support across diverse geographic markets.

Innovation & Technology should back startups developing next-generation inspection technologies including hyperspectral imaging, three-dimensional defect detection, and artificial intelligence platforms providing enhanced capabilities. Market Integration should support strategic partnerships between vision system manufacturers and pharmaceutical equipment companies creating integrated production solutions, finance acquisitions consolidating complementary technologies and market positions, and enable vertical integration combining camera manufacturing with software development and system integration capabilities creating complete inspection solutions.

| Item | Value |

|---|---|

| Quantitative Units | USD 1,128.5 million |

| Automation Level | Semi-automatic, Fully Automatic |

| Application | Medicines, Health Products, Skin Care Products, Other |

| Regions Covered | Asia Pacific, Europe, North America, Latin America, Middle East & Africa |

| Country Covered | China, India, Germany, Brazil, USA, UK, Japan, and 40+ countries |

| Key Companies Profiled | AGC, Daiichi Jitsugyo (Thailand) Co., Ltd., Pomeas, Proditec, Sensum, OPTEL, FSI Technologies, Cognex, Fitow, Angshi Intelligence (Shenzhen) Co., Ltd., Wuxi Jingzhi Vision Technology Co., Ltd., Knapp, Enclony, Syntegon |

| Additional Attributes | Dollar sales by automation level and application categories, regional adoption trends across Asia Pacific, North America, and Europe, competitive landscape with vision system manufacturers and pharmaceutical equipment suppliers, technical specifications and detection capabilities, integration with pharmaceutical manufacturing systems and quality management platforms, innovations in artificial intelligence algorithms and multi-spectral imaging, and development of specialized solutions with enhanced defect detection and validation support capabilities. |

The global capsule vision inspection solution market is estimated to be valued at USD 1.1 billion in 2025.

The market size for the capsule vision inspection solution market is projected to reach USD 2.2 billion by 2035.

The capsule vision inspection solution market is expected to grow at a 6.8% CAGR between 2025 and 2035.

The key product types in capsule vision inspection solution market are fully automatic and semi-automatic.

In terms of application, medicines segment to command 54.0% share in the capsule vision inspection solution market in 2025.

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Capsule Filling Machines Market Size and Share Forecast Outlook 2025 to 2035

Capsule Hotels Market Size and Share Forecast Outlook 2025 to 2035

Capsule Endoscope and Workstations Market - Growth & Demand 2025 to 2035

Market Share Breakdown of Capsule Filling Machine Manufacturers

Capsule Coffee Machines Market

Wine Capsule Market Insights – Trends & Forecast 2024-2034

Resin Capsule Market Forecast and Outlook 2025 to 2035

Empty Capsule Market Report - Growth, Demand & Forecast 2025 to 2035

Flavor Capsule Cigarette Market Analysis - Size, Share, and Forecast 2025 to 2035

Liquid Capsule Filling Machines Market Trends – Growth & Forecast 2025 to 2035

Coffee Capsules Market Analysis - Growth & Forecast 2025 to 2035

Coffee Capsules and Pods Market

Flavor Capsule Cigarettes Market

Washing Capsules Market Size and Share Forecast Outlook 2025 to 2035

Softgel Capsules Market Overview - Growth & Forecast 2025 to 2035

Cryogenic Capsules Market Growth - Demand & Forecast 2025 to 2035

Market Share Distribution Among Tablets And Capsules Packaging Companies

Tablets and Capsules Packaging Market Growth, Trends, Forecast 2025-2035

Hard Gelatin Capsules Market Analysis - Size, Share, and Forecast Outlook 2025 to 2035

Liquid Filled Capsule Market Size and Share Forecast Outlook 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA