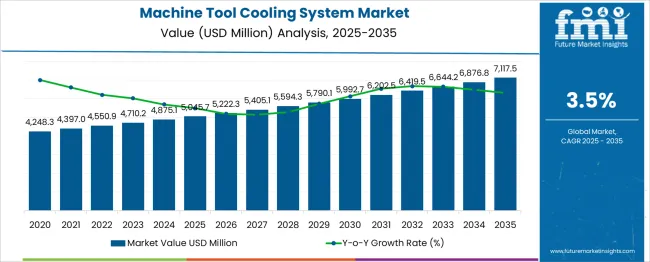

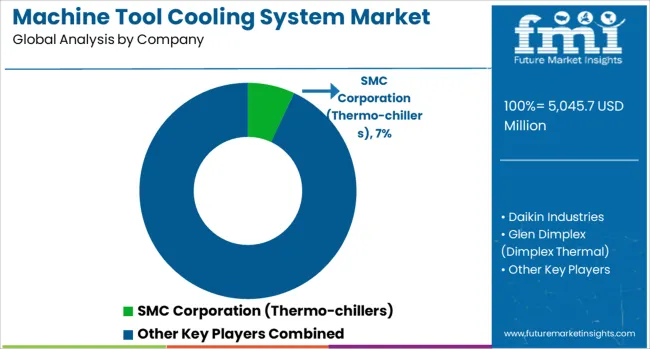

The global machine tool cooling system market is projected to grow from USD 5,045.7 million in 2025 to approximately USD 7,117.4 million by 2035, recording an absolute increase of USD 2,071.5 million over the forecast period. This translates into a total growth of 41.1%, with the market forecast to expand at a compound annual growth rate (CAGR) of 3.5% between 2025 and 2035. The overall market size is expected to grow by nearly 1.41X during the same period, supported by the rising adoption of advanced manufacturing technologies and increasing demand for precision cooling systems in industrial applications.

Between 2025 and 2030, the machine tool cooling system market is projected to expand from USD 5,045.7 million to USD 5,992.6 million, resulting in a value increase of USD 946.9 million, which represents 45.7% of the total forecast growth for the decade. This phase of growth will be shaped by rising penetration of CNC machining centers in global manufacturing facilities, increasing precision requirements in metalworking operations, and growing awareness among manufacturers about the importance of thermal management in maintaining tool life and product quality.

From 2030 to 2035, the market is forecast to grow from USD 5,992.6 million to USD 7,117.4 million, adding another USD 1,124.6 million, which constitutes 54.3% of the overall ten-year expansion. This period is expected to be characterized by expansion of smart cooling technologies, integration of IoT-enabled monitoring systems, and development of energy-efficient cooling solutions across different manufacturing sectors. The growing adoption of Industry 4.0 technologies and automated manufacturing systems will drive demand for more sophisticated cooling systems with advanced control capabilities.

Between 2020 and 2025, the machine tool cooling system market experienced steady expansion, growing from USD 4,360.9 million to USD 5,045.7 million, driven by increasing automation in manufacturing industries and growing adoption of precision machining technologies. The market developed as manufacturing facilities recognized the need for specialized cooling equipment to maintain optimal operating temperatures and extend equipment life cycles.

| Metric | Value |

|---|---|

| Estimated Value in (2025E) | USD 5,045.7 million |

| Forecast Value in (2035F) | USD 7,117.4 million |

| Forecast CAGR (2025 to 2035) | 3.5% |

Market expansion is being supported by the rapid increase in precision manufacturing requirements and the corresponding need for specialized cooling systems to maintain optimal operating conditions. Modern machine tools require precise temperature control to ensure dimensional accuracy, extend tool life, and maintain consistent product quality. Even minor temperature variations can significantly impact machining precision and tool performance, making effective cooling systems essential for competitive manufacturing operations.

The growing complexity of manufacturing processes and increasing quality standards are driving demand for advanced cooling solutions from certified providers with appropriate technology and expertise. Manufacturers are increasingly requiring comprehensive cooling system documentation and performance monitoring to maintain quality certifications and ensure production consistency. Industry standards and equipment manufacturer specifications are establishing standardized cooling requirements that demand specialized systems and trained technical support.

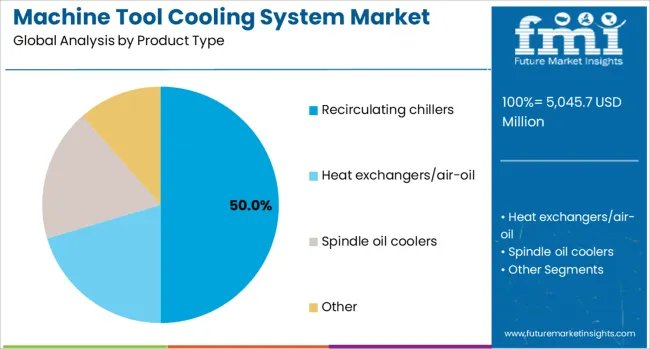

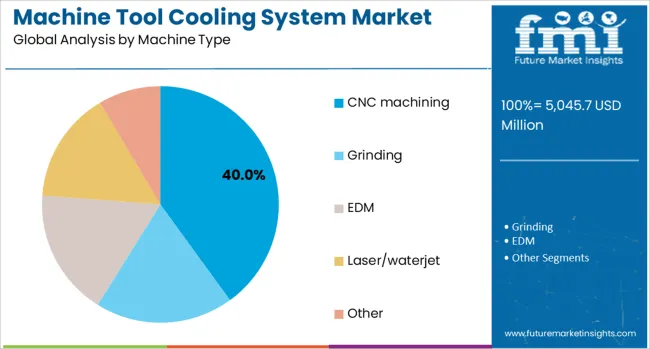

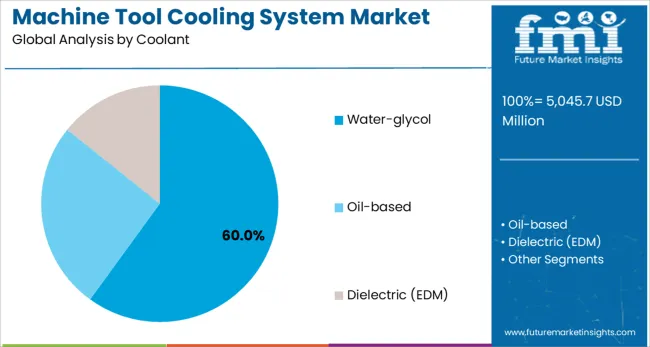

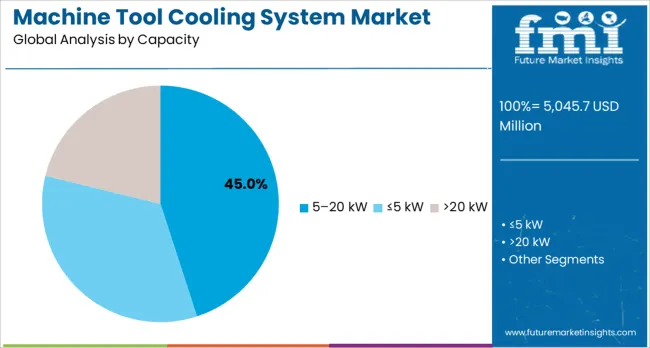

The market is segmented by product type, coolant type, machine type, capacity, and region. By product type, the market is divided into recirculating chillers, heat exchangers/air-oil systems, spindle oil coolers, and other cooling solutions. Based on coolant type, the market is categorized into water-glycol, oil-based, and dielectric (EDM) coolants. In terms of machine type, the market is segmented into CNC machining, grinding, EDM, laser/waterjet, and other applications. By capacity, the market is classified into ≤5 kW, 5–20 kW, and >20 kW systems. Regionally, the market spans across major manufacturing regions including Asia Pacific, North America, Europe, and other key markets.

The recirculating chillers segment is projected to account for 50% of the machine tool cooling system market in 2025, underscoring its role as the preferred solution for high-precision machining environments. Recirculating chillers provide stable, closed-loop cooling with precise temperature control, which is critical for CNC machining centers, grinding systems, and other high-performance equipment. By maintaining consistent coolant flow and temperature, these systems minimize thermal distortion, extend tool life, and improve machining accuracy.

Their widespread adoption is supported by the availability of standardized equipment from multiple global suppliers, offering solutions across both entry-level and advanced manufacturing facilities. With increasing demand for dimensional accuracy in industries such as aerospace, automotive, and medical devices, recirculating chillers are positioned as the most reliable cooling option. Their scalability and compatibility with diverse machine tools further reinforce dominance, ensuring strong growth within the machine tool cooling systems market.

CNC machining applications are forecasted to represent 40% of cooling system demand in 2025, reflecting the segment’s pivotal role in modern industrial production. CNC machining centers are the backbone of precision manufacturing, widely used in sectors such as automotive, aerospace, and electronics. These machines generate significant heat during extended production cycles, making precise cooling essential for maintaining dimensional accuracy, surface quality, and tool longevity.

Cooling systems tailored to CNC operations are designed to stabilize thermal loads, reduce downtime, and optimize energy efficiency. The segment is also driven by the increasing automation of CNC processes, where uninterrupted production runs heighten the need for reliable cooling. With global manufacturing moving toward tighter tolerances and higher productivity standards, CNC machining continues to be the largest driver of demand for advanced cooling systems, solidifying its leadership position in this market.

The water-glycol coolant segment is projected to account for 60% of the machine tool cooling system market in 2025, representing the most widely adopted coolant solution for general machining operations. Water-glycol blends are favored for their strong heat transfer capabilities, corrosion resistance, and compatibility with diverse machine tool materials. These systems balance cost-effectiveness with reliable performance, making them the default choice for most medium-scale manufacturing applications.

Their widespread use is supported by established global supply chains and proven track records in machining centers, grinding systems, and automated production lines. With increasing emphasis on operational efficiency and machine longevity, water-glycol formulations provide the necessary thermal stability while meeting safety and environmental standards. Their versatility and affordability ensure continued dominance, positioning them as the go-to coolant type in the majority of industrial cooling system deployments.

The 5–20 kW medium-capacity cooling systems segment is expected to represent 45% of the machine tool cooling system market in 2025, reflecting its alignment with the requirements of most machining facilities. This range provides an optimal balance between cooling power and energy efficiency, making it suitable for standard CNC machining centers, grinding machines, and multi-operation production lines. Medium-capacity units deliver sufficient cooling to ensure precision and operational stability while maintaining manageable operating costs.

Their popularity is also linked to their adaptability, as manufacturers can easily integrate these systems into existing setups without significant infrastructure changes. For most medium-scale production facilities, 5–20 kW systems deliver the best performance-to-cost ratio, offering reliable cooling without overinvestment in larger, higher-capacity solutions. This balance of capability and affordability cements the segment’s role as the dominant capacity category in the market.

The machine tool cooling system market is advancing steadily due to increasing manufacturing precision requirements and growing recognition of thermal management importance. However, the market faces challenges including high system costs, need for continuous maintenance, and varying cooling requirements across different machining applications. Energy efficiency regulations and environmental considerations continue to influence technology development and market adoption patterns.

The growing deployment of IoT-enabled cooling systems is enabling real-time monitoring of coolant temperature, flow rates, and system performance. Smart cooling solutions provide predictive maintenance capabilities and automated temperature control that optimize machining performance while reducing energy consumption. These systems are particularly valuable for high-volume manufacturing operations that require consistent cooling performance and minimal downtime.

Modern cooling system manufacturers are incorporating advanced heat exchange technologies and variable-speed drives that improve energy efficiency and reduce operating costs. Integration of heat recovery systems and optimized coolant circulation enables more sustainable manufacturing operations. Advanced systems also support compliance with environmental regulations while maintaining superior cooling performance for precision manufacturing applications.

| Countries | CAGR (2025 to 2035) |

|---|---|

| China | 4.4% |

| Brazil | 4.3% |

| India | 4.1% |

| Germany | 3.2% |

| United States | 3.1% |

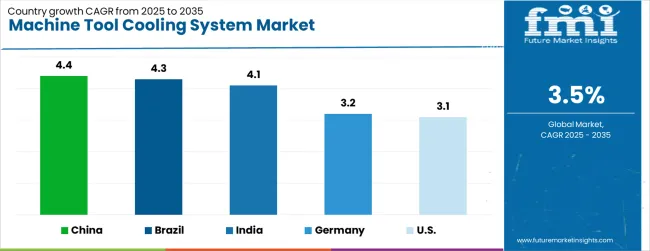

The machine tool cooling system market is growing robustly, with China leading at a 4.4% CAGR through 2035, driven by massive manufacturing expansion, government industrial modernization initiatives, and growing precision manufacturing requirements. Brazil follows closely at 4.3%, supported by automotive and aerospace manufacturing growth and increasing adoption of advanced cooling technologies. India grows steadily at 4.1%, integrating cooling systems into its expanding manufacturing base. Germany records 3.2%, emphasizing precision engineering, quality standards, and advanced cooling expertise. The USA shows steady growth at 3.1%, focusing on manufacturing automation, energy efficiency, and technological innovation. Overall, China and Brazil emerge as the leading drivers of global cooling system market expansion.

The report covers an in-depth analysis of 40+ countries; five top-performing countries are highlighted below.

Revenue from machine tool cooling systems in China is projected to exhibit the highest growth rate with a CAGR of 4.4% through 2035, driven by rapid expansion of manufacturing capacity and increasing adoption of precision machining technologies. The country's massive automotive, aerospace, and electronics manufacturing sectors are creating significant demand for advanced cooling solutions. Major manufacturing hubs are establishing comprehensive cooling system networks to support the growing population of high-precision machine tools across industrial and commercial markets.

Revenue from machine tool cooling systems in Brazil is expanding at a CAGR of 4.3%, supported by growing automotive manufacturing and increasing adoption of precision machining technologies. The country's expanding industrial base and modernization of manufacturing facilities are driving demand for professional cooling solutions. Manufacturing centers and specialized facilities are gradually establishing capabilities to serve the growing population of advanced machine tools.

Revenue from machine tool cooling systems in India is growing at a CAGR of 4.1%, driven by increasing precision manufacturing adoption and growing recognition of thermal management importance in quality production. The country's established manufacturing industry is gradually integrating advanced cooling capabilities to serve modern production technologies. Manufacturing facilities and authorized service centers are investing in cooling equipment and training to address growing market demand.

Demand for machine tool cooling systems in Germany is projected to grow at a CAGR of 3.2%, supported by the country's emphasis on precision manufacturing and advanced engineering solutions. German manufacturing facilities are implementing comprehensive cooling capabilities that meet stringent quality standards and equipment specifications. The market is characterized by focus on technical excellence, advanced system integration, and compliance with comprehensive industrial safety and efficiency regulations.

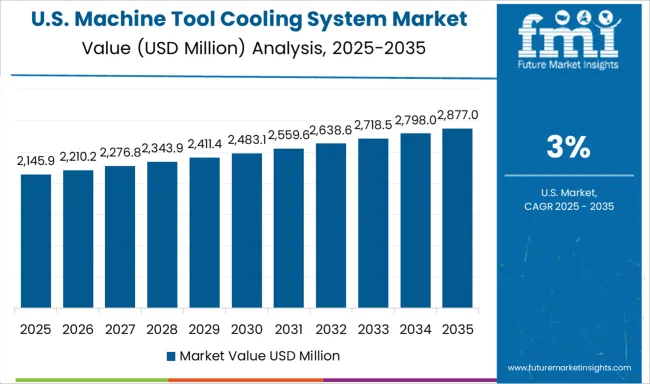

Demand for machine tool cooling systems in the USA is expanding at a CAGR of 3%, driven by increasing manufacturing automation and growing emphasis on standardized cooling procedures. Large manufacturing networks and specialized facilities are establishing comprehensive cooling capabilities to serve diverse production needs. The market benefits from industry requirements for proper thermal management documentation and equipment manufacturer warranty compliance.

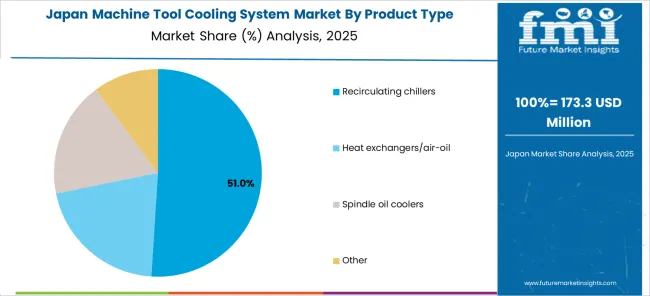

The machine tool cooling system market in Japan demonstrates strong development with CNC machining commanding 51% market share, reflecting the country's advanced precision manufacturing sector and leadership in computer-controlled machining technologies. Companies like Daikin Industries, Mitsubishi Electric, and SMC Corporation (Thermo-chillers) leverage Japan's manufacturing excellence to develop sophisticated cooling solutions for diverse applications. Grinding operations represent 30% of the market, driven by Japan's expertise in precision grinding technology and automotive component manufacturing requirements.

EDM applications account for 15% market share, supporting specialized electrical discharge machining processes, while other applications hold 10%, representing emerging opportunities in advanced manufacturing technologies. The market benefits from Japan's focus on manufacturing precision, quality control, and technological innovation, creating strong demand for premium cooling systems that ensure optimal machining performance. Growing emphasis on energy efficiency and sustainable manufacturing practices positions Japan as a key innovation center for next-generation thermal management technologies across diverse precision machining applications and industrial manufacturing processes.

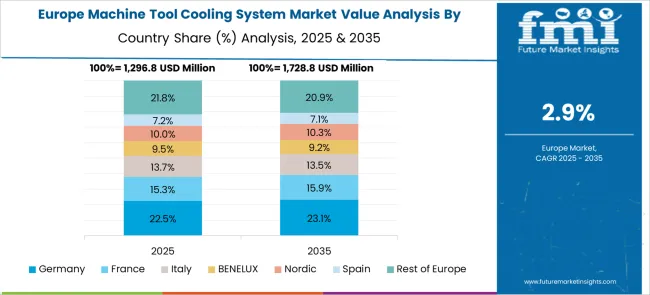

The machine tool cooling system market in Europe demonstrates sophisticated development across major economies with Germany leading through its precision engineering capabilities and strong machine tool manufacturing sector, supported by companies like Rittal GmbH, Pfannenberg, and Glen Dimplex (Dimplex Thermal) pioneering innovative cooling technologies for diverse machining applications. France and the UK show significant growth in aerospace and automotive manufacturing, where high-precision machining demands advanced thermal management solutions.

German companies leverage their engineering expertise to develop comprehensive cooling systems, while international players like Parker Hannifin and SMC Corporation establish strong European presence. Italy and Spain exhibit expanding adoption in precision machining and grinding applications, driven by manufacturing modernization and Industry 4.0 initiatives. Nordic countries emphasize energy-efficient cooling solutions and sustainable manufacturing practices, while Eastern European markets show growing interest in upgrading machine tool infrastructure. The market benefits from strict environmental regulations, energy efficiency mandates, and the region's leadership in precision manufacturing, positioning Europe as a key innovation center for next-generation machine tool cooling solutions across multiple industrial machining segments.

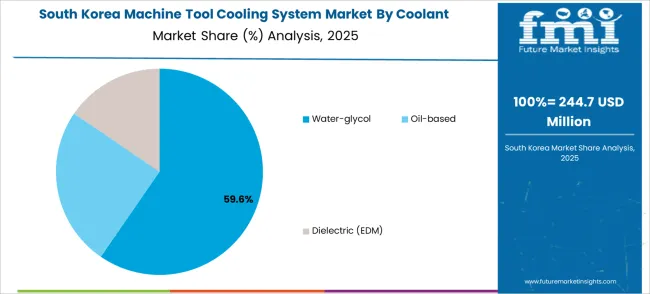

The machine tool cooling system market in South Korea shows sophisticated technological adoption with recirculating chillers commanding 59.6% market share, demonstrating preference for comprehensive cooling solutions that offer superior temperature control and energy efficiency for advanced manufacturing operations. Companies like HYFRA, Habor Precise (CNC Chillers), and LNEYA contribute through their specialized cooling technologies, supporting South Korea's growing precision manufacturing and electronics sectors.

Heat exchangers maintain 20% market share, serving efficient heat transfer needs across diverse machining applications, while spindle oil coolers hold 15% market share, addressing critical spindle temperature management requirements. Other cooling solutions represent 10% of the market, supporting specialized thermal management needs in advanced manufacturing processes. The market's emphasis on recirculating chiller technology reflects South Korea's focus on manufacturing efficiency and precision, driving demand for integrated cooling solutions with enhanced performance and reliability. Integration with Korean expertise in manufacturing technology and industrial automation positions the market as both a significant consumer base and innovation catalyst for advanced machine tool cooling applications worldwide.

The machine tool cooling system market is defined by competition among specialized equipment manufacturers, industrial cooling solution providers, and manufacturing technology companies. Companies are investing in advanced cooling technologies, energy-efficient systems, standardized solutions, and technical support services to deliver precise, reliable, and cost-effective cooling solutions. Strategic partnerships, technological innovation, and geographic expansion are central to strengthening product portfolios and market presence.

Daikin Industries, Japan-based, offers comprehensive industrial cooling solutions with a focus on energy efficiency, reliability, and advanced control systems. Glen Dimplex (Dimplex Thermal), operating from Ireland, provides specialized cooling technologies integrated with manufacturing equipment and process optimization. HYFRA, Germany, delivers precision cooling systems with standardized procedures and digital integration capabilities. Habor Precise (CNC Chillers), Taiwan, emphasizes specialized CNC cooling solutions and comprehensive technical support.

LNEYA, China, offers cost-effective cooling solutions integrated with comprehensive manufacturing support services. Mitsubishi Electric, Japan, provides technologically advanced cooling systems with automation integration and energy optimization. Parker Hannifin, USA, delivers comprehensive cooling solutions with global service networks. Pfannenberg, Germany, offers industrial cooling expertise with specialized enclosure and process cooling applications. Rittal GmbH, Germany, provides integrated cooling solutions for manufacturing automation, while SMC Corporation (Thermo-chillers), Japan, offers precision cooling systems with pneumatic and automation integration.

| Items | Values |

|---|---|

| Quantitative Units (2025) | USD 5,045.7 million |

| Product Type | Recirculating chillers, Heat exchangers/air-oil, Spindle oil coolers, Other |

| Coolant | Water-glycol, Oil-based, Dielectric (EDM) |

| Machine Type | CNC machining, Grinding, EDM, Laser/waterjet, Other |

| Capacity | ≤5 kW, 5–20 kW, >20 kW |

| Regions Covered | Asia Pacific, North America, Europe, Latin America, Middle East & Africa |

| Countries Covered | United States, Canada, United Kingdom, Germany, France, China, Japan, South Korea, Brazil, India and 40+ countries |

| Key Companies Profiled | Daikin Industries, Glen Dimplex (Dimplex Thermal), HYFRA, Habor Precise (CNC Chillers), LNEYA, Mitsubishi Electric, Parker Hannifin, Pfannenberg, Rittal GmbH, and SMC Corporation (Thermo-chillers) |

| Additional Attributes | Dollar sales by cooling technology and system capacity, regional demand trends, competitive landscape, buyer preferences for water-based versus oil-based solutions, integration with smart manufacturing platforms, innovations in energy-efficient chillers, IoT monitoring, and closed-loop recycling systems |

The global machine tool cooling system market is estimated to be valued at USD 5,045.7 million in 2025.

The market size for the machine tool cooling system market is projected to reach USD 7,117.5 million by 2035.

The machine tool cooling system market is expected to grow at a 3.5% CAGR between 2025 and 2035.

The key product types in machine tool cooling system market are recirculating chillers, heat exchangers/air-oil, spindle oil coolers and other.

In terms of coolant, water-glycol segment to command 60.0% share in the machine tool cooling system market in 2025.

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Machine Glazed Paper Market Size and Share Forecast Outlook 2025 to 2035

Machine Glazed Kraft Paper Market Forecast and Outlook 2025 to 2035

Machine Condition Monitoring Market Size and Share Forecast Outlook 2025 to 2035

Machine Glazed Paper Industry Analysis in Asia Pacific Forecast Outlook 2025 to 2035

Machine Vision Camera Market Size and Share Forecast Outlook 2025 to 2035

Machine Glazed Paper Industry Analysis in Western Europe Size and Share Forecast Outlook 2025 to 2035

Machine Glazed Paper Industry Analysis in Korea Size and Share Forecast Outlook 2025 to 2035

Machine Glazed Paper Industry Analysis in Japan Size and Share Forecast Outlook 2025 to 2035

Machine Mount Market Analysis - Size & Industry Trends 2025 to 2035

Machine Automation Controller Market Growth – Trends & Forecast 2025 to 2035

Machine-to-Machine (M2M) Connections Market – IoT & Smart Devices 2025 to 2035

Machine Safety Market Analysis by Component, Industry, and Region Through 2035

Key Players & Market Share in Machine Glazed Paper Industry

Machine Vision Market Insights – Growth & Forecast 2024-2034

Machine Learning As A Services Market

Machine Vision System And Services Market Size and Share Forecast Outlook 2025 to 2035

Machine Control System Market Growth – Trends & Forecast 2025 to 2035

Machine Tool Oils Market Size and Share Forecast Outlook 2025 to 2035

Machine Tool Touch Probe Market Analysis - Size, Growth, and Forecast 2025 to 2035

BMI Machine Market Size and Share Forecast Outlook 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA