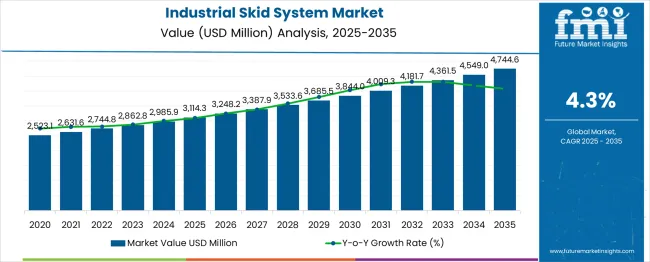

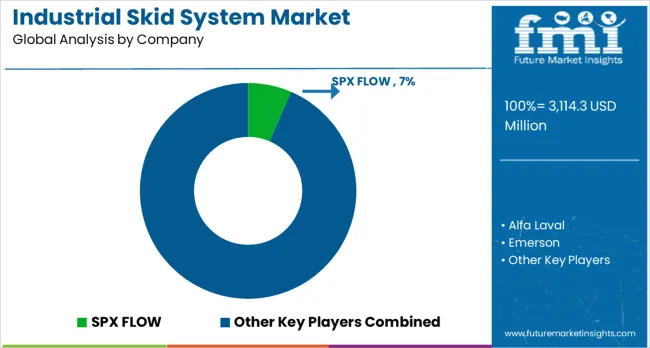

The global industrial skid system market is projected to grow from USD 3,114.3 million in 2025 to approximately USD 4,744.6 million by 2035, recording an absolute increase of USD 1,630.3 million over the forecast period. This translates into a total growth of 52.4%, with the market forecast to expand at a compound annual growth rate (CAGR) of 4.3% between 2025 and 2035. The overall market size is expected to grow by nearly 1.52X during the same period, supported by the rising adoption of modular process solutions and increasing demand for specialized skid systems across various industrial applications.

Between 2025 and 2030, the industrial skid system market is projected to expand from USD 3,114.3 million to USD 3,844.0 million, resulting in a value increase of USD 729.7 million, which represents 44.7% of the total forecast growth for the decade. This phase of growth will be shaped by rising adoption of pre-engineered process solutions in manufacturing industries, increasing focus on modular construction approaches, and growing demand for standardized skid systems that reduce installation time and costs. Service providers are expanding their capabilities to address the growing complexity of modern industrial process requirements.

| Metric | Value |

|---|---|

| Estimated Value in (2025E) | USD 3,114.3 million |

| Forecast Value in (2035F) | USD 4,744.6 million |

| Forecast CAGR (2025 to 2035) | 4.3% |

From 2030 to 2035, the market is forecast to grow from USD 3,844.0 million to USD 4,744.6 million, adding another USD 900.6 million, which constitutes 55.2% of the overall ten-year expansion. This period is expected to be characterized by expansion of smart skid solutions with IoT integration, development of specialized cleanroom and hygienic skid systems, and advancement of corrosion-resistant technologies for harsh industrial environments. The growing adoption of Industry 4.0 principles will drive demand for more sophisticated monitoring and control capabilities integrated within skid systems.

Between 2020 and 2025, the industrial skid system market experienced steady expansion, driven by increasing industrialization in emerging markets and growing preference for modular process solutions that offer faster deployment and lower capital expenditure compared to traditional stick-built approaches. The market developed as industries recognized the benefits of factory-assembled, pre-tested systems that ensure quality control and reduce on-site installation risks.

Market expansion is being supported by the increasing adoption of modular construction approaches across various industrial sectors and the corresponding need for standardized, pre-engineered process solutions. Modern industrial facilities are increasingly relying on skid-mounted systems to achieve faster project execution, improved quality control, and reduced overall project costs. The modular approach allows for parallel manufacturing and testing while site preparation occurs, significantly reducing project timelines and minimizing operational disruptions.

The growing complexity of industrial processes and increasing regulatory compliance requirements are driving demand for specialized skid systems from certified manufacturers with appropriate expertise and quality certifications. Industries are increasingly requiring comprehensive documentation, testing protocols, and compliance with international standards such as ISO, ANSI, and ASME specifications. Environmental regulations and safety requirements are establishing standardized design criteria that favor factory-built solutions over field construction.

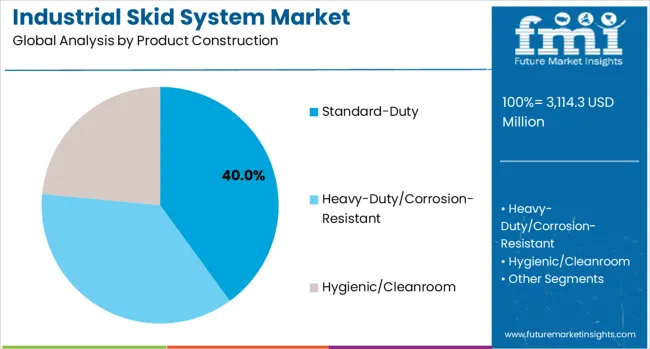

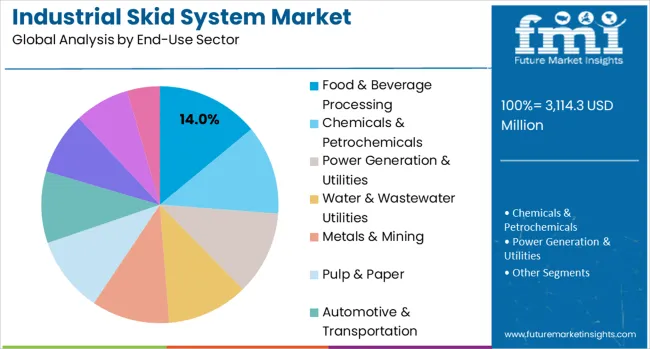

The market is segmented by product construction, capacity/size class, end-use sector, compliance/standard, and region. By product construction, the market is divided into standard-duty, heavy-duty/corrosion-resistant, and hygienic/cleanroom systems. Based on capacity/size class, the market is categorized into small, medium, and large systems. In terms of end-use sector, the market spans food & beverage processing, chemicals & petrochemicals, power generation & utilities, water & wastewater utilities, and other industrial applications. By compliance/standard, the market is classified into ISO/EN, ANSI/ASME, and customer/other specifications. Regionally, the market is divided into North America, Europe, Asia Pacific, Latin America, and Middle East & Africa.

The standard-duty construction segment is projected to account for 40% of the industrial skid system market in 2025, making it the leading construction class. Standard-duty skids are widely adopted across industries such as chemicals, utilities, and general manufacturing, where process conditions are relatively stable and do not demand specialized materials or heavy-duty reinforcements. These systems deliver reliable performance for routine applications including water treatment, chemical dosing, and utility distribution.

Their dominance is supported by well-established engineering practices, abundant raw material availability, and global supplier networks that streamline manufacturing and maintenance. By offering a cost-effective balance between durability and affordability, standard-duty skids provide a practical solution for facilities seeking efficient process integration without over-engineering. The segment also benefits from modularity and compatibility with existing infrastructure, making it the go-to choice for most mainstream industrial projects.

Medium-capacity skid systems are expected to represent 45% of the industrial skid system market in 2025, reflecting their versatility in serving a wide range of industrial processes. These systems provide an optimal balance between processing capability and project economics, making them suitable for diverse sectors such as food and beverage, petrochemicals, and water treatment. Medium-sized skids are easier to transport and install than large-scale systems, yet still offer the capacity to support critical industrial operations.

They are frequently used for both new installations and retrofit projects, where footprint and integration flexibility are key considerations. Standardized design approaches and modular construction allow manufacturers to reduce lead times and production costs, while still meeting varied customer requirements. This combination of adaptability, cost efficiency, and scalability ensures that medium-capacity skid systems remain the most widely adopted size class across industrial applications.

The food and beverage processing sector is projected to contribute 14% of the industrial skid system market in 2025, representing the largest single end-use sector. Skid systems in this industry must meet stringent hygiene and safety requirements, incorporating stainless steel construction, sanitary fittings, and clean-in-place (CIP) features to prevent contamination.

These systems are commonly deployed for mixing, blending, filtration, and sterilization processes, all of which demand consistent compliance with food safety regulations such as FDA, USDA, and EU standards. Skid-based modular systems also enable faster installation and easier validation, which is critical for minimizing production downtime in high-volume food operations. Growing global demand for processed foods and beverages, combined with rising automation in production facilities, continues to drive adoption of hygienically designed industrial skid systems tailored for food sector applications.

The ISO/EN compliance segment is estimated to hold 40% of the industrial skid system market in 2025, reflecting the global adoption of European and international standards for equipment design and manufacturing. ISO/EN frameworks ensure uniform quality, safety, and environmental performance, which are critical for industries operating across international markets. Compliance provides manufacturers with a competitive edge, as it facilitates easier trade, streamlined documentation, and equipment interoperability across regions. For end users, ISO/EN-certified skid systems reduce regulatory risks and enhance confidence in product reliability and safety.

With global industrial supply chains increasingly interconnected, adherence to ISO/EN standards supports consistency in design, reduces re-engineering costs, and accelerates project approvals. As cross-border industrial projects expand, ISO/EN-compliant skid systems will remain the benchmark for standardized, globally accepted equipment solutions.

The industrial skid system market is advancing steadily due to increasing adoption of modular construction approaches and growing recognition of the benefits of factory-built process solutions. However, the market faces challenges including transportation limitations for large skids, need for specialized lifting and installation equipment, and varying local codes and standards across different regions. Standardization efforts and modular design innovations continue to influence market development patterns and enable broader application of skid-mounted solutions.

The growing deployment of smart sensors and IoT connectivity within skid systems is enabling real-time monitoring, predictive maintenance, and remote operation capabilities. Smart skids equipped with advanced control systems provide enhanced process visibility and automated optimization while reducing operational costs. These technologies are particularly valuable for distributed facilities and remote installations where local expertise may be limited but centralized monitoring and support can be provided.

Modern skid manufacturers are incorporating advanced hygienic design principles and cleanroom-compatible materials to serve pharmaceutical, biotechnology, and high-purity applications. Integration of specialized surface treatments, contained transfer systems, and validation-ready documentation enables skid systems to meet the most stringent contamination control requirements. Advanced hygienic designs also support automated cleaning and sterilization processes that reduce manual intervention and improve operational safety.

| Country | CAGR (2025 to 2035) |

|---|---|

| China | 5.7% |

| Saudi Arabia | 5.6% |

| Australia | 5.0% |

| United States | 4.2% |

| United Kingdom | 4.1% |

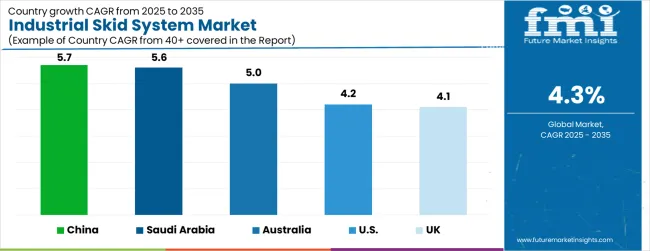

The industrial skid system market is experiencing robust growth globally, with China leading at a 5.7% CAGR through 2035, driven by massive industrial expansion, infrastructure development, and growing adoption of modular construction approaches. Saudi Arabia follows closely at 5.6%, supported by Vision 2030 initiatives, petrochemical industry growth, and diversification into new industrial sectors. Australia maintains strong growth at 5.0%, benefiting from mining sector expansion and water treatment infrastructure development. The United States records steady growth at 4.2%, focusing on industrial modernization and replacement of aging process equipment. The United Kingdom shows consistent expansion at 4.1%, driven by pharmaceutical and food processing industry investments.

The report covers an in-depth analysis of 40+ countries; five top-performing countries are highlighted below.

Revenue from Industrial Skid Systems in China is projected to exhibit the highest growth rate with a CAGR of 5.7% through 2035, driven by rapid industrial expansion, infrastructure development, and increasing adoption of advanced manufacturing technologies. The country's massive chemical and petrochemical industry development is creating significant demand for modular process solutions. Major industrial projects and government initiatives supporting manufacturing modernization are establishing comprehensive skid system supply chains to serve domestic and export markets.

Revenue from Industrial Skid Systems in Saudi Arabia is expanding at a CAGR of 5.6%, supported by Vision 2030 diversification initiatives, NEOM project development, and expansion of petrochemical and mining sectors. The country's massive infrastructure projects and industrial development programs are driving demand for advanced skid solutions. Specialized process skids are increasingly being deployed to support water treatment, petrochemical processing, and renewable energy applications.

Revenue from Industrial Skid Systems in Australia is growing at a CAGR of 5.0%, driven by mining sector expansion, water treatment infrastructure development, and growing adoption of modular solutions for remote applications. The country's mining industry increasingly relies on skid-mounted process equipment that can be rapidly deployed to remote locations with minimal site preparation. Water treatment and environmental compliance requirements are creating demand for specialized treatment skids.

Demand for Industrial Skid Systems in the United States is projected to grow at a CAGR of 4.2%, supported by industrial modernization initiatives, aging infrastructure replacement, and increasing focus on energy efficiency. American manufacturers are implementing advanced skid solutions to improve process efficiency, reduce environmental impact, and ensure regulatory compliance. The market benefits from well-established supply chains and comprehensive service networks that support diverse industrial applications.

Demand for Industrial Skid Systems in the United Kingdom is expanding at a CAGR of 4.1%, driven by pharmaceutical industry growth, food processing modernization, and increasing emphasis on hygienic design standards. British manufacturers are implementing specialized skid solutions that meet stringent regulatory requirements for pharmaceutical and food applications. The market is characterized by focus on high-value, specialized systems that provide superior performance and comprehensive validation documentation.

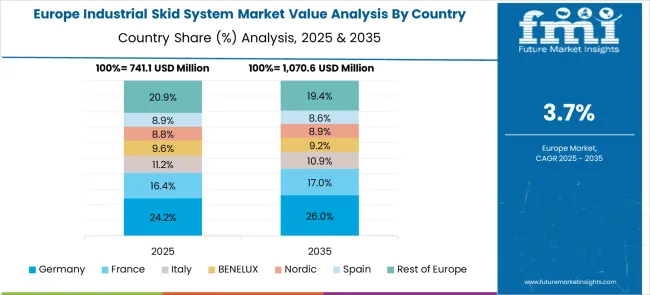

The European industrial skid system market demonstrates advanced development across major economies with Germany leading through its precision engineering capabilities and strong process equipment manufacturing sector, supported by companies like Endress+Hauser, WIKA, and Sulzer pioneering innovative skid technologies for diverse industrial applications. The UK and France show significant growth in chemical processing and oil & gas sectors, where modular skid systems provide efficient process solutions. German companies leverage their automation expertise to develop comprehensive skid systems, while international players like Emerson and Alfa Laval establish strong European presence.

Italy and Spain exhibit expanding adoption in pharmaceutical and food processing industries, driven by regulatory compliance and process optimization requirements. Nordic countries emphasize sustainable process solutions and energy efficiency, while Eastern European markets show growing interest in modernizing industrial infrastructure. The market benefits from strict safety regulations, Industry 4.0 integration, and the region's leadership in process automation, positioning Europe as a key innovation center for next-generation industrial skid systems across multiple process applications requiring modular, efficient, and automated solutions.

The industrial skid system market is characterized by competition among specialized system integrators, equipment manufacturers, and engineering service providers. Companies are investing in advanced manufacturing capabilities, standardized design platforms, digital engineering tools, and global service networks to deliver cost-effective, reliable, and compliant skid solutions. Strategic partnerships, technological innovation, and vertical integration are central to strengthening service portfolios and market presence.

Alfa Laval, Sweden-based, offers comprehensive skid solutions with focus on food processing, pharmaceutical, and marine applications, emphasizing hygienic design and energy efficiency. Emerson, USA-based, provides integrated skid systems with advanced automation and control technologies for process industries. Endress+Hauser, Switzerland-based, delivers instrumentation-intensive skids with comprehensive measurement and control capabilities. Pentair Engineered Skids, USA-based, emphasizes standardized platforms and rapid delivery for water treatment and industrial applications.

SPX FLOW, USA-based, offers specialized skids for food, pharmaceutical, and industrial applications with focus on hygienic design and process optimization. Sulzer, Switzerland-based, provides pumping and mixing skids for chemical and water treatment applications. TechnipFMC, UK/USA-based, delivers complex process skids for oil & gas and petrochemical applications. Veolia Water Technologies, France-based, specializes in water and wastewater treatment skids with comprehensive service support. WIKA, Germany-based, offers instrumentation and measurement solutions integrated within skid systems. Xylem Custom Skids, USA-based, provides water treatment and industrial process skids with emphasis on efficiency and reliability.

| Items | Values |

|---|---|

| Quantitative Units (2025) | USD 3,114.3 million |

| Product Construction | Standard-Duty, Heavy-Duty/Corrosion-Resistant, Hygienic/Cleanroom |

| Capacity/Size Class | Small, Medium, Large |

| End-Use Sector | Food & Beverage Processing, Chemicals & Petrochemicals, Power Generation & Utilities, Water & Wastewater Utilities, and others |

| Compliance/Standard | ISO/EN, ANSI/ASME, Customer/Other |

| Regions Covered | North America, Europe, Asia Pacific, Latin America, Middle East & Africa |

| Countries Covered | United States, Canada, United Kingdom, Germany, France, China, Japan, South Korea, Brazil, Australia and 40+ countries |

| Key Companies Profiled | Alfa Laval, Emerson, Endress+Hauser, Pentair Engineered Skids, SPX FLOW, Sulzer, TechnipFMC, Veolia Water Technologies, WIKA, and Xylem Custom Skids |

| Additional Attributes | Dollar sales by skid type and capacity range, regional demand trends, competitive landscape, buyer preferences for modular versus custom-engineered systems, integration with smart factory automation, innovations in compact design, IoT-enabled monitoring, and sustainable material usage |

The global industrial skid system market is estimated to be valued at USD 3,114.3 million in 2025.

The market size for the industrial skid system market is projected to reach USD 4,744.6 million by 2035.

The industrial skid system market is expected to grow at a 4.3% CAGR between 2025 and 2035.

The key product types in industrial skid system market are standard-duty, heavy-duty/corrosion-resistant and hygienic/cleanroom.

In terms of capacity/size class, medium segment to command 45.0% share in the industrial skid system market in 2025.

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Industrial Wired Routers Market Size and Share Forecast Outlook 2025 to 2035

Industrial Robot Controller Market Size and Share Forecast Outlook 2025 to 2035

Industrial Evaporative Condensers Market Size and Share Forecast Outlook 2025 to 2035

Industrial Insulation Market Size and Share Forecast Outlook 2025 to 2035

Industrial Safety Gloves Market Size and Share Forecast Outlook 2025 to 2035

Industrial Cleaner Market Size and Share Forecast Outlook 2025 to 2035

Industrial Vertical Washing Tower Market Size and Share Forecast Outlook 2025 to 2035

Industrial Pepper Market Size and Share Forecast Outlook 2025 to 2035

Industrial Electronics Packaging Market Forecast and Outlook 2025 to 2035

Industrial Absorbent Market Forecast and Outlook 2025 to 2035

Industrial Furnace Industry Analysis in Europe Forecast and Outlook 2025 to 2035

Industrial Electronic Pressure Switch Market Size and Share Forecast Outlook 2025 to 2035

Industrial WiFi Module Market Size and Share Forecast Outlook 2025 to 2035

Industrial Film Market Forecast Outlook 2025 to 2035

Industrial Floor Mat Market Forecast Outlook 2025 to 2035

Industrial Process Water Coolers Market Forecast and Outlook 2025 to 2035

Industrial Grade Ammonium Hydrogen Fluoride Market Forecast and Outlook 2025 to 2035

Industrial Grade Sodium Bifluoride Market Forecast and Outlook 2025 to 2035

Industrial Evaporative Condenser Market Size and Share Forecast Outlook 2025 to 2035

Industrial Power Supply Market Size and Share Forecast Outlook 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA