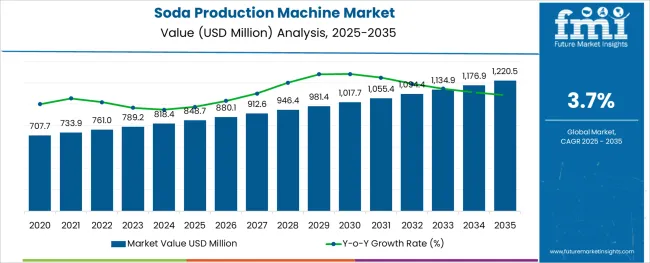

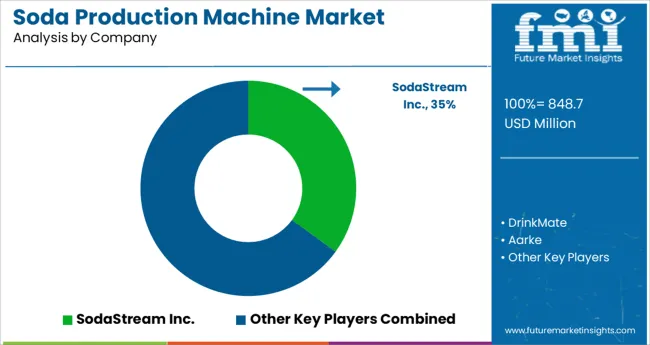

The Soda Production Machine Market is estimated to be valued at USD 848.7 million in 2025 and is projected to reach USD 1220.5 million by 2035, registering a compound annual growth rate (CAGR) of 3.7% over the forecast period.

The soda production machine market is demonstrating steady growth as automation, customization, and efficiency become central to beverage production strategies. Rising demand for on-demand carbonated beverages, coupled with the need to optimize production workflows, is driving the adoption of advanced soda machines across commercial and institutional environments.

Regulatory emphasis on hygiene and consistency in food and beverage operations has encouraged investment in machines that reduce manual intervention while maintaining quality. Future expansion is anticipated to be supported by technological advancements in carbonation systems, energy-efficient designs, and user-friendly interfaces that cater to evolving operational requirements.

Growth opportunities are emerging from innovations in modular configurations and integration with digital monitoring tools, which are paving the way for broader adoption and operational scalability.

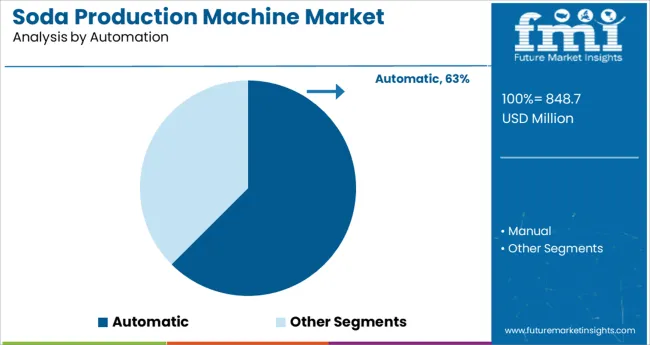

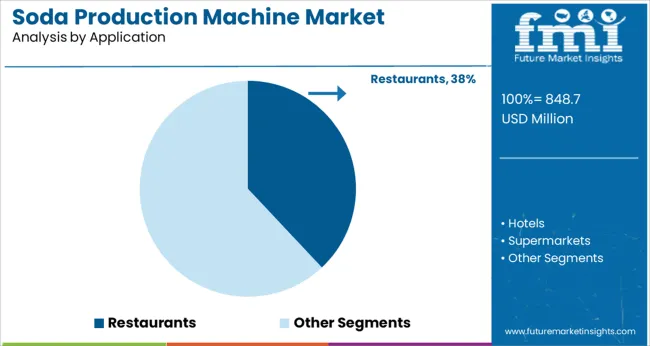

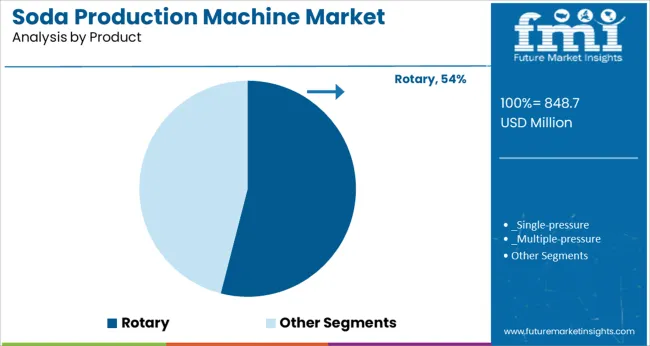

The market is segmented by Automation, Application, and Product and region. By Automation, the market is divided into Automatic and Manual. In terms of Application, the market is classified into Restaurants, Hotels, Supermarkets, and Convenience Stores. Based on Product, the market is segmented into Rotary and Linear. Regionally, the market is classified into North America, Latin America, Western Europe, Eastern Europe, Balkan & Baltic Countries, Russia & Belarus, Central Asia, East Asia, South Asia & Pacific, and the Middle East & Africa.

When segmented by automation, the automatic segment is expected to hold 62.5% of the total market revenue in 2025, establishing itself as the leading category. This dominance has been attributed to the growing preference for fully automated systems that minimize human error and maximize output consistency.

The ability of automatic soda production machines to deliver higher throughput, ensure precise carbonation levels, and reduce operational costs has significantly influenced their widespread adoption. Enhanced safety standards and the need for compliance with stringent food processing regulations have further driven investments in automatic systems.

The integration of programmable settings, self-cleaning features, and real-time monitoring capabilities has reinforced their appeal among operators aiming to improve productivity and product quality, securing their leadership in the market.

In terms of application, the restaurants segment is projected to account for 38.0% of the market revenue share in 2025, positioning it as the top-performing application area. This prominence has been driven by the rising consumer demand for freshly prepared, customizable soda beverages in dining settings.

Restaurants have increasingly adopted soda production machines to enhance customer experience, reduce dependency on bottled beverages, and improve operational efficiency. The capacity to produce a variety of flavors on-site while maintaining consistency has been a key factor attracting investments in this segment.

Moreover, the ability of these machines to align with sustainability goals by minimizing packaging waste has further reinforced their adoption in restaurant environments where customer expectations and operational margins are closely intertwined.

When segmented by product, the rotary segment is anticipated to capture 54.0% of the market revenue in 2025, marking it as the leading product type. This leadership has been supported by the rotary machines’ superior efficiency, compact design, and ability to handle high-volume production with minimal downtime.

The continuous rotational mechanism enables seamless filling, carbonation, and capping processes, which has proven advantageous in environments where speed and reliability are critical. The adaptability of rotary machines to varying container sizes and their durability in demanding operational conditions have further strengthened their market position.

Enhanced mechanical precision and reduced maintenance requirements have contributed to their preference among operators seeking cost-effective and dependable soda production solutions.

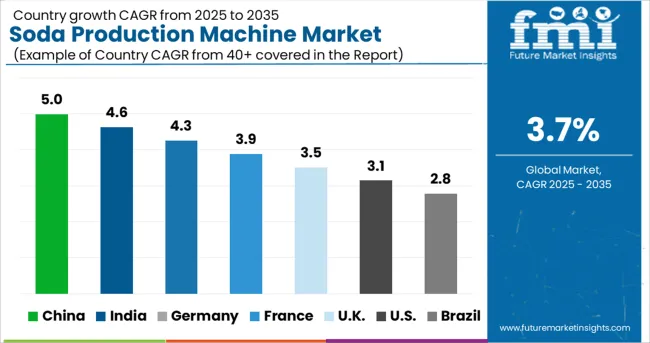

The global market for soda production machinery increased from USD 707.7 million to USD 761.0 million between 2020 and 2025 with a CAGR of 5.0%.

The historical performance of the soda production machine market shows that the market has been growing at a steady pace over the last few years. However, future projections for the market show that growth is expected to accelerate in the future.

One of the key factors driving the growth of the soda production machine market is the increasing demand for carbonated drinks. Carbonated drinks are becoming increasingly popular, especially among young adults and teenagers. This is due to the fact that they are refreshing and have a wide range of flavors. In addition, carbonated drinks are also considered to be healthy as they contain less sugar than other types of drinks, such as juices and sodas.

During the forecast period, the global Soda Production Machine Market is anticipated to grow from USD 848.7 billion in 2025 to USD 1,134.9 billion by 2035 with a strong CAGR of 3.7%.

An automatic soda production machine offers many advantages over traditional methods of soda production. Perhaps the most significant advantage is increased efficiency. An automatic machine can produce a much higher volume of soda in a shorter period of time than a manual process. This increased efficiency can lead to lower production costs and faster turnaround times for new products.

In addition, an automatic soda production machine can offer greater accuracy and consistency in the finished product. This is due to the fact that the machine can control all aspects of the production process, from ingredient proportions to carbonation levels. This consistent quality can be especially important for large-scale production runs or for products that require strict adherence to regulatory standards.

In the restaurant industry, soda production machines are used most often to provide customers with soft drinks. These machines typically use carbon dioxide and water to create the soda and can be programmed to make a variety of different flavors. The most common type of machine used in restaurants is the fountain soda machine, which is designed to dispense multiple drinks simultaneously.

There are two types of soda production machines: rotary and linear. Rotary machines are more common in small production facilities, while linear machines are used in large-scale operations. Both types of machines have their own advantages and disadvantages.

Rotary soda production machines are less expensive and easier to maintain than linear machines. However, they are not as efficient, and can only produce a limited amount of soda per hour. Linear soda production machines are more expensive, but they are much faster and can produce large quantities of soda per hour.

Soda production machines reduce the cost of packaging and bottling and give higher profit margins to their owners. Furthermore, fine-dining restaurants, bars, and small-town diners have witnessed high adoption of soda production machines. In addition, most consumers consider it to be a fresh drink option, compared to the aerated drinks readily available in the market which are high in sugar.

By deploying soda production machines, the over manufacturing of plastic and glass containers is curbed which begets environmental protection. Moreover, the transportation cost for the delivery of bottle containers gets reduced by the incorporation of these soda production machines as well. Additionally, consumers are further attracted by the option to mix various flavors in a single drink.

Key players are focusing on innovative and attractive features that complement bars and kitchens such as manufacturing them using aluminum and stainless steel. In addition, the carbonated drinks made from these machines can be used as a sugar-free mixer option for cocktails. These factors are expected to drive the global soda production machine market growth.

A lack of consumer awareness regarding the use or benefits of these machines is expected to restrain product demand. Moreover, the initial cost of these machines may be too high for people with limited disposable income, especially in developing economies. These factors are likely to be major challenges that impede the market growth.

On the contrary, manufacturers of soda production machines are focusing more on research and development (R&D) of the product, such as aiding the consumption of these carbonated drinks by blending them with certain food, which is anticipated to increase its demand in the culinary world. Moreover, they are also using lighter materials on these machines to make them more portable. These factors are anticipated to inspire creative opportunities in the market.

North America holds the largest share of the soda production machine market, with a revenue share of 34.4%. This is attributed to the growing number of health-conscious consumers who wish to reduce their intake of soft drinks and yet hydrate themselves. Moreover, most of these machines do not use sugar during processing which caters to their needs.

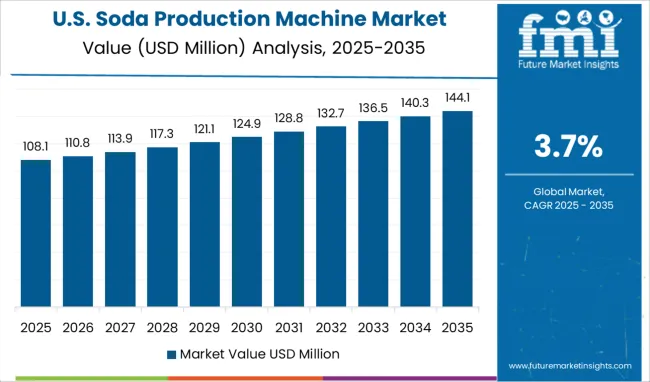

In the United States, the market has witnessed a shift from sugary soda drinks to healthier options like sparkling water and seltzer. Moreover, owing to the proliferation of smart kitchens across restaurants and households in the USA, the adoption of the soda production machine is likely to rise, especially among consumers with a reasonable per capita income.

Key players in the country produce compact soda production machines that are easily portable and can be packed into luggage for customers who travel around the year, especially for business. They are easy-to-use an appliance that can be utilized almost anywhere without the need for additional power. Furthermore, it saves customers the hassle of going for a bottled version of soda and soft drinks that are high in sugar content.

Owing to the rise in awareness regarding environmental sustainability, key players are manufacturing soda production machines using green materials. In addition, most of the machines are battery-operated, which makes them energy-efficient as well. These factors are estimated to surge the soda production machine market growth.

Europe holds the second largest share of the air classifying mill market, with the United Kingdom being the most profitable market. Moreover, the United Kingdom holds a revenue share of 6.3% over the projection period. This is attributed to the growing demand for their strong manufacturing base and skilled workforce.

Owing to the presence of significant manufacturers in the United Kingdom, the key players are able to produce high-quality soda production machines at competitive prices. Additionally, the region has an extensive distribution network which ensures that products are available to consumers in all parts of the country.

Contrary to other countries, key players are in the United Kingdom. are known to incorporate smart technologies, such as the Smart Soda Sync, into the machines, which facilitates the process of making both carbonated and non-carbonated drinks. Moreover, these machines also have a small carbon footprint and customizable LED lighting patterns, which makes it simple kitchen vanity decor.

The demand for soda production machines is expected to increase, especially amongst the millennial population, as they are offered alternative beverage offerings, as well as multiple flavor options. In addition, they are available in different weight options that can either be permanently set on the kitchen vanity or carried along. These aspects contribute to the regional market share.

Germany is a lucrative soda production machine market in Europe, owing to the use of flexible, cutting-edge robot technology used to develop these machines by the key manufacturers. This technology facilitates production through easy production, fully automatic product changeovers, exact reproducibility, and sustainability. Moreover, they aim to partner with small and medium-sized companies.

Key players in the country focus on using sustainable raw materials to reduce their carbon footprint. They ensure that the demand for soda production machines remains at an all-time high through the integration of various features such as a quick-lock bottle mechanism and low noise. These factors are estimated to expand the global market size.

India is a growing soda production machine market with a revenue share of 6.1%. This is owing to the growth in the consumption of soda, coupled with the increasing awareness about environmental sustainability as well as the need for adequate hydration. Moreover, these machines are available at different prices for all kinds of customers.

High-quality soda machines are rising in demand as they make water intake more enjoyable, owing to the fizzy texture of the carbonated drinks they produce. Furthermore, key players manufacture these machines made from aluminum or stainless steel with attractive designs. Additionally, the machines can also be used to make seltzer water from taps, water filters, or any bottled water without harmful or sugar additives.

Consumers in India tend to be influenced by western culture, and owing to their changing lifestyle, the sales of soda production machine in the country is expected to increase in the forecast period. Furthermore, these machines are mostly battery-operated or require a simple plug-in and are built so they can fill any type of bottle or glass; and operates with a single push of a button. These factors are estimated to drive global market growth.

Somerville-based Hydration Labs - It launched an environmentally-friendly water cooler called Bevi, which dispenses flavoured water at offices, and has landed USD 1.56 million, according to a regulatory filing. It is estimated that they will develop a similar device that dispenses fizzy flavoured water. The equity investment, which appears to be the start-up's first, comes from about 30 undisclosed investors.

Bevi is described as a machine that mixes still and sparkling drinks with healthy flavours and vitamins. The vending machines filter and bottle beverages at the point of use, instead of at a bottling plant. According to Greentown Labs, the start-up cuts the variable costs and carbon footprint of companies in the beverage vending industry by 80 per cent.

The global soda production machine market is highly competitive. The competition among these companies is intense as they constantly strive to gain market share through new product launches, innovative marketing campaigns, and expansion into new geographical regions.

| Attribute | Details |

|---|---|

| Forecast Period | 2025 to 2035 |

| Historical Data Available for | 2020 to 2024 |

| Market Analysis | million for Value and Units for Volume |

| Key Regions Covered | North America; Latin America; Europe; Asia Pacific; Oceania; Middle East and Africa (MEA) |

| Key Countries Covered | The USA, Mexico, Canada, The United Kingdom, Germany, France, Italy, China, Spain, India, Japan, South Korea, Australia, Argentina, Brazil, South Africa, UAE |

| Key Segments Covered | Product, Automation, Application, Region |

| Key Companies Profiled | Aarke; DrinkMate; SodaStream Inc.; Drinkworks; Sparkel Beverage Systems; Mr. Butler; Nuvantee; Mysoda; Wild and Kind; iSi GmbH |

| Report Coverage | Company Share Analysis, DROT Analysis, Market Dynamics and Challenges, Strategic Growth Initiatives, Market Forecast, Competitive Landscape, |

| Customization & Pricing | Available upon Request |

The global soda production machine market is estimated to be valued at USD 848.7 million in 2025.

It is projected to reach USD 1,220.5 million by 2035.

The market is expected to grow at a 3.7% CAGR between 2025 and 2035.

The key product types are automatic and manual.

restaurants segment is expected to dominate with a 38.0% industry share in 2025.

Our Research Products

The "Full Research Suite" delivers actionable market intel, deep dives on markets or technologies, so clients act faster, cut risk, and unlock growth.

The Leaderboard benchmarks and ranks top vendors, classifying them as Established Leaders, Leading Challengers, or Disruptors & Challengers.

Locates where complements amplify value and substitutes erode it, forecasting net impact by horizon

We deliver granular, decision-grade intel: market sizing, 5-year forecasts, pricing, adoption, usage, revenue, and operational KPIs—plus competitor tracking, regulation, and value chains—across 60 countries broadly.

Spot the shifts before they hit your P&L. We track inflection points, adoption curves, pricing moves, and ecosystem plays to show where demand is heading, why it is changing, and what to do next across high-growth markets and disruptive tech

Real-time reads of user behavior. We track shifting priorities, perceptions of today’s and next-gen services, and provider experience, then pace how fast tech moves from trial to adoption, blending buyer, consumer, and channel inputs with social signals (#WhySwitch, #UX).

Partner with our analyst team to build a custom report designed around your business priorities. From analysing market trends to assessing competitors or crafting bespoke datasets, we tailor insights to your needs.

Supplier Intelligence

Discovery & Profiling

Capacity & Footprint

Performance & Risk

Compliance & Governance

Commercial Readiness

Who Supplies Whom

Scorecards & Shortlists

Playbooks & Docs

Category Intelligence

Definition & Scope

Demand & Use Cases

Cost Drivers

Market Structure

Supply Chain Map

Trade & Policy

Operating Norms

Deliverables

Buyer Intelligence

Account Basics

Spend & Scope

Procurement Model

Vendor Requirements

Terms & Policies

Entry Strategy

Pain Points & Triggers

Outputs

Pricing Analysis

Benchmarks

Trends

Should-Cost

Indexation

Landed Cost

Commercial Terms

Deliverables

Brand Analysis

Positioning & Value Prop

Share & Presence

Customer Evidence

Go-to-Market

Digital & Reputation

Compliance & Trust

KPIs & Gaps

Outputs

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Soda Ash Market Size and Share Forecast Outlook 2025 to 2035

Soda Maker Market Size and Share Forecast Outlook 2025 to 2035

Craft Soda Market Analysis by Flavor, Packaging, Distribution Channel, and Region Forecast Through 2035

Baking Soda Substitute Market Analysis - Size, Share, & Forecast Outlook 2025 to 2035

Prebiotic Soda Market Analysis by Type, Packaging, Flavor and Distribution Channel Through 2035

Low- and No-calorie Soda Market Analysis by Product Type and Region through 2035

Production Logistics Market Size and Share Forecast Outlook 2025 to 2035

Production Printer Market - Growth, Demand & Forecast 2025 to 2035

Early Production Facility Market Size and Share Forecast Outlook 2025 to 2035

Oilfield Production Chemicals Market – Trends & Forecast 2025 to 2035

Aluminium Production Chemicals Market

E&P Software Market Trends – Demand & Forecast 2025-2035

Composite Textile Production Equipment Market Size and Share Forecast Outlook 2025 to 2035

Technical Textile Production Equipment Market Size and Share Forecast Outlook 2025 to 2035

Alternative Protein Production Equipment Market Size and Share Forecast Outlook 2025 to 2035

Veterinary Assistive Reproduction Technology Market Size and Share Forecast Outlook 2025 to 2035

Induced Pluripotent Stem Cells Production Market Size and Share Forecast Outlook 2025 to 2035

Machine Glazed Paper Market Size and Share Forecast Outlook 2025 to 2035

Machine Glazed Kraft Paper Market Forecast and Outlook 2025 to 2035

Machine Condition Monitoring Market Size and Share Forecast Outlook 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA