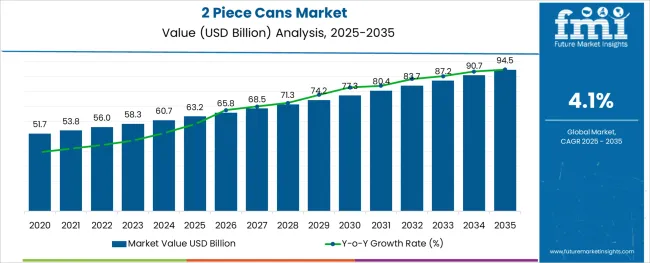

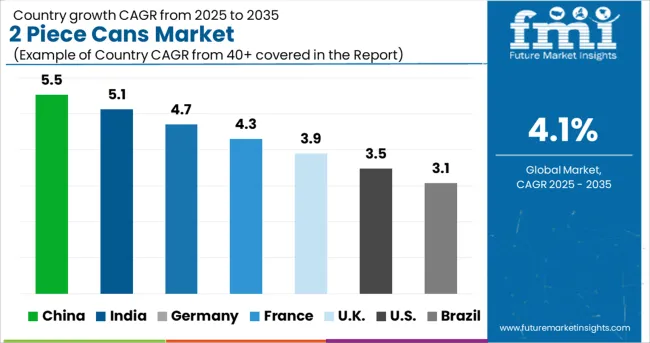

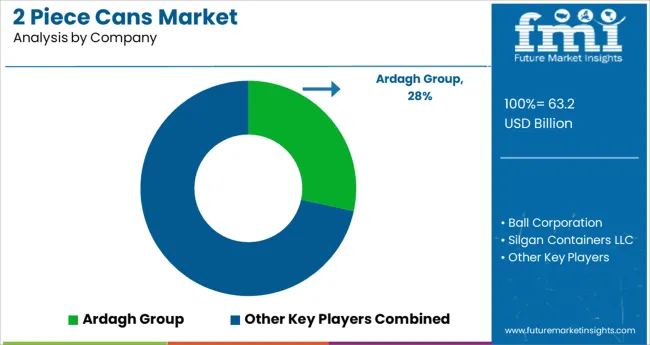

The 2 Piece Cans Market is estimated to be valued at USD 63.2 billion in 2025 and is projected to reach USD 94.5 billion by 2035, registering a compound annual growth rate (CAGR) of 4.1% over the forecast period.

The 2 piece cans market is witnessing robust growth driven by increased demand for lightweight durable and high barrier packaging solutions across the food and beverage sector. Heightened regulatory focus on recyclability and sustainability has accelerated the transition from plastic and glass to metal can formats particularly in North America and Europe.

The minimal seam structure of 2 piece cans enhances product safety and shelf life while also offering superior printability and brand visibility. Technological advancements in can manufacturing machinery and high speed production lines are contributing to increased output efficiency and lower production costs.

Furthermore the compatibility of 2 piece cans with both hot fill and cold fill applications has expanded their adoption across a wider array of liquid and solid food products. As consumer preference shifts toward portable and sustainable packaging formats the 2 piece cans market is expected to experience consistent growth with major opportunities emerging in ready to drink beverages canned meals and export grade food packaging.

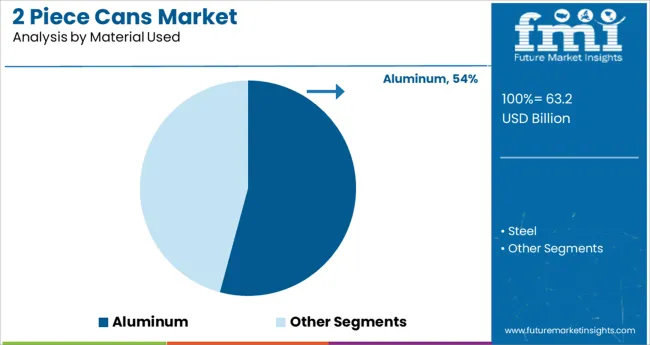

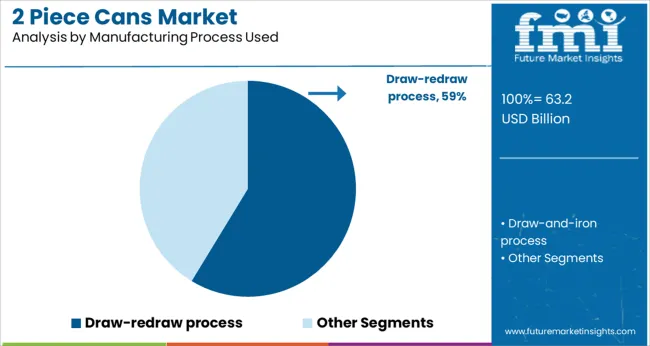

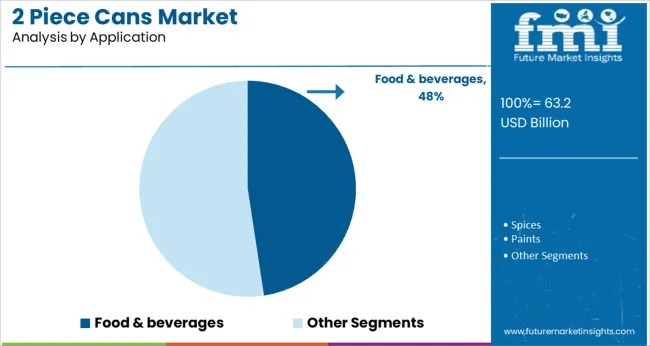

The market is segmented by Material Used, Manufacturing Process Used, Application, and End Use Industry and region. By Material Used, the market is divided into Aluminum and Steel. In terms of Manufacturing Process Used, the market is classified into Draw-redraw process and Draw-and-iron process. Based on Application, the market is segmented into Food & beverages, Spices, Paints, Brewery, Aerosols, and Other products.

By End Use Industry, the market is divided into Food & beverage industry, Paint & coating industry, Consumer goods, and Others. Regionally, the market is classified into North America, Latin America, Western Europe, Eastern Europe, Balkan & Baltic Countries, Russia & Belarus, Central Asia, East Asia, South Asia & Pacific, and the Middle East & Africa.

It has been observed that aluminum accounts for 54.20 percent of the material usage in the 2 piece cans market positioning it as the leading material choice. This dominance is attributed to aluminum's lightweight properties corrosion resistance and recyclability making it the preferred material for sustainable packaging.

Its ability to provide a strong barrier against light oxygen and contaminants ensures extended shelf life and product freshness. The metal’s high thermal conductivity also supports rapid processing in canning lines enhancing manufacturing efficiency.

Additionally aluminum’s infinite recyclability aligns with global circular economy initiatives making it increasingly attractive for both manufacturers and consumers. The material’s strength to weight ratio further supports cost effective transportation and logistics reinforcing its market leadership within this segment.

The draw redraw manufacturing process constitutes 58.70 percent of the overall market share making it the predominant production method in the 2 piece cans landscape. This process is favored due to its ability to produce deeper cans with uniform wall thickness and high structural integrity suitable for both food and beverage packaging.

The draw redraw technique enables precision forming which supports tight dimensional tolerances and compatibility with automated filling systems. Its application is especially prominent in segments requiring enhanced can strength to withstand high internal pressures such as carbonated beverages and canned meals.

Moreover the process allows for high speed production with reduced material wastage enhancing operational cost efficiency. The resulting seamless structure not only improves can aesthetics but also strengthens resistance to leaks and contamination thereby boosting consumer trust and product reliability.

The food and beverages sector holds a 47.60 percent share of the total market representing the dominant application for 2 piece cans. This segment’s leadership is driven by rising demand for long shelf life products convenience packaging and regulatory compliant storage solutions.

In the beverage industry 2 piece cans have gained traction due to their suitability for carbonated drinks energy beverages and ready to drink teas offering a tamper proof and lightweight alternative to glass. In food applications the structure supports vacuum sealing and thermal processing preserving nutritional value and taste over extended periods.

Additionally growing consumer preference for on the go consumption and portion controlled packaging formats has reinforced the use of 2 piece cans. The ability to combine branding durability and recyclability has solidified their position as a reliable and eco conscious packaging choice in the food and beverage segment.

Consumers use cans for a variety of purposes, it is the most widely used containers worldwide. It is estimated that about more than 100 million cans are consumed each day within USA only. The can manufacturing process has changed remarkably since its beginning.

The labor-intensive industries some years ago, now have been replaced by automated means, and produces billions of cans per year. Raw materials and energy accounts for the largest share of the variable 2 piece can production. Also, the prices of aluminum and steel plates, sheets readily change. With the surge of import and export of steel since last decades, the cost of steel has dropped.

It creates an opportunity for the manufacturers looking forward to investing in the 2 piece cans production. Also, 2 piece cans have various advantages over other types of cans, some of the benefits are-

Also, these 2 piece cans are hermetically sealed containers designed to keep food inside fresh in texture and taste. These factors are expected to drive the growth of global 2 piece cans market share over the forecast period.

The sources which have been used to validate the estimated market size include annual reports of key market players, industry journals & magazines, research papers, and other relevant data available in the public domain. Primary sources referred include focused discussions with C level executives, distributors, independent consultants, and key industry experts, among others.

Among materials which are used for the manufacturing of 2 piece cans, aluminum is expected to be the most sustainable package. Aluminum cans have a higher recycling rate and it has more recycled content than other competing packaging types. The below exhibit represents the advantage of aluminum over other beverage packaging types and comparative analysis on the basis of recycling rate.

The report is a compilation of first-hand information, qualitative and quantitative assessment by industry analysts, inputs from industry experts and industry participants across the value chain. The report provides in-depth analysis of parent market trends, macro-economic indicators and governing factors along with market attractiveness as per segments. The report also maps the qualitative impact of various market factors on market segments and geographies.

Tier 1 Companies in 2 piece cans market, revenue above USD 100 Million:

Tier 2 Companies 2 piece cans market, between USD 50 Million to USD 100 Million:

Tier 3 Companies 2 piece cans market, revenue below USD 50 Million:

The research report presents a comprehensive assessment of the market and contains thoughtful insights, facts, historical data, and statistically supported and industry-validated market data. It also contains projections using a suitable set of assumptions and methodologies. The research report provides analysis and information according to market segments such as geographies, application, and industry.

The global 2 piece cans market is estimated to be valued at USD 63.2 billion in 2025.

It is projected to reach USD 94.5 billion by 2035.

The market is expected to grow at a 4.1% CAGR between 2025 and 2035.

The key product types are aluminum and steel.

draw-redraw process segment is expected to dominate with a 58.7% industry share in 2025.

Our Research Products

The "Full Research Suite" delivers actionable market intel, deep dives on markets or technologies, so clients act faster, cut risk, and unlock growth.

The Leaderboard benchmarks and ranks top vendors, classifying them as Established Leaders, Leading Challengers, or Disruptors & Challengers.

Locates where complements amplify value and substitutes erode it, forecasting net impact by horizon

We deliver granular, decision-grade intel: market sizing, 5-year forecasts, pricing, adoption, usage, revenue, and operational KPIs—plus competitor tracking, regulation, and value chains—across 60 countries broadly.

Spot the shifts before they hit your P&L. We track inflection points, adoption curves, pricing moves, and ecosystem plays to show where demand is heading, why it is changing, and what to do next across high-growth markets and disruptive tech

Real-time reads of user behavior. We track shifting priorities, perceptions of today’s and next-gen services, and provider experience, then pace how fast tech moves from trial to adoption, blending buyer, consumer, and channel inputs with social signals (#WhySwitch, #UX).

Partner with our analyst team to build a custom report designed around your business priorities. From analysing market trends to assessing competitors or crafting bespoke datasets, we tailor insights to your needs.

Supplier Intelligence

Discovery & Profiling

Capacity & Footprint

Performance & Risk

Compliance & Governance

Commercial Readiness

Who Supplies Whom

Scorecards & Shortlists

Playbooks & Docs

Category Intelligence

Definition & Scope

Demand & Use Cases

Cost Drivers

Market Structure

Supply Chain Map

Trade & Policy

Operating Norms

Deliverables

Buyer Intelligence

Account Basics

Spend & Scope

Procurement Model

Vendor Requirements

Terms & Policies

Entry Strategy

Pain Points & Triggers

Outputs

Pricing Analysis

Benchmarks

Trends

Should-Cost

Indexation

Landed Cost

Commercial Terms

Deliverables

Brand Analysis

Positioning & Value Prop

Share & Presence

Customer Evidence

Go-to-Market

Digital & Reputation

Compliance & Trust

KPIs & Gaps

Outputs

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Industry Share Analysis for 2-Piece Cans Companies

2-(4-(Bromomethyl)phenyl)propionic Acid (BMPPA) Market Forecast and Outlook 2025 to 2035

2-tert-Butylcyclohexanol Market Forecast and Outlook 2025 to 2035

2-Fluorobenzotrifluoride Market Forecast and Outlook 2025 to 2035

2-Methoxynaphthalene-1-Boronic Acid Market Forecast and Outlook 2025 to 2035

20MnCr5 Steel Market Size and Share Forecast Outlook 2025 to 2035

2-Ethoxy Propene Market Size and Share Forecast Outlook 2025 to 2035

2-in-1 Material Rack Correction Machine Market Size and Share Forecast Outlook 2025 to 2035

2-Ethyl-3,4-ethylenedioxythiophene Market Size and Share Forecast Outlook 2025 to 2035

2D Barcode Reader Market Size and Share Forecast Outlook 2025 to 2035

2-Methylfuran Market Size and Share Forecast Outlook 2025 to 2035

2 Loop FIBC Bags Market Size and Share Forecast Outlook 2025 to 2035

2K Epoxy Adhesives Market Size and Share Forecast Outlook 2025 to 2035

2D Transition Metal Carbides Nitrides Market Size and Share Forecast Outlook 2025 to 2035

2-Hexyldecanol Market Size and Share Forecast Outlook 2025 to 2035

2-EthylHexyl Acetate Market Size and Share Forecast Outlook 2025 to 2035

2 Seal Pouches Market Size and Share Forecast Outlook 2025 to 2035

2-ethylhexanol (2-EH) Market Growth - Trends & Forecast 2025 to 2035

2D Bar Code Marketing Market Analysis by Technology, Code Types, Applications, and Region Through 2035

Breaking Down Market Share in 2 Loop FIBC Bags

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA