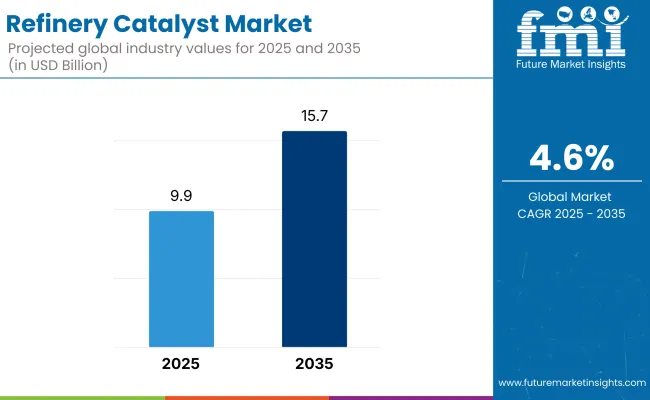

The global refinery catalyst market is estimated at USD 9.9 billion in 2025. This surge was driven by the rising global emphasis on fuel upgrading, stricter environmental mandates, and evolving refinery configurations. With a CAGR of 4.6% from 2025 to 2035, the market is projected to reach USD 15.7 billion by 2035.

Hydroprocessing catalyst demand has been reinforced by the 0.5% sulfur content cap enforced under the IMO 2020 mandate. In February 2025, Honeywell UOP reported a double-digit increase in orders for its hydrocracking catalyst line, as disclosed in its corporate performance brief. The firm stated that adoption rates were highest in China, Singapore, and Germany due to refinery revamps driven by sulfur emission compliance.

FCC catalyst requirements have also risen steadily, supported by increased demand for lighter petroleum fractions. In a press statement released by Grace Catalysts Technologies in January 2025, two deployments were confirmed at mega-refineries operated by Indian Oil Corporation and SK Energy in South Korea. Grace President Denise Butchko emphasized that “efficiency and yield optimization are non-negotiables in today’s refining economics.”

Zeolite-based FCC catalysts remain the dominant class. In a March 2024 report published by the Japan Petroleum Institute, the Y-type rare-earth zeolite catalyst demonstrated a 4.2% uplift in gasoline yield at East Asian refinery test beds. These catalysts were found to withstand thermal cycling conditions beyond 750°C, improving unit throughput and stability.

Residue upgrading has expanded in Latin America. According to BASF’s 2025 Annual Innovation Review, more than 40% of resid feedstock processed in Brazil, Mexico, and Colombia now utilizes its catalyst platform designed for asphaltene-heavy crude blends. CEO Michael Heinz noted that “catalyst-led innovation is essential for bottom-of-the-barrel valorization.”

Technological partnerships have been ramped up across the Middle East. In March 2025, Aramco and Axens jointly launched a pilot research unit in Dhahran to develop selective hydrogenation catalysts for aromatics purification. The facility is part of a broader R&D roadmap co-financed under Aramco’s sustainability innovation fund.

Despite steady progress, rare earth price volatility and substrate cost spikes continue to challenge producers. To offset this, Grace has initiated a multi-site recycling program for spent catalyst recovery, as confirmed in its April 2025 ESG statement. Parallel advancements in nano-dispersion and binder-free catalyst formulations are being explored by researchers at the Korea Institute of Energy Research.

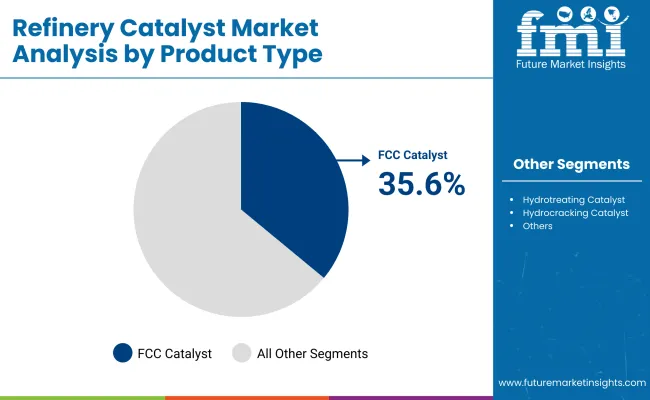

The section explains the market share analysis of the leading segments in the industry. In terms of product type, the fluid catalytic cracking (FCC) catalyst type will likely dominate and generate a share of around 35.6% in 2025.

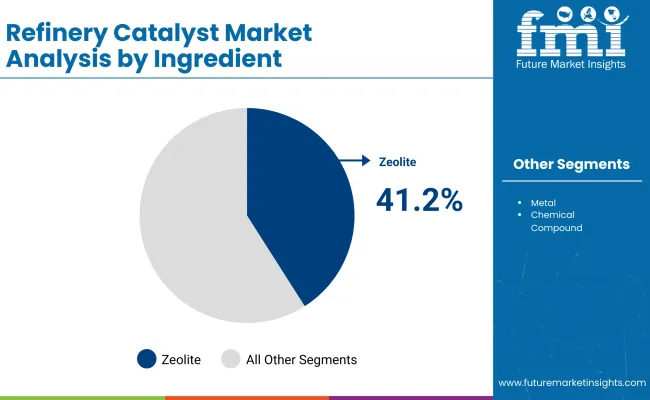

Based on the ingredient, the zeolites is projected to hold a major share of 41.2% in 2025. The analysis would enable potential clients to make effective business decisions for investment purposes.

| Segment | Value Share (2025) |

|---|---|

| Fluid Catalytic Cracking (FCC) Catalyst (Product Type) | 35.6% |

Fluidized catalytic cracking (FCC) unit is the most important secondary processing unit in a refinery for cracking gas oil or residual feedstock. It is considered as the workhorse of a refinery.

FCC units operate either on maximum gasoline mode or on the maximum distillate mode, which depends on seasonal product demand. The FCC unit could be operated in high severity mode to produce high yields of light olefins than conventional FCC operation.

The olefins produced in FCC unit are the important source for petrochemicals. Catalyst and additives play vital roles in changing the product slate of the FCC unit.

Key players in the FCC catalyst are providing innovative products that tend to increase the efficiency of the FFC process. For example, HP Green R&D Centre (HPGRDC) has developed a novel catalyst formulation and process technology, Hindustan Petroleum High Propylene FCC Technology comprising of catalyst and hardware system for maximizing propylene and minimizing CLO yields.

| Segment | Value Share (2025) |

|---|---|

| Zeolites (Ingredients) | 41.2% |

Fluid catalytic cracking is by far the largest user of zeolite catalysts. Industrial estimates suggest that worldwide sales of zeolite FCC catalysts are approximately USD 1 billion per year.

Recent advances in FCC catalysts have concentrated on modifying zeolite Y for improved coke selectivity, higher cracking activity, and greater stability through manipulation of extra framework aluminum or through the generation of mesoporosity of the zeolite crystals.

Extra framework aluminum is introduced either by steaming or via ion exchange. The development of improved FCC catalysts constitutes an interesting case study of the merits of selectively modifying a single crystal structure to achieve multiple catalytic objectives.

The annual growth rates of the refinery catalyst market from 2025 to 2035 are illustrated below in the table. Starting with the base year 2024 and going up to the present year 2025, the report examined how the industry growth trajectory changes from the first half of the year, i.e. January through June (H1) to the second half consisting of July through December (H2).

This gives stakeholders a comprehensive picture of the sector’s performance over time and insights into potential future developments.

The table provided shows the growth of the sector for each half-year between 2024 and 2025. The market was projected to grow at a CAGR of 3.5% in the first half (H1) of 2024. However, in the second half (H2), there is a noticeable increase in the growth rate.

| Particular | Value CAGR |

|---|---|

| H1 2024 | 3.5% (2024 to 2034) |

| H2 2024 | 3.7% (2024 to 2034) |

| H1 2025 | 3.7% (2025 to 2035) |

| H2 2025 | 3.9% (2025 to 2035) |

Moving into the subsequent period, from H1 2025 to H2 2025, the CAGR is projected as 3.7% in the first half and grow to 3.9% in the second half. In the first half (H1) and second half (H2), the market witnessed an increase of 20 BPS each.

Between 2020 and 2024, the target market registered growth rate of 3.6% by reaching a value of USD 9,614.9 million in 2024 from USD 8,356.9 million in 2020.

Industry 4.0 concept has become a worldwide revolution that has been mainly led by the manufacturing sector. Continuous process industry is part of this global trend where there are aspects of the “fourth industrial revolution” that must be adapted to the particular context and needs of big continuous processes such as oil refineries that have evolved to control paradigms supported by sector-specific technologies where big volumes of operation-driven data are continuously captured from a plethora of sensors.

The introduction of artificial intelligence (AI) techniques can overcome the current limitations of Advanced Control Systems (mainly MPCs) by providing better performance on highly non-linear and complex systems and by operating with a broader scope in terms of signals/data and sub-systems.

Moreover, the state of the art of traditional PID/MPC based solutions is showing an asymptotic improvement that requires a disruptive approach in order to reach relevant improvements in terms of efficiency, optimization, maintenance, and others.

These technological developments in the refinery has pushed the need for refinery catalyst to support the growth of digitalization.

All these factors have played pivotal role in expanding the demand for refinery catalyst industry in 2020 to 2024.

Looking ahead to 2025 to 2035, the market is anticipated to grow faster. Catalysis plays a key role in petroleum refining as most of the processes are catalytic. Petroleum fractions produced via fractional distillation of crude oil do not fulfill the quality standards to be used as fuels and the increasing market demands.

The high demand in gasoline with anti-knocking characteristics is fulfilled with catalytic cracking of heavy petroleum fractions at high temperature in the presence of highly active and selective catalysts, zeolites.

Improvements in octane number of light and heavy naphtha are accomplished in isomerization and reforming processes respectively in the presence of hydrogen and metallic noble catalysts. High quality gasoline without aromatics is also formed via alkylation reactions of light olefins with isobutane in the presence of strong acid catalysts.

Catalytic addition of hydrogen to various refinery streams results to the removal of heteroatoms mainly of S and N, which have a negative environmental impact, the reduction in olefins and to a lesser extent to aromatics.

Hydroprocessing of final product and intermediate hydrocarbon streams and hydrocracking units for upgrading heavy intermediate products operating under various conditions consist an important part of a modern refinery. These factors underscores the need for catalyst for accomplishing refinery process thus anticipated to show strong growth demand in the forecast period.

Nanoporous materials forge a path forward to enable sustainable growth: technology advancements in fluid catalytic cracking

The fluid catalytic cracking (FCC) process represents an integral part of a refinery complex, providing the majority of gasoline consumed throughout the world in addition to other important transportation fuels. The FCC, in its current design, utilizes a well fluidizable catalyst that is continually added and withdrawn.

The catalyst facilitates the cracking of crude oil into important products including gasoline, diesel, jet fuel, and liquefied petroleum gases (LPGs). The FCC has been utilized in the industry for over 70 years, going from a single FCC unit in the USA to over 400 in operation today around the world. Since FCC's inception, the technology has undergone major transformations, including changes in both hardware and catalyst technologies.

Importantly, these transformations have ripple effects as a result of the flexibilities afforded by technology changes, the FCC is continually being pushed to its limits. Ancillary units have been implemented and have undergone dramatic changes as well, including crude oil desalters and particulate matter collectors.

Regulatory requirements have been put in place to push FCC limits even harder. For instance, improvements in hardware and catalyst technologies have enabled increased control of emissions, including particulate matter, NOx, and SOx.

To maximize profitability of a refinery, the FCC catalyst is specially designed to meet specific requirements of each unit including architectural concepts such as metals tolerance, surface area, rare earth on zeolite, matrix type, and carefully designed pore architecture.

In addition to significant catalyst developments since FCC's inception, additives have also played a large role in advancing FCC technology and capabilities.

Environmental additives aim to meet strict global regulations and to minimize the emission of pollutants; this category includes sulfur oxide (SOx) reduction additives, nitrogen oxide (NOx) reduction additives, and low NOx carbon monoxide (CO) promoter.

Performance additives were designed to meet moving economic and market trends and aim at shifting the yield slate off the FCC unit; this category includes olefins maximization additives, octane enhancement additives, CO promoters, gasoline sulfur reduction additives, and a variety of others including bottoms cracking, metals traps, fluidization aids, and co-catalysts.

Growing oil refinery industry propels the demand for refinery catalyst

Nowadays, the worldwide refining industry is focused on improving profit margins by cutting costs, making low capital investments, increasing operational efficiency, consolidating operations and outsourcing services.

This has motivated acquisition and mergers among oil companies, which have reduced the market base for catalyst producers. Large players benefit from strong buying power, which makes it difficult for catalyst manufacturers to raise prices. Mergers often lead to plant rationalization, with a true impact on catalyst consumption.

Catalyst companies have felt the profit margin pressures exerted by refiners that request speedy new product developments for complying with future fuel specifications, more technical support, engineering solutions and catalyst price concessions.

The catalyst companies are responding in a variety of ways to refinery profit margin pressure and the increased outsourcing demands of their customers. Some have stepped up their service offers; others have dissolved alliances and some have exited the business.

Like the refining industry, the catalyst companies have experienced numerous mergers and acquisitions in the past 5 years to reduce cost, improve profit margin and satisfy customers’ needs.

New trends in hydroprocessing spent catalysts utilization

The petroleum refinery may have multiple processes that use a catalyst. An essential component of the total cost of the refinery is the management of the catalyst stockpile. The expansion of catalyst use is intimately linked to the development of refining. Previously, more than half of the global catalyst usage came from refining catalysts.

Refinement catalysts now make up around one-third of all catalyst use due to the significance of environmental catalysis. The total amount of refinery catalyst used may be further reduced by future developments in the creation of more stable and active catalysts.

Worldwide refiners need to produce cleaner fuels and operate to meet environmental regulations. Therefore, refineries should convert more heavy feedstock's to satisfy regional fuel market needs, and minimize their profit margins which guides the developments in the refining catalyst market.

Refiners require more processing capacity and higher efficiency to satisfy regional fuel market needs, therefore, more catalyst consumption is needed and in the same be more resistant to deactivate under sever operating conditions.

Environmental laws concerning spent catalyst disposal have becomes increasingly more severe in recent years. Spent hydroprocessing catalysts have been classified as hazardous wastes by the Environmental Protection Agency (EPA) in the USA The most important hazardous characteristic of spent hydroprocessing catalysts is their toxic nature. Metals such as V, Ni, Mo and Co present in the catalyst can leached by water after disposal and pollute the environment.

Several alternative methods such as disposal in landfills, reclamation of metals, regeneration/ rejuvenation and reuse, and utilization as raw materials to produce other useful products are available to the refiners to deal with the spent catalyst problem. The choice between these options depends on technical feasibility and economic consideration.

To overcome the shortage of domestic resources and improve the environmental condition, many countries in the world pay much attention to the comprehensive utilization of the secondary resources. In Japan, recycling of the waste catalysts has already been in place since several years.

Increasing refinery capacity to meet the growing demand of fuel globally drives adoption of refinery catalysts

In 2023, global refining capacity was estimated at 103.5 million barrels per day (b/d). Refiners add capacity to meet customers’ fuel demands and to profit from market opportunities. In some countries, refiners are state-owned enterprises and may pursue refining projects to secure stable fuel supplies, reduce imports, or other reasons. Government mandates to produce cleaner fuels may also drive some expansions or investments in new units.

Through 2028, refining projects are concentrated in growing demand centers such as Asia and the Middle East. The economies and populations in these countries are generally growing faster than in the USA, Western Europe, and Japan. Countries in Asia and the Middle East face growing incomes and middle classes, will increase consumption of consumer goods and transportation fuels within the next 10 years.

As a result of these trends, refiners are adding capacity through at least 2028 to satisfy expected demand growth to 2050. Although there is significant growth in liquid fuels consumption in Africa after 2030, potential refinery capacity expansion projects in African countries are likely to face significant competitive pressure from imports from either the Atlantic or Indian Ocean basins.

The adoption of new refineries are being setup in the regions that have witnessed strong growth. In 2023, the world refining capacity stood at 103.5 million barrels per day, of which nearly half was in the USA, Western Europe, and Japan.

The refinery capacity in the Middle East, China, and India has showcased steady growth and made up more than one-third of the global refining capacity. All these factors are foreseen to drive the adoption of refinery catalyst in the near future.

Fluctuation oil prices, environmental regulations, and supply chain vulnerabilities is expected to hamper the market growth

Instability in oil prices directly hampers the entire oil and gas industry, including the refinery catalyst market. Fluctuating oil prices can lead to uncertainty in operational costs and investment planning. It necessitates adaptive strategies to maintain profitability and efficiency amidst variable economic conditions.

Stringent environmental regulations impact the design, operation, and maintenance of refineries. Buyers must seek catalysts that enhance operational efficiency and comply with the ever-evolving environmental standards. This has increased demand for innovative, eco-friendly catalyst solutions that align with global sustainability goals.

Supply chain disruptions can have a cascading effect on the refinery catalyst market and its clientele. The availability, timely delivery, and cost of catalysts are subject to the robustness of the global supply chain. End-users, particularly, have to develop contingency plans to mitigate the impact of potential supply chain disruptions on their operations.

For end-users, optimizing the use of catalysts to achieve maximum operational efficiency while minimizing costs and environmental impact is a prevailing challenge. It involves continuous monitoring, maintenance, and upgrading of catalyst systems to align with industry best practices and regulatory requirements.

Tier 1 companies comprise players with a revenue of above USD 1,000 million capturing a significant share of 40-45% in the global market. These players are characterized by high production capacity and a wide product portfolio.

These leaders are distinguished by their extensive expertise in manufacturing and reconditioning across multiple refinery catalysts and a broad geographical reach, underpinned by a robust consumer base. Prominent companies within Tier 1 include BASF, Shell, Clariant, Honeywell International Inc., and other players.

Tier 2 companies include mid-size players with revenue of below USD 1,000 million having a presence in specific regions and highly influencing the local industry. These are characterized by a strong presence overseas and strong industry knowledge.

These players have good technology and ensure regulatory compliance but may not have advanced technology and wide global reach. Prominent companies in tier 2 include Albemarle Corporation, W. R. Grace & Co., Haldor Topsoe, and other player.

The section below covers the industry analysis for refinery catalyst demand in different countries. The demand analysis on key countries in several regions of the globe, including North America, Latin America, East Asia, South Asia Pacific, Western Europe, Eastern Europe, Middle East, and Africa is provided.

China will hold 60.5% in East Asia due to its extensive refining capacity and strategic focus on maintaining energy security. The USA will capture 72.8% in North America owing to due to its substantial refining capacity, advanced infrastructure, and adherence to stringent environmental regulations.

Germany will lead Western Europe with 38.1% due to its advanced industrial base, significant refining capacity, and commitment to environmental sustainability.

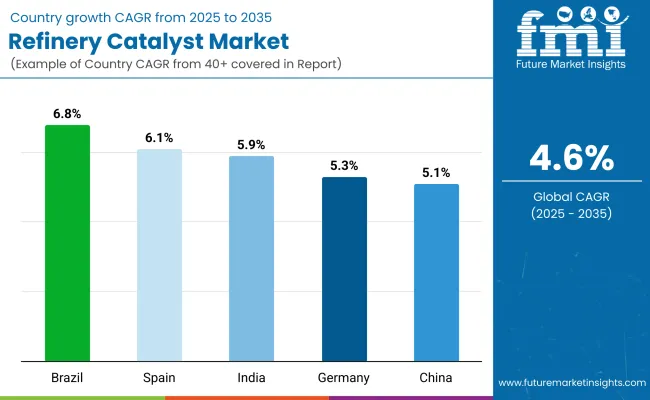

| Countries | Value CAGR (2025 to 2035) |

|---|---|

| Spain | 6.1% |

| India | 5.9% |

| Brazil | 6.8% |

| Germany | 5.3% |

| China | 5.1% |

The sales of refinery catalyst in China is projected to reach USD 2,266.8 million and is estimated to grow at an 5.1% CAGR by 2035.

China has largest refiners such as Sinopec’s Zhenhai and PetroChina’s Dalian refineries. These refiners contribute towards country’s gasoline production. As per the publication by USA Energy Information Administration (EIA), the total crude oil processing capacity stood at 14.8 million barrels per day in 2023. This indicates the strong demand for refinery catalyst in the China.

China’s strong domestic catalyst manufacturing industry bolsters its leadership position. Companies like Sinopec Catalyst Co. and CNPC-affiliated manufacturers have established themselves as key players, ensuring a reliable supply chain for domestic refineries.

Combined with governmental support for industrial innovation and infrastructure development, these factors solidify China’s dominance in the East Asian refinery catalyst market.

The sales of refinery catalyst in the USA are projected to reach USD 2,522.3 million by 2035.

Substantial refining capacity, advanced infrastructure, and adherence to stringent environmental regulations. The USA has large number of refineries thus seeking towards the development of refinery catalyst. For example, according to report by EIA the total refinery in USA stood at 132 (operable) as compared to 129 in 2022. This large number of refiners will further need refinery catalyst for producing gasoline products.

The presence of strong network of refineries primarily located along the Gulf Coast is another driving factor for refinery catalyst. These refineries not only meet domestic demand but also serve as significant exporters of refined petroleum products, necessitating consistent and advanced catalyst usage to optimize operations and ensure high output quality.

The sale of refinery catalyst in Germany is projected to reach USD 627.2 million and grow at a CAGR of 5.3% by 2035.

Germany has well-established refineries, such as those operated by Shell, BP, and TotalEnergies, which serve both domestic and regional markets. These refineries are strategically located and equipped with cutting-edge technologies, enabling efficient processing of crude oil and production of high-quality refined products.

This robust infrastructure ensures a steady demand for catalysts used in key processes like hydrocracking, hydrotreating, and fluid catalytic cracking (FCC).

Germany’s leadership is also driven by its stringent environmental regulations aimed at reducing greenhouse gas emissions and improving air quality. The country is a pioneer in adopting cleaner fuel standards, such as ultra-low sulfur diesel, which necessitates the use of advanced catalysts to meet regulatory requirements.

These measures not only support catalyst demand but also encourage the adoption of innovative catalyst technologies for cleaner and more efficient refining processes.

Key companies producing refinery catalyst are slightly consolidate the market with about 50-55% share that are prioritizing technological advancements, integrating sustainable practices, and expanding their footprints in the region.

Customer satisfaction remains paramount, with a keen focus on producing refinery catalyst to meet diverse applications. These industry leaders actively foster collaborations to stay at the forefront of innovation, ensuring their refinery catalyst align with the evolving demands and maintain the highest standards of quality and adaptability.

Recent Industry Developments

The Product Type segment is further categorized into Reforming Catalyst, Fluid Catalytic Cracking (FCC) Catalyst, Hydrotreating Catalyst, Hydrocracking Catalyst, Isomerization Catalyst, and Others.

The Ingredient segment is classified into Zeolites, Metals, and Chemical Compounds.

Regions considered in the study include North America, Latin America, Western Europe, Eastern Europe, East Asia, South Asia & Pacific, and the Middle East and Africa.

The global Refinery Catalyst Market is valued at USD 9.9 billion in 2025.

The demand for refinery catalyst industry is set to reach USD 15.7 billion in 2035.

The growth of the refinery catalyst market is driven by a combination of increasing energy demand, stricter environmental regulations, and advancements in refinery technologies. As the global population continues to grow, urbanization and industrialization have led to a surge in energy consumption, particularly in emerging economies such as China, India, and Southeast Asia.

The refinery catalyst demand was valued at USD 8,356.9 million in 2020 and is projected to reach USD 15.7 billion by 2035 growing at CAGR of 4.6% in the forecast period.

Zeolites is expected to lead during the forecast period.

Table 01: Global Refinery Catalyst Market Size Volume (Tons) and Value (US$ Mn) Forecast by Product Type, 2015–2030

Table 02: Global Refinery Catalyst Market Size Volume (Tons) and Value (US$ Mn) Forecast by Ingredient, 2015–2030

Table 03: Global Refinery Catalyst Market Size Volume (Tons) and Value (US$ Mn) Forecast by Region, 2015–2030

Table 04: North America Refinery Catalyst Market Size (US$ Mn) and Volume (Tons) Forecast by Country, 2015–2030

Table 05: North America Refinery Catalyst Market Volume (Tons) and Value (US$ Mn) Forecast by Product Type, 2015–2030

Table 06: North America Refinery Catalyst Market Size (US$ Mn) and Volume (Tons) Forecast by Ingredient, 2015–2030

Table 07: Latin America Refinery Catalyst Market Size (US$ Mn) and Volume (Tons) Forecast by Country, 2015–2030

Table 08: Latin America Refinery Catalyst Market Volume (Tons) and Value (US$ Mn) Forecast by Product Type, 2015–2030

Table 09: Latin America Refinery Catalyst Market Size (US$ Mn) and Volume (Tons) Forecast by Ingredient, 2015–2030

Table 10: Europe Refinery Catalyst Market Size (US$ Mn) and Volume (Tons) Forecast by Country, 2015–2030

Table 11: Europe Refinery Catalyst Market Volume (Tons) and Value (US$ Mn) Forecast by Product Type, 2015–2030

Table 12: Europe Refinery Catalyst Market Size (US$ Mn) and Volume (Tons) Forecast by Ingredient, 2015–2030

Table 13: Asia Pacific Refinery Catalyst Market Size (US$ Mn) and Volume (Tons) Forecast by Country, 2015–2030

Table 14: Asia Pacific Refinery Catalyst Market Volume (Tons) and Value (US$ Mn) Forecast by Product Type, 2015–2030

Table 15: Asia Pacific Refinery Catalyst Market Size (US$ Mn) and Volume (Tons) Forecast by Ingredient, 2015–2030

Table 16: MEA Refinery Catalyst Market Size (US$ Mn) and Volume (Tons) Forecast by Country, 2015–2030

Table 17: MEA Refinery Catalyst Market Volume (Tons) and Value (US$ Mn) Forecast by Product Type, 2015–2030

Table 18: MEA Refinery Catalyst Market Size (US$ Mn) and Volume (Tons) Forecast by Ingredient, 2015–2030

Figure 01: Global Refinery Catalyst Market Historical, Current and Forecast Volume (Tons), 2015 - 2030

Figure 02: Global Refinery Catalyst Market Historical, Current and Forecast Value (US$ Mn), 2015 - 2030

Figure 03: Global Refinery Catalyst Market Incremental $ Opportunity (US$ Mn), 2015 - 2030

Figure 04: Global Refinery Catalyst Market Share and BPS Analysis by Product Type– 2015, 2022 & 2030

Figure 05: Global Refinery Catalyst Market Y-o-Y Growth Projections by Product Type, 2021 - 2030

Figure 06: Global Refinery Catalyst Market Absolute $ Opportunity by FCC Segment

Figure 07: Global Refinery Catalyst Market Absolute $ Opportunity by Reforming Segment

Figure 08: Global Refinery Catalyst Market Absolute $ Opportunity by hydrotreating Segment

Figure 09: Global Refinery Catalyst Market Absolute $ Opportunity by Hydro Cracking Segment

Figure 10: Global Refinery Catalyst Market Absolute $ Opportunity by Isomerization & Alkylation Segment

Figure 11: Global Refinery Catalyst Market Attractiveness Analysis by Product Type, 2022-2030

Figure 12: Global Refinery Catalyst Market Share and BPS Analysis by Ingredient – 2015, 2022 & 2030

Figure 13: Global Refinery Catalyst Market Y-o-Y Growth Projections by Ingredient, 2021 - 2030

Figure 14: Global Refinery Catalyst Market Absolute $ Opportunity by Zeolites Segment

Figure 15: Global Refinery Catalyst Market Absolute $ Opportunity by Metals Segment

Figure 16: Global Refinery Catalyst Market Absolute $ Opportunity by Chemical Compound Segment

Figure 17: Global Refinery Catalyst Market Attractiveness Analysis by Ingredient, 2022-2030

Figure 18: Global Refinery Catalyst Market Share and BPS Analysis by Region– 2015, 2022 & 2030

Figure 19: Global Refinery Catalyst Market Y-o-Y Growth Projections by Region, 2021 - 2030

Figure 20: Global Refinery Catalyst Market Absolute $ Opportunity by North America Region, 2015-2030

Figure 21: Global Refinery Catalyst Market Absolute $ Opportunity by Latin America Region, 2015-2030

Figure 22: Global Refinery Catalyst Market Absolute $ Opportunity by Europe Region, 2015-2030

Figure 23: Global Refinery Catalyst Market Absolute $ Opportunity by Asia Pacific Region, 2015-2030

Figure 24: Global Refinery Catalyst Market Absolute $ Opportunity by MEA region, 2015-2030

Figure 25: Global Refinery Catalyst Market Attractiveness Analysis by Region, 2022-2030

Figure 26: North America Refinery Catalyst Market Share and BPS Analysis by Country– 2015, 2022 & 2030

Figure 27: North America Refinery Catalyst Market Y-o-Y Growth Projections by Country, 2021 - 2030

Figure 28: North America Refinery Catalyst Market Attractiveness Analysis by Country, 2022-2030

Figure 29: North America Refinery Catalyst Market Share and BPS Analysis by Product Type– 2015, 2022 & 2030

Figure 30: North America Refinery Catalyst Market Y-o-Y Growth Projections by Product Type, 2021 - 2030

Figure 31: North America Refinery Catalyst Market Attractiveness Analysis by Product Type, 2022-2030

Figure 32: North America Refinery Catalyst Market Share and BPS Analysis by Ingredient– 2015, 2022 & 2030

Figure 33: North America Refinery Catalyst Market Y-o-Y Growth Projections by Ingredient, 2021 - 2030

Figure 34: North America Refinery Catalyst Market Attractiveness Analysis by Ingredient, 2022-2030

Figure 35: Latin America Refinery Catalyst Market Share and BPS Analysis by Country– 2015, 2022 & 2030

Figure 36: Latin America Refinery Catalyst Market Y-o-Y Growth Projections by Country, 2021 - 2030

Figure 37: Latin America Refinery Catalyst Market Attractiveness Analysis by Country, 2022-2030

Figure 38: Latin America Refinery Catalyst Market Share and BPS Analysis by Product Type– 2015, 2022 & 2030

Figure 39: Latin America Refinery Catalyst Market Y-o-Y Growth Projections by Product Type, 2021 - 2030

Figure 40: Latin America Refinery Catalyst Market Attractiveness Analysis by Product Type, 2022-2030

Figure 41: Latin America Refinery Catalyst Market Share and BPS Analysis by Ingredient– 2015, 2022 & 2030

Figure 42: Latin America Refinery Catalyst Market Y-o-Y Growth Projections by Ingredient, 2021 - 2030

Figure 43: Latin America Refinery Catalyst Market Attractiveness Analysis by Ingredient, 2022-2030

Figure 44: Europe Refinery Catalyst Market Share and BPS Analysis by Country– 2015, 2022 & 2030

Figure 45: Europe Refinery Catalyst Market Y-o-Y Growth Projections by Country, 2021 - 2030

Figure 46: Europe Refinery Catalyst Market Attractiveness Analysis by Country, 2022-2030

Figure 47: Europe Refinery Catalyst Market Share and BPS Analysis by Product Type– 2015, 2022 & 2030

Figure 48: Europe Refinery Catalyst Market Y-o-Y Growth Projections by Product Type, 2021 - 2030

Figure 49: Europe Refinery Catalyst Market Attractiveness Analysis by Product Type, 2022-2030

Figure 50: Europe Refinery Catalyst Market Share and BPS Analysis by Ingredient– 2015, 2022 & 2030

Figure 51: Europe Refinery Catalyst Market Y-o-Y Growth Projections by Ingredient, 2021 - 2030

Figure 52: Europe Refinery Catalyst Market Attractiveness Analysis by Ingredient, 2022-2030

Figure 53: Asia Pacific Refinery Catalyst Market Share and BPS Analysis by Country– 2015, 2022 & 2030

Figure 54: Asia Pacific Refinery Catalyst Market Y-o-Y Growth Projections by Country, 2021 - 2030

Figure 55: Asia Pacific Refinery Catalyst Market Attractiveness Analysis by Country, 2022-2030

Figure 56: Asia Pacific Refinery Catalyst Market Share and BPS Analysis by Product Type– 2015, 2022 & 2030

Figure 57: Asia Pacific Refinery Catalyst Market Y-o-Y Growth Projections by Product Type, 2021 - 2030

Figure 58 Asia Pacific Refinery Catalyst Market Attractiveness Analysis by Product Type, 2022-2030

Figure 59: Asia Pacific Refinery Catalyst Market Share and BPS Analysis by Ingredient– 2015, 2022 & 2030

Figure 60: Asia Pacific Refinery Catalyst Market Y-o-Y Growth Projections by Ingredient, 2021 - 2030

Figure 61: Asia Pacific Refinery Catalyst Market Attractiveness Analysis by Ingredient, 2022-2030

Figure 62: MEA Refinery Catalyst Market Share and BPS Analysis by Country– 2015, 2022 & 2030

Figure 63: MEA Refinery Catalyst Market Y-o-Y Growth Projections by Country, 2021 - 2030

Figure 64: MEA Refinery Catalyst Market Attractiveness Analysis by Country, 2022-2030

Figure 65: MEA Refinery Catalyst Market Share and BPS Analysis by Product Type– 2015, 2022 & 2030

Figure 66: MEA Refinery Catalyst Market Y-o-Y Growth Projections by Product Type, 2021 - 2030

Figure 67: MEA Refinery Catalyst Market Attractiveness Analysis by Product Type, 2022-2030

Figure 68: MEA Refinery Catalyst Market Share and BPS Analysis by Ingredient– 2015, 2022 & 2030

Figure 69: MEA Refinery Catalyst Market Y-o-Y Growth Projections by Ingredient, 2021 - 2030

Figure 70: MEA Refinery Catalyst Market Attractiveness Analysis by Ingredient, 2022-2030

Our Research Products

The "Full Research Suite" delivers actionable market intel, deep dives on markets or technologies, so clients act faster, cut risk, and unlock growth.

The Leaderboard benchmarks and ranks top vendors, classifying them as Established Leaders, Leading Challengers, or Disruptors & Challengers.

Locates where complements amplify value and substitutes erode it, forecasting net impact by horizon

We deliver granular, decision-grade intel: market sizing, 5-year forecasts, pricing, adoption, usage, revenue, and operational KPIs—plus competitor tracking, regulation, and value chains—across 60 countries broadly.

Spot the shifts before they hit your P&L. We track inflection points, adoption curves, pricing moves, and ecosystem plays to show where demand is heading, why it is changing, and what to do next across high-growth markets and disruptive tech

Real-time reads of user behavior. We track shifting priorities, perceptions of today’s and next-gen services, and provider experience, then pace how fast tech moves from trial to adoption, blending buyer, consumer, and channel inputs with social signals (#WhySwitch, #UX).

Partner with our analyst team to build a custom report designed around your business priorities. From analysing market trends to assessing competitors or crafting bespoke datasets, we tailor insights to your needs.

Supplier Intelligence

Discovery & Profiling

Capacity & Footprint

Performance & Risk

Compliance & Governance

Commercial Readiness

Who Supplies Whom

Scorecards & Shortlists

Playbooks & Docs

Category Intelligence

Definition & Scope

Demand & Use Cases

Cost Drivers

Market Structure

Supply Chain Map

Trade & Policy

Operating Norms

Deliverables

Buyer Intelligence

Account Basics

Spend & Scope

Procurement Model

Vendor Requirements

Terms & Policies

Entry Strategy

Pain Points & Triggers

Outputs

Pricing Analysis

Benchmarks

Trends

Should-Cost

Indexation

Landed Cost

Commercial Terms

Deliverables

Brand Analysis

Positioning & Value Prop

Share & Presence

Customer Evidence

Go-to-Market

Digital & Reputation

Compliance & Trust

KPIs & Gaps

Outputs

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

UK Refinery Catalyst Market Insights – Growth, Applications & Outlook 2025-2035

USA Refinery Catalyst Market Report - Trends & Innovations 2025 to 2035

Japan Refinery Catalyst Market Report – Trends, Demand & Industry Forecast 2025-2035

ASEAN Refinery Catalyst Market Analysis

Germany Refinery Catalyst Market Analysis – Size, Share & Forecast 2025-2035

Refinery Process Chemical Market Size and Share Forecast Outlook 2025 to 2035

Refinery fuel additives Market Size and Share Forecast Outlook 2025 to 2035

Refinery and Petrochemical Filtration Market Analysis by Filter Type, Application, End-User and Region 2025 to 2035

Catalyst Bins Market Insights – Growth & Forecast 2025 to 2035

Biocatalyst Market Size and Share Forecast Outlook 2025 to 2035

Nanocatalysts Market Size and Share Forecast Outlook 2025 to 2035

Titanium Catalyst for Polyester Market Size and Share Forecast Outlook 2025 to 2035

Chemical Catalyst Market Size and Share Forecast Outlook 2025 to 2035

Petroleum Refinery Merchant Hydrogen Generation Market Size and Share Forecast Outlook 2025 to 2035

Petroleum Refinery Hydrogen Market Size and Share Forecast Outlook 2025 to 2035

Polyolefin Catalyst Market Size and Share Forecast Outlook 2025 to 2035

Polyurethane Catalyst Market Size and Share Forecast Outlook 2025 to 2035

BDO Synthesis Catalyst Market Size and Share Forecast Outlook 2025 to 2035

Environmental Catalysts Market Trends & Growth 2025 to 2035

Copper Bismuth Catalyst Market Size and Share Forecast Outlook 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA