The 2 Loop FIBC (Flexible Intermediate Bulk Container) bag market is seeing considerable growth with rising demand for effective, high-strength, and economical bulk packaging solutions. Companies emphasize strength, sustainability, and regulatory requirements to cater to varied industry requirements, especially in agriculture, chemicals, and construction.

Businesses incorporate woven polypropylene fabrics of high strength, UV stabilization, and water-resistant coatings to improve the strength and lifespan of bags. Growth in world trade and logistics enhances the penetration of bulk bags with enhanced security features, tamper-evident designs, and optimized payload capacity. Business actors invest in automatic production lines and eco-friendly polymer technologies to save costs and lower environmental footprint.

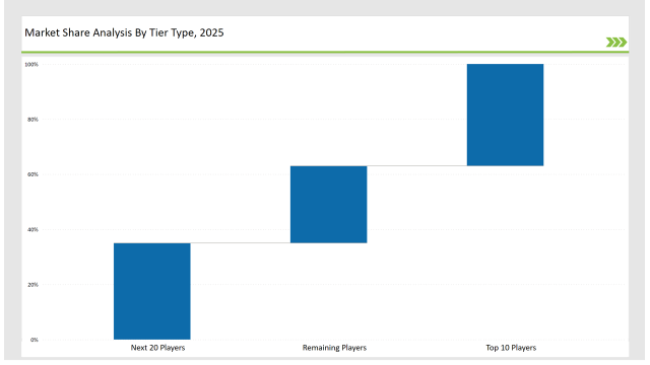

Tier 1 players like Greif, Berry Global, and Conitex Sonoco possess 37% market share through advanced manufacturing ability, extensive distribution worldwide, and higher quality control systems.

Tier 2 players such as LC Packaging, Rishi FIBC Solutions, and Plastene India hold 35% of the market share through the provision of customized, recyclable, and high-volume bags for various industrial uses.

Tier 3 is made up of regional and specialty manufacturers targeting specialized applications, specialty printing, and biodegradable substitutes, dominating the other 28% of the market.

Global Market Share by Key Players (2025)

| Category | Market Share (%) |

|---|---|

| Top 3 (Greif, Berry Global, Conitex Sonoco) | 17% |

| Rest of Top 5 (LC Packaging, Rishi FIBC Solutions) | 12% |

| Next 5 of Top 10 (Plastene India, Taihua Group, Bulk-Pack, Emmbi Industries, Intertape Polymer Group) | 8% |

The 2 Loop FIBC bag industry caters to multiple sectors where safety, strength, and efficiency are crucial. Companies develop innovative solutions to enhance bulk packaging capabilities and regulatory compliance. They design specialized coatings to resist chemical corrosion. Manufacturers introduce ergonomic lifting features to improve handling and worker safety.

Manufacturers refine FIBC bags with reinforced designs, safety-enhanced features, and eco-friendly alternatives. They incorporate automation, RFID tracking, and advanced polymer blends to maximize efficiency. They develop breathable fabric options to prevent moisture buildup. Companies integrate tamper-proof seals to enhance security. Firms design stackable FIBC bags for improved storage efficiency.

Automation and sustainability drive transformations in the 2 Loop FIBC bag market. Companies introduce high-strength woven fabrics, tamper-proof sealing mechanisms, and RFID-enabled tracking solutions. Businesses leverage AI-powered production optimization to improve quality consistency and efficiency. Leading manufacturers expand bio-based and circular polymer solutions to meet regulatory compliance and sustainability goals. They implement robotic-assisted quality inspections to reduce defects. Firms enhance UV protection technologies to extend product lifespan. Companies integrate predictive maintenance systems to minimize production downtime.

Year-on-Year Leaders

Technology suppliers should focus on automation, sustainability, and high-performance materials to meet growing industry demands. Collaborating with logistics, agricultural, and chemical industries will accelerate adoption. They should integrate AI-driven monitoring systems to enhance production efficiency. Firms must explore biodegradable polymer alternatives to reduce environmental impact.

| Tier Type | Example of Key Players |

|---|---|

| Tier 1 | Greif, Berry Global, Conitex Sonoco |

| Tier 2 | LC Packaging, Rishi FIBC Solutions, Plastene India |

| Tier 3 | Taihua Group, Bulk-Pack, Emmbi Industries, Intertape Polymer Group |

Leading manufacturers advance safety, sustainability, and durability in bulk packaging. They integrate high-barrier polymer technology, AI-driven quality control, and RFID-based tracking for superior logistics solutions. Companies enhance UV protection to extend the lifespan of FIBC bags. They improve seam strength to prevent ruptures during transportation. Businesses adopt advanced anti-static coatings for safer handling in chemical industries.

| Manufacturer | Latest Developments |

|---|---|

| Greif | Launched fully recyclable FIBC solutions in March 2024. |

| Berry Global | Developed UV-stabilized bulk bags in April 2024. |

| Conitex Sonoco | Strengthened moisture-resistant packaging solutions in May 2024. |

| LC Packaging | Introduced biodegradable FIBC materials in June 2024. |

| Rishi FIBC Solutions | Expanded anti-static packaging options in July 2024. |

| Plastene India | Innovated reinforced bulk bags for construction in August 2024. |

| Taihua Group | Enhanced tamper-proof features in pharmaceutical bulk bags in September 2024. |

The 2 Loop FIBC bag industry evolves as manufacturers invest in stronger materials, RFID-enabled tracking, and sustainable bulk packaging. Companies optimize production automation and regulatory-compliant materials to enhance safety and efficiency. They develop advanced bulk bag liners to improve contamination resistance. Firms implement reinforced loop structures to enhance lifting and handling safety.

Manufacturers will develop AI-driven production, ultra-durable materials, and intelligent bulk bag tracking. Companies will invest in sustainable alternatives, high-capacity designs, and regulatory-compliant innovations to optimize packaging efficiency and environmental impact. They will implement reinforced stitching techniques to enhance bag durability. Firms will develop smart sensors for real-time weight and condition monitoring. Businesses will integrate automated quality control systems to minimize defects. Industry leaders will expand partnerships with recycling firms to create closed-loop sustainability solutions. Companies will introduce high-strength lifting loops to improve safety during transport. Manufacturers will adopt biodegradable coatings to enhance environmental sustainability.

Leading players include Greif, Berry Global, Conitex Sonoco, LC Packaging, and Rishi FIBC Solutions.

The top 3 players collectively hold 17% of the global market.

The market shows medium concentration, with top players holding 37% of the industry share.

Automation, high-strength materials, sustainability, and smart tracking solutions.

Our Research Products

The "Full Research Suite" delivers actionable market intel, deep dives on markets or technologies, so clients act faster, cut risk, and unlock growth.

The Leaderboard benchmarks and ranks top vendors, classifying them as Established Leaders, Leading Challengers, or Disruptors & Challengers.

Locates where complements amplify value and substitutes erode it, forecasting net impact by horizon

We deliver granular, decision-grade intel: market sizing, 5-year forecasts, pricing, adoption, usage, revenue, and operational KPIs—plus competitor tracking, regulation, and value chains—across 60 countries broadly.

Spot the shifts before they hit your P&L. We track inflection points, adoption curves, pricing moves, and ecosystem plays to show where demand is heading, why it is changing, and what to do next across high-growth markets and disruptive tech

Real-time reads of user behavior. We track shifting priorities, perceptions of today’s and next-gen services, and provider experience, then pace how fast tech moves from trial to adoption, blending buyer, consumer, and channel inputs with social signals (#WhySwitch, #UX).

Partner with our analyst team to build a custom report designed around your business priorities. From analysing market trends to assessing competitors or crafting bespoke datasets, we tailor insights to your needs.

Supplier Intelligence

Discovery & Profiling

Capacity & Footprint

Performance & Risk

Compliance & Governance

Commercial Readiness

Who Supplies Whom

Scorecards & Shortlists

Playbooks & Docs

Category Intelligence

Definition & Scope

Demand & Use Cases

Cost Drivers

Market Structure

Supply Chain Map

Trade & Policy

Operating Norms

Deliverables

Buyer Intelligence

Account Basics

Spend & Scope

Procurement Model

Vendor Requirements

Terms & Policies

Entry Strategy

Pain Points & Triggers

Outputs

Pricing Analysis

Benchmarks

Trends

Should-Cost

Indexation

Landed Cost

Commercial Terms

Deliverables

Brand Analysis

Positioning & Value Prop

Share & Presence

Customer Evidence

Go-to-Market

Digital & Reputation

Compliance & Trust

KPIs & Gaps

Outputs

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

2-(4-(Bromomethyl)phenyl)propionic Acid (BMPPA) Market Forecast and Outlook 2025 to 2035

2-tert-Butylcyclohexanol Market Forecast and Outlook 2025 to 2035

2-Fluorobenzotrifluoride Market Forecast and Outlook 2025 to 2035

2-Methoxynaphthalene-1-Boronic Acid Market Forecast and Outlook 2025 to 2035

20MnCr5 Steel Market Size and Share Forecast Outlook 2025 to 2035

2-Ethoxy Propene Market Size and Share Forecast Outlook 2025 to 2035

2-in-1 Material Rack Correction Machine Market Size and Share Forecast Outlook 2025 to 2035

2-Ethyl-3,4-ethylenedioxythiophene Market Size and Share Forecast Outlook 2025 to 2035

2D Barcode Reader Market Size and Share Forecast Outlook 2025 to 2035

2-Methylfuran Market Size and Share Forecast Outlook 2025 to 2035

2K Epoxy Adhesives Market Size and Share Forecast Outlook 2025 to 2035

2D Transition Metal Carbides Nitrides Market Size and Share Forecast Outlook 2025 to 2035

2-Hexyldecanol Market Size and Share Forecast Outlook 2025 to 2035

2-EthylHexyl Acetate Market Size and Share Forecast Outlook 2025 to 2035

2 Piece Cans Market Size and Share Forecast Outlook 2025 to 2035

2 Seal Pouches Market Size and Share Forecast Outlook 2025 to 2035

2-ethylhexanol (2-EH) Market Growth - Trends & Forecast 2025 to 2035

2D Bar Code Marketing Market Analysis by Technology, Code Types, Applications, and Region Through 2035

2-Iodophenol Market Growth - Trends & Forecast 2025 to 2035

2K Coatings Market Growth – Trends & Forecast 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA