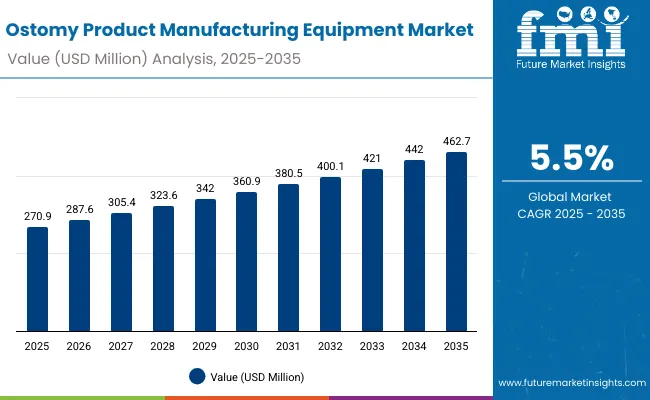

The global ostomy product manufacturing equipment market is projected to grow from USD 270.9 million in 2025 to approximately USD 462.7 million by 2035, recording an absolute increase of USD 191.8 million over the forecast period. This translates into a total growth of 70.8%, with the market forecast to expand at a compound annual growth rate (CAGR) of 5.5% between 2025 and 2035.

Ostomy Product Manufacturing Equipment Market Key Takeaways

| Metric | Value |

|---|---|

| Estimated Value in (2025E) | USD 270.9 million |

| Forecast Value in (2035F) | USD 462.7 million |

| Forecast CAGR (2025 to 2035) | 5.5% |

The overall market size is expected to grow by nearly 1.7X during the same period, supported by increasing demand for advanced ostomy care solutions, growing geriatric population requiring ostomy procedures, and rising adoption of innovative manufacturing technologies across the global healthcare manufacturing sector.

Between 2025 and 2030, the ostomy product manufacturing equipment market is projected to expand from USD 270.9 million to USD 380.5 million, resulting in a value increase of USD 109.6 million, which represents 57.1% of the total forecast growth for the decade. This phase of development will be shaped by increasing ostomy care awareness, rising demand for quality ostomy products, and growing utilization in healthcare manufacturing applications. Medical device manufacturers and healthcare equipment specialists are expanding their manufacturing capabilities to address the growing preference for advanced ostomy care solutions and efficient production systems.

From 2030 to 2035, the market is forecast to grow from USD 380.5 million to USD 462.7 million, adding another USD 82.2 million, which constitutes 42.9% of the overall ten-year expansion. This period is expected to be characterized by the expansion of advanced manufacturing technologies, the integration of automated production systems for premium ostomy products, and the development of specialized equipment for innovative ostomy care applications. The growing emphasis on patient comfort and quality manufacturing will drive demand for sophisticated ostomy product manufacturing equipment with enhanced precision capabilities and improved operational efficiency.

Between 2020 and 2024, the ostomy product manufacturing equipment market experienced steady growth, driven by increasing healthcare infrastructure investments and growing recognition of advanced ostomy care solutions' superior quality capabilities across healthcare and pharmaceutical manufacturing applications. The market developed as manufacturers recognized the potential for automated production systems to enhance product quality while meeting strict regulatory requirements for medical device manufacturing. Technological advancement in manufacturing precision and automation began emphasizing the critical importance of maintaining product consistency while extending manufacturing efficiency and improving quality control effectiveness.

The ostomy product manufacturing equipment market represents a specialized healthcare manufacturing opportunity at the intersection of medical device technology, automation systems, and patient care solutions, with the market projected to expand from USD 270.9 million in 2025 to USD 462.7 million by 2035 at a steady 5.5% CAGR-a 1.7X growth driven by aging population demographics, increasing ostomy procedures, and the demand for high-quality ostomy care products requiring advanced manufacturing capabilities.

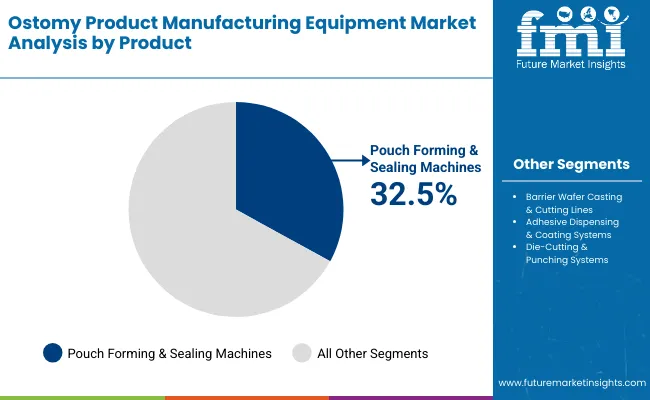

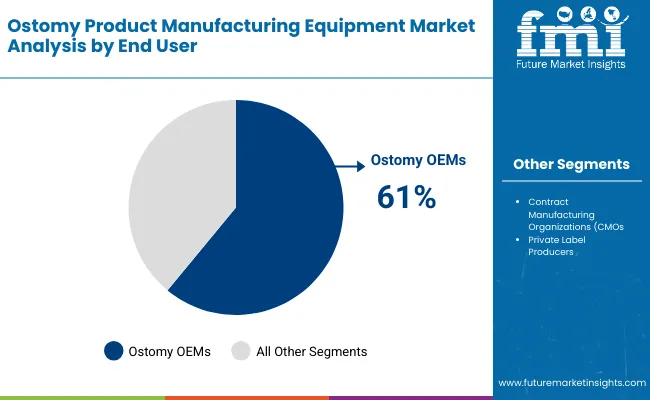

This convergence opportunity leverages the growing ostomy patient population, the need for reliable manufacturing systems, and advances in automation technology to create equipment that offers precise production control in a highly regulated medical device environment. Pouch forming and sealing machines lead with 32.5% market share due to their critical role in primary ostomy product manufacturing, while ostomy OEMs dominate demand with 61% market share as direct manufacturers increasingly invest in advanced production capabilities. Geographic growth is strongest in India (7.8% CAGR) and China (7.5% CAGR), where healthcare infrastructure development and medical device manufacturing expansion create ideal market conditions.

Pathway A - Pouch Forming & Sealing Machine Technology Leadership

The dominant equipment category offers superior production efficiency, consistent quality control, and reliable sealing performance essential for ostomy product manufacturing. Companies developing advanced pouch forming systems with enhanced precision capabilities, intelligent quality monitoring, and flexible production configurations will capture the leading technology segment. Expected revenue pool: USD 150-200 million.

Pathway B - Ostomy OEMs Manufacturing Solutions

The largest end-user segment benefits from growing demand for in-house production capabilities and quality control optimization. Providers developing comprehensive manufacturing solutions with integrated automation systems, regulatory compliance features, and scalable production capacity will dominate this primary market. Opportunity: USD 280-320 million.

Pathway C - Advanced Automation and Quality Control Systems

Next-generation equipment requires sophisticated automation capable of precise material handling, real-time quality monitoring, and regulatory documentation. Companies investing in advanced control systems, machine learning capabilities, and integrated quality assurance will create competitive differentiation and premium positioning. Revenue uplift: USD 80-120 million.

Pathway D - Geographic Expansion in High-Growth Asian Markets

India and China's expanding healthcare infrastructure and growing medical device manufacturing create substantial opportunities. Local partnerships, regulatory compliance expertise, and cost-effective manufacturing strategies enable market penetration in these high-growth regions. Pool: USD 60-100 million.

Pathway E - Specialized Application Equipment Development

Modern ostomy care includes diverse product types requiring specialized manufacturing approaches. Developing equipment for barrier wafer production, adhesive systems, and accessories manufacturing addresses growing product diversification demands while enabling manufacturers to serve broader market segments. Expected upside: USD 50-80 million.

Pathway F - Integration with Digital Manufacturing Systems

Advanced production environments require connectivity with enterprise systems, real-time monitoring, and data analytics capabilities. Systems offering comprehensive digital integration, remote diagnostics, and predictive maintenance create enhanced value propositions for modern manufacturing facilities. USD 40-70 million.

Pathway G - Contract Manufacturing Organization Solutions

Healthcare contract manufacturers represent growing opportunities for flexible production capabilities, multi-product manufacturing, and cost optimization services. Developing specialized solutions for CMO operations, batch flexibility, and rapid changeover capabilities expands beyond traditional OEM markets. Pool: USD 30-60 million.

Pathway H - Regulatory Compliance and Validation Services

Medical device manufacturing requires extensive validation and regulatory documentation. Companies developing equipment with built-in compliance features, validation support services, and regulatory expertise will capture premium pricing opportunities in this highly regulated industry. Expected revenue: USD 25-50 million.

Market expansion is being supported by the increasing global demand for ostomy care solutions and the corresponding shift toward advanced manufacturing technologies that can provide superior product quality while meeting stringent regulatory requirements for medical device production. Modern healthcare manufacturers and medical device companies are increasingly focused on incorporating automated ostomy product manufacturing equipment to enhance production efficiency while satisfying demands for consistent product quality and regulatory compliance in medical device manufacturing operations. Ostomy product manufacturing equipment's proven ability to deliver superior production consistency, operational efficiency, and quality assurance makes them essential systems for pharmaceutical manufacturing facilities and medical device production applications.

The growing emphasis on patient care quality and healthcare manufacturing excellence is driving demand for high-quality ostomy product manufacturing equipment that can support reliable production processes and premium product positioning across pharmaceutical, medical device, and healthcare manufacturing categories. Healthcare manufacturer preference for equipment that combines production excellence with advanced automation capabilities is creating opportunities for innovative manufacturing implementations in both traditional and emerging medical device applications. The rising influence of regulatory compliance requirements and quality management systems is also contributing to increased adoption of premium ostomy product manufacturing equipment that can provide authentic regulatory compliance characteristics and validated production processes.

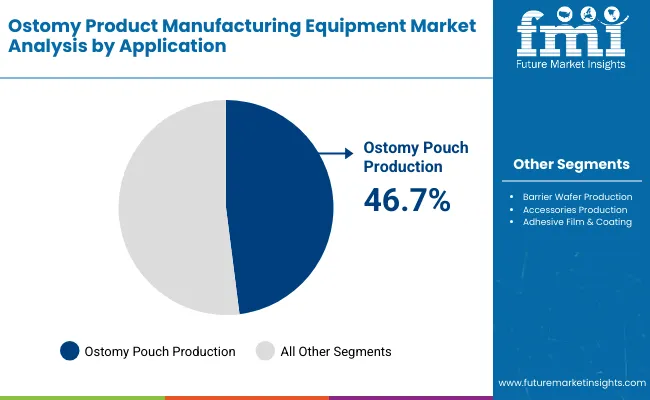

The market is segmented by product, application, and end user. The demand for product types is divided into pouch forming and sealing machines, barrier wafer casting and cutting lines, adhesive dispensing and coating systems, die-cutting and punching systems, and others. Based on application, the market is categorized into ostomy pouch production, barrier wafer production, accessories production, and adhesive film and coating applications. By end user, the market is divided into ostomy OEMs, contract manufacturing organizations (CMOs), and private label producers.

The pouch forming and sealing machines segment is projected to account for 32.5% of the ostomy product manufacturing equipment market in 2025, reaffirming its position as the leading product category. Medical device manufacturers and ostomy product producers increasingly utilize pouch forming and sealing machine technology for their superior production efficiency, consistent sealing performance, and ease of integration in automated ostomy product manufacturing applications across diverse healthcare manufacturing installations. Pouch forming technology's standardized production processes and reliable quality control directly address the industrial requirements for consistent product manufacturing and efficient production utilization in medical device manufacturing operations.

This product segment forms the foundation of modern ostomy manufacturing applications, as it represents the technology with the greatest production efficiency potential and established compatibility across multiple ostomy product manufacturing systems. Manufacturer investments in pouch forming optimization and automation integration continue to strengthen adoption among medical device equipment producers. With healthcare manufacturers prioritizing production consistency and regulatory compliance, pouch forming and sealing systems align with both quality objectives and efficiency requirements, making them the central component of comprehensive ostomy product manufacturing strategies.

Ostomy pouch production applications are projected to represent the largest share of ostomy product manufacturing equipment demand in 2025 with 46.7% market share, underscoring their critical role as the primary application for specialized manufacturing solutions in ostomy care product development and medical device manufacturing facilities. Healthcare manufacturers and ostomy product companies prefer ostomy pouch production equipment for their exceptional manufacturing precision, quality consistency features, and ability to maintain strict product standards while supporting modern regulatory compliance requirements during ostomy product manufacturing operations. Positioned as essential applications for high-performance medical device manufacturing installations, ostomy pouch production equipment offers both technological advancement and production efficiency advantages.

The segment is supported by continuous growth in ostomy patient population and the growing availability of advanced pouch technologies that enable enhanced patient comfort and product performance at the healthcare application level. Additionally, ostomy manufacturers are investing in specialized pouch production technologies to support product innovation and competitive positioning in healthcare markets. As ostomy care continues to advance and manufacturers seek superior production capabilities, ostomy pouch production will continue to dominate the application landscape while supporting technology advancement and product quality optimization strategies.

Ostomy OEMs are projected to represent the largest share of ostomy product manufacturing equipment demand in 2025 with 61% market share, underscoring their critical role as the primary end users for advanced manufacturing solutions in direct ostomy product manufacturing and medical device production facilities. Healthcare manufacturers and ostomy product companies prefer advanced manufacturing systems for their exceptional production control capabilities, quality management features, and ability to maintain consistent manufacturing standards while supporting modern regulatory compliance requirements during ostomy product manufacturing operations. Positioned as essential equipment for high-performance medical device manufacturing installations, ostomy product manufacturing equipment offers both technological advancement and operational excellence advantages.

The segment is supported by continuous growth in ostomy care demand and the growing availability of advanced manufacturing technologies that enable enhanced production efficiency and quality optimization at the manufacturing facility level. Additionally, ostomy manufacturers are investing in premium production technologies to support product quality enhancement and competitive positioning in healthcare markets. As ostomy care continues to expand and manufacturers seek superior automation solutions, ostomy OEMs will continue to dominate the end user landscape while supporting technology advancement and manufacturing optimization strategies.

The ostomy product manufacturing equipment market is advancing steadily due to increasing healthcare infrastructure development and growing demand for reliable manufacturing solutions that emphasize superior product quality across medical device and pharmaceutical manufacturing applications. However, the market faces challenges, including high equipment costs compared to traditional manufacturing alternatives, technical complexity in automation integration, and competition from alternative manufacturing technologies. Innovation in manufacturing precision and regulatory compliance continues to influence market development and expansion patterns.

Expansion of Advanced Healthcare Manufacturing Applications

The growing adoption of ostomy product manufacturing equipment in comprehensive medical device manufacturing systems and healthcare applications is enabling equipment manufacturers to develop products that provide distinctive automation capabilities while commanding premium positioning and enhanced production efficiency characteristics. Advanced applications provide superior quality control while allowing more sophisticated healthcare manufacturing development across various medical device categories and technology segments. Manufacturers are increasingly recognizing the competitive advantages of automation integration positioning for premium product development and healthcare manufacturing market penetration.

Integration of Quality Management and Regulatory Compliance Programs

Modern ostomy product manufacturing equipment suppliers are incorporating advanced quality control systems, regulatory documentation capabilities, and validation technologies to enhance production compliance, improve manufacturing consistency, and meet healthcare industry demands for validated and traceable manufacturing solutions. These programs improve equipment performance while enabling new applications, including automated quality management and integrated compliance systems. Advanced compliance integration also allows suppliers to support premium market positioning and regulatory leadership beyond traditional commodity manufacturing equipment.

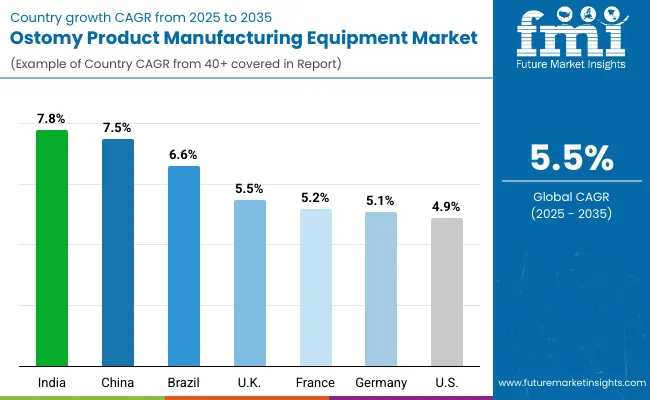

| Country | CAGR (2025 to 2035) |

|---|---|

| India | 7.8% |

| China | 7.5% |

| Brazil | 6.6% |

| UK | 5.5% |

| France | 5.2% |

| Germany | 5.1% |

| USA | 4.9% |

The ostomy product manufacturing equipment market is experiencing steady growth globally, with India leading at a 7.8% CAGR through 2035, driven by the rapidly expanding healthcare infrastructure sector, significant investments in medical device manufacturing, and increasing adoption of advanced healthcare manufacturing systems. China follows at 7.5%, supported by growing medical device production demand, rising healthcare technology investments, and expanding pharmaceutical manufacturing activities. Brazil shows growth at 6.6%, emphasizing emerging healthcare manufacturing applications and medical device production development. The UK records 5.5%, focusing on advanced healthcare technology and premium medical device manufacturing. Europe demonstrates 5.3% growth, prioritizing advanced manufacturing technology innovation and premium healthcare equipment automation. France exhibits 5.2% growth, supported by healthcare manufacturing adoption and advanced medical device technology development. Germany shows 5.1% growth, emphasizing precision manufacturing excellence and high-quality healthcare product development. The USA demonstrates 4.9% growth, focusing on mature market optimization and established healthcare manufacturing systems.

The report covers an in-depth analysis of 40+ countries; seven top-performing countries are highlighted below.

Revenue from ostomy product manufacturing equipment in India is projected to exhibit exceptional growth with a CAGR of 7.8% through 2035, driven by the rapidly expanding healthcare infrastructure sector and significant government investments in medical device manufacturing development across major industrial centers. The country's growing healthcare manufacturing market and increasing adoption of advanced medical device production technologies are creating substantial demand for automated manufacturing solutions in both domestic and export-oriented applications. Major healthcare equipment manufacturers and medical device companies are establishing comprehensive research and production capabilities to serve both domestic consumption and international markets.

Revenue from ostomy product manufacturing equipment in China is expanding at a CAGR of 7.5%, supported by growing medical device production demand, increasing healthcare technology investments, and expanding pharmaceutical manufacturing with advanced automation features. The country's developing healthcare manufacturing ecosystem and expanding technology infrastructure are driving demand for sophisticated manufacturing equipment across both domestic healthcare and export-oriented applications. International healthcare equipment companies and domestic medical device manufacturers are establishing comprehensive production and assembly capabilities to address growing market demand for advanced healthcare manufacturing solutions.

Revenue from ostomy product manufacturing equipment in Brazil is projected to grow at a CAGR of 6.6% through 2035, driven by the country's expanding healthcare manufacturing sector, growing medical device applications, and increasing adoption of modern manufacturing technologies requiring advanced production solutions. Brazilian healthcare manufacturers and medical device companies consistently seek innovative manufacturing products that enhance production efficiency for both domestic applications and regional export markets. The country's position as a regional healthcare hub continues to drive innovation in medical device manufacturing applications and equipment standards.

Revenue from ostomy product manufacturing equipment in the United Kingdom is projected to grow at a CAGR of 5.5% through 2035, supported by the country's healthcare technology sector, advanced medical device development capabilities, and established market for premium healthcare manufacturing solutions. British healthcare manufacturers and medical device companies prioritize innovation, quality, and technical excellence, making ostomy product manufacturing equipment essential products for both healthcare facility upgrades and new manufacturing facility projects. The country's comprehensive healthcare ecosystem and manufacturing adoption patterns support continued market development.

Revenue from ostomy product manufacturing equipment in France is projected to grow at a CAGR of 5.2% through 2035, supported by the country's healthcare technology development programs, advanced medical device manufacturing capabilities, and growing focus on premium healthcare manufacturing solutions. French healthcare manufacturers and medical device companies consistently seek innovative automation products that enhance production quality for both domestic healthcare applications and European export markets. The country's position as a European healthcare technology leader continues to drive innovation in medical device manufacturing applications and quality standards.

Revenue from ostomy product manufacturing equipment in Germany is projected to grow at a CAGR of 5.1% through 2035, supported by the country's precision manufacturing excellence, advanced healthcare technology expertise, and established reputation for producing superior medical device automation products while working to enhance manufacturing capabilities and develop next-generation healthcare production technologies. Germany's healthcare technology industry continues to benefit from its reputation for producing high-quality manufacturing equipment while focusing on innovation and precision engineering.

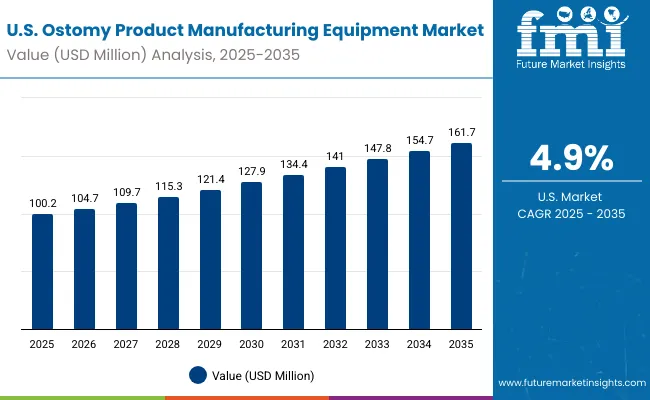

Revenue from ostomy product manufacturing equipment in the United States is projected to grow at a CAGR of 4.9% through 2035, supported by the country's mature healthcare manufacturing sector, innovation leadership capabilities, and established market for advanced medical device production solutions. American healthcare manufacturers and technology companies prioritize innovation, regulatory compliance, and operational excellence, making ostomy product manufacturing equipment essential systems for both facility upgrades and new healthcare manufacturing projects. The country's comprehensive regulatory ecosystem and manufacturing adoption patterns support continued market development.

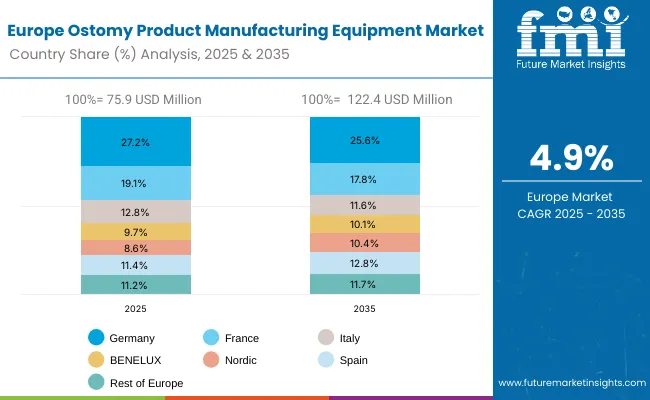

The ostomy product manufacturing equipment market in Europe is projected to grow from USD 75.9 million in 2025 to USD 122.4 million by 2035, registering a CAGR of 4.9% over the forecast period. Germany is expected to maintain its leadership position with a 27.2% market share in 2025, declining slightly to 25.6% by 2035, supported by its advanced manufacturing technology sector, precision healthcare equipment manufacturing industry, and comprehensive innovation capabilities serving European and international markets.

France follows with a 19.1% share in 2025, projected to reach 17.8% by 2035, driven by healthcare technology development programs, advanced medical device manufacturing capabilities, and growing focus on premium healthcare manufacturing solutions for quality healthcare facilities. Italy holds a 12.8% share in 2025, expected to maintain 11.6% by 2035, supported by healthcare manufacturing market demand and advanced technology applications, but facing challenges from market competition and economic considerations. Spain commands an 11.4% share in 2025, projected to reach 12.8% by 2035, while BENELUX accounts for 9.7% in 2025, expected to reach 10.1% by 2035. Nordic maintains an 8.6% share in 2025, growing to 10.4% by 2035.

The Rest of Europe region, including Eastern Europe, Switzerland, Austria, and other smaller countries, is anticipated to hold 11.2% in 2025, declining slightly to 11.7% by 2035, attributed to mixed growth patterns with strong expansion in some Eastern European healthcare markets balanced by moderate growth in smaller countries implementing premium healthcare manufacturing development programs.

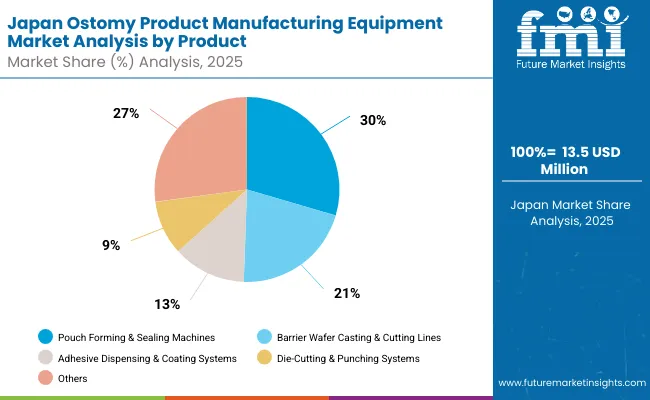

The ostomy product manufacturing equipment market in Japan is valued at USD 13.5 million in 2025, with steady growth projected through 2035, supported by advanced manufacturing capabilities, precision engineering, and strong medical device adoption.

Pouch forming & sealing machines are expected to lead with a 30.0% market share in 2025, projected to sustain 29.8% by 2035, reflecting consistent demand for high-quality pouch manufacturing. Barrier wafer casting & cutting lines follow with 21.0% in 2025, expected to maintain 21.0% by 2035, supported by increasing requirements for wafer precision and production scalability.

Adhesive dispensing & coating systems account for 13.0% in 2025, projected at 13.2% by 2035, driven by innovations in adhesive formulations for skin-friendly ostomy applications. Die-cutting & punching systems represent 9.0% in 2025, expected to sustain 9.0% by 2035, reflecting stable but niche demand. Others hold 27.0% in 2025, projected to remain significant at 27.0% by 2035, highlighting the role of supporting technologies in the broader ecosystem.

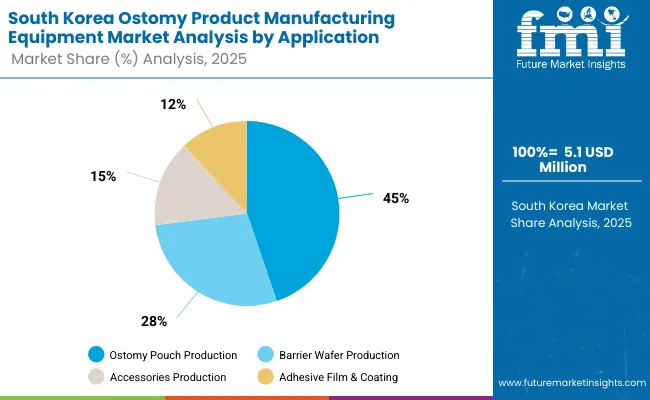

The ostomy product manufacturing equipment market in South Korea is valued at USD 5.1 million in 2025, projected to grow steadily through 2035, driven by strong industrial capabilities, rising domestic demand, and increasing investment in healthcare technology manufacturing.

Ostomy pouch production is expected to dominate with a 45.0% market share in 2025, projected at 44.8% by 2035, reflecting strong demand for pouch manufacturing efficiency. Barrier wafer production follows with 28.0% in 2025, projected to remain stable at 28.0% by 2035, supported by integration of automated systems for precision wafer output.

Accessories production accounts for 15.0% in 2025, forecast to remain steady at 15.0% by 2035, reflecting consistent demand in supporting ostomy product categories. Adhesive film & coating represents 12.0% in 2025, projected to remain stable at 12.0% by 2035, with incremental improvements in material innovation and coating technology.

The ostomy product manufacturing equipment market is characterized by competition among established medical device equipment manufacturers, specialized healthcare automation companies, and integrated manufacturing solution suppliers. Companies are investing in advanced manufacturing technologies, healthcare automation systems, application-specific equipment development, and comprehensive quality management capabilities to deliver consistent, high-performance, and reliable healthcare manufacturing equipment. Innovation in manufacturing precision enhancement, regulatory compliance optimization, and customized healthcare manufacturing compatibility is central to strengthening market position and customer satisfaction.

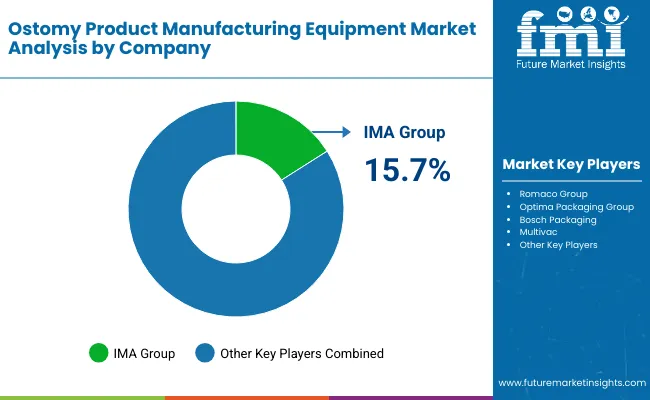

IMA Group leads the market with a strong focus on pharmaceutical and healthcare equipment innovation and comprehensive automation solutions, offering advanced ostomy product manufacturing equipment with emphasis on manufacturing excellence and technology integration capabilities. Romaco Group provides integrated healthcare manufacturing system capabilities with a focus on precision automation and global healthcare distribution networks. Optima Packaging Group delivers specialized healthcare packaging and manufacturing technology with a focus on premium equipment development and market leadership. Bosch Packaging specializes in advanced packaging and manufacturing systems with an emphasis on automation integration and operational efficiency. Multivac focuses on healthcare packaging solutions and advanced manufacturing technologies with comprehensive system integration and manufacturing convenience.

Key Players in the Ostomy Product Manufacturing Equipment Market

| Items | Values |

|---|---|

| Quantitative Units (2025) | USD 270.9 million |

| Product | Pouch Forming & Sealing Machines, Barrier Wafer Casting & Cutting Lines, Adhesive Dispensing & Coating Systems, Die-Cutting & Punching Systems, Others |

| Application | Ostomy Pouch Production, Barrier Wafer Production, Accessories Production, Adhesive Film & Coating |

| End User | Ostomy OEMs, Contract Manufacturing Organizations (CMOs), Private Label Producers |

| Regions Covered | North America, Europe, East Asia, South Asia & Pacific, Latin America, Middle East & Africa |

| Countries Covered | United States, Canada, United Kingdom, Germany, France, China, Japan, South Korea, India, Brazil, Australia and 40+ countries |

| Key Companies Profiled | IMA Group, Romaco Group, Optima Packaging Group, Bosch Packaging, and Multivac |

| Additional Attributes | Dollar sales by product and application, regional demand trends, competitive landscape, technological advancements in manufacturing automation, healthcare equipment integration initiatives, quality management optimization programs, and regulatory compliance enhancement strategies |

The ostomy product manufacturing equipment market is valued at USD 270.9 million in 2025.

The size for the ostomy product manufacturing equipment market is projected to reach USD 462.7 million by 2035.

The ostomy product manufacturing equipment market is expected to grow at a 5.5% CAGR between 2025 and 2035.

The key product segments in the ostomy product manufacturing equipment market are pouch forming & sealing machines, barrier wafer casting & cutting lines, adhesive dispensing & coating systems, die-cutting & punching systems, and others.

In terms of end users, ostomy OEMs segment is set to command 61% share in the ostomy product manufacturing equipment market in 2025.

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Ileostomy Market

Nephrostomy Devices Market

Stoma/Ostomy Care Market Growth - Trends & Forecast 2025 to 2035

Tracheostomy Securement Tapes Market

Product Life-Cycle Management (PLM) IT Market Size and Share Forecast Outlook 2025 to 2035

Product Analytics Software Market Size and Share Forecast Outlook 2025 to 2035

Products from Food Waste Industry Analysis in Korea Size, Share and Forecast Outlook 2025 to 2035

Products from Food Waste in Japan - Size, Share, and Forecast Outlook 2025 to 2035

Production Logistics Market Size and Share Forecast Outlook 2025 to 2035

Products from Food Waste Market Analysis - Size, Growth, and Forecast 2025 to 2035

Product Design Verification And Validation Solution Market Size and Share Forecast Outlook 2025 to 2035

Production Printer Market - Growth, Demand & Forecast 2025 to 2035

Product Information Management Market Growth – Trends & Forecast 2024-2034

Product Dispensing Machinery Market

Product Cost Management Market

CBD Product Packaging Market Size and Share Forecast Outlook 2025 to 2035

USA Products from Food Waste Market Growth – Trends, Demand & Outlook 2025-2035

Competitive Overview of CBD Product Packaging Market Share

Soda Production Machine Market Size and Share Forecast Outlook 2025 to 2035

Competitive Overview of Date Product Market Share

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA