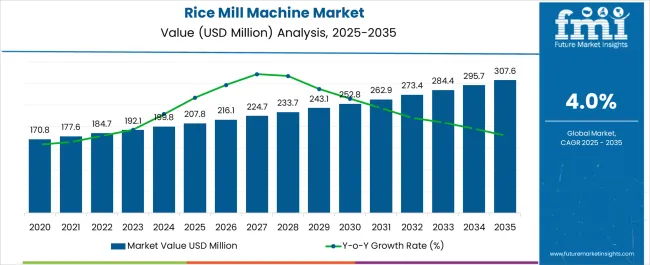

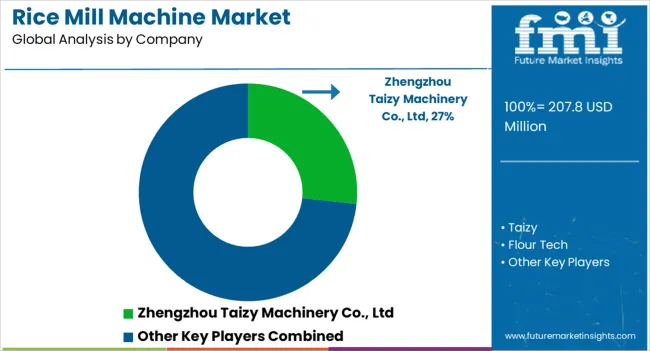

The rice mill machine market is estimated to be valued at USD 207.8 million in 2025 and is projected to reach USD 307.6 million by 2035, registering a compound annual growth rate (CAGR) of 4.0% over the forecast period. The market demonstrates steady expansion driven by rice processing modernization, agricultural mechanization trends, and food security requirements that necessitate efficient grain processing equipment capable of converting paddy rice into polished consumer-ready products while minimizing broken grain percentages and maximizing processing yields.

Rice millers implement integrated processing systems that coordinate cleaning, dehusking, milling, and polishing operations within automated production lines that reduce labor requirements while maintaining consistent grain quality throughout large-scale rice processing operations. The technology's evolution toward precision milling and quality control integration creates demand for machines that optimize head rice recovery rates while reducing processing losses and energy consumption throughout commercial rice production facilities.

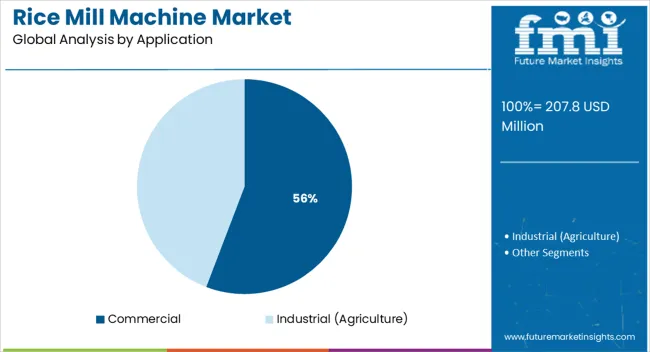

Commercial rice processing represents the dominant application segment where industrial milling systems enable high-capacity paddy processing for wholesale distribution and retail packaging while maintaining grain quality standards necessary for consumer acceptance and export market requirements.

Rice processing facility operators specify equipment combinations that accommodate diverse rice varieties and moisture content variations while achieving optimal milling degree and appearance characteristics demanded by different market segments. Quality control protocols emphasize broken grain percentage monitoring, whiteness measurement, and foreign material removal that ensure finished rice products meet food safety standards and customer specifications throughout commercial distribution channels.

Small-scale milling operations demonstrate increasing adoption of compact rice milling equipment that enables local processing of farmer harvests while providing community-level rice processing services that reduce transportation costs and support rural economic development.

Village-level rice mills utilize single-pass milling systems and small-capacity equipment that process local rice varieties while maintaining affordability for small farming communities with limited capital resources. Custom milling services enable farmers to process their own rice harvests while maintaining control over grain quality and avoiding middleman costs throughout local food supply chains.

Technology advancement trajectories concentrate on yield optimization and energy efficiency improvements that reduce processing costs while maximizing head rice recovery through precise milling pressure control and optimized processing sequences.

Optical sorting systems incorporate color sorting and defect removal technologies that eliminate damaged grains and foreign materials while maintaining processing speed necessary for commercial production volumes. Automation systems coordinate multiple processing stages while providing real-time monitoring and adjustment capabilities that optimize processing parameters based on grain characteristics and quality objectives.

| Metric | Value |

|---|---|

| Rice Mill Machine Market Estimated Value in (2025 E) | USD 207.8 million |

| Rice Mill Machine Market Forecast Value in (2035 F) | USD 307.6 million |

| Forecast CAGR (2025 to 2035) | 4.0% |

The rice mill machine market is experiencing robust expansion driven by rising demand for efficient processing technologies, increasing mechanization in agriculture, and the push for higher productivity across emerging economies. Growing consumer preference for high quality rice with minimal breakage and uniform polishing is encouraging adoption of advanced milling solutions.

Government initiatives promoting modernization of rice milling infrastructure and subsidies for small and medium farmers are further boosting the demand. Technological improvements such as energy efficient motors, compact mini mills, and automated systems have enhanced operational performance while reducing costs.

The market outlook remains positive as food security priorities, urban consumption patterns, and the need for scalable commercial rice milling solutions continue to shape long term growth opportunities.

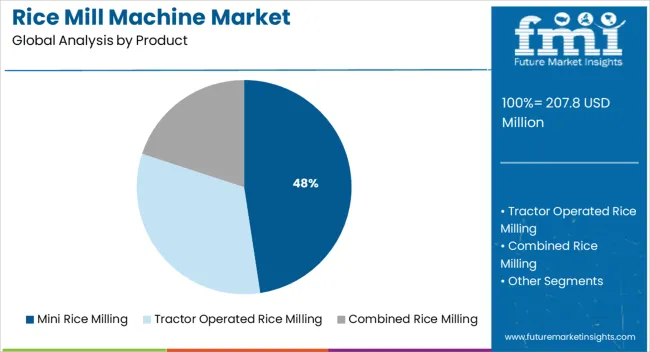

The mini rice milling product segment is projected to hold 47.60% of total revenue by 2025 within the product category, making it the leading segment. This dominance is supported by its affordability, compact size, and suitability for small and medium scale operations.

Mini mills are favored in rural and semi urban regions where investment capacity is limited yet demand for efficient processing remains high. Their ease of installation, low maintenance requirements, and ability to deliver consistent quality output have contributed to their widespread adoption.

As more small scale farmers and entrepreneurs seek localized milling solutions, the mini rice milling segment continues to strengthen its position as the preferred product type.

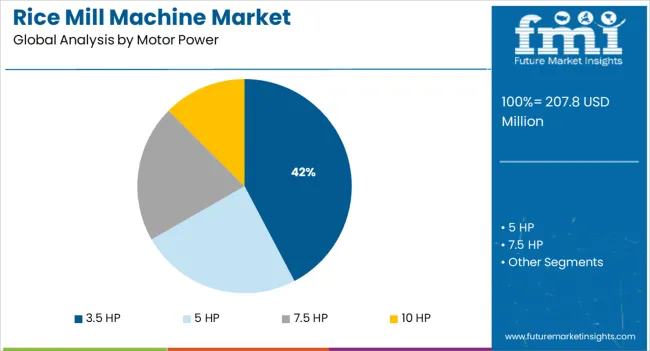

The 3.5 HP motor power segment is expected to account for 42.30% of total market revenue by 2025, establishing itself as the dominant motor capacity. This growth is linked to its balance between power efficiency and affordability, making it well suited for both small and medium processing setups.

The 3.5 HP motor offers reliable performance for mini and semi commercial mills, ensuring consistent throughput without excessive energy consumption. Farmers and millers value this motor power capacity for its durability, low operating costs, and compatibility with compact machines.

As the demand for energy efficient and cost effective solutions grows, this motor power segment maintains its leadership position.

The commercial application segment is anticipated to represent 55.80% of total revenue by 2025 under the application category, positioning it as the most significant contributor. Growth in this segment is being driven by rising rice consumption worldwide, urbanization, and the need for large scale milling capacity.

Commercial mills are increasingly adopting advanced automated systems that ensure higher output, consistent grain quality, and reduced wastage. Strategic investments by mill operators to enhance productivity and meet export quality standards are further supporting this segment.

The commercial category is thus expected to dominate as large processing facilities remain essential in meeting both domestic demand and international trade requirements.

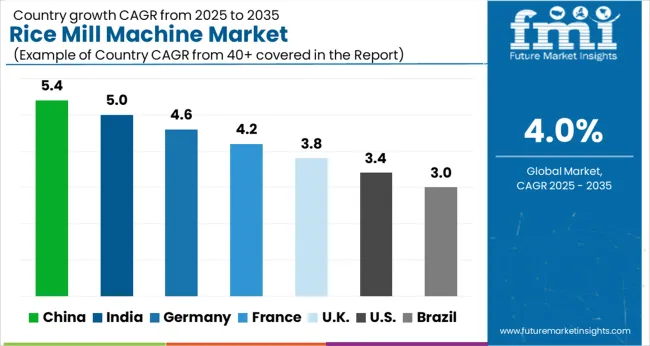

Between 2020 and 2025, the global rice mill machine market was estimated to register a sluggish 2.6% CAGR. So, it’s fair to say that the anticipated 4.0% CAGR from 2025 to 2035 indicates a marginal acceleration in market expansion.

The rice mill machine market is anticipated to be driven by factors such as the growing demand for rice in developing countries, the increasing use of rice as a staple food in developed countries, and the growing popularity of rice-based packaged and ready-to-eat foods.

FMI also predicts increasing adoption of automated rice mill machines. Fully automated rice mill machines deliver high output and efficiency. Manufacturers are anticipated to innovate more and more in the years ahead to deliver more energy-efficient and environment-friendly solutions.

FMI has assessed the rice mill market thoroughly to determine the factors that are likely to affect the market between 2025 and 2035. FMI’s lead analysts have taken into consideration emerging opportunities, restraints, and threats in their assessment.

The Drivers, Restraints, Opportunities, and Threats identified are as follows:

DRIVERS

RESTRAINTS

OPPORTUNITIES

THREATS

Potential natural disasters fueled by climate change such as floods and draughts are poised to threaten the expansion of the global rice mill machine market.

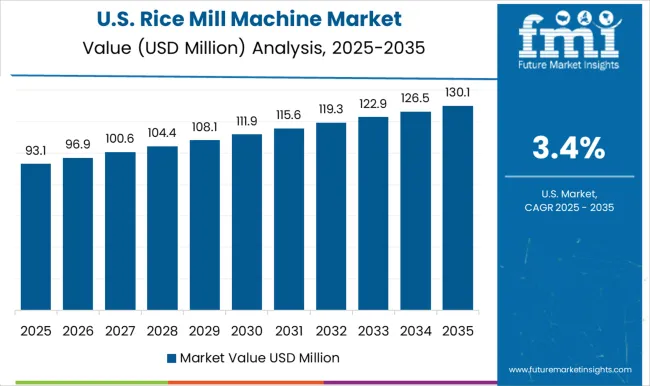

Demand for Rice Mill Machines to Decrease in the United States Due to Growing Focus on Exports

Rice milling machine sales are expected to be adversely affected in the United States In recent years, the country’s rice production has declined and this trend looks set to continue as the United States government looks to increase rise imports for meeting its consumption demands. This is resulting in decreasing demand for rice milling machines in the country.

In the coming years, FMI expects husk-removing rice mill machines to generate more sales in the United States market compared to machines that do not remove husk. Husk-removing rice mill machines have become popular in the United States owing to their ability of producing clean rice with almost no impurities.

India Rice Mill Machine Market to Register Substantial Expansion Owing To Government’s Ambitious Goals

India is the world’s second largest producer of rice, despite the forecast of declined production in the 2025/2025 market year in a Grain and Feed Update shared by the United States Department of Agriculture’s Foreign Agricultural Service (FAS). As it is also the home to big players, the country also has several small and medium-sized enterprises (SMEs) that produce rice.

In India, rice mill machine sales are expected to surge during the forecast period. According to the Central Rice Research Institute, a part of the Indian Council of Agricultural Research, India’s rice production needs to be increased to 307.6 million tons for feeding its population by 2035. This is poised to stimulate the country’s market for rice mill machines as all efforts are made to step up production.

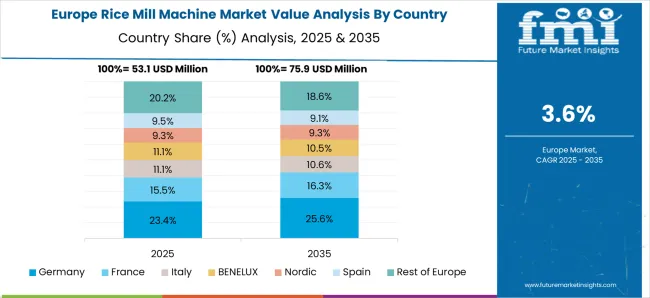

Strong Presence of Rice Mill Machine Manufacturers to Spur Market Expansion In Germany

Germany is home to renowned rice mill machine manufacturers such as Bühler GmbH and SCHULE Mühlenbau, which are known for high-quality products, competitive prices, and excellent customer service.

As the demand for automated and energy-efficient rice mill machines is anticipated to increase from 2025 to 2035, these companies are expected to be at the forefront of research and development efforts. Ultimately, their products are poised to offer solutions based on the problems being faced by the global rice production sector right now.

Economic Reforms Set to Help International Manufacturers Establish Their Presence in China

As the world’s most populous country with a burgeoning middle class, China is an obvious choice for businesses in the rice mill market looking to expand their reach. However, despite its size and economic growth, China has been notoriously difficult for foreign companies to crack. That’s starting to change, however, as the Chinese government has been making gradual reforms to open up the economy.

These reforms, combined with China’s growing appetite for luxury goods and services, have made it an increasingly attractive market for businesses across a range of industries.

Mini Rice Mill Machines to Gain Traction Due to their Cost-Effectiveness

A mini rice mill machine is a small machine that can be used to process rice. It is usually operated by one or two people. The mini rice mill machine is easy to use and more affordable than their industrial-sized counterparts.

For small and medium-sized manufacturers, investing in mini rice mill machines makes more sense from a financial standpoint compared to investing in industrial-sized machines. FMI expects sales of mini rice mill machines to grow, particularly in developing economies.

Ease of Comparison and Discount Prices to Fuel Online Sales of Rice Mill Machines

Online sales channels have made it easier than ever before for people to purchase rice mill machines. They offer a wide variety of products and allow customers to compare prices and find the best deals quickly.

Several manufacturers have started selling their products exclusively through online channels in recent years. This trend is likely to continue as the penetration of online sales channels is expected to increase in the years ahead.

Use of Rice Mill Machines in Agriculture to Fuel Due to Rising Demand For Impurity-Free Rice

Rice is one of the most important crops in the world, and rice milling is a vital part of the rice production process. The rice mill machine is an essential piece of equipment in the rice production process, as it helps to remove the husks and bran from the rice grain.

Every rice mill machine consists of a pair of rotating abrasive discs that shear and grind the rice grain. The top disc rotates clockwise, while the bottom disc rotates counter clockwise. The two discs are separated by a small gap, through which the husk and bran are removed from the grain. The abrasive action of the discs removes the husk and bran from the grain, while leaving the edible portion of the rice intact. The husk and bran are then discharged from the machine through a chute.

The rice mill machine market is shaped by a combination of global and regional manufacturers delivering efficient, automated solutions for rice processing, polishing, and grading. Satake Corporation leads the industry with advanced rice milling systems known for high precision, grain yield optimization, and minimal breakage, serving both industrial and commercial milling facilities worldwide. Zhengzhou Taizy Machinery Co., Ltd. and Taizy cater to small and medium-scale producers with cost-effective, compact rice milling machines designed for local processing and easy maintenance.

Flour Tech (FlourTech Engineers Pvt Ltd) and Rising Industries provide customized rice milling and cleaning solutions suited to diverse regional requirements in India and neighboring markets, focusing on energy efficiency and automation. Mill Master Machinery Private Limited emphasizes fully integrated rice milling plants offering high throughput and consistent output quality. Alvan Blanch Development Company specializes in post-harvest and grain processing equipment, including rice milling systems tailored for developing agricultural economies. Savco Sales supports the market as a distributor and machinery supplier offering installation and maintenance services across key agricultural hubs.

| Attributes | Details |

|---|---|

| Value-based CAGR (2025 to 2035) | 4% |

| Forecast Period | 2025 to 2035 |

| Historical Data Available for | 2020 to 2025 |

| Market Analysis | Value (USD million) |

| Key Regions Covered | North America; Latin America; Europe; Asia Pacific; Oceania; Middle East and Africa |

| Key Countries Covered | United States, Canada, Mexico, Germany, United Kingdom, France, Italy, Spain, China, Japan, India, South Korea, Australia, Brazil, Argentina, South Africa, UAE |

| Key Segments Covered | Product Type, Mode of Operation, Motor power, Application, Region |

| Key Companies Profiled | Zhengzhou Taizy Machinery Co., Ltd.; Taizy; Flour Tech (FlourTech Engineers Pvt Ltd); Rising Industries; Mill Master Machinery Private Limited; Satake Corporation; Alvan Blanch Development Company; Savco Sales |

| Report Coverage | Market Forecast, Company Share Analysis, Competitive Landscape, Drivers, Restraints, Opportunities and Threats Analysis, Market Dynamics and Challenges, and Strategic Growth Initiatives |

The global rice mill machine market is estimated to be valued at USD 207.8 million in 2025.

The market size for the rice mill machine market is projected to reach USD 307.6 million by 2035.

The rice mill machine market is expected to grow at a 4.0% CAGR between 2025 and 2035.

The key product types in rice mill machine market are mini rice milling, tractor operated rice milling and combined rice milling.

In terms of motor power, 3.5 hp segment to command 42.3% share in the rice mill machine market in 2025.

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Rice Milling Machine Market Size and Share Forecast Outlook 2025 to 2035

Rice Bran Fatty Alcohols Market Size and Share Forecast Outlook 2025 to 2035

Rice Water Skincare Market Forecast and Outlook 2025 to 2035

Rice Water Haircare Market Size and Share Forecast Outlook 2025 to 2035

Rice Shampoo Bar Market Size and Share Forecast Outlook 2025 to 2035

Rice Bran Oil for Skin Care Market Size and Share Forecast Outlook 2025 to 2035

Rice Bran Oil Infusions Market Analysis - Size and Share Forecast Outlook 2025 to 2035

Rice Bran Derivatives Market Size and Share Forecast Outlook 2025 to 2035

Rice Derivative Market Size and Share Forecast Outlook 2025 to 2035

Rice Water Shampoo Market Size and Share Forecast Outlook 2025 to 2035

Rice Bran Oil Market Analysis by Type, End User, and Region Through 2035

Rice Bran Wax Market Analysis - Size, Share, and Forecast 2025 to 2035

Rice Cake Market Analysis - Size, Share, and Forecast Outlook 2025 to 2035

Rice Milk Market Trends - Dairy-Free Nutrition & Industry Growth 2025 to 2035

Rice-based Products Market Analysis by Product Type, Distribution Channel, and Region Through 2035

Key Players & Market Share in Rice Water Haircare Sector

Market Share Breakdown of Rice Shampoo Bar Manufacturers

Rice Paper Stand Up Pouch Market Growth & Sustainable Packaging 2024-2034

Rice Protein Market

Rice Polishing Machines Market Size and Share Forecast Outlook 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA