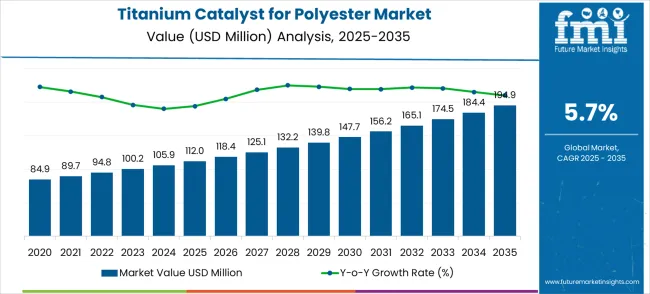

The titanium catalyst for polyester market is valued at USD 112.0 million in 2025 and is projected to grow to USD 194.9 million by 2035, reflecting a CAGR of 5.7%. The market growth curve demonstrates a consistent upward trajectory, characterized by incremental annual growth, with a slight acceleration over time. From 2021 to 2025, the market increases steadily from USD 84.9 million to USD 112.0 million. Early-stage growth is marked by slower progression, with the market moving through USD 89.7 million in 2022, USD 94.8 million in 2023, USD 100.2 million in 2024, and USD 105.9 million in 2025.

Between 2026 and 2030, the market's growth curve becomes slightly steeper, with values advancing from USD 112.0 million to USD 147.7 million. During this period, growth is supported by technological innovations and rising demand for eco-friendlier production methods, contributing to a sharper market expansion. The market is projected to progress to USD 118.4 million in 2026, USD 125.1 million in 2027, and USD 132.2 million in 2028, driven by the accelerating adoption of titanium catalysts in polyester production. By 2035, the market is expected to reach USD 194.9 million, with intermediate growth values of USD 156.2 million, USD 165.1 million, USD 174.5 million, and USD 184.4 million. The curve shape in this phase illustrates stable growth, underpinned by the continued preference for eco-friendly, high-performance materials.

| Metric | Value |

|---|---|

| Market Value (2025) | USD 112.0 million |

| Market Forecast Value (2035) | USD 194.9 million |

| Market Forecast CAGR | 5.7% |

The polyester production market is the largest contributor, accounting for around 30–35%, as titanium catalysts are essential for enhancing reaction efficiency and product quality during the polymerization process. The chemical catalysts market contributes approximately 20–25%, where titanium-based catalysts are favored for their high efficiency, durability, and ability to facilitate polymerization at lower temperatures and pressures. In the textile manufacturing market, which holds about 15–18%, the demand for titanium catalysts is driven by their use in producing high-quality polyester fibers, which are crucial for durable textiles, garments, and industrial applications.

The automotive market accounts for around 10–12%, with polyester-based materials used in interior upholstery, carpeting, and composite parts, all of which benefit from titanium catalysts. The packaging market, which contributes approximately 8–10%, relies on titanium catalysts to enhance the strength, clarity, and performance of polyester films, particularly in food and beverage packaging applications.

Market expansion is being supported by the rapid shift toward eco-friendly polyester production worldwide and the corresponding need for environmentally friendly catalyst systems that provide superior performance and regulatory compliance. Modern polyester manufacturing operations rely on consistent catalyst performance and environmental safety to ensure optimal production efficiency including PET bottle production, textile fiber manufacturing, and specialty polyester applications. Even minor catalyst impurities or environmental concerns can result in substantial regulatory issues requiring comprehensive catalyst system upgrades to maintain optimal manufacturing standards and environmental compliance.

The growing complexity of polyester production requirements and increasing demand for high-purity, environmentally safe catalyst solutions are driving demand for titanium catalysts from certified manufacturers with appropriate performance capabilities and environmental expertise. Polyester manufacturers and chemical companies are increasingly requiring documented environmental safety and product purity to maintain production quality and regulatory effectiveness. Industry specifications and environmental standards are establishing standardized polyester production procedures that require specialized titanium catalyst technologies and trained process engineers.

The titanium catalyst for polyester market is entering a transformative growth phase driven by increasing environmental awareness, rising demand for green manufacturing, and technological advancement. As polyester producers, packaging companies, and chemical manufacturers across both developed and emerging markets seek solutions that deliver superior catalytic performance, environmental safety, and comprehensive production capabilities, titanium catalysts are evolving from alternative catalyst options to essential enablers of eco-friendly polyester production integrated with advanced formulation technologies, enhanced selectivity features, and environmental monitoring capabilities.

Rising polyester production and green manufacturing adoption in Asia-Pacific, Latin America, and Middle East & Africa amplify demand, while manufacturers are advancing innovations in catalyst formulation, selectivity optimization, and environmental compatibility features. Pathways like nanotechnology integration, bio-based catalyst development, and circular economy solutions promise strong margin uplift, especially in mature markets. Geographic expansion and localization will capture volume growth, particularly where polyester manufacturing infrastructure is developing programs are expanding. Environmental regulation pressures, food safety requirements, and eco-friendly packaging initiatives provide structural market support.

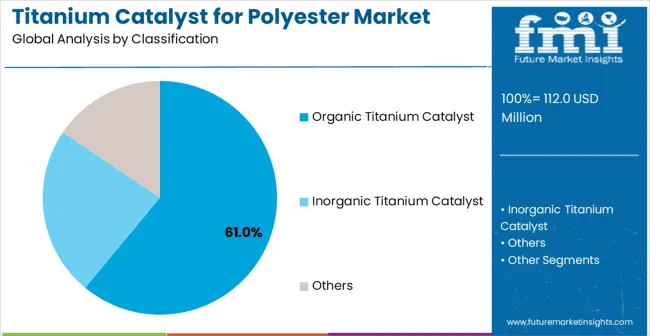

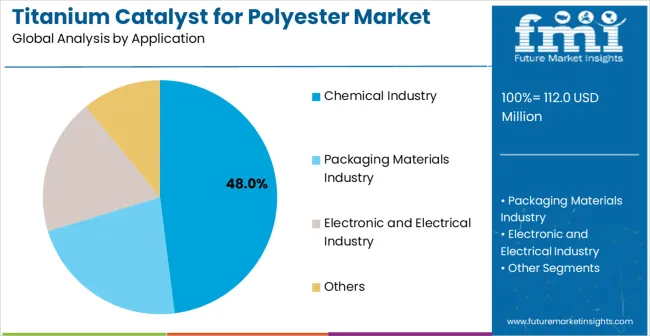

The market is segmented by catalyst type, application, and region. By catalyst type, the market is divided into organic titanium catalyst, inorganic titanium catalyst, and others. Based on application, the market is categorized into chemical industry, packaging materials industry, electronic and electrical industry, and others. Regionally, the market is divided into North America, Europe, East Asia, South Asia & Pacific, Latin America, and Middle East & Africa.

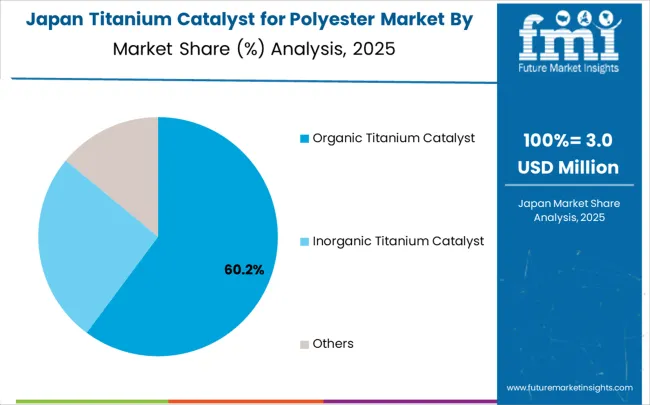

In 2025, the organic titanium catalyst segment is projected to capture around 61% of the total market share, making it the leading catalyst type category. This dominance is largely driven by the widespread adoption of organic titanium compounds that deliver superior catalytic performance with excellent selectivity and reduced environmental impact in polyester production processes. The organic titanium catalyst segment is particularly favored for its ability to provide consistent polymerization control and high-quality end products while maintaining environmental safety standards required for food-contact packaging applications. Polyester manufacturers, packaging producers, chemical companies, and specialty polymer facilities increasingly prefer organic titanium catalyst technology, as it meets stringent purity requirements without imposing excessive environmental concerns or regulatory complications. The availability of well-established organic titanium formulations, along with comprehensive technical support and application expertise from leading catalyst manufacturers, further reinforces the segment's market position. This catalyst type benefits from consistent demand across regions, as it is considered a proven solution for applications requiring high purity and environmental compliance. The combination of catalytic efficiency, product quality, and environmental safety makes organic titanium catalysts a preferred choice, ensuring continued popularity in the polyester catalyst market. Advanced formulation capabilities and enhanced environmental compatibility features continue to drive adoption among professional polyester and packaging manufacturers seeking superior catalytic performance.

The chemical industry segment is expected to represent 48% of titanium catalyst for polyester demand in 2025, solidifying its position as the largest application sector. This dominance arises from the critical role catalyst performance plays in large-scale polyester production, where consistent catalytic activity and product quality are essential for maintaining production efficiency and economic viability. Chemical industry applications often involve continuous production processes that demand reliable catalyst performance over extended manufacturing campaigns, requiring stable and effective titanium catalyst systems. Titanium catalysts are particularly well-suited for these applications, offering consistent polymerization results and high-quality polyester resins, all while ensuring environmental compliance and safety standards. As chemical companies expand globally and emphasize enhanced production efficiency and environmental stewardship, the demand for titanium catalysts continues to grow. The segment also benefits from a heightened focus on eco-friendly manufacturing practices, with chemical producers prioritizing safe catalysts and responsible production methods as key components of their broader environmental programs. With increased investments in production optimization and regulatory compliance, titanium catalysts serve as a critical solution to support high-performance polyester production. The rise of green chemistry initiatives, alongside a greater emphasis on environmental responsibility, guarantees that the chemical industry will remain the largest and most stable driver of titanium catalyst demand during the forecast period. Enhanced catalytic efficiency and improved environmental performance continue to bolster the segment's market position

The Titanium Catalyst for Polyester market is advancing steadily due to increasing environmental regulations and growing recognition of titanium catalyst technology advantages over conventional antimony-based catalyst systems in polyester production. The market faces challenges including higher costs compared to traditional catalyst systems, need for specialized handling and storage procedures for optimal performance, and varying regulatory requirements across different regions and applications. Technology advancement efforts and environmental compliance optimization programs continue to influence catalyst development and market adoption patterns.

The growing development of advanced titanium catalyst formulations is enabling improved catalytic efficiency with enhanced selectivity and reduced side reaction characteristics. Enhanced formulation technologies and optimized catalyst compositions provide superior polymerization performance while maintaining strict environmental and purity standards required for polyester applications. These technologies are particularly valuable for polyester and packaging manufacturers that require reliable catalyst performance supporting extensive production operations with consistent quality and environmental compliance.

Modern titanium catalyst manufacturers are incorporating advanced process monitoring features and comprehensive optimization systems that enhance production efficiency and quality control capabilities. Integration of advanced analytical technologies and optimized process control algorithms enables superior production results and comprehensive quality monitoring capabilities. Advanced monitoring features support operation in diverse production environments while meeting various quality requirements and regulatory specifications, including food-contact packaging, textile production, and specialty polyester applications.

The continuous development of eco-friendly catalyst technologies and circular economy principles is minimizing environmental impact while maintaining consistent catalytic performance throughout production processes. Advanced green features and intelligent environmental management offer reduced ecological footprints that support comprehensive polyester manufacturing activities without compromising performance. These eco-innovations are particularly valuable for manufacturers engaged in environmentally-conscious production operations, where environmental stewardship and consistent performance are essential for maintaining effective production and ensuring regulatory compliance.

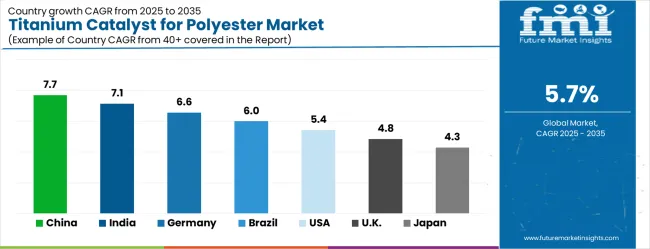

| Country | CAGR (2025-2035) |

|---|---|

| China | 7.7% |

| India | 7.1% |

| Germany | 6.6% |

| Brazil | 6.0% |

| United States | 5.4% |

| United Kingdom | 4.8% |

| Japan | 4.3% |

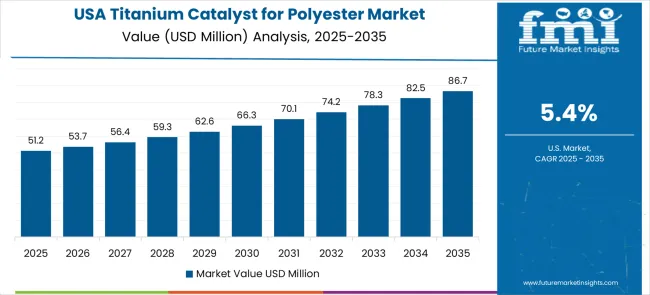

The titanium catalyst for polyester market is expanding rapidly, with China leading at a 7.7% CAGR through 2035, fueled by robust polyester manufacturing growth and the increasing adoption of eco-friendly catalyst technologies. India follows closely at 7.1%, driven by the expansion of chemical industry infrastructure and rising awareness of environmental catalyst solutions. Germany experiences steady growth at 6.6%, incorporating advanced titanium catalyst systems into its well-established chemical and packaging manufacturing sectors. Brazil shows a 6.0% increase, focusing on chemical industry modernization and environmental compliance efforts. The United States demonstrates solid growth at 5.4%, with an emphasis on eco-consciousness and regulatory compliance improvements. The United Kingdom exhibits steady progress at 4.8%, maintaining its established eco-friendly manufacturing applications. Japan achieves a 4.3% growth, focusing on technology refinement and quality optimization.

The report covers an in-depth analysis of 40+ countries, with top-performing countries highlighted below.

Revenue from titanium catalysts for polyester in China is projected to exhibit the highest growth rate, with a CAGR of 7.7% through 2035, driven by rapid expansion of polyester manufacturing infrastructure and growing demand for eco-friendly catalyst systems. The country’s increasing focus on modernizing its chemical industry and expanding polyester production capacity is generating substantial demand for advanced titanium catalyst solutions. Major polyester manufacturers and chemical companies are building comprehensive supply chains to support the rising needs of production facilities and packaging companies, particularly in PET bottle manufacturing and textile fiber applications. Government-backed environmental initiatives are facilitating the development of green manufacturing capabilities and advanced catalyst systems, fueling the need for sophisticated titanium catalyst technology throughout major chemical clusters and manufacturing corridors. Chemical industry modernization programs are encouraging the integration of environmentally conscious catalyst technology, enhancing both production efficiency and environmental compliance across manufacturing networks. The Chinese government’s commitment to environmental protection and eco-conscious manufacturing is accelerating investments in advanced catalyst technologies, including titanium-based systems. Urban development projects and packaging industry initiatives are adopting responsible production practices, which require high-performance catalyst solutions. The expansion of commercial polyester production and a focus on environmental compliance are further driving demand for professional-grade titanium catalyst equipment that meets international performance and environmental standards.

Revenue from titanium catalyst for polyester in India is expanding at a CAGR of 7.1%, supported by increasing chemical industry development and growing awareness of eco-friendly catalyst technology benefits. The country's expanding chemical infrastructure and rising environmental compliance standards are driving demand for professional-grade titanium catalyst solutions. Chemical companies and polyester manufacturers are gradually implementing advanced titanium catalyst technology to maintain production standards and environmental effectiveness. Chemical sector growth and infrastructure development are creating opportunities for suppliers that can support diverse production requirements and environmental compliance specifications. Professional training and technology adoption programs are building technical expertise among chemical industry personnel, enabling effective utilization of titanium catalyst technology that meets production standards and environmental requirements across industrial regions. India's rapid chemical industry development and increasing polyester production are intensifying the need for effective catalyst management and environmental compliance capabilities. National chemical development programs and industrial park construction projects are establishing comprehensive production systems that require advanced catalyst equipment. State government initiatives focusing on chemical industry improvement and environmental protection are driving procurement of modern titanium catalyst technology for chemical and packaging companies. The growing emphasis on green manufacturing and environmental compliance is supporting adoption of internationally certified catalyst systems.

Demand for titanium catalyst for polyester in Germany is projected to grow at a CAGR of 6.6%, supported by the country's emphasis on chemical manufacturing excellence and advanced environmental technology adoption. German chemical and packaging manufacturers are implementing sophisticated titanium catalyst systems that meet stringent performance requirements and environmental specifications. The market is characterized by focus on catalyst efficiency, environmental compliance, and integration with comprehensive standards. Chemical industry investments are prioritizing advanced catalyst technology that demonstrates superior performance and environmental responsibility while meeting German engineering and quality standards. Professional certification programs are ensuring comprehensive technical expertise among chemical industry personnel, enabling specialized catalyst capabilities that support diverse chemical manufacturing applications and operational requirements across industrial networks. Germany's commitment to maintaining the highest chemical manufacturing and environmental standards in Europe drives continuous investment in cutting-edge catalyst technology. The country's comprehensive chemical manufacturing infrastructure requires sophisticated catalyst equipment that meets strict performance and environmental control standards. Integration with digital manufacturing systems and automated production networks is creating demand for advanced titanium catalyst technology with enhanced monitoring capabilities. Regional chemical companies are modernizing their production capabilities through procurement of state-of-the-art catalyst equipment that supports both polyester and packaging manufacturing operations.

Revenue from titanium catalyst for polyester in Brazil is growing at a CAGR of 6.0%, driven by increasing chemical industry development and growing recognition of eco-friendly catalyst technology advantages. The country's expanding chemical production system is gradually integrating professional-grade titanium catalyst technology to enhance manufacturing capabilities and environmental effectiveness. Chemical companies and manufacturing facilities are investing in catalyst technology to address evolving environmental requirements and production standards. Industrial modernization is facilitating adoption of advanced catalyst technologies that support comprehensive manufacturing capabilities across chemical production regions. Professional development programs are enhancing technical capabilities among chemical industry personnel, enabling effective titanium catalyst utilization that meets evolving environmental standards and operational requirements throughout manufacturing networks. Brazil's expanding chemical sector and growing packaging industry are driving demand for sophisticated production catalyst equipment. Federal and state government initiatives focused on improving chemical industry capabilities and environmental protection are supporting procurement of modern titanium catalyst technology. Chemical industry development and increasing production efficiency in major industrial areas require enhanced catalyst capabilities that can support effective manufacturing operations. The expansion of green manufacturing services and specialized chemical programs is creating sustained demand for reliable, environmentally compliant catalyst equipment.

The titanium catalyst for polyester market in the USA is expanding at a CAGR of 5.4%, driven by established chemical and packaging industries and a growing focus on enhancing environmental responsibility. Large chemical manufacturers and packaging companies are implementing comprehensive titanium catalyst systems to meet diverse production needs while adhering to environmental regulations. The market benefits from well-established chemical technology distribution networks and professional training programs that support a wide range of manufacturing applications. Chemical industry leadership is facilitating standardized catalyst usage across multiple production types, ensuring consistent performance and comprehensive environmental coverage throughout regional markets. Professional development and certification programs are fostering specialized technical expertise among chemical industry personnel, enabling effective utilization of titanium catalysts to meet evolving environmental requirements across manufacturing operations. The USA market is characterized by ongoing environmental progress and integration with modern manufacturing systems. Federal environmental initiatives are driving the procurement of advanced catalyst equipment that meets stringent performance and environmental standards. Chemical and packaging companies are modernizing their production capabilities by adopting cutting-edge catalyst technologies. The emphasis on eco-conscious practices and resource efficiency is fueling demand for environmentally safe, high-performance catalyst solutions that enhance manufacturing while upholding environmental and safety standards.

Demand for titanium catalyst for polyester in the UK is projected to grow at a CAGR of 4.8%, supported by established chemical sectors and growing emphasis on environmental manufacturing capabilities. British chemical operations and packaging companies are implementing titanium catalyst equipment that meets industry performance standards and environmental requirements. The market benefits from established chemical manufacturing infrastructure and comprehensive training programs for technical professionals. Environmental responsibility investments are prioritizing advanced catalyst equipment that supports diverse manufacturing applications while maintaining established performance and environmental standards. Professional development programs are building technical expertise among chemical industry personnel, enabling specialized titanium catalyst operation capabilities that meet evolving environmental requirements and quality standards throughout regional manufacturing networks. The United Kingdom's comprehensive environmental strategy and commitment to green manufacturing drives continued investment in advanced catalyst technology. Chemical operations across England, Wales, Scotland, and Northern Ireland are standardizing their catalyst equipment to ensure consistent environmental manufacturing capabilities. Integration with national environmental monitoring systems and coordination with regulatory compliance programs requires sophisticated titanium catalyst technology. The emphasis on professional chemical training and equipment certification is supporting adoption of high-quality catalyst systems that meet regulatory approval standards and operational requirements.

Revenue from titanium catalyst for polyester in Japan is growing at a CAGR of 4.3%, driven by the country's focus on chemical technology refinement and quality enhancement applications. Japanese chemical and materials companies are implementing advanced titanium catalyst systems that demonstrate superior performance reliability and operational efficiency. The market is characterized by emphasis on technological excellence, quality assurance, and integration with established chemical manufacturing workflows. Technology industry investments are prioritizing innovative catalyst solutions that combine advanced chemical technology with superior quality control while maintaining Japanese engineering and reliability standards. Professional development programs are ensuring comprehensive technical expertise among chemical industry personnel, enabling specialized catalyst capabilities that support diverse chemical manufacturing applications and operational requirements throughout metropolitan industrial networks. Japan's commitment to maintaining the highest standards of chemical manufacturing and quality control drives continuous innovation in catalyst technology. The integration of titanium catalyst systems with intelligent manufacturing infrastructure and automated chemical networks requires sophisticated catalyst capabilities. Chemical companies across Japan's industrial regions are modernizing their production equipment through procurement of cutting-edge catalyst technology that meets strict performance and reliability standards. The emphasis on precision chemistry and technological refinement is supporting development of next-generation catalyst systems with enhanced performance and operational capabilities.

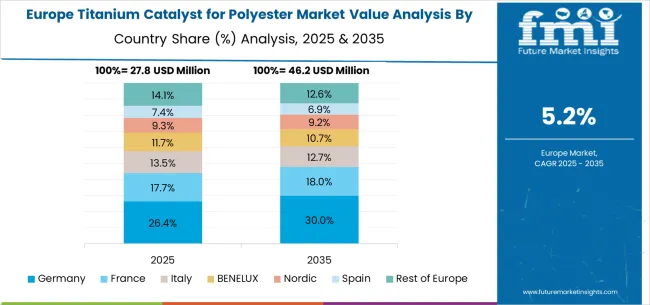

The titanium catalyst for polyester market in Europe is anticipated to expand from USD 26.8 million in 2025 to approximately USD 42.1 million by 2035, reflecting a CAGR of 4.6% during the forecast period. Germany is set to reinforce its leading position, commanding a 36.2% share of the European market in 2025, supported by its established chemical manufacturing infrastructure, high standards for environmental compliance, and continuous investment in advanced catalyst technologies. The United Kingdom follows with a market share of 16.4%, benefiting from standardized chemical manufacturing procedures, professional training programs, and a robust focus on environmental responsibility modernization. France is projected to capture 14.8% of the regional market, fueled by steady integration of modern catalyst equipment and enhancements in chemical manufacturing operations. Italy and Spain together represent 19.7% of total demand, as both countries advance their chemical manufacturing modernization efforts and invest in professional-grade catalyst solutions for polyester and packaging companies. The Rest of Europe, comprising Nordic countries, BENELUX, and Eastern European markets, accounts for 12.9%, driven by regulatory convergence, infrastructure upgrading, and broader adoption of advanced titanium catalyst technology to support evolving environmental requirements and green manufacturing programs.

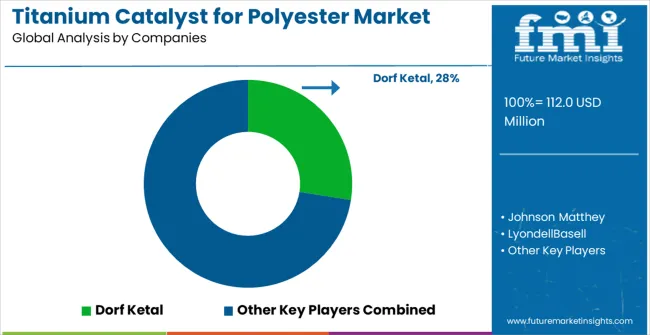

The titanium catalyst for polyester market is defined by competition among specialized catalyst manufacturers, chemical technology companies, and green manufacturing solution providers. Companies are investing in advanced catalyst formulation development, environmental compliance optimization, performance enhancement improvements, and comprehensive service capabilities to deliver effective, environmentally safe, and cost-efficient polyester production solutions. Strategic partnerships, technological innovation, and market expansion are central to strengthening product portfolios and market presence.

Dorf Ketal offers comprehensive titanium catalyst solutions with established manufacturing expertise and professional-grade catalytic performance capabilities. Johnson Matthey provides specialized chemical catalyst equipment with focus on environmental compliance and operational efficiency. LyondellBasell delivers advanced catalyst technology solutions with emphasis on sustainability and performance optimization. Clariant specializes in professional chemical catalyst systems with advanced titanium formulation integration.

Mitsubishi Chemical offers advanced catalyst equipment with comprehensive environmental performance support capabilities. Wanhua Chemical delivers established polyester catalyst solutions with advanced titanium technologies. Zhejiang Huangma Technology provides specialized catalyst equipment with focus on performance optimization. Zhejiang Lixing Technology, Eastman Chemical, and Huntsman Corporation offer specialized manufacturing expertise, catalyst reliability, and comprehensive product development across global and regional market segments.

| Item | Value |

|---|---|

| Quantitative Units | USD 112.0 million |

| Catalyst Type | Organic Titanium Catalyst, Inorganic Titanium Catalyst, and Others |

| Application | Chemical Industry, Packaging Materials Industry, Electronic and Electrical Industry, and Others |

| Regions Covered | North America, Europe, East Asia, South Asia & Pacific, Latin America, Middle East & Africa |

| Country Covered | China, India, Germany, Brazil, United States, United Kingdom, Japan, and 40+ countries |

| Key Companies Profiled | Dorf Ketal, Johnson Matthey, LyondellBasell, Clariant, Mitsubishi Chemical, Wanhua Chemical, Zhejiang Huangma Technology, Zhejiang Lixing Technology, Eastman Chemical, Huntsman Corporation |

| Additional Attributes | Dollar sales by catalyst type and application segment, regional demand trends across major markets, competitive landscape with established catalyst manufacturers and emerging sustainable technology providers, customer preferences for different catalyst formulations and environmental options, integration with polyester production systems and quality protocols, innovations in catalyst formulation and environmental compliance technologies, and adoption of sustainable manufacturing features with enhanced performance capabilities for improved production workflows. |

The global titanium catalyst for polyester market is estimated to be valued at USD 112.0 million in 2025.

The market size for the titanium catalyst for polyester market is projected to reach USD 194.9 million by 2035.

The titanium catalyst for polyester market is expected to grow at a 5.7% CAGR between 2025 and 2035.

The key product types in titanium catalyst for polyester market are organic titanium catalyst, inorganic titanium catalyst and others.

In terms of application, chemical industry segment to command 48.0% share in the titanium catalyst for polyester market in 2025.

Our Research Products

The "Full Research Suite" delivers actionable market intel, deep dives on markets or technologies, so clients act faster, cut risk, and unlock growth.

The Leaderboard benchmarks and ranks top vendors, classifying them as Established Leaders, Leading Challengers, or Disruptors & Challengers.

Locates where complements amplify value and substitutes erode it, forecasting net impact by horizon

We deliver granular, decision-grade intel: market sizing, 5-year forecasts, pricing, adoption, usage, revenue, and operational KPIs—plus competitor tracking, regulation, and value chains—across 60 countries broadly.

Spot the shifts before they hit your P&L. We track inflection points, adoption curves, pricing moves, and ecosystem plays to show where demand is heading, why it is changing, and what to do next across high-growth markets and disruptive tech

Real-time reads of user behavior. We track shifting priorities, perceptions of today’s and next-gen services, and provider experience, then pace how fast tech moves from trial to adoption, blending buyer, consumer, and channel inputs with social signals (#WhySwitch, #UX).

Partner with our analyst team to build a custom report designed around your business priorities. From analysing market trends to assessing competitors or crafting bespoke datasets, we tailor insights to your needs.

Supplier Intelligence

Discovery & Profiling

Capacity & Footprint

Performance & Risk

Compliance & Governance

Commercial Readiness

Who Supplies Whom

Scorecards & Shortlists

Playbooks & Docs

Category Intelligence

Definition & Scope

Demand & Use Cases

Cost Drivers

Market Structure

Supply Chain Map

Trade & Policy

Operating Norms

Deliverables

Buyer Intelligence

Account Basics

Spend & Scope

Procurement Model

Vendor Requirements

Terms & Policies

Entry Strategy

Pain Points & Triggers

Outputs

Pricing Analysis

Benchmarks

Trends

Should-Cost

Indexation

Landed Cost

Commercial Terms

Deliverables

Brand Analysis

Positioning & Value Prop

Share & Presence

Customer Evidence

Go-to-Market

Digital & Reputation

Compliance & Trust

KPIs & Gaps

Outputs

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Titanium Strips Market Size and Share Forecast Outlook 2025 to 2035

Titanium Diboride Market Size and Share Forecast Outlook 2025 to 2035

Titanium Aluminide Market Size and Share Forecast Outlook 2025 to 2035

Titanium Tetrachloride (TiCl4) Market Size and Share Forecast Outlook 2025 to 2035

Titanium Powder Market Size and Share Forecast Outlook 2025 to 2035

Titanium Nitride Coating Market Size and Share Forecast Outlook 2025 to 2035

Titanium Aluminides (TiAl) Market Analysis - Size, Share, and Forecast Outlook 2025 to 2035

Titanium-Free Food Color Market Analysis - Size, Share & Forecast 2025 to 2035

Titanium Dioxide Color Market Trends - Applications & Industry Demand 2025 to 2035

Titanium-Free Food Color Alternatives Market

Titanium Market

Titanium Dioxide Market

Titanium Wire for Glasses Market Forecast Outlook 2025 to 2035

Aviation Titanium Alloy Market Analysis by Type, Application, Microstructure, and Region: Forecast for 2025 to 2035

Anodized Titanium Market Growth - Trends & Forecast 2025 to 2035

Aerospace Titanium Market Size and Share Forecast Outlook 2025 to 2035

Free-from Titanium Dioxide Market Size, Growth, and Forecast for 2025 to 2035

Orthopedic Titanium Plate with Loop Market Size and Share Forecast Outlook 2025 to 2035

Food Grade Titanium Dioxide Market Analysis by Dairy Products, Bakery and Confectionery, Sauces and Savoury products and Others Applications Through 2035

Extra Low Interstitial Titanium Market Size and Share Forecast Outlook 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA