The jerry cans market is growing steadily as industries demand durable, versatile, and sustainable storage solutions for liquids and chemicals. Manufacturers are innovating with lightweight materials, advanced designs, and eco-friendly options to meet the needs of sectors like chemicals, petroleum, and food and beverages. By 2035, this market is projected to exceed USD 3.8 billion, growing at a compound annual growth rate (CAGR) of 4.6%.

The focus on safety, convenience, and sustainability drives market growth. Companies are delivering jerry cans that ensure safe transport, enhance user experience, and reduce environmental impact.

| Attribute | Details |

|---|---|

| Projected Value by 2035 | USD 3.8 billion |

| CAGR (2025 to 2035) | 4.6% |

Factors Driving Market Growth

| Category | Market Share (%) |

|---|---|

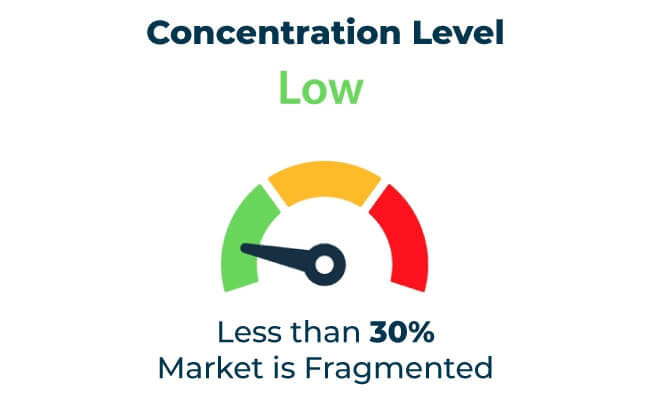

| Top 3 Players (Greif, Mauser Packaging, SCHÜtz) | 13% |

| Rest of Top 5 Players (Time Technoplast, Scepter) | 7% |

| Next 5 of Top 10 Players | 5% |

Type of Player & Industry Share

| Type of Player | Market Share (%) |

|---|---|

| Top 10 Players | 25% |

| Next 20 Players | 44% |

| Remaining Players | 26% |

Emerging markets in Asia-Pacific, Africa, and Latin America offer significant growth potential. Rising industrialization and increasing exports of chemicals and petroleum products drive demand for durable and cost-effective jerry cans. Exporters aligned with local regulations and preferences can capture these opportunities.

| Region | North America |

|---|---|

| Market Share (%) | 35% |

| Key Drivers | Focuses on safety standards and advanced material adoption. |

| Region | Europe |

|---|---|

| Market Share (%) | 30% |

| Key Drivers | Leads in sustainable practices and innovative designs. |

| Region | Asia-Pacific |

|---|---|

| Market Share (%) | 25% |

| Key Drivers | Industrialization and export growth drive demand. |

| Region | Other Regions |

|---|---|

| Market Share (%) | 10% |

| Key Drivers | Affordable, durable solutions gain traction in emerging markets |

The jerry cans market will grow through advancements in sustainable materials, smart technologies, and automation. Companies focusing on eco-friendly practices and global market expansion will strengthen their competitive positions. Collaboration with logistics providers and regulatory agencies will drive innovation and adoption.

| Tier | Key Companies |

|---|---|

| Tier 1 | Greif, Mauser Packaging, SCHÜtz |

| Tier 2 | Time Technoplast, Scepter |

| Tier 3 | Scholle IPN, RPC Group |

The jerry cans market is set for robust growth as sustainability, industrial expansion, and innovation shape industry trends. Companies prioritizing eco-friendly practices, advanced materials, and global market expansion will lead the competitive landscape. Collaboration with industry stakeholders and compliance with regulations will enhance opportunities.

Key Definitions

Abbreviations

Methodology

This report integrates primary research, secondary data, and expert insights. Findings are validated through interviews with industry professionals and end-users to ensure accuracy and reliability.

The jerry cans market includes the production and application of durable, sustainable containers for chemicals, petroleum, food, and industrial goods. These solutions prioritize safety, usability, and environmental responsibility.

Jerry cans are widely used for storing and transporting liquids like chemicals, fuels, and edible oils across industries.

Manufacturers use recyclable materials, promote reuse, and adopt energy-efficient production methods to make jerry cans eco-friendly.

North America and Europe lead the market due to strict safety regulations and strong industrial growth, while Asia-Pacific shows rapid expansion driven by industrialization.

Challenges include high production costs for sustainable materials, regulatory complexity, and gaps in recycling infrastructure.

Smart cans with tracking features, advanced sealing systems, and lightweight designs are key innovations driving market growth.

Our Research Products

The "Full Research Suite" delivers actionable market intel, deep dives on markets or technologies, so clients act faster, cut risk, and unlock growth.

The Leaderboard benchmarks and ranks top vendors, classifying them as Established Leaders, Leading Challengers, or Disruptors & Challengers.

Locates where complements amplify value and substitutes erode it, forecasting net impact by horizon

We deliver granular, decision-grade intel: market sizing, 5-year forecasts, pricing, adoption, usage, revenue, and operational KPIs—plus competitor tracking, regulation, and value chains—across 60 countries broadly.

Spot the shifts before they hit your P&L. We track inflection points, adoption curves, pricing moves, and ecosystem plays to show where demand is heading, why it is changing, and what to do next across high-growth markets and disruptive tech

Real-time reads of user behavior. We track shifting priorities, perceptions of today’s and next-gen services, and provider experience, then pace how fast tech moves from trial to adoption, blending buyer, consumer, and channel inputs with social signals (#WhySwitch, #UX).

Partner with our analyst team to build a custom report designed around your business priorities. From analysing market trends to assessing competitors or crafting bespoke datasets, we tailor insights to your needs.

Supplier Intelligence

Discovery & Profiling

Capacity & Footprint

Performance & Risk

Compliance & Governance

Commercial Readiness

Who Supplies Whom

Scorecards & Shortlists

Playbooks & Docs

Category Intelligence

Definition & Scope

Demand & Use Cases

Cost Drivers

Market Structure

Supply Chain Map

Trade & Policy

Operating Norms

Deliverables

Buyer Intelligence

Account Basics

Spend & Scope

Procurement Model

Vendor Requirements

Terms & Policies

Entry Strategy

Pain Points & Triggers

Outputs

Pricing Analysis

Benchmarks

Trends

Should-Cost

Indexation

Landed Cost

Commercial Terms

Deliverables

Brand Analysis

Positioning & Value Prop

Share & Presence

Customer Evidence

Go-to-Market

Digital & Reputation

Compliance & Trust

KPIs & Gaps

Outputs

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Jerry Cans Market Size and Share Forecast Outlook 2025 to 2035

Market Share Distribution Among Bowl Cans Manufacturers

Market Share Insights of Paint Can Manufacturers

Industry Share Analysis for 2-Piece Cans Companies

Market Share Breakdown of the Aluminum Cans Market

United States Jerry Cans Market Insights – Demand and Growth Forecast 2025 to 2035

Market Share Breakdown of Metal Food Cans Industry

Market Share Breakdown of Composite Paper Cans Manufacturers

Competitive Overview of the Aluminum Aerosol Cans Market Share

Market Positioning & Share in Beverage Aluminum Cans Production

Cans Market Analysis – Innovations & Industry Forecast 2025 to 2035

Tin Cans Market

Bowl Cans Market Size and Share Forecast Outlook 2025 to 2035

Food Cans Market

Beer Cans Market

Paint Cans Market Size and Share Forecast Outlook 2025 to 2035

Drink Cans Market Insights - Growth & Trends 2025 to 2035

2 Piece Cans Market Size and Share Forecast Outlook 2025 to 2035

Beta-Glucans Market Trends – Growth, Demand & Forecast 2025 to 2035

Malaysia Plastic Jerry Can Market Trends & Forecast 2024-2034

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA