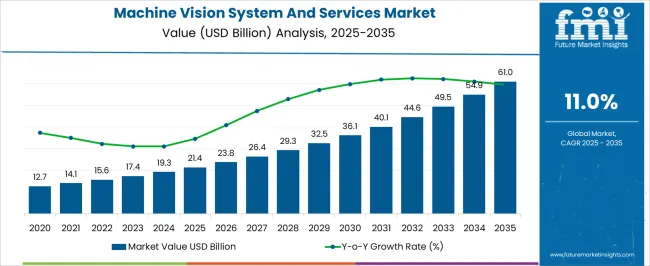

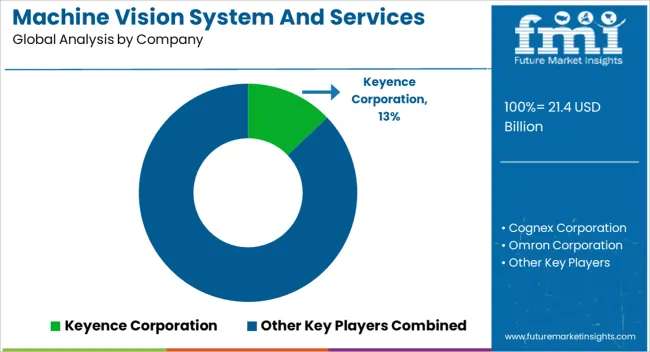

The Machine Vision System And Services Market is estimated to be valued at USD 21.4 billion in 2025 and is projected to reach USD 61.0 billion by 2035, registering a compound annual growth rate (CAGR) of 11.0% over the forecast period.

| Metric | Value |

|---|---|

| Machine Vision System And Services Market Estimated Value in (2025 E) | USD 21.4 billion |

| Machine Vision System And Services Market Forecast Value in (2035 F) | USD 61.0 billion |

| Forecast CAGR (2025 to 2035) | 11.0% |

The Machine Vision System and Services market is witnessing strong growth, driven by increasing automation across manufacturing, automotive, electronics, and quality inspection industries. Demand is being fueled by the need for precise measurement, defect detection, and process optimization in production lines. The integration of AI-powered analytics, high-resolution imaging, and real-time monitoring is enhancing operational efficiency while reducing errors and downtime.

Advancements in 3D measurement technologies, including laser scanning and structured light imaging, are enabling highly accurate inspections for complex components. Adoption is further supported by the growing emphasis on smart factories, Industry 4.0 initiatives, and predictive maintenance strategies. Market expansion is being reinforced by increasing investments in industrial automation, research, and development of cost-effective vision solutions.

The ability to integrate vision systems with robotics, data analytics, and cloud-based platforms allows organizations to optimize productivity and maintain quality standards Regulatory compliance and safety monitoring requirements are also driving the adoption of machine vision systems and services, positioning the market for sustained growth in the coming decade.

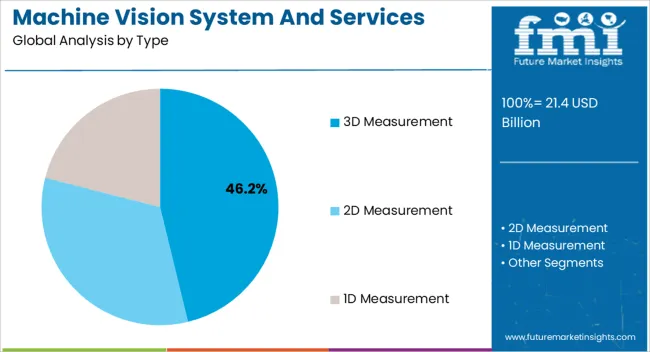

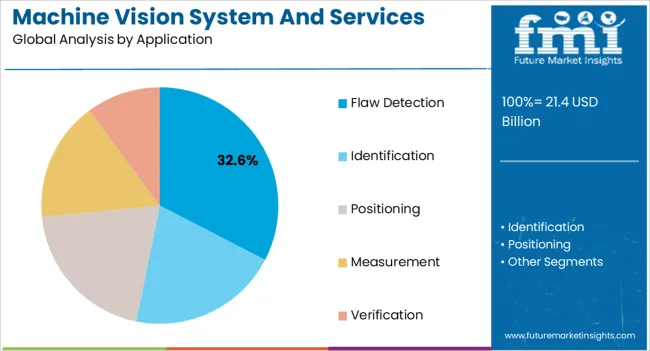

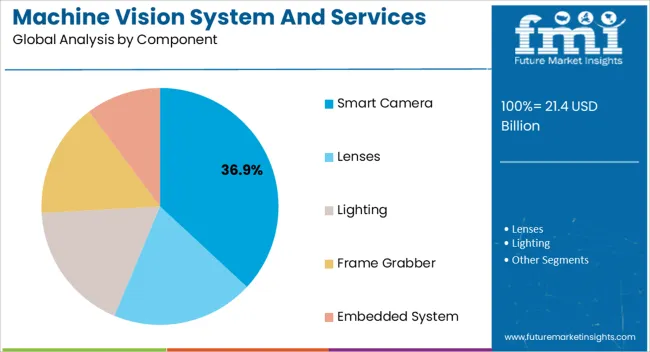

The machine vision system and services market is segmented by type, application, component, end-user vertical, and geographic regions. By type, machine vision system and services market is divided into 3D Measurement, 2D Measurement, and 1D Measurement. In terms of application, machine vision system and services market is classified into Flaw Detection, Identification, Positioning, Measurement, and Verification. Based on component, machine vision system and services market is segmented into Smart Camera, Lenses, Lighting, Frame Grabber, and Embedded System. By end-user vertical, machine vision system and services market is segmented into Automotive, Electronics, Healthcare, Industrial, and Others. Regionally, the machine vision system and services industry is classified into North America, Latin America, Western Europe, Eastern Europe, Balkan & Baltic Countries, Russia & Belarus, Central Asia, East Asia, South Asia & Pacific, and the Middle East & Africa.

The 3D measurement type segment is projected to hold 46.2% of the market revenue in 2025, establishing it as the leading type. Growth is being driven by the ability of 3D measurement systems to deliver highly accurate spatial data for complex geometries and assemblies, which is critical for quality control and process optimization. These systems allow manufacturers to perform precise dimensional analysis, reduce scrap, and minimize rework costs.

Advancements in structured light scanning, laser triangulation, and photogrammetry are enhancing measurement speed and resolution, enabling real-time inspection of high-volume production lines. Integration with software analytics and AI enables automated decision-making, further improving efficiency and reducing human error.

The versatility of 3D measurement systems across industries such as automotive, electronics, and aerospace reinforces their adoption As organizations prioritize precision, efficiency, and traceability in production processes, the 3D measurement segment is expected to maintain its leadership, supported by continuous technological innovation and improved system integration capabilities.

The flaw detection application segment is anticipated to account for 32.6% of the market revenue in 2025, making it the leading application area. Its growth is being driven by the critical need to identify defects, anomalies, and quality inconsistencies in production lines to ensure compliance with stringent quality standards. Machine vision systems enable real-time detection of surface defects, assembly errors, and dimensional inaccuracies, reducing operational losses and improving product reliability.

The integration of AI and deep learning algorithms enhances detection accuracy under varying environmental conditions and complex component geometries. Flaw detection applications are increasingly being adopted in industries such as electronics, automotive, and pharmaceuticals, where precision and safety are paramount.

Automation of inspection processes reduces reliance on manual checks, increasing throughput while maintaining high quality As manufacturers continue to pursue zero-defect production strategies and improve operational efficiency, the flaw detection application segment is expected to remain a primary driver of market growth, supported by advancements in imaging, software analytics, and integration with industrial automation systems.

The smart camera component segment is projected to hold 36.9% of the market revenue in 2025, establishing it as the leading component type. Its adoption is being driven by the integration of imaging sensors, processing units, and software in a single compact device, enabling real-time data acquisition and analysis. Smart cameras provide high-speed inspection, automated decision-making, and seamless connectivity with industrial networks, enhancing productivity and reducing errors.

These devices are increasingly being deployed in automated production lines for quality control, object recognition, and process monitoring across manufacturing, logistics, and electronics industries. Advances in embedded AI, high-resolution optics, and edge computing are further improving accuracy, performance, and scalability.

The ability to adapt functionality via software without major hardware modifications offers cost efficiency and flexibility As industrial automation and smart manufacturing adoption accelerate, smart cameras are expected to maintain their market leadership, supported by continuous innovation, operational efficiency improvements, and enhanced integration with machine vision systems and robotics.

Machine vision technology is a vital part of industrial automated production process that serves to improve the overall speed and quality of a final product. Superior to normal human visual sense, machine vision technology offers a critical capability of judging a product being manufactured.

Machine vision system and service providers allow manufacturers to achieve rapid production lines with accurate, precise non-contact product measurement, and closed-loop process control. High quality product inspection, lesser setup time and quick downtime, and increased production flexibility are among top advantages machine vision systems offer.

Virtually employed by all industrial manufacturing verticals, vision inspection enabled early detection and resolution of production inconsistency. In addition to boosting production efficiency, it also helps increase product integrity and thereby fulfil all associated legal compliance standards. In a nutshell, manufacturers cannot afford to bypass machine vision technology during the production process, as it ultimately helps companies to preserve their brands’ reputation in the long run.

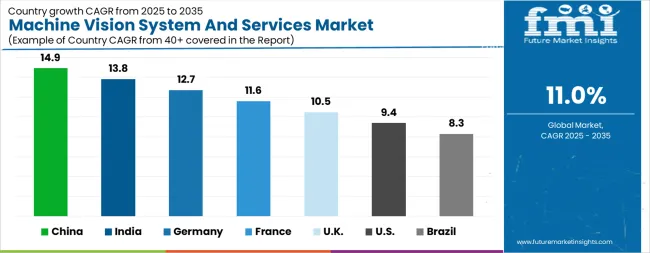

| Country | CAGR |

|---|---|

| China | 14.9% |

| India | 13.8% |

| Germany | 12.7% |

| France | 11.6% |

| UK | 10.5% |

| USA | 9.4% |

| Brazil | 8.3% |

The Machine Vision System And Services Market is expected to register a CAGR of 11.0% during the forecast period, exhibiting varied country level momentum. China leads with the highest CAGR of 14.9%, followed by India at 13.8%. Developed markets such as Germany, France, and the UK continue to expand steadily, while the USA is likely to grow at consistent rates. Brazil posts the lowest CAGR at 8.3%, yet still underscores a broadly positive trajectory for the global Machine Vision System And Services Market. In 2024, Germany held a dominant revenue in the Western Europe market and is expected to grow with a CAGR of 12.7%. The USA Machine Vision System And Services Market is estimated to be valued at USD 7.7 billion in 2025 and is anticipated to reach a valuation of USD 18.8 billion by 2035. Sales are projected to rise at a CAGR of 9.4% over the forecast period between 2025 and 2035. While Japan and South Korea markets are estimated to be valued at USD 1.2 billion and USD 716.5 million respectively in 2025.

| Item | Value |

|---|---|

| Quantitative Units | USD 21.4 Billion |

| Type | 3D Measurement, 2D Measurement, and 1D Measurement |

| Application | Flaw Detection, Identification, Positioning, Measurement, and Verification |

| Component | Smart Camera, Lenses, Lighting, Frame Grabber, and Embedded System |

| End-User Vertical | Automotive, Electronics, Healthcare, Industrial, and Others |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, Middle East & Africa |

| Country Covered | United States, Canada, Germany, France, United Kingdom, China, Japan, India, Brazil, South Africa |

| Key Companies Profiled | Keyence Corporation, Cognex Corporation, Omron Corporation, SICK AG, Atlas Copco AB, ISRA Vision AG, Balser AG, National Instruments Corporation, TKH Group, Datalogic S.P.A, MVTEC Software GMBH, Optotune, Deci AI, Relation Therapeutics, and Lenovo |

The global machine vision system and services market is estimated to be valued at USD 21.4 billion in 2025.

The market size for the machine vision system and services market is projected to reach USD 61.0 billion by 2035.

The machine vision system and services market is expected to grow at a 11.0% CAGR between 2025 and 2035.

The key product types in machine vision system and services market are 3D measurement, 2d measurement and 1d measurement.

In terms of application, flaw detection segment to command 32.6% share in the machine vision system and services market in 2025.

Our Research Products

The "Full Research Suite" delivers actionable market intel, deep dives on markets or technologies, so clients act faster, cut risk, and unlock growth.

The Leaderboard benchmarks and ranks top vendors, classifying them as Established Leaders, Leading Challengers, or Disruptors & Challengers.

Locates where complements amplify value and substitutes erode it, forecasting net impact by horizon

We deliver granular, decision-grade intel: market sizing, 5-year forecasts, pricing, adoption, usage, revenue, and operational KPIs—plus competitor tracking, regulation, and value chains—across 60 countries broadly.

Spot the shifts before they hit your P&L. We track inflection points, adoption curves, pricing moves, and ecosystem plays to show where demand is heading, why it is changing, and what to do next across high-growth markets and disruptive tech

Real-time reads of user behavior. We track shifting priorities, perceptions of today’s and next-gen services, and provider experience, then pace how fast tech moves from trial to adoption, blending buyer, consumer, and channel inputs with social signals (#WhySwitch, #UX).

Partner with our analyst team to build a custom report designed around your business priorities. From analysing market trends to assessing competitors or crafting bespoke datasets, we tailor insights to your needs.

Supplier Intelligence

Discovery & Profiling

Capacity & Footprint

Performance & Risk

Compliance & Governance

Commercial Readiness

Who Supplies Whom

Scorecards & Shortlists

Playbooks & Docs

Category Intelligence

Definition & Scope

Demand & Use Cases

Cost Drivers

Market Structure

Supply Chain Map

Trade & Policy

Operating Norms

Deliverables

Buyer Intelligence

Account Basics

Spend & Scope

Procurement Model

Vendor Requirements

Terms & Policies

Entry Strategy

Pain Points & Triggers

Outputs

Pricing Analysis

Benchmarks

Trends

Should-Cost

Indexation

Landed Cost

Commercial Terms

Deliverables

Brand Analysis

Positioning & Value Prop

Share & Presence

Customer Evidence

Go-to-Market

Digital & Reputation

Compliance & Trust

KPIs & Gaps

Outputs

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Machine Glazed Paper Market Size and Share Forecast Outlook 2025 to 2035

Machine Glazed Kraft Paper Market Forecast and Outlook 2025 to 2035

Machine Condition Monitoring Market Size and Share Forecast Outlook 2025 to 2035

Machine Glazed Paper Industry Analysis in Asia Pacific Forecast Outlook 2025 to 2035

Machine Tool Oils Market Size and Share Forecast Outlook 2025 to 2035

Machine Glazed Paper Industry Analysis in Western Europe Size and Share Forecast Outlook 2025 to 2035

Machine Glazed Paper Industry Analysis in Korea Size and Share Forecast Outlook 2025 to 2035

Machine Glazed Paper Industry Analysis in Japan Size and Share Forecast Outlook 2025 to 2035

Machine Tool Touch Probe Market Analysis - Size, Growth, and Forecast 2025 to 2035

Machine Mount Market Analysis - Size & Industry Trends 2025 to 2035

Machine Automation Controller Market Growth – Trends & Forecast 2025 to 2035

Machine-to-Machine (M2M) Connections Market – IoT & Smart Devices 2025 to 2035

Machine Safety Market Analysis by Component, Industry, and Region Through 2035

Key Players & Market Share in Machine Glazed Paper Industry

Machine Learning As A Services Market

Machine Control System Market Growth – Trends & Forecast 2025 to 2035

Machine Tool Cooling System Market Analysis - Size, Share, and Forecast Outlook 2025 to 2035

Machine Vision Camera Market Size and Share Forecast Outlook 2025 to 2035

Machine Vision Market Insights – Growth & Forecast 2024-2034

BMI Machine Market Size and Share Forecast Outlook 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA