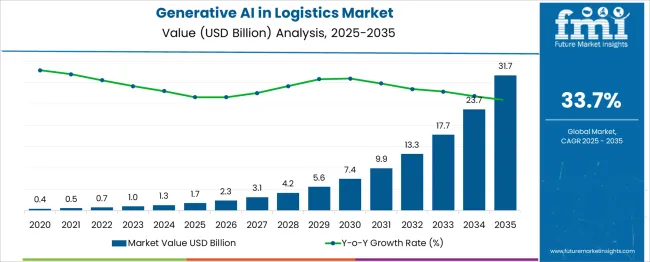

The Generative AI in Logistics Market is estimated to be valued at USD 1.7 billion in 2025 and is projected to reach USD 31.7 billion by 2035, registering a compound annual growth rate (CAGR) of 33.7% over the forecast period. This growth is propelled by the integration of AI models into core logistics functions such as route optimization, predictive maintenance, inventory forecasting, and real-time supply chain visibility. From 2025 to 2030, the market is expected to increase from USD 1.7 billion to USD 7.4 billion, achieving a five-year absolute growth of USD 5.7 billion.

Year-over-year growth is steep, with the market expanding by 35.3% in 2026, 34.8% in 2027, and sustaining above 30% YoY through 2030. The rapid expansion is fueled by rising operational complexity and the need for scalable, data-driven logistics models across industries such as retail, automotive, e-commerce, and manufacturing.

Generative AI tools are being deployed to generate simulation-based forecasts, automate transportation scheduling, and enhance load balancing. As models become more refined and capable of contextual decision-making, their adoption is accelerating among global logistics providers. The sector is poised for structural transformation, where speed, cost-efficiency, and resilience will be increasingly AI-driven and performance-optimized.

| Metric | Value |

|---|---|

| Generative AI in Logistics Market Estimated Value in (2025 E) | USD 1.7 billion |

| Generative AI in Logistics Market Forecast Value in (2035 F) | USD 31.7 billion |

| Forecast CAGR (2025 to 2035) | 33.7% |

The warehouse management segment leads the market, contributing approximately 24% of total demand. Generative AI excels in optimizing inventory placement, streamlining picking/packing, and forecasting shortages via intelligent data analysis. These capabilities enhance throughput and reduce fulfillment costs.

The retail logistics parent market emerges as the dominant end-user sector with about 44% share, as retailers increasingly deploy generative AI for demand forecasting, omni‑channel fulfillment coordination, and personalized delivery experiences.

Additional application areas include route optimization and transportation planning, which account for roughly 20–25% of market usage. Here, AI adapts in real-time to traffic, weather, and delivery constraints, significantly cutting transit time, fuel use, and last‑mile errors. The customer service and automated order processing segment represents around 10–12% of demand. AI-powered chatbots and automated email systems manage inquiries, update order statuses, and streamline customer interactions with minimal manual intervention.

Predictive maintenance and equipment diagnostics contribute about 8–10% of usage, where AI forecasts failure risks based on sensor outputs, reducing downtime. The supplier, procurement, and trade compliance planning application takes up the remaining 5–7%, focusing on optimized supplier selection, risk anticipation, and cost-effective sourcing strategies. Together, these parent markets demonstrate that the Generative AI in Logistics Market is anchored by retail and warehouse operations, with growing traction in transport, customer interaction, and infrastructure resilience.

The generative AI in logistics market is expanding rapidly, fueled by the need for real-time decision-making, predictive analytics, and autonomous logistics operations. As global supply chains become increasingly complex, generative AI is being leveraged to simulate operational scenarios, generate dynamic delivery routes, and streamline warehouse workflows. The convergence of large language models with enterprise data and operational technology platforms is enabling logistics providers to forecast demand, manage disruptions, and automate planning functions.

Strong enterprise interest in generative models is being observed across last-mile delivery optimization, procurement intelligence, and multimodal network planning. Regulatory emphasis on digitalization, along with rising customer expectations for faster and transparent deliveries, is accelerating investment in AI-based logistics platforms.

The scalability and adaptability of generative models to various supply chain functions, when integrated with ERP and transport management systems, are creating long-term efficiency gains. Looking ahead, continued advancements in edge inferencing, API interoperability, and self-learning systems are expected to redefine how logistics operations are designed and executed globally.

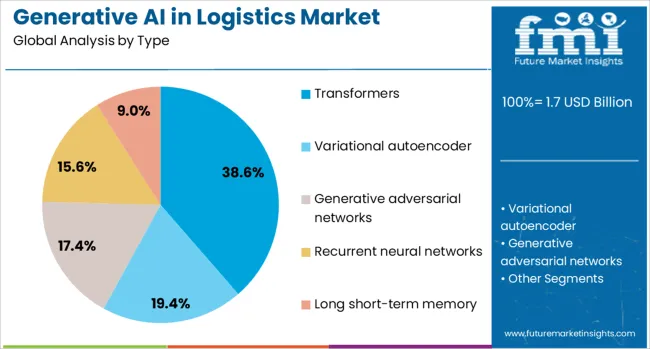

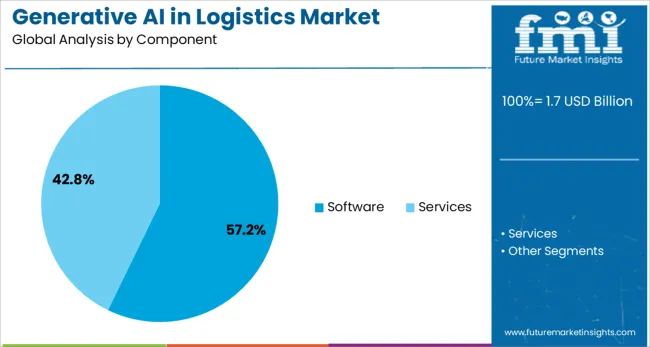

The generative AI in the logistics market is segmented by type, component, deployment mode, application, end use, and geographic regions. The generative AI in the logistics market is divided into Transformers, Variational autoencoder, Generative adversarial networks, Recurrent neural networks, and Long short-term memory. In terms of components of generative AI in the logistics market, it is classified into Software and Services.

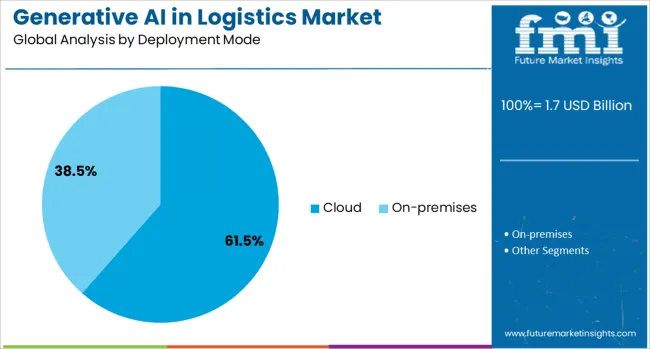

Based on the deployment mode of the generative AI in the logistics market, it is segmented into Cloud and On-premises. The application of generative AI in the logistics market is segmented into Warehouse and inventory management, Route optimization, Demand forecasting, Supply chain automation, Predictive maintenance, Risk management, Customized logistics solution, and Others.

The end use of generative AI in the logistics market is segmented into E-commerce companies, Third-party logistics providers, Freight forwarders, and Manufacturers. Regionally, the generative AI in the logistics industry is classified into North America, Latin America, Western Europe, Eastern Europe, Balkan & Baltic Countries, Russia & Belarus, Central Asia, East Asia, South Asia & Pacific, and the Middle East & Africa.

Transformers are projected to hold 38.6% of the revenue share in the generative AI in logistics market in 2025, positioning them as the dominant type of generative model. This leadership is being supported by their exceptional ability to process vast amounts of structured and unstructured logistics data while maintaining contextual relevance across diverse operational environments.

Their performance in tasks such as multi-modal planning, inventory forecasting, and anomaly detection has enabled their widespread implementation in both strategic and tactical logistics applications. The scalability of transformer models, combined with their ability to fine-tune outputs based on historical supply chain behavior, has proven valuable in enhancing delivery accuracy and risk mitigation.

These models are also being integrated with digital twins and intelligent control systems to simulate real-time logistics conditions, helping enterprises adapt to demand shifts or route blockages. The adaptability and language understanding of transformers continue to drive innovation in conversational AI interfaces for fleet management and procurement operations.

Software is estimated to account for 57.2% of the total market revenue in the generative AI in logistics sector in 2025, making it the most significant component segment. The strong growth of this segment is attributed to the increasing demand for integrated platforms that can support predictive modeling, generative scenario planning, and dynamic route generation.

Software platforms embedded with generative capabilities are being widely deployed across third-party logistics, e-commerce, and manufacturing sectors for use cases ranging from warehouse simulation to digital freight matching. Enterprises are prioritizing software-driven AI models due to their flexibility, modularity, and ease of integration with existing IT infrastructure.

Software tools are also enabling real-time insights into logistics KPIs, including cost per shipment, delivery lead times, and CO2 emissions, which are becoming essential in sustainability reporting. As software platforms evolve to include low-code interfaces and customizable workflows, their role in democratizing generative AI for logistics professionals continues to expand.

The cloud segment is expected to contribute 61.5% of the revenue share in the generative AI in logistics market in 2025, indicating a clear shift toward scalable and collaborative AI deployments. Cloud-based solutions are enabling real-time data ingestion from multiple sources including GPS, RFID, IoT devices, and WMS, thereby supporting continuous learning and adaptive decision-making in logistics operations.

The deployment of generative AI on cloud infrastructure facilitates faster model training, global access, and instant scalability, which are essential for handling fluctuating demand and supply chain disruptions. Logistics providers are increasingly adopting cloud-native architectures to lower IT overhead, enhance system uptime, and streamline cross-functional collaboration.

Cloud deployment also supports seamless updates and integration with APIs from carriers, customs authorities, and warehouse partners, accelerating digital transformation. As security protocols and compliance features continue to mature in cloud environments, trust in deploying sensitive logistics and trade data on cloud-hosted generative AI systems is growing significantly.

Opportunities in adaptive planning, predictive routing, and real-time decision support are expanding the role of generative AI across logistics. These tools help optimize operations, manage risk, and improve service reliability.

Generative AI strengthens demand planning by simulating outcomes based on sales history, market trends, and seasonal fluctuations. Logistics companies use these insights to adjust inventory levels across warehouses and regional hubs, reducing excess stock and minimizing shortages. The technology helps supply chain planners visualize multiple demand scenarios and identify how best to distribute goods. These simulations also fine-tune safety stock thresholds, enabling leaner operations without compromising service reliability. With better visibility into possible outcomes, businesses can preemptively adjust procurement schedules and distribution priorities. This improves responsiveness during high-demand periods and limits inefficiencies during slowdowns. The ability to act early and with more precision enhances supply chain flexibility and reduces costs, giving companies a competitive edge in fast-paced sectors like retail, pharma, and consumer goods.

Logistics companies are adopting generative AI to simulate and select delivery routes that respond to real-time conditions. These tools process traffic flow, road closures, weather data, and vehicle availability to generate optimized delivery schedules. Unlike fixed-route systems, AI platforms continuously adapt and adjust to emerging conditions without human intervention. By simulating possible disruptions such as port congestion or fuel access issues, logistics teams can identify the best alternatives before delays occur. This proactive planning limits downtime, ensures delivery accuracy, and helps maintain service-level targets. AI-powered routing also improves vehicle utilization and reduces fuel costs by minimizing idle time and detours. Companies using these systems benefit from increased delivery reliability and lower operating risks, especially when managing high volumes or time-sensitive shipments. As customer expectations grow, generative AI enables logistics providers to deliver faster, smarter, and more consistently.

Generative AI solutions in logistics are increasingly hosted in the cloud, capturing approximately 60–67 percent market share through flexibility and scalability benefits. Cloud platforms enable real-time ingestion of data from IoT sensors, telematics, weather feeds, and tracking systems, powering continuous route optimization and inventory recalibration. Organizations benefit from rapid deployment, lower upfront costs, and access to updated models without infrastructure investment. The ability to share data seamlessly across multiple warehouses, hubs, carriers, and planning units ensures unified operational visibility. Cloud-based solutions also centralize software maintenance and security updates, reducing internal IT burdens. This deployment model supports logistics firms seeking to scale AI tools globally with minimal friction, making it the dominant choice among midsize carriers, retailers, and fulfillment providers.

Generative AI is reshaping demand planning and last-mile routing by synthesizing large datasets to produce more accurate forecasts and dynamic dispatch adjustments. AI models reduce demand forecast errors significantly, enabling facilities to balance inventory across warehouses and minimize stockouts or overstock situations. Real-time routing algorithms incorporate traffic conditions, delivery priorities, and vehicle load, reducing fuel usage and transit times. Industries such as retail, e‑commerce, pharmaceuticals, and food & beverages are converging on this technology to gain better operational transparency. Logistics providers using generative AI report up to 15% cost savings per delivery, 20–30% inventory reduction, and faster customer response rates.

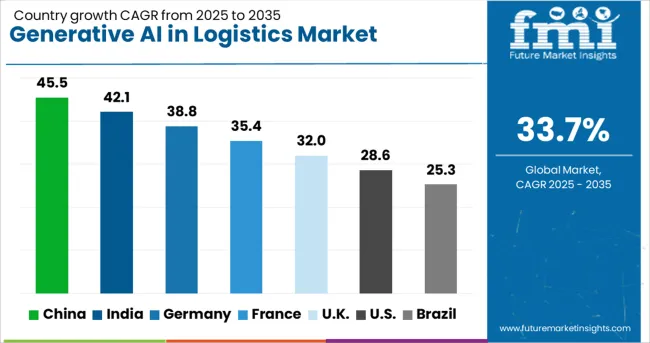

| Country | CAGR |

|---|---|

| China | 45.5% |

| India | 42.1% |

| Germany | 38.8% |

| France | 35.4% |

| UK | 32.0% |

| USA | 28.6% |

| Brazil | 25.3% |

The global Generative AI in Logistics Market is expected to expand rapidly at a CAGR of 33.7% through 2035, fueled by increasing demand for automated planning and decision-making tools. Among BRICS nations, China leads with 45.5% growth, driven by extensive adoption in freight optimization and warehouse automation. India follows at 42.1%, where digital transformation initiatives have accelerated AI integration in supply chains. In the OECD region, Germany reports 38.8% growth, supported by strategic investments in intelligent logistics solutions and regulatory oversight. France, growing at 35.4%, has seen adoption across industrial logistics and urban delivery networks. The United Kingdom, at 32.0%, reflects steady deployment in freight management and real-time tracking platforms. Market evolution has been influenced by data governance policies, algorithm transparency requirements, and procurement frameworks. This report includes insights on 40+ countries; the top five markets are shown here for reference.

The generative AI market in logistics in China is advancing at a CAGR of 45.5%, with extensive deployments in warehousing, route mapping, and demand prediction. Predictive modules based on generative frameworks have been utilized to reconfigure logistics scheduling in urban freight zones. Operational decisions have been supported by AI-generated scenario modeling. Fleet utilization has been improved by deploying adaptive routing systems based on real-time data inputs. Logistics providers have adopted AI-integrated cloud tools to manage time-sensitive shipments. Cold chain logistics has been optimized using machine-generated delivery templates. Dispatch systems have been adjusted using synthetic datasets for variable peak hours. Warehouse automation has been restructured using AI-simulated floor layouts. Backend workflows have been synchronized through auto-generated alerts and performance simulations.

In India, generative AI logistics market is growing at a CAGR of 42.1%, driven by deployments across freight handling and order dispatch systems. AI-generated models have been applied to dynamic vehicle assignment and trip planning in high-density corridors. Multi-drop deliveries have been arranged using machine-simulated route combinations. Third-party logistics operators have adopted AI-led analytics to manage transit volatility and service time deviation. Inventory holding periods have been reduced by deploying self-learning reorder triggers. Parcel tracking workflows have been configured using generative status prediction tools. Remote fleet operators have employed voice-to-text interfaces built with natural language generation layers. Routine documentation such as delivery notes and scheduling memos has been standardized through AI-generated templates.

Generative AI logistics market in Germany is expanding at a CAGR of 38.8%, influenced by applications in fleet coordination and automated warehouse movement. Vehicle routing protocols have been revised through AI-generated historical pattern matching. Staffing assignments across cross-docking hubs have been modeled using algorithm-driven simulations. Regional distribution centers have adopted AI modules for load balancing and shift planning. Predictive asset tracking dashboards have been generated to detect lag in delivery milestones. Labeling systems and handling instructions have been automatically created using text-generation models. Forecast accuracy has been improved through auto-generated demand assumptions based on seasonality data. Freight flow optimization has been executed using visual route generators trained on delivery maps.

In France, generative AI logistics market is recording a CAGR of 35.4%, supported by advancements in real-time logistics modeling and order flow prediction. Distribution chains have been modeled using automated scenario generation tools for emergency and peak-day logistics. Inventory buffers have been optimized based on synthetic demand simulation. AI-led text generators have been used to produce packing notes, loading labels, and delivery summaries. Carrier allocation tools have been reprogrammed using machine-generated performance grading. Chat-based status updates and email content for delivery exceptions have been structured using generative outputs. Vehicle scheduling windows have been narrowed through repetitive pattern modeling. Demand surge behavior during public holidays has been pre-forecasted by using synthetic spike prediction datasets.

The generative AI logistics market in the United Kingdom is growing at a CAGR of 32.0%, led by deployments in demand estimation and last-mile delivery modeling. Route congestion points have been identified through AI-generated geographic overlays. Autonomous handoff scheduling between fleet hubs has been piloted using scenario simulation frameworks. Forecast modules built on generative data sets have been used for predicting no-contact delivery rates. Repeated delivery failure locations have been flagged by AI-generated spatial behavior mapping. Order batching for local courier runs has been determined using generative clustering models. Transport analytics teams have applied model-generated journey summaries for fleet review documentation. Communication templates for delivery agents have been created using AI-based sentence construction routines.

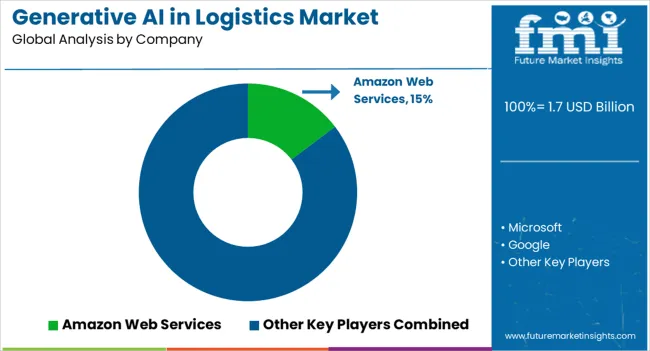

The Generative AI in logistics market is evolving rapidly as cloud providers, tech innovators, and logistics firms embed AI into every layer of the supply chain to boost speed, accuracy, and responsiveness. Amazon Web Services (AWS) leads the market with a 14.7% share, offering scalable generative AI tools that power predictive analytics, demand forecasting, and real-time route optimization for logistics operators.

Microsoft Azure follows closely, providing cloud-native AI platforms that support warehouse automation, inventory simulation, and fleet management. Google Cloud contributes through its advanced models focused on delivery optimization, disruption prediction, and supply chain visibility across geographies. IBM's Watson platform integrates generative AI to enable automated scenario planning, risk evaluation, and adaptive logistics workflows. Logistics giants like DHL Group apply proprietary AI algorithms for dynamic dispatching, demand simulation, and operational efficiency in last-mile and warehousing processes.

NVIDIA plays a critical enabling role, offering high-performance computing hardware that powers many of these AI workloads, from edge inference to cloud-based simulations. Enterprise software firms like SAP and Oracle are embedding generative AI into their supply chain management suites, supporting real-time planning, anomaly detection, and cost control. Companies like Palantir Technologies and Maersk are also leveraging AI to optimize shipping routes, resource allocation, and global logistics operations, especially for complex, multi-modal transport networks. These players collectively drive a shift toward autonomous, data-driven supply chains by harnessing generative AI for smarter, faster, and more resilient logistics decision-making.

In September 2024, PostNL launched “SuperTracy,” a generative AI-powered track-and-trace assistant using LLMs and Retrieval-Augmented Generation (RAG). The MVP enhanced parcel tracking, internal knowledge handling, and disruption detection, boosting efficiency and communication accuracy. This innovation reflects PostNL’s digital strategy for smarter logistics.

| Item | Value |

|---|---|

| Quantitative Units | USD 1.7 Billion |

| Type | Transformers, Variational autoencoder, Generative adversarial networks, Recurrent neural networks, and Long short-term memory |

| Component | Software and Services |

| Deployment Mode | Cloud and On-premises |

| Application | Warehouse and inventory management, Route optimization, Demand forecasting, Supply chain automation, Predictive maintenance, Risk management, Customized logistics solution, and Others |

| End Use | E-commerce companies, Third party logistics providers, Freight forwarders, and Manufacturers |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, Middle East & Africa |

| Country Covered | United States, Canada, Germany, France, United Kingdom, China, Japan, India, Brazil, South Africa |

| Key Companies Profiled | AmazonWebServices, Microsoft, Google, IBM, DHLGroup, NVIDIA, SAP, Oracle, PalantirTechnologies, and Maersk |

| Additional Attributes | Dollar sales by generative AI applications in logistics, including demand forecasting, route optimization, inventory management, and warehouse automation, by deployment mode such as cloud-based and on-premises solutions, and by geographic region including North America, Europe, and Asia-Pacific; demand driven by the need for real-time optimization, cost reduction, and enhanced supply chain resilience; innovation in AI-driven predictive analytics, autonomous robotics, and digital twins; costs influenced by data infrastructure investments and AI model training; and emerging use cases in cold chain monitoring, e-commerce logistics, and dynamic pricing strategies. |

The global generative ai in logistics market is estimated to be valued at USD 1.7 billion in 2025.

The market size for the generative ai in logistics market is projected to reach USD 31.7 billion by 2035.

The generative ai in logistics market is expected to grow at a 33.7% CAGR between 2025 and 2035.

The key product types in generative ai in logistics market are transformers, variational autoencoder, generative adversarial networks, recurrent neural networks and long short-term memory.

In terms of component, software segment to command 57.2% share in the generative ai in logistics market in 2025.

Our Research Products

The "Full Research Suite" delivers actionable market intel, deep dives on markets or technologies, so clients act faster, cut risk, and unlock growth.

The Leaderboard benchmarks and ranks top vendors, classifying them as Established Leaders, Leading Challengers, or Disruptors & Challengers.

Locates where complements amplify value and substitutes erode it, forecasting net impact by horizon

We deliver granular, decision-grade intel: market sizing, 5-year forecasts, pricing, adoption, usage, revenue, and operational KPIs—plus competitor tracking, regulation, and value chains—across 60 countries broadly.

Spot the shifts before they hit your P&L. We track inflection points, adoption curves, pricing moves, and ecosystem plays to show where demand is heading, why it is changing, and what to do next across high-growth markets and disruptive tech

Real-time reads of user behavior. We track shifting priorities, perceptions of today’s and next-gen services, and provider experience, then pace how fast tech moves from trial to adoption, blending buyer, consumer, and channel inputs with social signals (#WhySwitch, #UX).

Partner with our analyst team to build a custom report designed around your business priorities. From analysing market trends to assessing competitors or crafting bespoke datasets, we tailor insights to your needs.

Supplier Intelligence

Discovery & Profiling

Capacity & Footprint

Performance & Risk

Compliance & Governance

Commercial Readiness

Who Supplies Whom

Scorecards & Shortlists

Playbooks & Docs

Category Intelligence

Definition & Scope

Demand & Use Cases

Cost Drivers

Market Structure

Supply Chain Map

Trade & Policy

Operating Norms

Deliverables

Buyer Intelligence

Account Basics

Spend & Scope

Procurement Model

Vendor Requirements

Terms & Policies

Entry Strategy

Pain Points & Triggers

Outputs

Pricing Analysis

Benchmarks

Trends

Should-Cost

Indexation

Landed Cost

Commercial Terms

Deliverables

Brand Analysis

Positioning & Value Prop

Share & Presence

Customer Evidence

Go-to-Market

Digital & Reputation

Compliance & Trust

KPIs & Gaps

Outputs

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Rail Logistics Market Size and Share Forecast Outlook 2025 to 2035

Retail Logistics Market Size and Share Forecast Outlook 2025 to 2035

Generative AI in Packaging Market Size and Share Forecast Outlook 2025 to 2035

Generative AI In Chemical Market Size and Share Forecast Outlook 2025 to 2035

Generative AI Market Analysis - Trends & Forecast 2025 to 2035

Sea Air Logistics Market Size and Share Forecast Outlook 2025 to 2035

Cold Chain Logistics Transport Insulated Truck Market Size and Share Forecast Outlook 2025 to 2035

Cold Chain Logistics Market Size and Share Forecast Outlook 2025 to 2035

Blockchain in Logistics Market Size and Share Forecast Outlook 2025 to 2035

Healthcare Cold Chain Logistics Market Size and Share Forecast Outlook 2025 to 2035

AI Code Assistant Market Size and Share Forecast Outlook 2025 to 2035

AI-Based Data Observability Software Market Size and Share Forecast Outlook 2025 to 2035

Air Fryer Paper Liners Market Size and Share Forecast Outlook 2025 to 2035

Air Struts Market Size and Share Forecast Outlook 2025 to 2035

AI-powered Wealth Management Solution Market Size and Share Forecast Outlook 2025 to 2035

Airless Paint Spray System Market Size and Share Forecast Outlook 2025 to 2035

AI Powered Software Testing Tool Market Size and Share Forecast Outlook 2025 to 2035

AI Document Generator Market Size and Share Forecast Outlook 2025 to 2035

AI in Fintech Market Size and Share Forecast Outlook 2025 to 2035

Air Caster Skids System Market Size and Share Forecast Outlook 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA