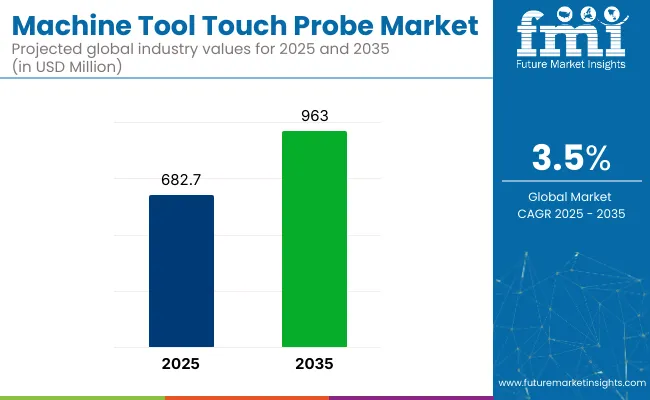

The global machine tool touch probe market is expected to grow from USD 682.7 million in 2025 to USD 963.0 million by 2035, reflecting a CAGR of 3.5%. This growth has been fueled by the rising integration of smart manufacturing systems and precision machining, particularly within the automotive and aerospace sectors.

| Metric | Value |

|---|---|

| Estimated Size (2025) | USD 682.7 million |

| Projected value (2035) | USD 963.0 million |

| CAGR (2025 to 2035) | 3.5% |

The increasing adoption of Industry 4.0 technologies, along with the need for real-time data collection and error correction, has boosted the deployment of touch probes in CNC machines worldwide.

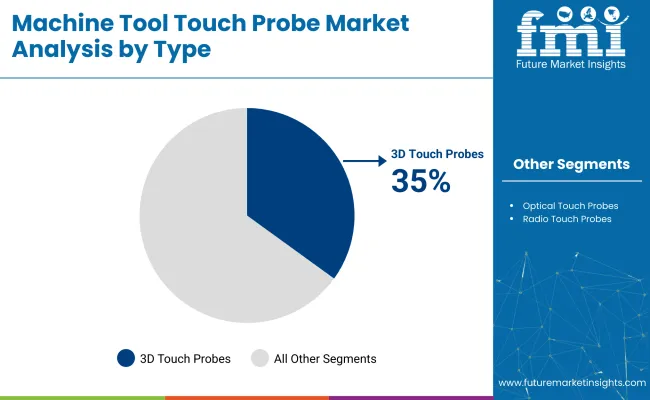

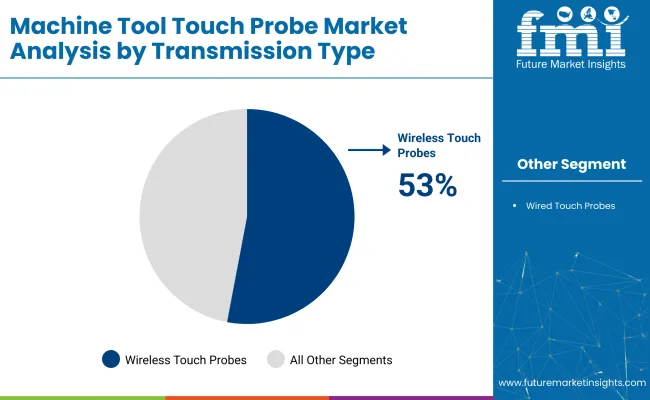

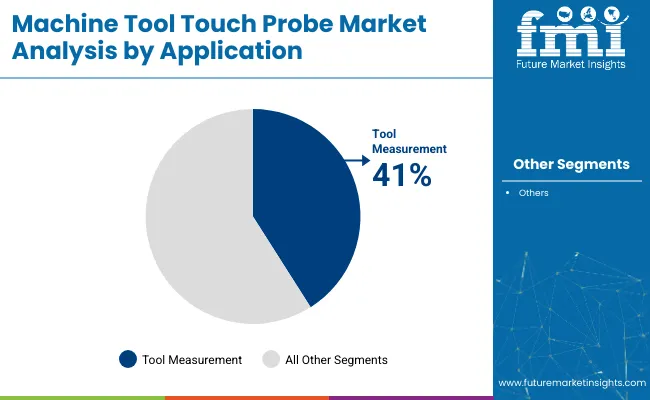

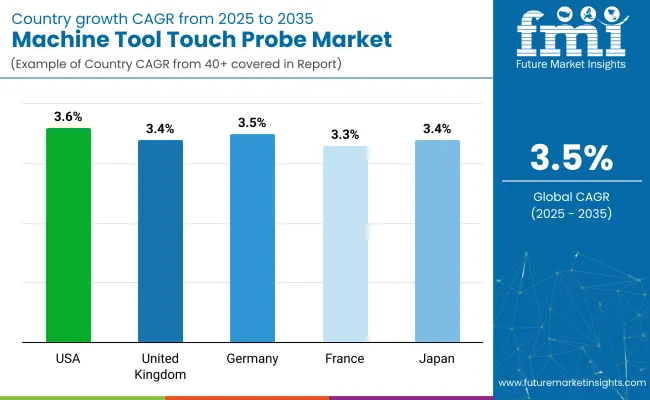

The USA is projected to hold the largest share of the global machine tool touch probe market by 2025, owing to its extensive demand in aerospace and automotive manufacturing, growing at a CAGR of 3.6%. Meanwhile, Japan is anticipated to register growth at a CAGR of 3.4%. Among all product categories, 3D touch probes are likely to retain a prominent share of 35% due to their vital role in high-complexity machining. Wireless touch probe leads the transmission type segment with 53% of the market share. Additionally, tool measurement by application accounts for 41% of the market share in 2025.

Profitability has been seen by firms such as Hexagon AB and Blum-Novotest GmbH, attributed to their early adoption of AI-enabled probes and integration with Industry 4.0 systems. On the other hand, certain cost-sensitive regions and small-scale manufacturers are expected to face adoption challenges, primarily due to the high ownership costs of wireless and predictive maintenance-integrated touch probes. Additionally, a shortage of skilled technicians, especially in emerging markets, has resulted in slow uptake despite increasing demand.

Looking ahead, the market is anticipated to benefit from ongoing investments in smart factories and the combination of wireless, optical, and AI technologies. Countries such as Japan and Germany are actively implementing digital twin strategies and CNC automation upgrades, expected to push the adoption curve forward. Furthermore, newer probes with 5G, predictive calibration, and real-time feedback are likely to reshape precision manufacturing, reducing downtime and material waste globally.

The machine tool touch probe market is segmented based on type, transmission type, application, end use, and region. In terms of type, it includes 3D touch probes, optical touch probes, and radio touch probes. By transmission type, the market is divided into wired touch probes and wireless touch probes.

By application, it includes tool measurement, workpiece measurement, and machine calibration. By end use, it covers automotive, aerospace & defense, electronics & semiconductor, industrial manufacturing, healthcare. Regionally, the market is divided into North America, Latin America, Western Europe, South Asia, East Asia, Eastern Europe, and the Middle East & Africa.

3D touch probes are anticipated to dominate the type segment due to their superior accuracy in multi-axis CNC machining operations, especially in aerospace and medical applications. The segment is expected to account for 35% of the market share by 2035. Their integration with high-speed machines for real-time surface and dimensional inspection is accelerating adoption across sectors.

Wireless touch probes are likely to lead the transmission type segment, capturing 53% share through 2035, owing to their flexibility, ease of installation, and ability to operate without physical constraints in high-speed environments. Demand is rising in Industry 4.0-enabled smart factories.

Tool measurement is projected to remain the primary application, holding a 41% market share in 2025, as precision in tool setting has become critical for minimizing tool wear and ensuring machining accuracy. Automated tool presetting directly boosts output consistency.

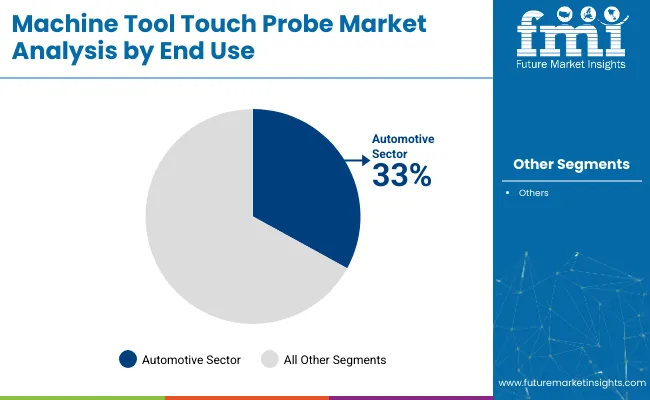

The automotive segment is expected to remain the leading segment with a 33% market share in 2025, led by EV production and the demand for lightweight, precision components. Touch probes are increasingly used for in-process QA during complex part machining.

Recent Trends in the Machine Tool Touch Probe Market

Key Challenges in the Machine Tool Touch Probe Market

The machine tool touch probe market in the USA is projected to grow at a CAGR of 3.6% from 2025 to 2035. This growth is driven by advanced aerospace and automotive sectors that demand real-time metrology and tool measurement precision. The rise of smart factories and Industry 4.0 technologies is facilitating widespread probe adoption in CNC operations across manufacturing clusters in states like Michigan, Texas, and California.

The UK machine tool touch probe market is forecasted to expand at a CAGR of 3.4% through 2035, fueled by growth in precision engineering and government-backed initiatives like Made Smarter. Leading aerospace firms and EV manufacturers are increasingly incorporating touch probes into high-precision CNC machining environments, with London and the Midlands emerging as notable hubs for adoption.

The German machine tool touch probe market is expected to grow at a CAGR of 3.5% over the forecast period, maintaining its position as a leader in industrial automation and high-speed CNC machining. With robust demand from the automotive, aerospace, and precision machinery sectors, German manufacturers are deploying AI-integrated touch probes to enhance productivity and quality assurance.

The French machine tool touch probe market is projected to expand at a CAGR of 3.3% between 2025 and 2035, supported by its expanding aerospace and electric vehicle industries. CNC machining centers in Toulouse and Paris are incorporating advanced touch probe systems for dimensional accuracy and process automation in aircraft and EV part manufacturing.

The Japanese machine tool touch probe market is poised to grow at a CAGR of 3.4% through 2035. The country's well-established robotics, semiconductor, and automotive industries are aggressively adopting high-accuracy probes for 5-axis and high-speed machining. Companies like Fanuc, Okuma, and Mazak are spearheading innovation in intelligent CNC systems.

The machine tool touch probe market is moderately consolidated, with a handful of global players commanding a significant portion of the revenue pool. Leading companies such as Renishaw plc, Hexagon AB, Blum-Novotest GmbH, Marposs S.p.A., and Heidenhain GmbH are known for their precision technologies and wide CNC integration portfolios.

These firms are competing through technology innovation, AI-integration, wireless enhancements, and real-time metrology solutions, often leveraging exclusive patents, customer-specific customization, and strategic distribution networks.

Company strategies are centered on improving accuracy, reducing cycle time, and embedding smart factory compatibility, particularly via AI-driven diagnostic features and optical/wireless connectivity. Pricing pressure exists for cost-sensitive regions, where regional players are attempting to outshine.

Tier-1 brands are increasingly forming technology alliances with CNC machine manufacturers and investing in R&D for predictive maintenance, real-time calibration, and digital twin integration. Expansion into Asia Pacific and South America continues through local partnerships and product localization efforts. In contrast, smaller firms such as Metrol and Midaco focus on niche machining needs and retrofit markets.

Recent Machine Tool Touch Probe Industry News

| Report Attributes | Details |

|---|---|

| Current Total Market Size (2025) | USD 682.7 million |

| Projected Market Size (2035) | USD 963.0 million |

| CAGR (2025 to 2035) | 3.5% |

| Base Year for Estimation | 2024 |

| Historical Period | 2020 to 2024 |

| Projections Period | 2025 to 2035 |

| Market Analysis Parameters | Revenue in USD millions/ Volume in units |

| By Type | 3D Touch Probes, Optical Touch Probes, Radio Touch Probes |

| By Transmission Type | Wired Touch Probes, Wireless Touch Probes |

| By Application | Tool Measurement, Workpiece Measurement, Machine Calibration |

| By End Use | Automotive, Aerospace & Defense, Electronics & Semiconductor, Industrial Manufacturing, Healthcare |

| Regions Covered | North America, Latin America, Western Europe, South Asia, East Asia, Eastern Europe, Middle East & Africa |

| Countries Covered | United States, Canada, United Kingdom, Germany, France, China, Japan, South Korea, Brazil, Australia |

| Key Players | Renishaw plc, Hexagon AB, Blum-Novotest GmbH, Marposs S.p.A., Heidenhain GmbH, OMRON Corporation, Metrol Co., Ltd., HAIMER GmbH, Tormach Inc., Midaco Corporation |

| Additional Attributes | Dollar sales by value, segment share analysis, region-wise market breakdown, and country-wise CAGR analysis |

The market is segmented into 3D Touch Probes, Optical Touch Probes, and Radio Touch Probes.

The industry is divided into Wired Touch Probes and Wireless Touch Probes.

The market caters to Tool Measurement, Workpiece Measurement, and Machine Calibration.

The report covers key sectors, including Automotive, Aerospace & Defense, Electronics & Semiconductor, Industrial Manufacturing, and Healthcare.

The report covers key regions, including North America, Latin America, Western Europe, Eastern Europe, East Asia, South Asia, and the Middle East & Africa (MEA).

The machine tool touch probe market is valued at USD 682.7 million in 2025.

The market is forecasted to reach USD 963.0 million by 2035, reflecting a CAGR of 3.5%.

3D touch probes are expected to lead the market, accounting for a 35% share in 2025.

Wireless probes are expected to hold 53% of the market share by 2035.

The USA is anticipated to be the fastest-growing market with a CAGR of 3.6% from 2025 to 2035.

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Machine Glazed Paper Market Size and Share Forecast Outlook 2025 to 2035

Machine Glazed Kraft Paper Market Forecast and Outlook 2025 to 2035

Machine Condition Monitoring Market Size and Share Forecast Outlook 2025 to 2035

Machine Glazed Paper Industry Analysis in Asia Pacific Forecast Outlook 2025 to 2035

Machine Vision Camera Market Size and Share Forecast Outlook 2025 to 2035

Machine Vision System And Services Market Size and Share Forecast Outlook 2025 to 2035

Machine Glazed Paper Industry Analysis in Western Europe Size and Share Forecast Outlook 2025 to 2035

Machine Glazed Paper Industry Analysis in Korea Size and Share Forecast Outlook 2025 to 2035

Machine Glazed Paper Industry Analysis in Japan Size and Share Forecast Outlook 2025 to 2035

Machine Mount Market Analysis - Size & Industry Trends 2025 to 2035

Machine Control System Market Growth – Trends & Forecast 2025 to 2035

Machine Automation Controller Market Growth – Trends & Forecast 2025 to 2035

Machine-to-Machine (M2M) Connections Market – IoT & Smart Devices 2025 to 2035

Machine Safety Market Analysis by Component, Industry, and Region Through 2035

Key Players & Market Share in Machine Glazed Paper Industry

Machine Vision Market Insights – Growth & Forecast 2024-2034

Machine Learning As A Services Market

Machine Tool Oils Market Size and Share Forecast Outlook 2025 to 2035

Machine Tool Cooling System Market Analysis - Size, Share, and Forecast Outlook 2025 to 2035

BMI Machine Market Size and Share Forecast Outlook 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA