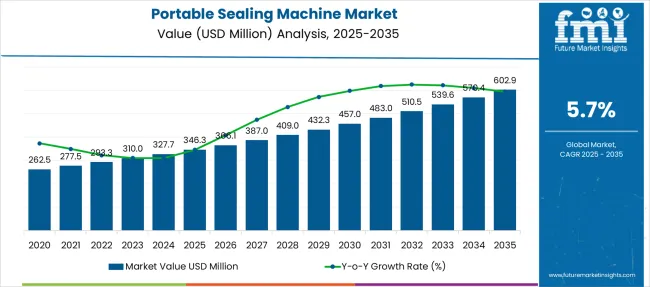

The Portable Sealing Machine Market is estimated to be valued at USD 346.3 million in 2025 and is projected to reach USD 602.9 million by 2035, registering a compound annual growth rate (CAGR) of 5.7% over the forecast period. Growth accelerates post-2027 as e-commerce packaging demand and small-scale industrial applications expand. The market benefits from increased emphasis on portability and operational efficiency, opening white space for compact battery-operated solutions with smart heat-control mechanisms.

Regional competitiveness will center on Asia-Pacific, where fragmented retail and food delivery networks create large-scale adoption potential. Players integrating energy-efficient designs with IoT-based performance monitoring could achieve differentiation in industrial-grade models. High-margin opportunities lie in modular sealing attachments for diverse material thicknesses and temperature-sensitive packaging, creating an aftermarket revenue stream.

The Y-o-Y growth trajectory indicates steady expansion with innovation-driven inflection points around 2030, particularly from eco-friendly sealing solutions utilizing biodegradable film compatibility. Strategic investment in localized assembly hubs and omni-channel distribution partnerships will position brands favorably as customization trends dominate the market.

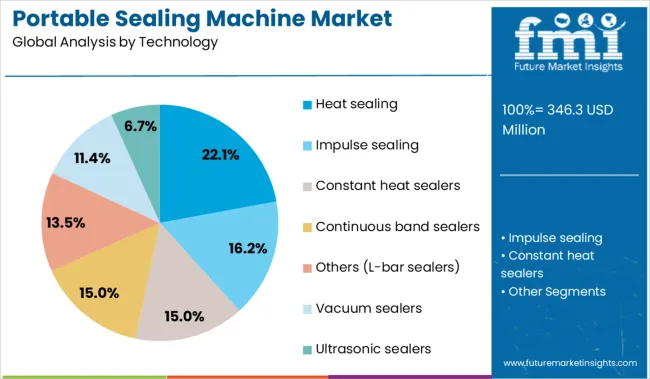

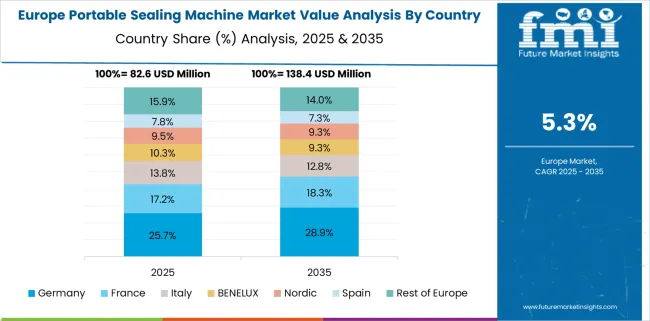

Heat sealing machines, contributing 22.1% share, remain the preferred option for their compatibility with multiple packaging substrates and ability to deliver airtight closures for food preservation. Asia-Pacific is emerging as the fastest-growing region, driven by an expanding packaged food industry and rising penetration of D2C businesses. North America sustains demand through retail packaging solutions and portable sealing requirements in logistics, while Europe emphasizes adoption in compliance-heavy sectors such as pharmaceuticals and nutraceuticals.

Innovation is likely to center on battery-powered, lightweight designs and temperature-control automation to ensure sealing consistency across varying material grades. Integration of smart features like sealing count tracking and IoT-enabled maintenance alerts could define the next phase of differentiation.

| Metric | Value |

|---|---|

| Portable Sealing Machine Market Estimated Value in (2025 E) | USD 346.3 million |

| Portable Sealing Machine Market Forecast Value in (2035 F) | USD 602.9 million |

| Forecast CAGR (2025 to 2035) | 5.7% |

The portable sealing machine market is witnessing steady expansion fueled by rising demand for flexible and efficient packaging solutions across various end-use industries. Compact sealing equipment is being increasingly adopted due to its portability, ease of integration in existing operations, and suitability for both on-site and field packaging tasks.

The market is benefitting from the growing emphasis on hygienic, tamper-proof, and shelf-life-extending packaging, particularly in food, pharmaceutical, and logistics sectors. With increased demand for on-demand sealing in remote or decentralized production environments, manufacturers are innovating compact devices that deliver professional-grade results with minimal setup time. Advances in battery efficiency, ergonomic designs, and temperature control mechanisms are enhancing user efficiency while meeting safety and compliance standards.

Rise in small-scale enterprises, especially in developing regions, is supporting strong demand for cost-effective and scalable sealing equipment. The market outlook remains positive as packaging standards evolve and product diversity drives adoption across consumer and industrial segments.

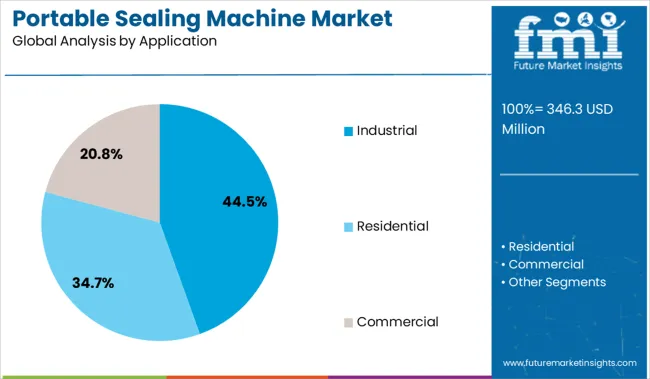

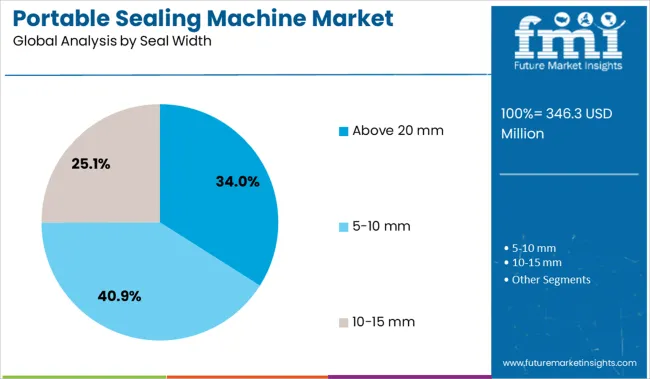

The portable sealing machine market is segmented by technology, application, seal width, mode of operation, and region. By technology, it includes heat sealing, impulse sealing, constant heat sealers, continuous band sealers, vacuum sealers, ultrasonic sealers, and others such as L-bar sealers, offering a range of sealing options for various packaging needs. In terms of application, the segmentation comprises industrial, residential, and commercial sectors. Based on seal width, the market is categorized into 5–10 mm, 10–15 mm, and above 20 mm for different sealing requirements. By mode of operation, it is divided into automatic, manual, and semi-automatic systems, providing flexibility for different usage scales. Regionally, the market spans North America, Latin America, Western and Eastern Europe, Balkan and Baltic countries, Russia and Belarus, Central Asia, East Asia, South Asia and Pacific, and the Middle East and Africa.

The heat sealing technology segment is projected to account for 22.1% of market revenue in 2025, leading within the technology category. This segment’s prominence is attributed to its wide applicability across material types and its ability to deliver durable, airtight seals.

Heat sealing has been favored for its low maintenance requirements, consistent seal quality, and compatibility with polyethylene, polypropylene, and laminated films. In portable devices, heat sealing technology offers a reliable and energy-efficient solution that does not require complex mechanisms, making it ideal for mobile and field applications.

Ongoing innovations such as instant-heating elements and adjustable sealing durations have further improved efficiency and reduced wait times between sealing cycles. These advantages have helped sustain heat sealing’s lead as a core technology within the portable sealing machine market.

The industrial segment is expected to dominate the application category with a projected 44.5% share of total market revenue in 2025. This leadership is driven by the need for mobile sealing solutions within manufacturing, warehousing, and logistics operations.

Industrial users rely on portable sealing equipment for batch packaging, secondary sealing, and temporary on-site operations where fixed machinery may not be feasible. The growth of e-commerce and global trade has increased demand for efficient and secure sealing in high-volume environments.

Additionally, portable sealing machines are being used in field operations such as agriculture, construction, and utilities, where power access is limited but secure packaging is essential. These versatile use cases have reinforced the adoption of portable sealing machines in industrial sectors, solidifying their top share within the application segment.

The seal width category above 20 mm is anticipated to account for 34.0% of total market revenue in 2025, making it the leading subsegment. This dominance is a result of growing preference for wide seals that offer enhanced strength, tamper resistance, and visual appeal.

Wider seals are particularly suited for heavy-duty or large-volume packaging where product integrity and security are critical. In portable sealing machines, the ability to deliver a wide seal without compromising compactness or ease of use has become a key differentiator.

Industries handling bulk materials, perishables, or medical supplies increasingly opt for above 20 mm sealers to ensure compliance with safety and durability requirements. The segment’s growth is further supported by advancements in jaw design, uniform heat distribution, and pressure control, all of which enable efficient wide sealing in field-ready equipment.

Lightweight sealing devices, including impulse and heat sealers, have gained popularity across food packaging, cosmetic units, pharmaceuticals, and agro-based product lines. Ease of operation, compatibility with various pouch materials, and minimal power requirements have increased usage across small-scale businesses and informal packaging setups.

Sealing machines are now commonly integrated into refill stations, mobile food counters, and craft-based production units. Market traction has also been supported by regulations that require tamper-evident closures and extended shelf life. Vendors have introduced compact machines with adjustable temperature settings, sealing widths, and built-in safety cutoffs.

Increased reliance on flexible packaging and decentralized product distribution has driven the adoption of portable sealing machines. Small manufacturers and regional brands have deployed hand-operated and electric sealers for retail packaging, especially for snacks, spices, confectionery, and dried foods. These machines offer low-cost sealing with adjustable temperature, compact size, and plug-and-play usability.

Portable units have become essential in settings where packaging is done manually or on-site, such as farmer markets, kiosks, refill stations, and mobile food vendors. Equipment compatibility with various laminate, foil, and compostable films has increased utility across use cases.

Additionally, packaging regulations for tamper evidence and shelf-life extension have supported the transition from twist ties and clips to heat-sealed finishes, enhancing perceived product hygiene and protection.

Opportunities are emerging through mobile sealing solutions aligned with direct-to-consumer delivery models and small-batch packaging. Portable sealing equipment is being adopted by e-commerce sellers, homegrown food businesses, subscription box providers, and refill retailers looking for adaptable, compact sealing systems.

Battery-powered and USB-compatible models are entering the market to serve on-the-go sealing needs, while tabletop impulse units are favored in small studios and pop-up locations. Growing preference for resealable and minimal packaging has driven machine makers to offer adjustable sealing options compatible with recyclable pouches and lightweight laminates.

Service providers offering mobile packing stations and co-packing services are integrating portable sealers into their toolkits. Equipment-as-a-service rental models and bundled packaging kits are being used to lower entry barriers for early-stage entrepreneurs and remote operators.

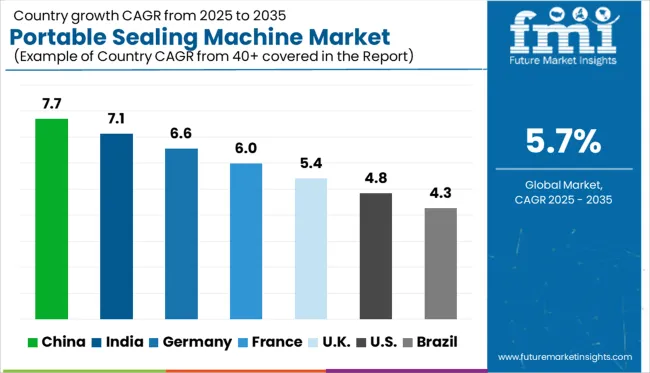

| Country | CAGR |

|---|---|

| China | 7.7% |

| India | 7.1% |

| Germany | 6.6% |

| France | 6.0% |

| UK | 5.4% |

| USA | 4.8% |

| Brazil | 4.3% |

The global portable sealing machine market is projected to grow at a CAGR of 5.7% from 2025 to 2035, influenced by expanding field-based packaging operations, last-mile inventory nodes, and format-specific sealing demands. China leads with a 7.7% CAGR, supported by high-density food packaging, agricultural outbound logistics, and multi-format machine adoption.

India follows at 7.1%, driven by mobile retail units, rural packaging services, and informal sector formalization. Germany grows at 6.6%, shaped by semi-automated sealing in diagnostics, refill stations, and decentralized pharma packaging.

France posts 6.0%, backed by small-format sealing integration in regulated food chains and pilot-scale laboratories. The United Kingdom grows at 5.4%, influenced by refilled brand adoption, in-field resealing needs, and compact device demand across mobility-first packaging. These five countries represent strategic coverage within a wider 40+ nation evaluation.

The portable sealing machine market in China is forecast to grow at a CAGR of 7.7%, supported by increasing integration of compact sealing units in agriculture export packaging, urban fresh food delivery, and flexible logistics hubs. Heat sealers, vacuum sealers, and impulse sealing tools have been adopted by fast-moving snack producers and mobile meal kit providers for precision sealing of variable film types.

Government emphasis on low-waste food distribution and improved cold chain handling has further strengthened equipment relevance. Portable machines with adjustable sealing widths and multi-voltage compatibility are being prioritized by regional manufacturers. Strong equipment turnover from e-commerce repacking centers and agro-export zones continues to reinforce the market trajectory.

Demand for portable sealing machine in India is projected to grow at a CAGR of 7.1%, shaped by rising use in food carts, rural collection centers, and informal distribution zones. Handheld and table-mounted sealers are being used to reduce post-harvest losses and improve product handling in small-scale retail.

Battery-compatible sealing units are gaining traction in low-power areas where fixed infrastructure is not viable. Field health units and mobile pharma sellers are incorporating portable heat sealers for sterile sample containment and temporary kit preparation. The market has responded to demand for low-maintenance, single-operator devices that function across poly, foil, and compostable substrates.

The sale of portable sealing machines in Germany is expected to expand at a CAGR of 6.6%, driven by growing demand for decentralized automation in laboratories, refill stations, and regulated food environments. Medical testing units and diagnostics labs are adopting portable sealers for tamper-evident packaging of test kits and sample pouches.

Compact machines with digital temperature control and cleanroom compatibility have gained relevance in sterile handling zones. Commercial refill points for dry goods and spices are also using desktop sealers for sustainable packaging. German manufacturers are introducing high-spec devices that support both manual and semi-automated workflows in tightly controlled sectors.

The portable sealing machine market in France is forecast to grow at a CAGR of 6.0%, supported by increased packaging control in artisanal food, mobile cheese retail, and laboratory sampling workflows. Heat-based sealers are being adopted in independent retail counters and on-site packaging services for fresh and specialty products.

Compact impulse sealers have been deployed in R&D facilities for vacuum-sealing chemical kits and biological specimens. Demand has increased for tabletop units that can process biodegradable film rolls, driven by small-batch packaging mandates in local food zones. Market preference remains aligned with devices offering repeatability, fast sealing cycles, and compliance with material-specific sealing thresholds.

The United Kingdom portable sealing machine market is projected to grow at a CAGR of 5.4%, shaped by demand from refill-focused retail brands, localized food prep units, and compact medical kit production. Portable sealers have been incorporated in zero-waste store formats and high-frequency delivery kitchens for on-site packaging flexibility.

Manual and semi-digital impulse sealers are preferred for sealing return pouches, compostable containers, and resealable pouches. Health product distributors are also adopting battery-powered models for kit assembly in small, distributed facilities. Market movement has been led by application-specific adoption, with a focus on machines that balance cost, compactness, and format adaptability.

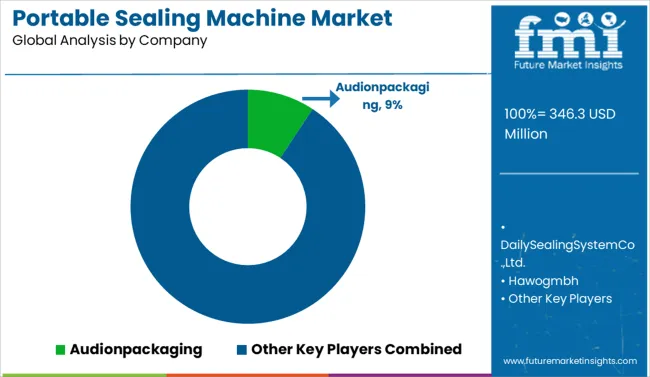

The portable sealing machine industry is led by Audion Packaging, holding significant market share, known for its robust impulse sealers and precision heat sealing systems widely used across food, pharma, and industrial applications.

Companies like Hawo GmbH and Syntegon Technology GmbH focus on high-performance sealing solutions with built-in compliance for sterile packaging environments. Impak Corp. and Pac Machinery offer customizable bench-top models catering to varied material types and seal widths.

Daily Sealing System Co., Ltd., Sepack India, and Sai Nam Packing System address demand in price-sensitive markets with compact, durable units. Nutrichef Kitchen and OTOVON appeal to home and small business users. Competitive priorities revolve around sealing consistency, energy efficiency, portability, and compatibility with barrier and multilayer films.

Key Developments in Portable Sealing Machine Market

| Item | Value |

|---|---|

| Quantitative Units | USD 346.3 Million |

| Technology | Heat sealing, Impulse sealing, Constant heat sealers, Continuous band sealers, Others (L-bar sealers), Vacuum sealers, and Ultrasonic sealers |

| Application | Industrial, Residential, and Commercial |

| Seal Width | Above 20 mm, 5-10 mm, and 10-15 mm |

| Mode of Operation | Automatic, Manual, and Semi-automatic |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, Middle East & Africa |

| Country Covered | United States, Canada, Germany, France, United Kingdom, China, Japan, India, Brazil, South Africa |

| Key Companies Profiled | Audionpackaging, DailySealingSystemCo.,Ltd., Hawogmbh, ImpakCorp., NutrichefKitchen., OTOVON, Pacmachinery, PromarksvacCorp., SaiNamPackingSystem, SepackIndiaPrivateLimited, SpackServices, SurnehaServices, Swisspack, SyntegonTechnologygmbh, and WenzhouHuaqiaoPackingMachineFactory |

| Additional Attributes | Dollar sales are segmented by sealing method, impulse, continuous, and vacuum sealing machines, with cordless, battery-powered units gaining share due to portability and ease of use. Rising demand is driven by on-site food packaging, medical sterilization, and industrial sample sealing. OEMs and CDMOs offer private-label and modular configurations. Adoption is strongest in North America and Europe, where compact, ergonomic designs and battery-life efficiency are key differentiators. |

The global portable sealing machine market is estimated to be valued at USD 346.3 million in 2025.

The market size for the portable sealing machine market is projected to reach USD 602.9 million by 2035.

The portable sealing machine market is expected to grow at a 5.7% CAGR between 2025 and 2035.

The key product types in portable sealing machine market are heat sealing, impulse sealing, constant heat sealers, continuous band sealers, others (l-bar sealers), vacuum sealers and ultrasonic sealers.

In terms of application, industrial segment to command 44.5% share in the portable sealing machine market in 2025.

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Portable Filtration System Market Size and Share Forecast Outlook 2025 to 2035

Portable Toilet Rental Market Size and Share Forecast Outlook 2025 to 2035

Portable NIR Moisture Meter Market Forecast and Outlook 2025 to 2035

Portable Appliance Tester (PAT) Market Size and Share Forecast Outlook 2025 to 2035

Portable Charging Units Market Size and Share Forecast Outlook 2025 to 2035

Portable Electronic Analgesic Pump Market Size and Share Forecast Outlook 2025 to 2035

Portable Ramps Market Size and Share Forecast Outlook 2025 to 2035

Portable Buffet and Drop-In Ranges Market Size and Share Forecast Outlook 2025 to 2035

Portable Cancer Screen Devices Market Size and Share Forecast Outlook 2025 to 2035

Portable Hydrogen Powered Generator Market Size and Share Forecast Outlook 2025 to 2035

Portable Power Quality Meter Market Size and Share Forecast Outlook 2025 to 2035

Portable Sandwich Maker Market Size and Share Forecast Outlook 2025 to 2035

Portable Conventional Generator Market Size and Share Forecast Outlook 2025 to 2035

Portable Projector Market Size and Share Forecast Outlook 2025 to 2035

Portable Printer Market Size and Share Forecast Outlook 2025 to 2035

Portable Video Wall Market Size and Share Forecast Outlook 2025 to 2035

Portable Gas Detection Equipment Market Size and Share Forecast Outlook 2025 to 2035

Portable Chromatography Systems Market Size and Share Forecast Outlook 2025 to 2035

Portable Band Saws Market Size and Share Forecast Outlook 2025 to 2035

Portable Cannabis Vaporizer Market Size and Share Forecast Outlook 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA