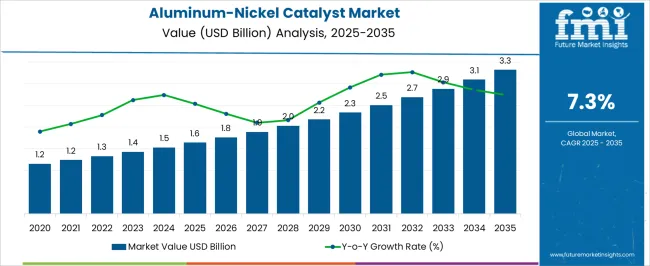

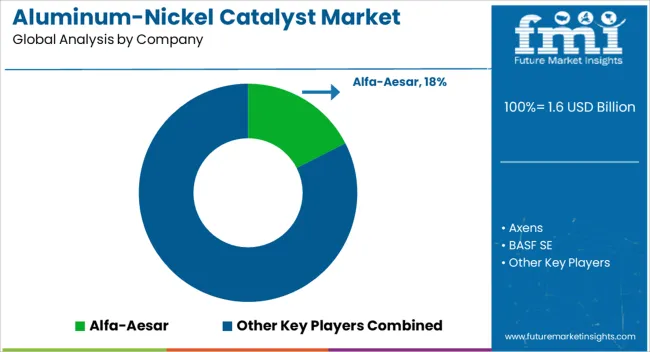

The Aluminum-Nickel Catalyst Market is estimated to be valued at USD 1.6 billion in 2025 and is projected to reach USD 3.3 billion by 2035, registering a compound annual growth rate (CAGR) of 7.3% over the forecast period.

| Metric | Value |

|---|---|

| Aluminum-Nickel Catalyst Market Estimated Value in (2025 E) | USD 1.6 billion |

| Aluminum-Nickel Catalyst Market Forecast Value in (2035 F) | USD 3.3 billion |

| Forecast CAGR (2025 to 2035) | 7.3% |

The Aluminum-Nickel Catalyst market is witnessing consistent expansion, supported by its growing role in chemical synthesis, refining processes, and industrial hydrogenation applications. Rising demand from petrochemical, pharmaceutical, and specialty chemical industries is a major driver of growth. Aluminum-nickel catalysts are valued for their high surface area, excellent activity, and durability, which make them critical in achieving efficiency across multiple reaction processes.

Refining companies are increasingly adopting these catalysts for hydrogenation and desulfurization activities, driven by the global push for cleaner fuels and stricter emission standards. At the same time, pharmaceutical firms rely on them for producing active pharmaceutical ingredients with greater precision and reliability. Ongoing technological advancements, including improvements in catalyst regeneration and recycling, are further supporting cost-effectiveness and sustainability.

Increasing focus on reducing environmental footprints across industries has also highlighted the importance of efficient catalytic processes Additionally, rising investments in industrial infrastructure and capacity expansions in emerging economies are expanding demand potential Collectively, these trends are reinforcing the Aluminum-Nickel Catalyst market as a critical enabler of industrial innovation and operational efficiency.

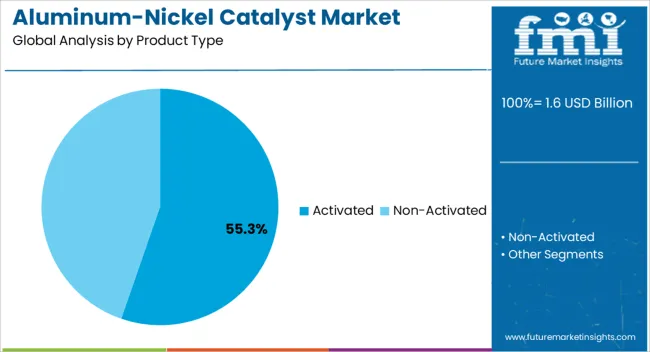

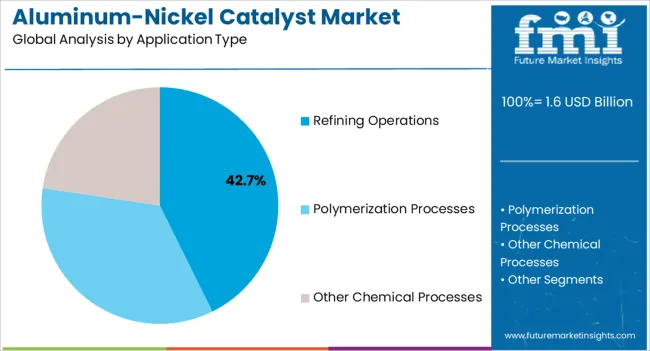

The aluminum-nickel catalyst market is segmented by product type, application type, and geographic regions. By product type, aluminum-nickel catalyst market is divided into Activated and Non-Activated. In terms of application type, aluminum-nickel catalyst market is classified into Refining Operations, Polymerization Processes, and Other Chemical Processes. Regionally, the aluminum-nickel catalyst industry is classified into North America, Latin America, Western Europe, Eastern Europe, Balkan & Baltic Countries, Russia & Belarus, Central Asia, East Asia, South Asia & Pacific, and the Middle East & Africa.

The activated product type segment is projected to account for 55.3% of the Aluminum-Nickel Catalyst market revenue share in 2025, making it the leading product category. This leadership is attributed to its superior reactivity, high surface area, and efficiency in enabling selective hydrogenation processes across industries. Activated aluminum-nickel catalysts are widely employed in fine chemical and pharmaceutical production, where consistent performance and high yields are essential.

Their application in hydrogenation reactions, such as converting nitro compounds into amines or refining edible oils, has strengthened demand in both industrial and consumer sectors. Refining companies are adopting activated variants to ensure compliance with environmental regulations that demand low-sulfur and high-quality fuels. Cost efficiency and adaptability for recycling further enhance their appeal, aligning with the growing emphasis on sustainable industrial practices.

The increasing number of chemical production plants and refining facilities in emerging economies is also driving demand As manufacturers prioritize performance, reliability, and sustainability, the activated product type segment is positioned to maintain dominance through innovation and expanded application scope.

The refining operations application segment is anticipated to hold 42.7% of the Aluminum-Nickel Catalyst market revenue in 2025, positioning it as the leading application area. This dominance stems from the critical role these catalysts play in hydrogenation and desulfurization processes that enable cleaner fuel production. Global regulatory frameworks mandating reduced sulfur content in fuels are compelling refiners to adopt efficient catalysts to meet stringent standards.

Aluminum-nickel catalysts provide consistent results under high-pressure conditions, ensuring reliability in large-scale refining operations. Their role in improving fuel quality while reducing environmental emissions has made them indispensable across global refining networks. Growing energy consumption, particularly in developing economies, is further boosting refining capacity expansions, thereby supporting demand for catalysts.

Additionally, advancements in catalyst regeneration technologies are helping refiners reduce operational costs while maintaining sustainability goals Strategic investments in upgrading refining infrastructure are reinforcing the reliance on aluminum-nickel catalysts As the global transition toward cleaner energy continues, refining operations are expected to remain the primary driver of market revenue, ensuring long-term demand stability for these catalysts.

Aluminum-nickel catalyst comprises fine particles of an aluminum-nickel alloy. This catalyst displays a high level of performance when used in catalytic hydrogenation reactions which are applied in the production of insecticide intermediates, rubber additives, sorbitol and dye and drug intermediates.

-nickel catalyst displays substantial structural as well as thermal stability, and hence finds application in high temperature, high pressure hydrogenation reactions. Aluminum-nickel catalyst is capable of participating in hydrogenation reactions involving any type of functional groups.

The inexpensiveness of aluminum-nickel catalyst is a major advantage, when compared with a noble element catalyst, such as a platinum catalyst. Another key advantage is the aluminum-nickel catalyst’s excellent performance.

However, its short lifespan and lower stability are proving to be of prime concerns in its commercial applications. For instance, upon drying, aluminum-nickel catalyst catches fire due to atmospheric conditions; thus, for storage it must be submerged in a suitable solvent such as ethanol or dioxane or water.

Also, aluminum-nickel catalyst displays some levels of toxicity, which could prove to be a restraint in its demand and hence, hamper market growth.

Hence, the study of the aluminum-nickel catalyst market makes for an important read with regard to the overall catalyst market.

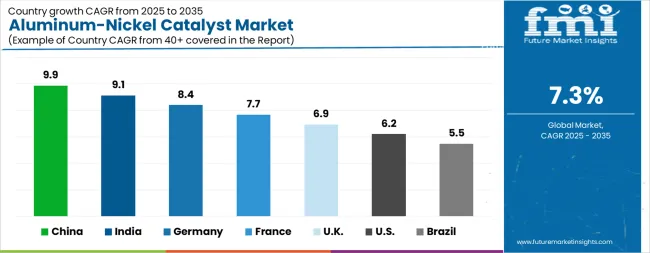

| Country | CAGR |

|---|---|

| China | 9.9% |

| India | 9.1% |

| Germany | 8.4% |

| France | 7.7% |

| UK | 6.9% |

| USA | 6.2% |

| Brazil | 5.5% |

The Aluminum-Nickel Catalyst Market is expected to register a CAGR of 7.3% during the forecast period, exhibiting varied country level momentum. China leads with the highest CAGR of 9.9%, followed by India at 9.1%. Developed markets such as Germany, France, and the UK continue to expand steadily, while the USA is likely to grow at consistent rates. Brazil posts the lowest CAGR at 5.5%, yet still underscores a broadly positive trajectory for the global Aluminum-Nickel Catalyst Market. In 2024, Germany held a dominant revenue in the Western Europe market and is expected to grow with a CAGR of 8.4%. The USA Aluminum-Nickel Catalyst Market is estimated to be valued at USD 606.6 million in 2025 and is anticipated to reach a valuation of USD 1.1 billion by 2035. Sales are projected to rise at a CAGR of 6.2% over the forecast period between 2025 and 2035. While Japan and South Korea markets are estimated to be valued at USD 86.9 million and USD 48.5 million respectively in 2025.

| Item | Value |

|---|---|

| Quantitative Units | USD 1.6 Billion |

| Product Type | Activated and Non-Activated |

| Application Type | Refining Operations, Polymerization Processes, and Other Chemical Processes |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, Middle East & Africa |

| Country Covered | United States, Canada, Germany, France, United Kingdom, China, Japan, India, Brazil, South Africa |

| Key Companies Profiled | Alfa-Aesar, Axens, BASF SE, Evonik In-dustries AG, Haldor Topsoe A/S, Hangzhou Jiali metal Technology Co. Ltd., Johnson Matthey, Sigma Aldrich, Vineeth Chemicals, and W. R. Grace & Co |

The global aluminum-nickel catalyst market is estimated to be valued at USD 1.6 billion in 2025.

The market size for the aluminum-nickel catalyst market is projected to reach USD 3.3 billion by 2035.

The aluminum-nickel catalyst market is expected to grow at a 7.3% CAGR between 2025 and 2035.

The key product types in aluminum-nickel catalyst market are activated and non-activated.

In terms of application type, refining operations segment to command 42.7% share in the aluminum-nickel catalyst market in 2025.

Our Research Products

The "Full Research Suite" delivers actionable market intel, deep dives on markets or technologies, so clients act faster, cut risk, and unlock growth.

The Leaderboard benchmarks and ranks top vendors, classifying them as Established Leaders, Leading Challengers, or Disruptors & Challengers.

Locates where complements amplify value and substitutes erode it, forecasting net impact by horizon

We deliver granular, decision-grade intel: market sizing, 5-year forecasts, pricing, adoption, usage, revenue, and operational KPIs—plus competitor tracking, regulation, and value chains—across 60 countries broadly.

Spot the shifts before they hit your P&L. We track inflection points, adoption curves, pricing moves, and ecosystem plays to show where demand is heading, why it is changing, and what to do next across high-growth markets and disruptive tech

Real-time reads of user behavior. We track shifting priorities, perceptions of today’s and next-gen services, and provider experience, then pace how fast tech moves from trial to adoption, blending buyer, consumer, and channel inputs with social signals (#WhySwitch, #UX).

Partner with our analyst team to build a custom report designed around your business priorities. From analysing market trends to assessing competitors or crafting bespoke datasets, we tailor insights to your needs.

Supplier Intelligence

Discovery & Profiling

Capacity & Footprint

Performance & Risk

Compliance & Governance

Commercial Readiness

Who Supplies Whom

Scorecards & Shortlists

Playbooks & Docs

Category Intelligence

Definition & Scope

Demand & Use Cases

Cost Drivers

Market Structure

Supply Chain Map

Trade & Policy

Operating Norms

Deliverables

Buyer Intelligence

Account Basics

Spend & Scope

Procurement Model

Vendor Requirements

Terms & Policies

Entry Strategy

Pain Points & Triggers

Outputs

Pricing Analysis

Benchmarks

Trends

Should-Cost

Indexation

Landed Cost

Commercial Terms

Deliverables

Brand Analysis

Positioning & Value Prop

Share & Presence

Customer Evidence

Go-to-Market

Digital & Reputation

Compliance & Trust

KPIs & Gaps

Outputs

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Catalyst Bins Market Insights – Growth & Forecast 2025 to 2035

Biocatalyst Market Size and Share Forecast Outlook 2025 to 2035

Nanocatalysts Market Size and Share Forecast Outlook 2025 to 2035

Titanium Catalyst for Polyester Market Size and Share Forecast Outlook 2025 to 2035

Chemical Catalyst Market Size and Share Forecast Outlook 2025 to 2035

Refinery Catalyst Market Growth - Trends & Forecast 2025 to 2035

Polyolefin Catalyst Market Size and Share Forecast Outlook 2025 to 2035

UK Refinery Catalyst Market Insights – Growth, Applications & Outlook 2025-2035

Polyurethane Catalyst Market Size and Share Forecast Outlook 2025 to 2035

USA Refinery Catalyst Market Report - Trends & Innovations 2025 to 2035

BDO Synthesis Catalyst Market Size and Share Forecast Outlook 2025 to 2035

Environmental Catalysts Market Trends & Growth 2025 to 2035

Copper Bismuth Catalyst Market Size and Share Forecast Outlook 2025 to 2035

Japan Refinery Catalyst Market Report – Trends, Demand & Industry Forecast 2025-2035

ASEAN Refinery Catalyst Market Analysis

Emission Control Catalyst for Small Engines Market - Size, Share, and Forecast 2025 to 2035

Motorcycle Emission Control Catalyst Market Growth - Trends & Forecast 2025 to 2035

High-Performance Catalyst Market Trend Analysis Based on Product, End-Use, and Region 2025-2035

Germany Refinery Catalyst Market Analysis – Size, Share & Forecast 2025-2035

Hydro-processing Catalysts Market Growth - Trends & Forecast 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA