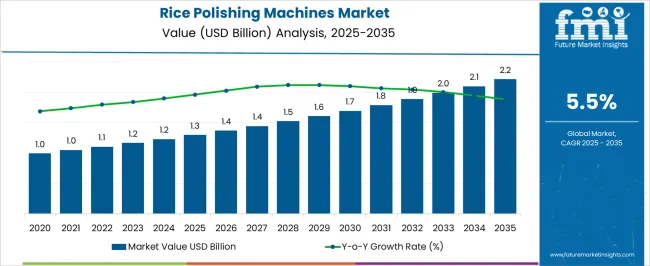

The Rice Polishing Machines Market is estimated to be valued at USD 1.3 billion in 2025 and is projected to reach USD 2.2 billion by 2035, registering a compound annual growth rate (CAGR) of 5.5% over the forecast period.

| Metric | Value |

|---|---|

| Rice Polishing Machines Market Estimated Value in (2025 E) | USD 1.3 billion |

| Rice Polishing Machines Market Forecast Value in (2035 F) | USD 2.2 billion |

| Forecast CAGR (2025 to 2035) | 5.5% |

The rice polishing machines market is experiencing consistent growth as milling operations worldwide prioritize efficiency, grain quality, and sustainability. Increasing demand for polished rice in domestic and export markets has elevated the importance of advanced polishing solutions in improving output while minimizing breakage and wastage.

Technological improvements in polishing mechanisms and materials are enhancing performance and reducing maintenance requirements, fostering wider adoption. Additionally, rising investments in modern milling facilities, driven by the need to meet international quality standards and consumer expectations, are further accelerating market penetration.

The future outlook remains positive as automation trends, energy-efficient designs, and regional capacity expansions pave the way for broader market opportunities. Demand is expected to remain strong as producers seek reliable, high-capacity, and cost-effective machines that deliver superior finish and higher yield.

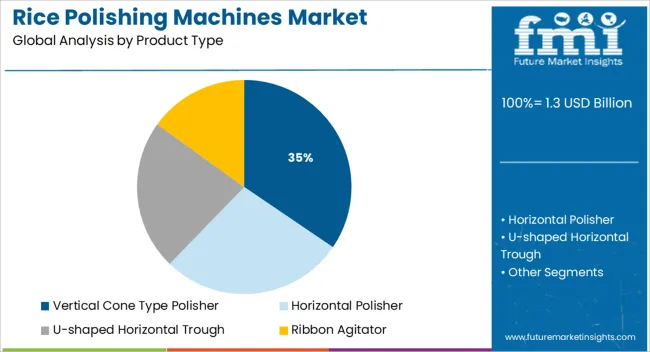

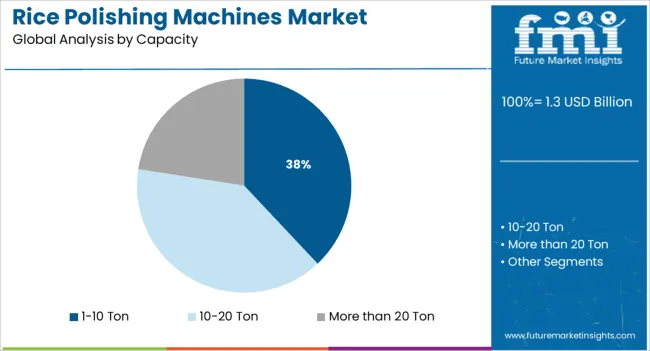

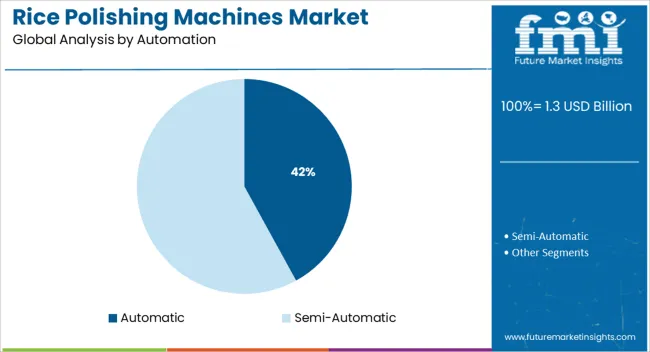

The market is segmented by Product Type, Capacity, Automation, and End Use and region. By Product Type, the market is divided into Vertical Cone Type Polisher, Horizontal Polisher, U-shaped Horizontal Trough, and Ribbon Agitator. In terms of Capacity, the market is classified into 1-10 Ton, 10-20 Ton, and More than 20 Ton. Based on Automation, the market is segmented into Automatic and Semi-Automatic. By End Use, the market is divided into Meat & Poultry, Fruit & Vegetables, Potatoes, Bread, Cheese, Fish & Seafood, and Others. Regionally, the market is classified into North America, Latin America, Western Europe, Eastern Europe, Balkan & Baltic Countries, Russia & Belarus, Central Asia, East Asia, South Asia & Pacific, and the Middle East & Africa.

When segmented by product type, the vertical cone type polisher is anticipated to account for 34.5 % of the total market revenue in 2025, establishing itself as the leading segment. This position has been reinforced by the robust construction and efficient polishing performance of vertical cone designs, which allow uniform abrasion and enhanced grain quality.

Their ability to handle high throughput while maintaining consistent polish levels has made them particularly suitable for commercial and industrial milling settings. Furthermore, the vertical cone configuration has been preferred due to its compact footprint and lower energy consumption, which contribute to operational cost savings.

Manufacturers have also been observed improving cone designs with advanced materials and adjustable settings to meet varied rice types and customer specifications, solidifying this segment’s leadership.

Segmented by capacity, the 1 to 10 ton category is projected to hold 38.0 % of the market revenue in 2025, making it the most prominent segment. This dominance has been driven by the widespread preference for mid-range capacity machines, which strike an optimal balance between production efficiency and capital investment.

The segment has been favored among small to medium scale millers due to its suitability for both localized and regional demand without incurring excessive operational costs. Machines within this capacity range have been adopted extensively because of their flexibility to handle diverse batch sizes and their ability to maintain high polish quality across varying rice varieties.

As production facilities in emerging economies modernize while maintaining manageable scales of operation, this capacity segment has sustained its prominence in the market.

When segmented by automation, the automatic segment is expected to command 42.0 % of the market revenue in 2025, securing its position as the leading automation category. This leadership has been attributed to the significant operational efficiencies, consistency, and labor savings offered by automatic machines.

Automatic systems have enabled mills to achieve uniform polishing outcomes with minimal operator intervention, reducing dependency on skilled labor and mitigating human error. Adoption has also been propelled by increasing focus on productivity, workplace safety, and quality assurance, as automatic machines offer integrated monitoring and control features.

Continuous improvements in automation technology and the integration of digital interfaces have further strengthened this segment’s appeal, establishing it as the preferred choice among forward-looking milling operations aiming for high output with precision.

The global rice polishing machines market exhibited lucrative growth at a CAGR of 4.5% during the historical period of 2020 to 2025. The rising demand for specialty rice varieties in numerous developing countries has pushed the trade for long-grain rice. It has further augmented the global rice polishing machines market.

Continuously changing food habits and lifestyles of consumers are set to drive the fast-food industry, which would subsequently propel the global market in the next ten years. Also, the increasing population and their high disposable income are anticipated to bode well for the global rice polishing machines market. Owing to the aforementioned factors, the market is set to exhibit considerable growth at a CAGR of 5.5% in the assessment period from 2025 to 2035.

High Demand for Long-grain Rice in the USA to Push Sales of Rice Milling and Polishing Machines

As per FMI, the USA rice polishing machines market is projected to remain at the forefront in North America during the forecast period. Growth is attributed to increasing awareness about the significance of a healthy diet among consumers in the country. Also, the easy availability of rice-based food items across the USA through restaurants and hotels is likely to aid growth in the country.

As per the USA Department of Agriculture, long-grain rice production in the USA is concentrated in the South. Arkansas mainly grows 56-58 percent of the USA's long-grain crop. California, on the other hand, is considered to be the main producer of medium-grain rice, usually 70-76 percent of the crop. All USA rice is cultivated in irrigated fields, thereby achieving some of the highest yields across the globe.

Availability of Advanced Rice Huller with Polisher in Japan to Drive Growth

The design and capability of technologically advanced rice polishing machines are not the same as that of a level rice polisher, which is frequently found in a rice shop to clean rice that is to be consumed by large families. The availability of such machines in Japan is set to create clean rice with high quality. These factors are estimated to propel the Japanese rice polishing machines market in the next ten years.

With the introduction of vertical rice mills, rice polishing technology was renewed in the 1930s in Japan, and Ginjo high-quality sake, which was brewed at a low temperature of 60% or less, was eventually mass-produced in the 1980s. Today, in addition to the conventional horizontal rice milling machine, vertical rice polishing machines are used to mill the rice one consumes in Japan, which would eventually propel the market.

Cultivation of Japonica Rice in the UK to Boost Sales of Rice Production Machines

Imports of rice specialties from countries other than Europe are increasing. A particularly attractive product in the UK market is rice husks or milled rice from long-grain Indica rice such as basmati rice. Rice imports are expected to increase in the country during the forecast period.

When it comes to rice, approximately 60% of the demand is covered by European in-house production and so 1.2 million tons of rice husk rice must be imported. The European Union (EU) Agricultural Outlook 2024-2035 assumes that demand for imported rice will increase until 2035. Over the next decade, imports will increase by about 250,000 tons, but this amount will only affect the EU-27 and not the UK.

Japonica varieties (about 75%) are mainly found in the UK and these are distributed & consumed primarily in Southern Europe. Europe is a net exporter of Japonica rice. Common Asian Indica strains are best known in Northern Europe. There are many types of long-grain, aromatic indicators such as basmati rice and jasmine rice in the UK

Availability of Suitable Climate for Cultivation to Drive the Demand for Rice Cleaning Equipment in India

Presence of various renowned rice polishing companies in India such as Panesar Industrial Corporation, Reliable Exports, Global Agro Tech Engineers, M.G. Industries, JAGGO OVERSEAS, Mill Master Machinery Pvt. Ltd., New Bihar Engineering Company, Prakash Industries, and Synergy Exports LLP among others are projected to drive the market in the evaluation period. India is considered to be one of the top ten rice-producing countries in the Asia Pacific.

India is endowed with a wet environment suitable, which is best suited for rice cultivation. Rice-based farming is also considered to be a significant economic activity for hundreds of millions of farmers residing in rural India. As per the India Brand Equity Foundation (IBEF), India captured about 50% of the world market for rice in FY22. It is set to surge at a rapid rate with an increasing population, thereby bolstering the rice polishing machines market.

Demand for Automatic Rice Polisher Machines to Surge by the End of 2035

Based on automation, the automatic segment is estimated to lead the global rice polishing machines market in the assessment period. Rising demand for specialty rice and fragrant rice in India and the USA is projected to compel manufacturers to provide their products on time to their clients. Automatic machines help in polishing the rice faster than semi-automatic machines. Owing to the aforementioned factors, the demand for automatic rice polishing machines is likely to increase in the forecast period.

The global rice polishing machines market is highly fragmented and competitive due to the presence of several local and regional companies. Key players are adopting a wide range of marketing strategies such as partnerships, expansions, mergers & acquisitions, and collaborations to compete with their rivals.

Some of the leading companies operating in the rice polishing machines market are SATAKE Group, FH SCHULE Muehlenbau, Pavan Group, Lianyungang Huantai Machinery, IndiaMART InterMESH Limited, Buhler AG, SATAKE INDIA, YANMAR, Hunan Sunfield Machinery, and MILLTEC Machinery among others.

Satake and IndiaMART InterMESH Limited Aim to Offer Sustainable Milling Machinery to Food Processing Zones Globally

A rice polishing machine modifies the physical characteristics of rice. It is applied to rice kernels to polish or buff them. The outer surface of rice kernels is polished by rough machines called rice polishers using talc or other very fine particles. By spraying water through the mixing chamber and causing friction between the grains, either by rubbing or by utilizing milling rollers, a rice polisher machine polishes the surface of the rice. Manufacturers across the globe are focusing on mergers and acquisitions to expand their position in the field of rice polishing machines.

Satake, a leading manufacturer is mainly focusing on maintaining a strong presence in several countries through the expansion strategy. For instance, Satake announced in August 2025 that it is planning to open its new office in Manama, the Kingdom of Bahrain, to further accelerate sales.

Similarly, Satake India, in 2024, declared its plans to supply its rice milling machines to processing units that are being established in the proposed special food processing zones across Telangana at a discounted price. They also offered to establish training and round-the-clock servicing centers within these food processing zones. The milling machinery manufactured by Satake Group uses modern technology with a capacity of 21 tons per hour and the necessary power supply can be generated using the rusk, which is a byproduct of milling.

Another leading rice polishing machine manufacturer is IndiaMART InterMESH Limited. It is primarily focusing on mergers and acquisitions. For instance, in March 2025, it announced an investment of approximately Rs. 45.98 crores in Finlite Technologies for acquiring a 51.09% stake in the company. Also, in 2024, it acquired a stake in trade receivable discounting system services firm M1xchange for Rs 32.4 crore.

| Attribute | Details |

|---|---|

| Estimated Market Size (2025) | USD 1.3 billion |

| Projected Market Valuation (2035) | USD 2.2 billion |

| Value-based CAGR (2025 to 2035) | 5.5% |

| Forecast Period | 2025 to 2035 |

| Historical Data Available for | 2020 to 2024 |

| Market Analysis | Value (USD Million) |

| Key Countries Covered | USA, UK, China, India, Japan, South Korea, Canada, Brazil, Mexico, Argentina, Germany, Spain, Russia, Poland, Nordics, Australia, New Zealand, Thailand, Indonesia |

| Key Segments Covered | Product Type, End Use, Region, Capacity, Automation |

| Key Companies Profiled | SATAKE INDIA Group; FHSCHULEMuehlenbau; Pavan Group; Lianyungang Huantai Machinery; IndiaMART InterMESH Limited; SATAKE INDIA; YANMAR; Hunan Sunfield Machinery; MILLTEC Machinery Ltd.; Bühler Holding AG; Osaw Industrial Products Pvt. Ltd.; Lianyungang Huantai Machinery Co. Ltd.; SATAKE CORPORATION |

| Report Coverage | Market Forecast, Company Share Analysis, Competitive Landscape, Drivers, Restraints, Opportunities and Threats Analysis, Market Dynamics and Challenges, and Strategic Growth Initiatives |

The global rice polishing machines market is estimated to be valued at USD 1.3 billion in 2025.

The market size for the rice polishing machines market is projected to reach USD 2.2 billion by 2035.

The rice polishing machines market is expected to grow at a 5.5% CAGR between 2025 and 2035.

The key product types in rice polishing machines market are vertical cone type polisher, horizontal polisher, u-shaped horizontal trough and ribbon agitator.

In terms of capacity, 1-10 ton segment to command 38.0% share in the rice polishing machines market in 2025.

Our Research Products

The "Full Research Suite" delivers actionable market intel, deep dives on markets or technologies, so clients act faster, cut risk, and unlock growth.

The Leaderboard benchmarks and ranks top vendors, classifying them as Established Leaders, Leading Challengers, or Disruptors & Challengers.

Locates where complements amplify value and substitutes erode it, forecasting net impact by horizon

We deliver granular, decision-grade intel: market sizing, 5-year forecasts, pricing, adoption, usage, revenue, and operational KPIs—plus competitor tracking, regulation, and value chains—across 60 countries broadly.

Spot the shifts before they hit your P&L. We track inflection points, adoption curves, pricing moves, and ecosystem plays to show where demand is heading, why it is changing, and what to do next across high-growth markets and disruptive tech

Real-time reads of user behavior. We track shifting priorities, perceptions of today’s and next-gen services, and provider experience, then pace how fast tech moves from trial to adoption, blending buyer, consumer, and channel inputs with social signals (#WhySwitch, #UX).

Partner with our analyst team to build a custom report designed around your business priorities. From analysing market trends to assessing competitors or crafting bespoke datasets, we tailor insights to your needs.

Supplier Intelligence

Discovery & Profiling

Capacity & Footprint

Performance & Risk

Compliance & Governance

Commercial Readiness

Who Supplies Whom

Scorecards & Shortlists

Playbooks & Docs

Category Intelligence

Definition & Scope

Demand & Use Cases

Cost Drivers

Market Structure

Supply Chain Map

Trade & Policy

Operating Norms

Deliverables

Buyer Intelligence

Account Basics

Spend & Scope

Procurement Model

Vendor Requirements

Terms & Policies

Entry Strategy

Pain Points & Triggers

Outputs

Pricing Analysis

Benchmarks

Trends

Should-Cost

Indexation

Landed Cost

Commercial Terms

Deliverables

Brand Analysis

Positioning & Value Prop

Share & Presence

Customer Evidence

Go-to-Market

Digital & Reputation

Compliance & Trust

KPIs & Gaps

Outputs

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Rice Bran Fatty Alcohols Market Size and Share Forecast Outlook 2025 to 2035

Rice Water Skincare Market Forecast and Outlook 2025 to 2035

Rice Water Haircare Market Size and Share Forecast Outlook 2025 to 2035

Rice Shampoo Bar Market Size and Share Forecast Outlook 2025 to 2035

Rice Bran Oil for Skin Care Market Size and Share Forecast Outlook 2025 to 2035

Rice Bran Oil Infusions Market Analysis - Size and Share Forecast Outlook 2025 to 2035

Rice Milling Machine Market Size and Share Forecast Outlook 2025 to 2035

Rice Bran Derivatives Market Size and Share Forecast Outlook 2025 to 2035

Rice Mill Machine Market Size and Share Forecast Outlook 2025 to 2035

Rice Derivative Market Size and Share Forecast Outlook 2025 to 2035

Rice Water Shampoo Market Size and Share Forecast Outlook 2025 to 2035

Rice Bran Oil Market Analysis by Type, End User, and Region Through 2035

Rice Processing Machine Market Size and Share Forecast Outlook 2025 to 2035

Rice Bran Wax Market Analysis - Size, Share, and Forecast 2025 to 2035

Rice Cake Market Analysis - Size, Share, and Forecast Outlook 2025 to 2035

Rice Milk Market Trends - Dairy-Free Nutrition & Industry Growth 2025 to 2035

Rice-based Products Market Analysis by Product Type, Distribution Channel, and Region Through 2035

Key Players & Market Share in Rice Water Haircare Sector

Market Share Breakdown of Rice Shampoo Bar Manufacturers

Rice Paper Stand Up Pouch Market Growth & Sustainable Packaging 2024-2034

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA