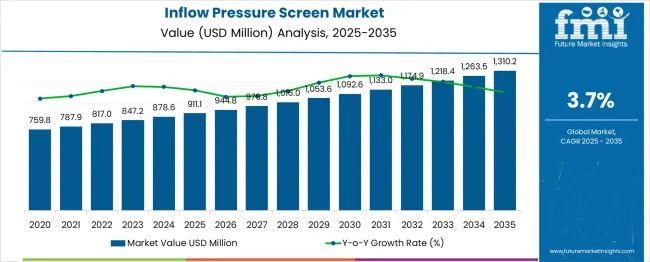

The global inflow pressure screen market is projected to grow from USD 911.1 million in 2025 to approximately USD 1,310.2 million by 2035, recording an absolute increase of USD 401.6 million over the forecast period. This translates into a total growth of 44.1%, with the market forecast to expand at a compound annual growth rate (CAGR) of 3.7% between 2025 and 2035. The overall market size is expected to grow by nearly 1.44X during the same period, supported by the rising adoption of advanced screening technologies and increasing demand for efficient filtration solutions across industrial applications.

Between 2025 and 2030, the inflow pressure screen market is projected to expand from USD 911.1 million to USD 1,090.5 million, resulting in a value increase of USD 179.4 million, which represents 44.7% of the total forecast growth for the decade. This phase of growth will be shaped by rising demand for efficient screening solutions in pulp and paper industries, increasing water treatment requirements, and growing awareness among industrial operators about the importance of proper filtration systems. Manufacturers are expanding their production capabilities to address the growing complexity of modern industrial screening requirements.

| Metric | Value |

|---|---|

| Estimated Value in (2025E) | USD 911.1 million |

| Forecast Value in (2035F) | USD 1,310.2 million |

| Forecast CAGR (2025 to 2035) | 3.7% |

From 2030 to 2035, the market is forecast to grow from USD 1,090.5 million to USD 1,310.2 million, adding another USD 222.2 million, which constitutes 55.3% of the overall ten-year expansion. This period is expected to be characterized by expansion of hygienic and cleanroom screening solutions, integration of advanced materials technology, and development of standardized screening protocols across different industrial applications. The growing adoption of sustainable manufacturing processes will drive demand for more sophisticated screening systems and specialized technical expertise.

Between 2020 and 2025, the inflow pressure screen market experienced steady expansion, driven by increasing industrialization rates and growing awareness of screening requirements in various manufacturing processes. The market developed as industrial facilities recognized the need for specialized equipment and maintenance to properly operate screening systems. Environmental regulations and industrial manufacturers began emphasizing proper screening procedures to maintain process efficiency and regulatory compliance.

Market expansion is being supported by the rapid increase in industrial manufacturing worldwide and the corresponding need for specialized screening solutions in processing, filtration, and separation applications. Modern industrial facilities rely on precise screening and filtration to ensure proper functioning of production systems including pulp processing, chemical separation, and water treatment. Even minor efficiency improvements in screening can result in significant cost savings and enhanced product quality for industrial operators.

The growing complexity of industrial processes and increasing environmental compliance requirements are driving demand for professional screening solutions from certified providers with appropriate equipment and expertise. Regulatory agencies are increasingly requiring proper screening documentation and efficiency standards to maintain environmental compliance and ensure operational safety. Industrial specifications and manufacturer requirements are establishing standardized screening procedures that require specialized equipment and trained technicians.

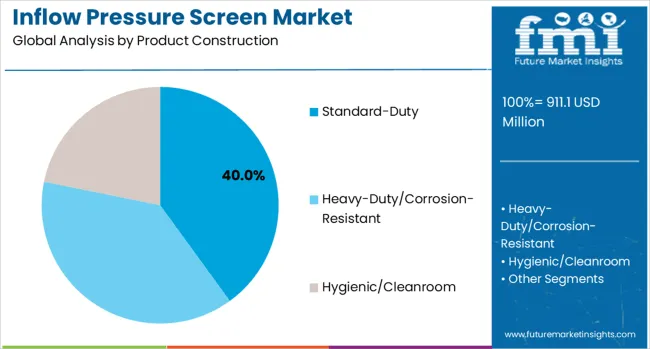

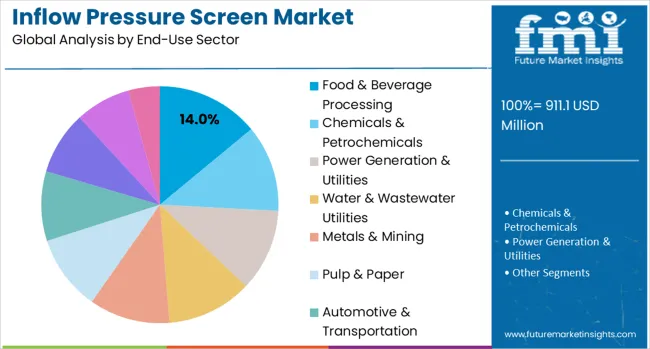

The market is segmented by product construction, capacity/size class, end-use sector, compliance/standard, and region. By product construction, the market is divided into standard-duty, heavy-duty/corrosion-resistant, and hygienic/cleanroom configurations. Based on capacity/size class, the market is categorized into small, medium, and large capacity systems. In terms of end-use sector, the market spans across food & beverage processing, chemicals & petrochemicals, power generation & utilities, and other industrial applications. By compliance/standard, the market is classified into ISO/EN, ANSI/ASME, and customer/other specifications. Regionally, the market includes major industrial regions with India, China, Australia, France, and the United States leading growth.

The standard-duty construction segment is projected to account for 40% of the inflow pressure screen market in 2025, establishing itself as the leading product class. Standard-duty screens are widely used across industries where general-purpose screening is sufficient, such as pulp and paper, municipal water treatment, and light industrial processing. Their appeal lies in reliable performance under normal operating conditions, supported by the use of proven materials and long-standing manufacturing processes.

This segment benefits from cost-effectiveness, broad product availability, and established supplier networks that streamline procurement and maintenance. Facilities often prefer standard-duty configurations as they balance performance and affordability without over-engineering. Their durability and compatibility with common screening systems make them the default choice for conventional applications, ensuring strong adoption across both developing and mature industrial markets.

Medium-capacity inflow pressure screens are expected to represent 45% of demand in 2025, making them the most dominant size class. These systems provide an optimal mix of processing capability and operational flexibility, allowing them to serve the needs of most industrial operations. Medium-capacity models are increasingly favored for their scalability, offering solutions that can adapt to both mid-sized and expanding production facilities.

The segment also benefits from the integration of advanced controls that optimize performance under variable loads, ensuring efficiency across a range of operating conditions. Medium-sized screens strike a balance between investment cost and throughput capacity, making them attractive for facilities seeking operational efficiency. With industries demanding reliable and flexible solutions, medium-capacity screens remain the most practical option for broad industrial adoption.

The food and beverage processing sector is projected to contribute 14% of the inflow pressure screen market in 2025, making it the single largest end-use application. Facilities in this sector require hygienic design, stainless steel materials, and strict compliance with international food safety standards. Multiple screening stages are often deployed to ensure product purity, consistent quality, and protection of downstream equipment.

This segment benefits from the rising demand for processed foods, dairy products, and beverages worldwide, as well as increasing automation in food production. Inflow pressure screens are vital for maintaining cleanliness and efficiency in high-volume operations. The emphasis on regulatory compliance, traceability, and sanitation ensures that food and beverage processors continue to be a primary driver of demand for specialized industrial screening solutions.

The ISO/EN compliance segment is estimated to hold 40% of the inflow pressure screen market in 2025, reflecting its strong global acceptance. ISO/EN frameworks set widely recognized benchmarks for quality, safety, and design consistency, making them the preferred standards for both equipment manufacturers and end users.

Adherence to these standards facilitates international trade and equipment interoperability, allowing manufacturers to serve global markets with confidence. Industrial facilities also benefit from reduced regulatory risks and easier integration when using ISO/EN-compliant equipment. As globalization accelerates, ISO/EN standards provide the framework for standardized processes, documentation, and service requirements, ensuring consistency across diverse industrial screening applications.

The inflow pressure screen market is advancing steadily due to increasing industrial automation and growing recognition of screening efficiency importance. However, the market faces challenges including high equipment costs, need for continuous maintenance training on new screening technologies, and varying performance requirements across different industrial applications. Standardization efforts and certification programs continue to influence equipment quality and market development patterns.

The growing deployment of hygienic and cleanroom screening systems is enabling specialized applications in pharmaceutical, food processing, and semiconductor manufacturing facilities. Advanced screening systems equipped with specialized materials and surface treatments provide contamination control and reduced maintenance requirements for customers while expanding application possibilities. These systems are particularly valuable for high-purity applications and regulated industries that require validated cleaning and sterilization procedures.

Modern screening system manufacturers are incorporating advanced materials and surface coating technologies that improve corrosion resistance and extend service life. Integration of specialty alloys, ceramic coatings, and polymer-based screening elements enables more precise screening performance and comprehensive operational documentation. Advanced materials also support screening of aggressive chemicals and high-temperature applications including specialized industrial processes and demanding operational environments.

| Country | CAGR (2025 to 2035) |

|---|---|

| India | 5.2% |

| China | 5.0% |

| Australia | 4.2% |

| France | 3.5% |

| United States | 3.3% |

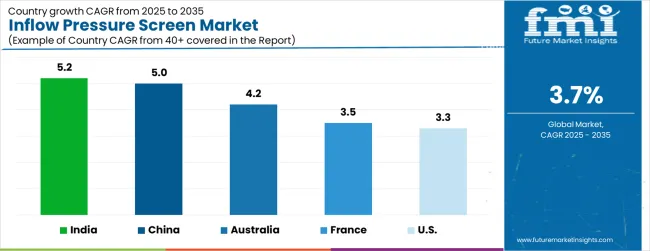

The inflow pressure screen market is growing rapidly, with India leading at a 5.2% CAGR through 2035, driven by strong industrial expansion, government infrastructure initiatives, and expanding manufacturing networks. China follows at 5.0%, supported by massive industrial production capacity and increasing environmental compliance requirements in manufacturing facilities. Australia grows steadily at 4.2%, integrating screening technology into its established mining and processing industries. France records 3.5%, emphasizing precision engineering, quality standards, and advanced industrial expertise. The USA shows steady growth at 3.3%, focusing on technological innovation, operational efficiency, and compliance-driven upgrades. Overall, India and China emerge as the leading drivers of global inflow pressure screen market expansion.

The report covers an in-depth analysis of 40+ countries; five top-performing countries are highlighted below.

Revenue from inflow pressure screens in India is projected to exhibit the highest growth rate with a CAGR of 5.2% through 2035, driven by rapid industrial development and increasing demand for efficient processing equipment. The country's expanding manufacturing sector and growing pulp and paper industry are creating significant demand for screening solutions. Major industrial manufacturers and equipment suppliers are establishing comprehensive distribution networks to support the growing population of industrial facilities across urban and rural markets.

Revenue from inflow pressure screens in China is expanding at a CAGR of 5.0%, supported by massive industrial production capacity and increasing environmental compliance requirements in manufacturing facilities. The country's established manufacturing sector and increasing focus on process efficiency are driving demand for professional screening solutions. Industrial facilities and specialized equipment suppliers are establishing capabilities to serve the growing demand for advanced screening systems.

Revenue from inflow pressure screens in Australia is growing at a CAGR of 4.2%, driven by the country's established mining and mineral processing industries and growing recognition of screening efficiency importance in resource extraction. The country's advanced industrial sector is integrating screening capabilities to serve modern processing technologies. Mining operations and processing facilities are investing in screening equipment upgrades to address growing operational demands.

Demand for inflow pressure screens in France is projected to grow at a CAGR of 3.5%, supported by the country's emphasis on industrial technology innovation and precision equipment manufacturing. French industrial equipment providers are implementing comprehensive screening capabilities that meet stringent quality standards and regulatory specifications. The market is characterized by focus on technical excellence, advanced materials integration, and compliance with comprehensive industrial safety and environmental regulations.

Demand for inflow pressure screens in the USA is expanding at a CAGR of 3.3%, driven by industrial modernization initiatives and growing emphasis on operational efficiency improvements. Large industrial facilities and specialized equipment providers are establishing comprehensive screening capabilities to serve diverse processing needs. The market benefits from environmental regulatory requirements for proper screening system operation and manufacturer compliance following equipment installation and maintenance activities.

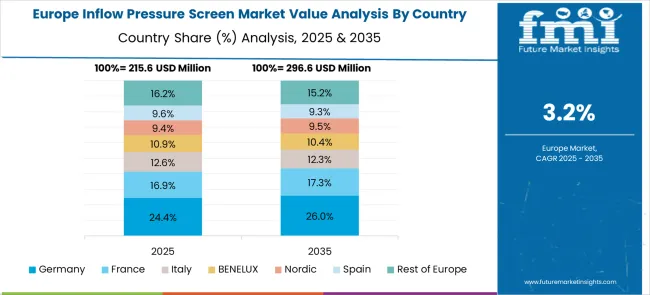

The inflow pressure screen market in Europe is projected to grow steadily, with France representing a significant portion of the regional market. France is expected to maintain strong growth supported by its established industrial manufacturing sector and advanced process industries. The country benefits from comprehensive environmental regulations that drive demand for efficient screening technologies and established supplier networks that provide comprehensive service coverage.

Other major European markets including Germany, UK, and Nordic countries contribute significantly to regional demand through their advanced manufacturing sectors and stringent environmental compliance requirements. These markets emphasize technological innovation, operational efficiency, and compliance with comprehensive industrial safety and environmental standards.

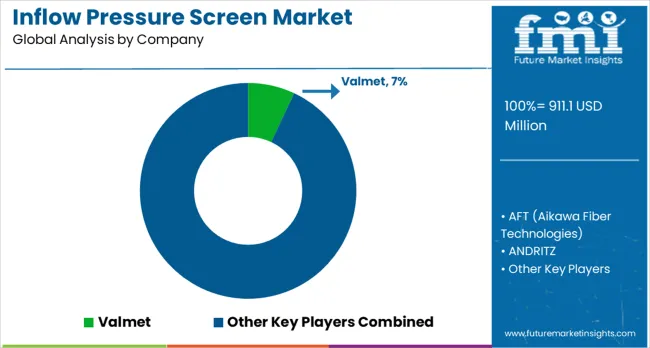

The inflow pressure screen market is defined by competition among specialized equipment manufacturers, industrial equipment suppliers, and process technology companies. Companies are investing in advanced screening technologies, comprehensive service capabilities, standardized manufacturing processes, and technical support programs to deliver precise, reliable, and cost-effective screening solutions. Strategic partnerships, technological innovation, and geographic expansion are central to strengthening product portfolios and market presence.

AFT (Aikawa Fiber Technologies), USA/Japan-based, offers advanced screening systems with a focus on precision engineering, operational efficiency, and technical expertise. ANDRITZ, operating from Austria globally, provides comprehensive screening solutions integrated with industrial process equipment and automation systems. Bellmer, Germany, delivers technologically advanced screening systems with standardized manufacturing procedures and digital integration. GL&V (Valmet legacy), Canada/Global, emphasizes comprehensive service and worldwide coverage for industrial screening applications.

Kadant Fiber Processing, USA, offers screening solutions integrated with fiber processing and pulp production operations. Leizhan Machinery, China, provides cost-effective screening systems with established manufacturing capabilities. PAPCEL, Czechia, delivers specialized screening expertise for pulp and paper applications. Parason Machinery, India, offers regionally-focused screening solutions with competitive pricing. Valmet, Finland, provides comprehensive industrial screening systems with global service support. Voith, Germany, offers specialized screening expertise, advanced engineering, and operational reliability across global and regional networks.

| Items | Values |

|---|---|

| Quantitative Units (2025) | USD 911.1 million |

| Product Construction | Standard-Duty, Heavy-Duty/Corrosion-Resistant, Hygienic/Cleanroom |

| Capacity/Size Class | Small, Medium, Large |

| End-Use Sector | Food & Beverage Processing, Chemicals & Petrochemicals, Power Generation & Utilities, Water & Wastewater Utilities, Metals & Mining, Pulp & Paper, Automotive & Transportation, Electronics & Semiconductors, Oil & Gas, Construction & Building Services |

| Compliance/Standard | ISO/EN, ANSI/ASME, Customer/Other |

| Regions Covered | North America, Europe, East Asia, South Asia & Pacific, Latin America, Middle East & Africa |

| Countries Covered | United States, Canada, United Kingdom, Germany, France, China, Japan, South Korea, Brazil, Australia and 40+ countries |

| Key Companies Profiled | AFT (Aikawa Fiber Technologies), ANDRITZ, Bellmer, GL&V (Valmet legacy), Kadant Fiber Processing, Leizhan Machinery, PAPCEL, Parason Machinery, Valmet, and Voith |

| Additional Attributes | Dollar sales by screen type and capacity range, regional demand trends, competitive landscape, buyer preferences for continuous versus batch systems, integration with pulp and paper processing lines, innovations in rotor design, energy efficiency, and wear-resistant materials |

The global inflow pressure screen market is estimated to be valued at USD 911.1 million in 2025.

The market size for the inflow pressure screen market is projected to reach USD 1,310.2 million by 2035.

The inflow pressure screen market is expected to grow at a 3.7% CAGR between 2025 and 2035.

The key product types in inflow pressure screen market are standard-duty, heavy-duty/corrosion-resistant and hygienic/cleanroom.

In terms of capacity/size class, medium segment to command 45.0% share in the inflow pressure screen market in 2025.

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Inflow Control Devices Market Analysis - Size, Growth, and Forecast 2025 to 2035

Pressure Compensated Pump Market Size and Share Forecast Outlook 2025 to 2035

Pressure Switch Market Forecast Outlook 2025 to 2035

Pressure Reducing Valve Market Size and Share Forecast Outlook 2025 to 2035

Pressure-Volume Loop Systems Market Size and Share Forecast Outlook 2025 to 2035

Pressure Transmitter Market Size and Share Forecast Outlook 2025 to 2035

Pressure Monitoring Extension Tubing Sets Market Size and Share Forecast Outlook 2025 to 2035

Pressure Sensitive Labeling Machine Market Size and Share Forecast Outlook 2025 to 2035

Pressure Bandages Market Size and Share Forecast Outlook 2025 to 2035

Pressure-Sensitive Adhesives Market Size and Share Forecast Outlook 2025 to 2035

Pressure Gauges Market Size and Share Forecast Outlook 2025 to 2035

Pressure Relief Valve Market Size and Share Forecast Outlook 2025 to 2035

Pressure-Controlled Vacuum Sealers Market Size and Share Forecast Outlook 2025 to 2035

Pressure Sensitive Tapes and Labels Market Size, Share & Forecast 2025 to 2035

Pressure Infusion Bags Market Analysis - Size, Share, and Forecast 2025 to 2035

Pressure Ulcer Detection Devices Market Trends – Growth & Forecast 2025 to 2035

Pressure Cushions Market Trends - Growth, Size & Forecast 2025 to 2035

Pressure Infusion Cuffs Market Growth – Trends & Future Outlook 2024-2034

Pressure Cookers Market

Pressure Calibrator Market

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA